What happened?

The Original Prusa XL is equipped with a loadcell, to detect that the nozzle is close enough to the steel sheet for printing, and to avoid damage that would be caused by the nozzle digging into the steel sheet.

In case the printer detects an incorrect loadcell configuration, but not related to the loadcell tare, or to the loadcell calbiration, the printer wil show the message: "The loadcell configuration is incorrect."

Error name: Loadcell Bad Configuration

Error code: #17527

How to fix it?

A visual inspection

- the filament is unloaded from the extruder

- the printer is turned OFF and unplugged from electricity

- the hotend and the heatbed are cooled down to ambient temperature

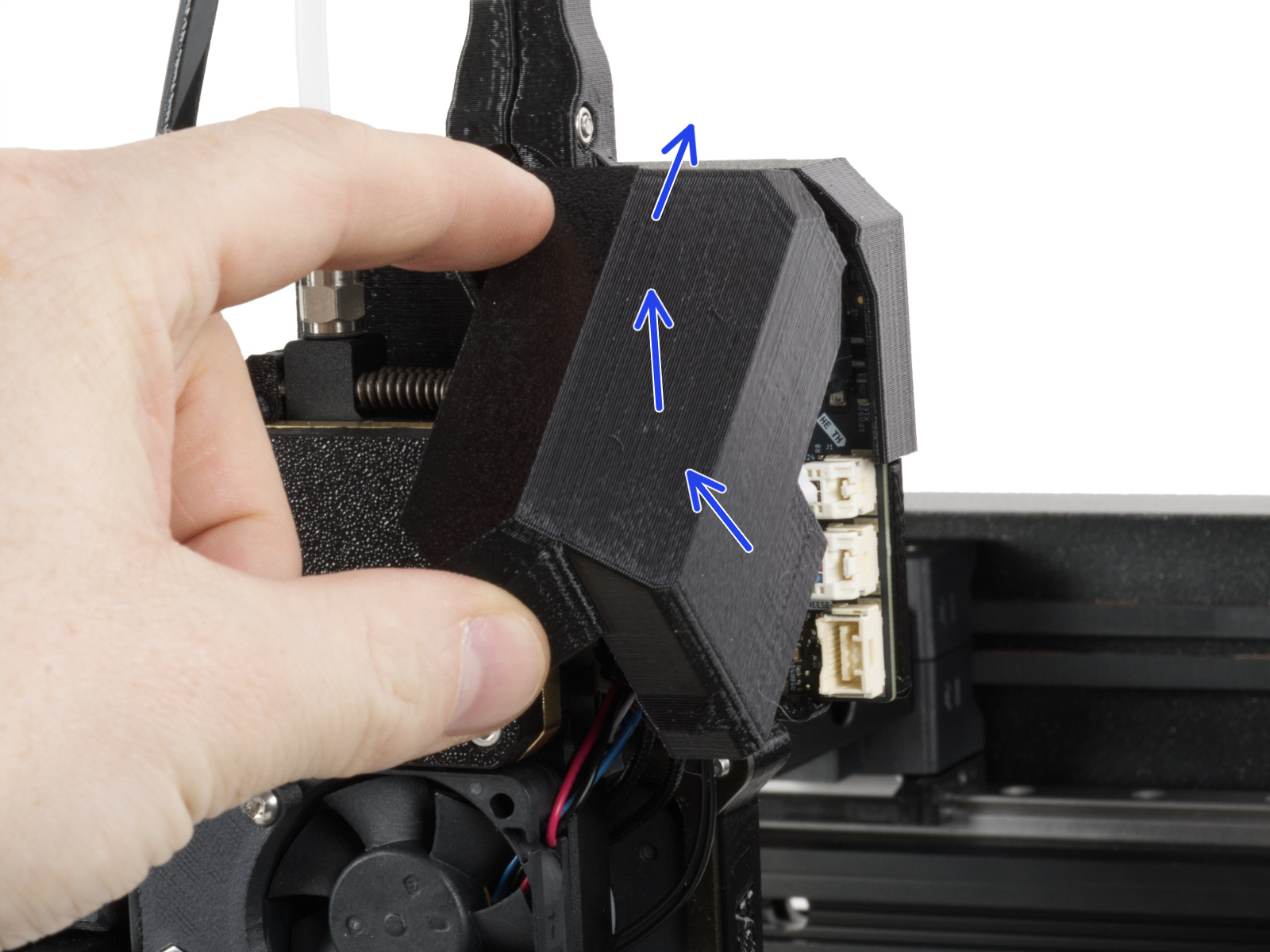

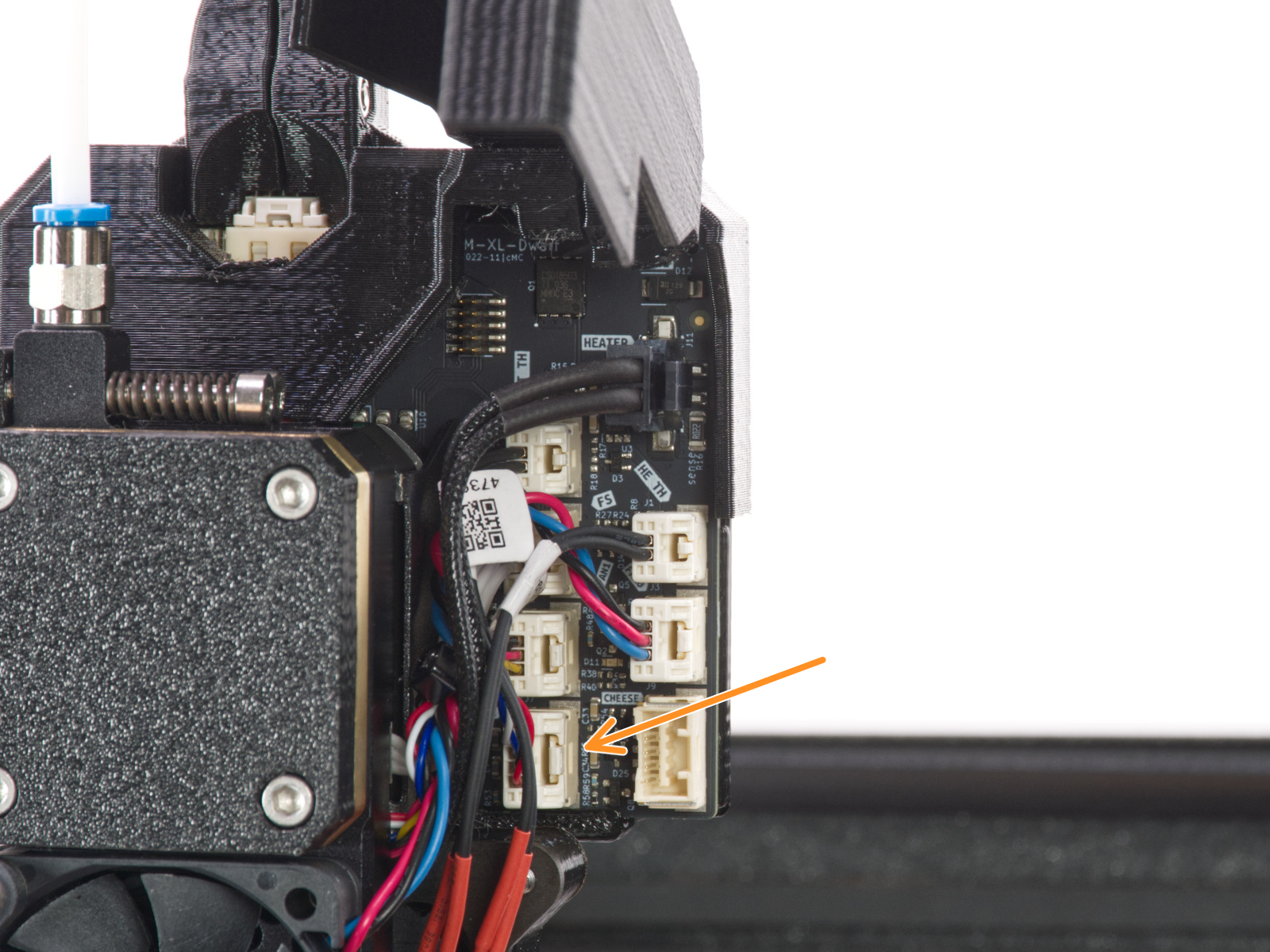

Open the dwarf-cover-door to access the Dwarf board. The loadcell connector is on the bottom left, check it for any loose cable, disconnected cable, or visible damage.

|  |

Re-calibrate the loadcell

Navigate to LCD Menu - Control - Calibration and test - Loadcell test to restart the loadcell calibration.

During the test, you will be asked to tap the nozzle at a specific time, and a progress bar on top of the screen will be filled. If the progress bar is not filled or the printer shows any errors, please contact our customer support.