What happened?

The printer shows the message "Extruder motor is not spinning on tool #". In place of #, the number of the Dwarf board is shown.

This problem occurs due to increased resistance between the Dwarf and the cable connector, caused by the cable and connector being held too firmly in position.

Error name: Extruder error

Error code: #17536

How to fix it?

Update firmware

Make sure that you have firmware 6.2.0 or newer.

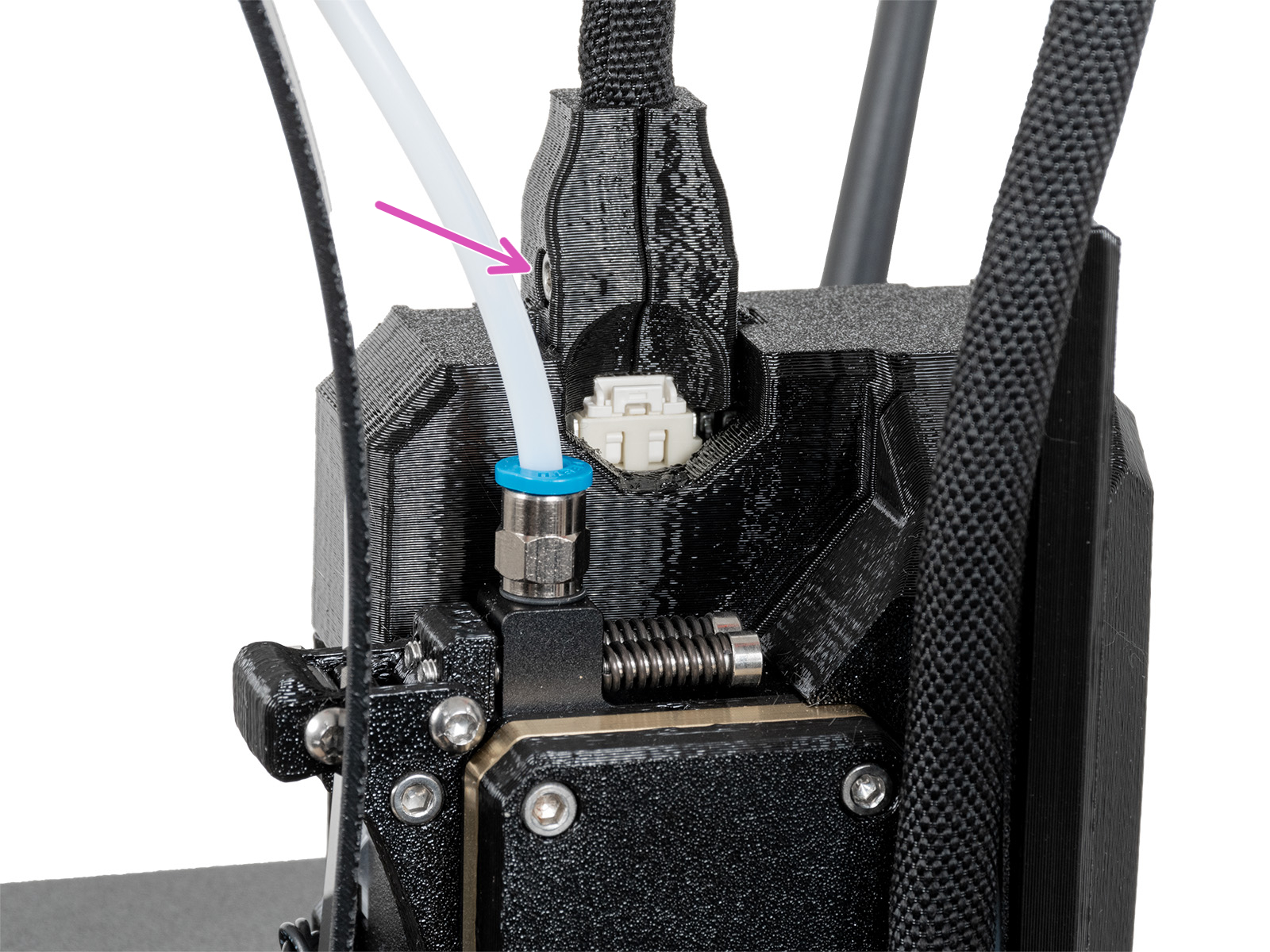

Remove the 'dwarf-cover-connector'

Remove the dwarf-cover connector, as it might hold the cable and connector too firmly. Fully loosen the bolt holding the part and remove the bolt. Repeat the print without the cover. If the issue is solved, replace the cover: How to replace the main cable connector cover (XL).

|  |

| Old main cable cover | New main cable cover |

If the issue is not solved, contact our customer support.

Was this article helpful?

This action is available only to registered users. Please log-in.

67 comments

By now, I really hate this printer and I hate that I, as an early adopter, am still a guinea pig for testing, and receiving fixes and "better" parts only after hours of bugfixing and then comlaining at support.