The Original Prusa magnetic heatbed is designed to hold a removable double-sided flexible spring-steel sheet, designed specifically for easy removal of printed objects from the print surface.

We offer six different types of sheets, with different strengths and attributes.

- Smooth sheet, provides excellent adhesion with most filaments and geometry. So much in fact, that some filaments, like TPU and PETG, will adhere too much and can damage the sheet when removed.

- Powder-coated textured sheet, aimed at production environments using PETG and other high-adhesion filaments.

- Satin sheet, which in both texture and properties lies between the smooth and the textured sheet.

- PA Nylon sheet, designed specifically for printing polyamides (Nylon) since their adhesion to standard PEI sheets is generally very poor.

- PP Sheet is suitable mostly for printing polypropylene since its adhesion to other print surfaces is very poor.

- HighTemp sheet is intended for printing with special high-temperature materials, such as PEEK, PEEK-CF, PEI, PEKK, and PPSU, which may otherwise have poor (or too strong) adhesion on standard steel sheets.

HT90 steel sheets

The Prusa Pro HT90 can use three types of print sheets. Textured, PP, PA Nylon, and HighTemp.

General information

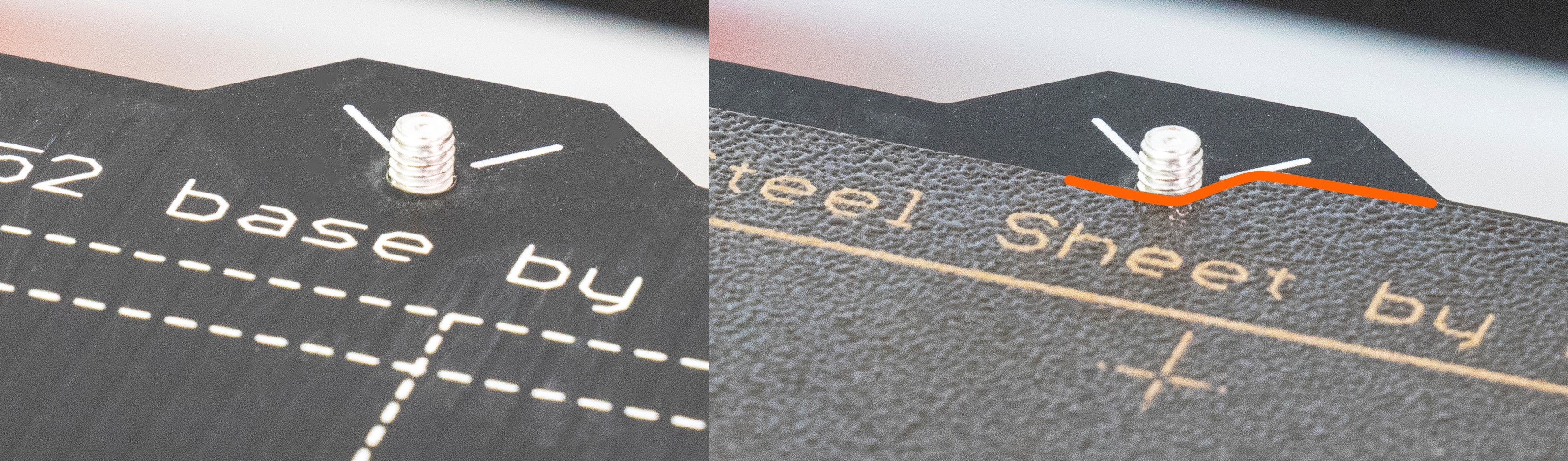

The removable spring steel sheet is held in place by a number of magnets glued to the heatbed, from the bottom side. On MK-series, MINI/+, XL, and HT90, the top of the heatbed has two pins that align perfectly with a notch in the spring steel sheet.

Before putting the steel sheet on the heatbed, make sure the heatbed is clean and free of any filament debris.

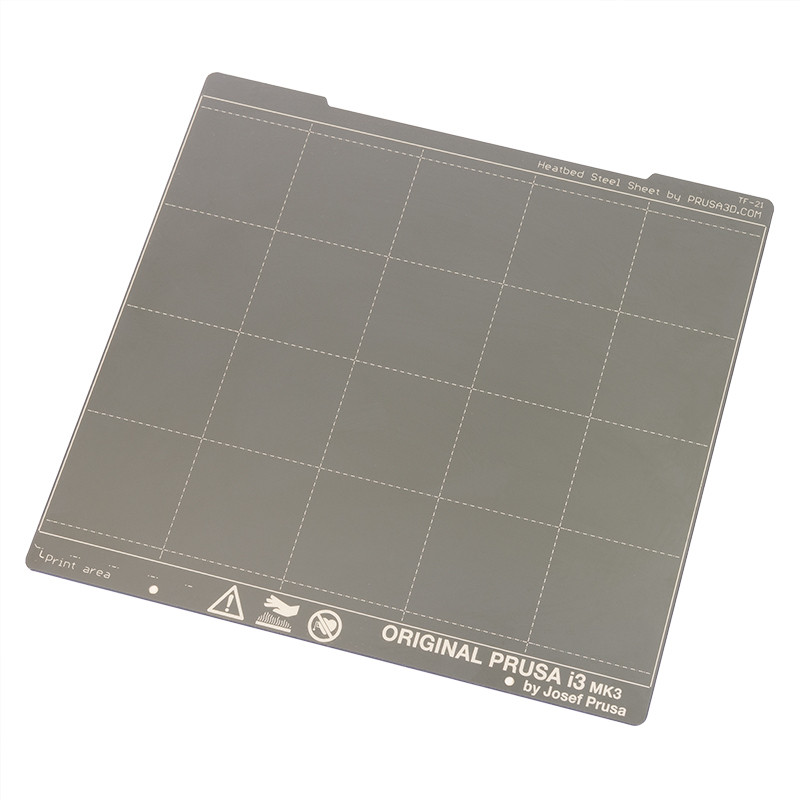

Steel sheet profiles (MK2/S, MK2.5/S, MK3/S/+, MK3.5/S, MINI/+)

For printers not equipped with a loadcell, each sheet needs a different Live-Z value, as they have slightly different thicknesses. If you are using multiple different sheets, the value for each sheet can be stored in the Steel sheet profiles. For more information see the article Steel sheet profiles.

Removing prints

To remove the printed object from the print surface, always wait until the steel sheet cools down to room temperature. Then you can take it off by bending the sheet inwards and outwards, but you may need to use a spatula to avoid damage to the sheet. For materials like PETG, ASA, ABS, and PC Blend, and/or prints with a large first layer surface, a separation layer in the form of gluestick may be required.

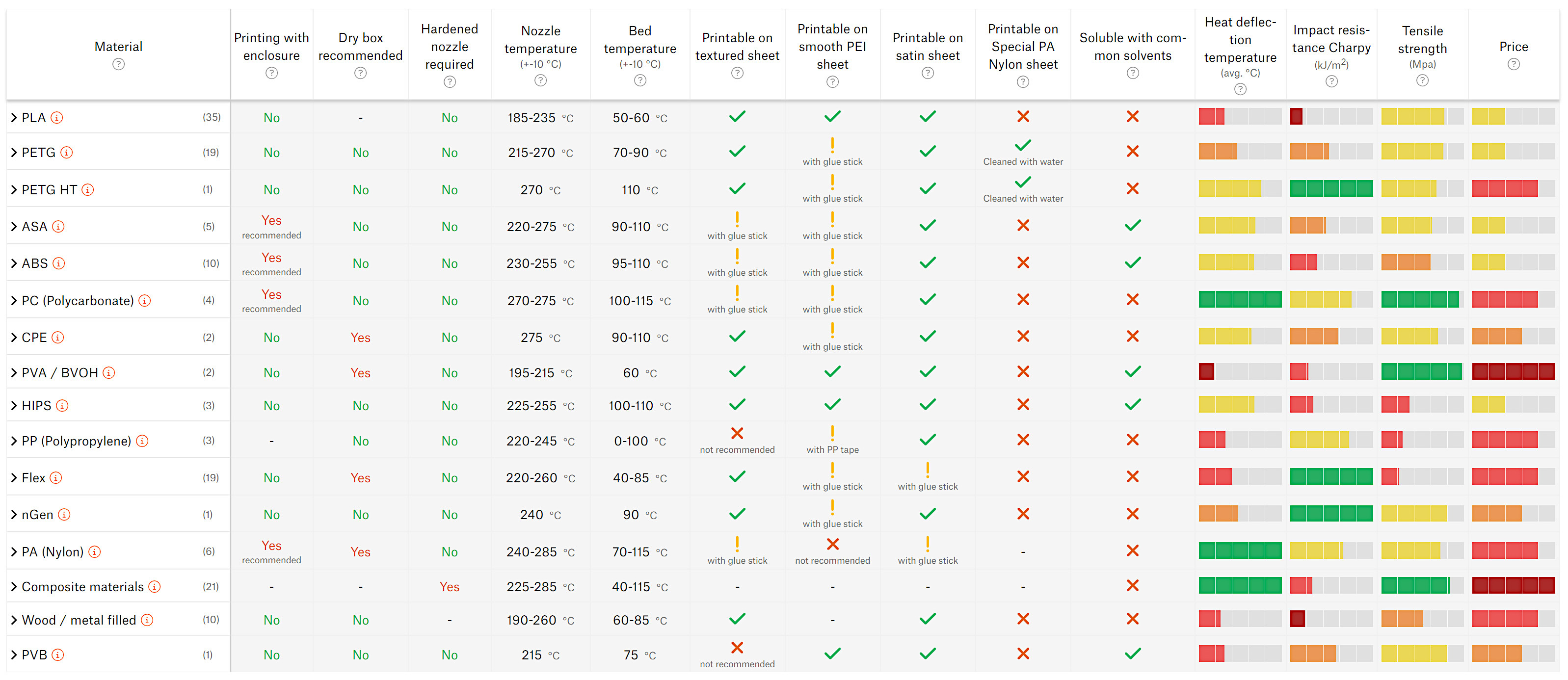

In case you are still having trouble removing the model even after letting it cool down or the surface got damaged during the removal (a piece of the surface was ripped off or cracked), you might be using a filament type that is not suitable for being printed on this kind of print sheet or the surface was not prepared correctly. Please see our Material table for filament and print sheet compatibility and surface preparation.

If you are using a spatula to help with the model removal, make sure to avoid damage to the sheet surface. Bend the sheet slightly and insert the spatula under the model whenever possible, instead of digging under the model on a flat surface.

For a stubborn print that refuses to be released from the print surface, you can try to re-heat the heatbed for a few minutes (to the original print temperature) and then let it cool down again. This can sometimes help with the removal of the prints that are too stuck to the print surface.

Differences between the sheets

We have done a lot of testing with filament material and sheet combinations and compiled our results. To easily see the sheet and material compatibility, and how to prepare your sheet for any filament type, please see our Material table.

*Values in this screenshot may not be up to date.

|  |  |  |

|

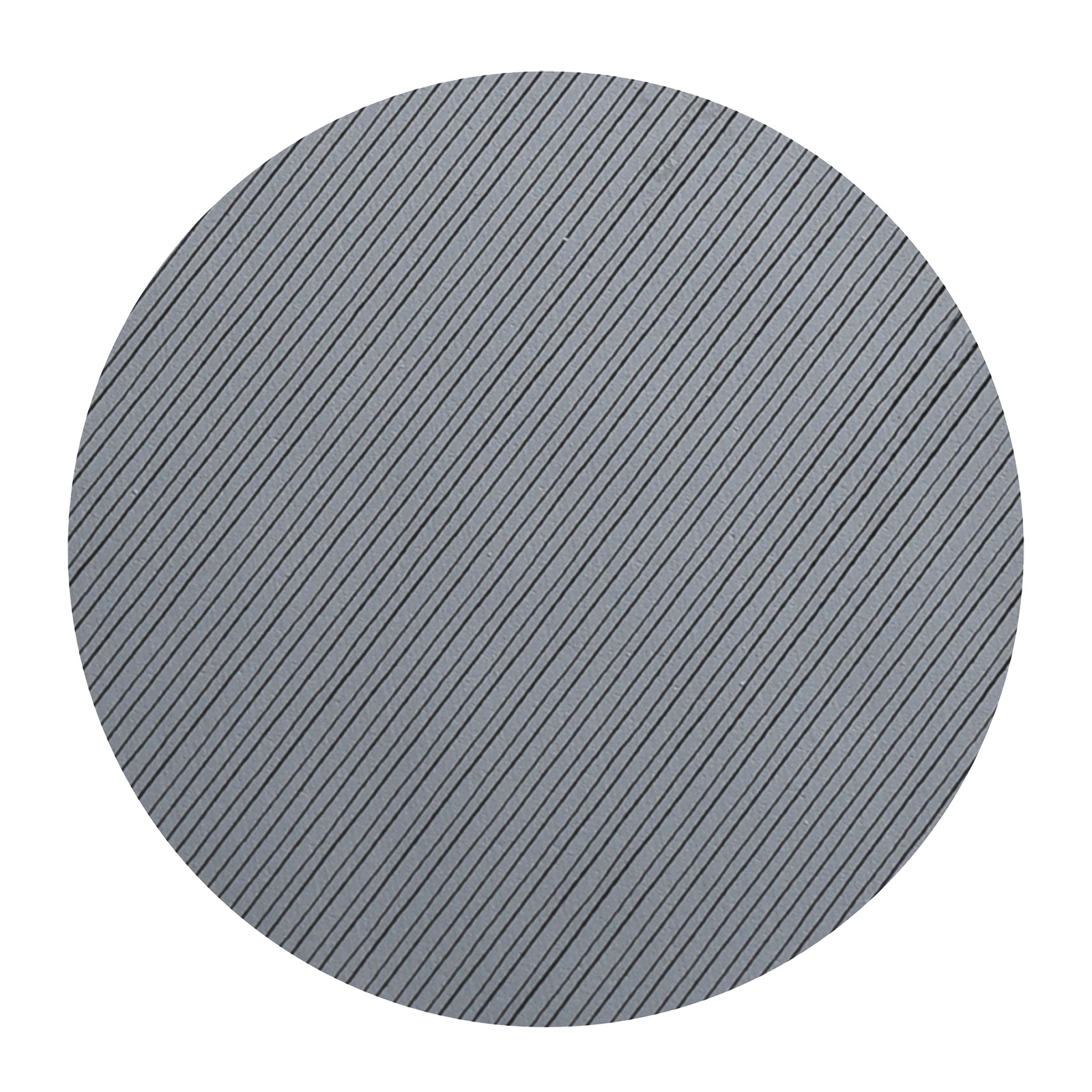

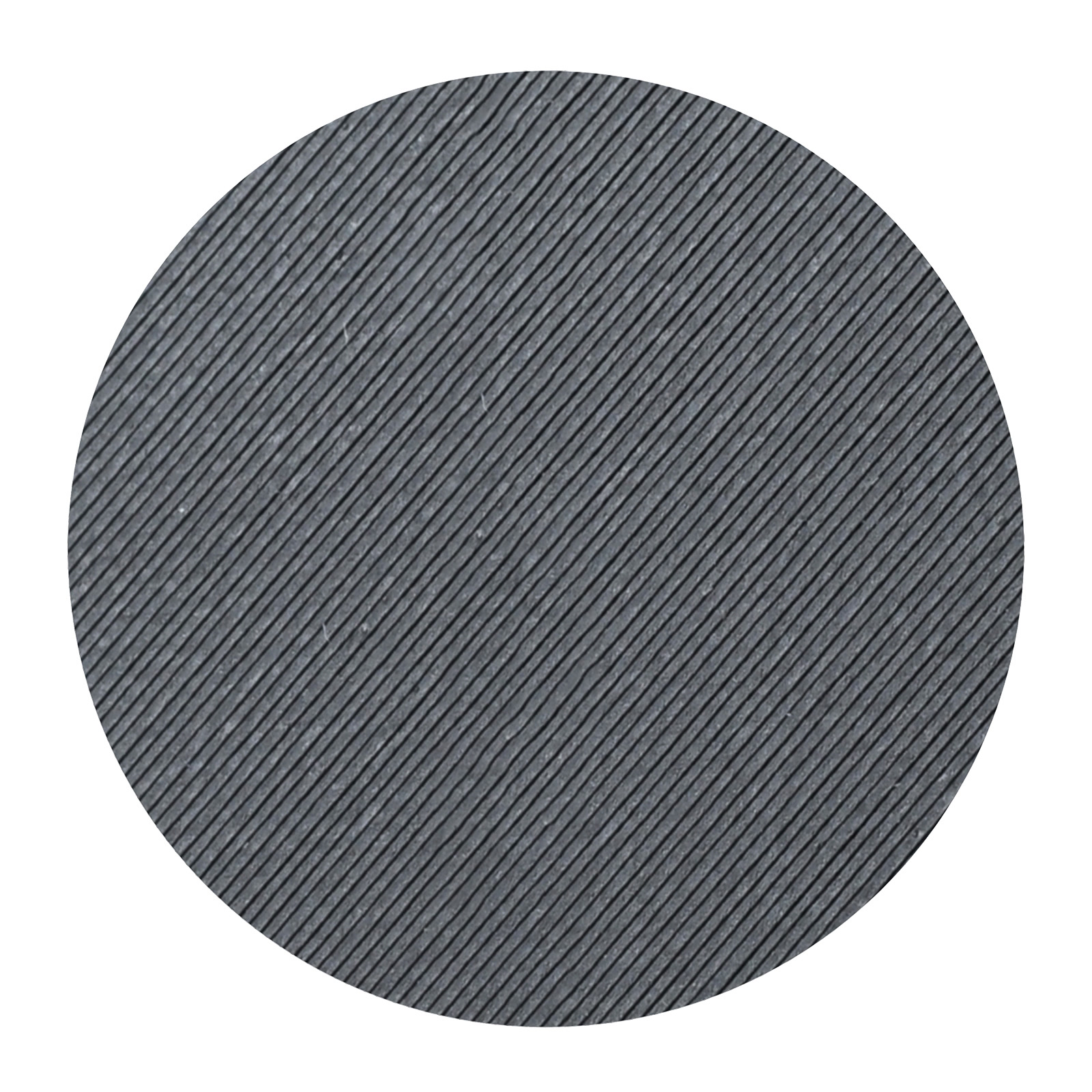

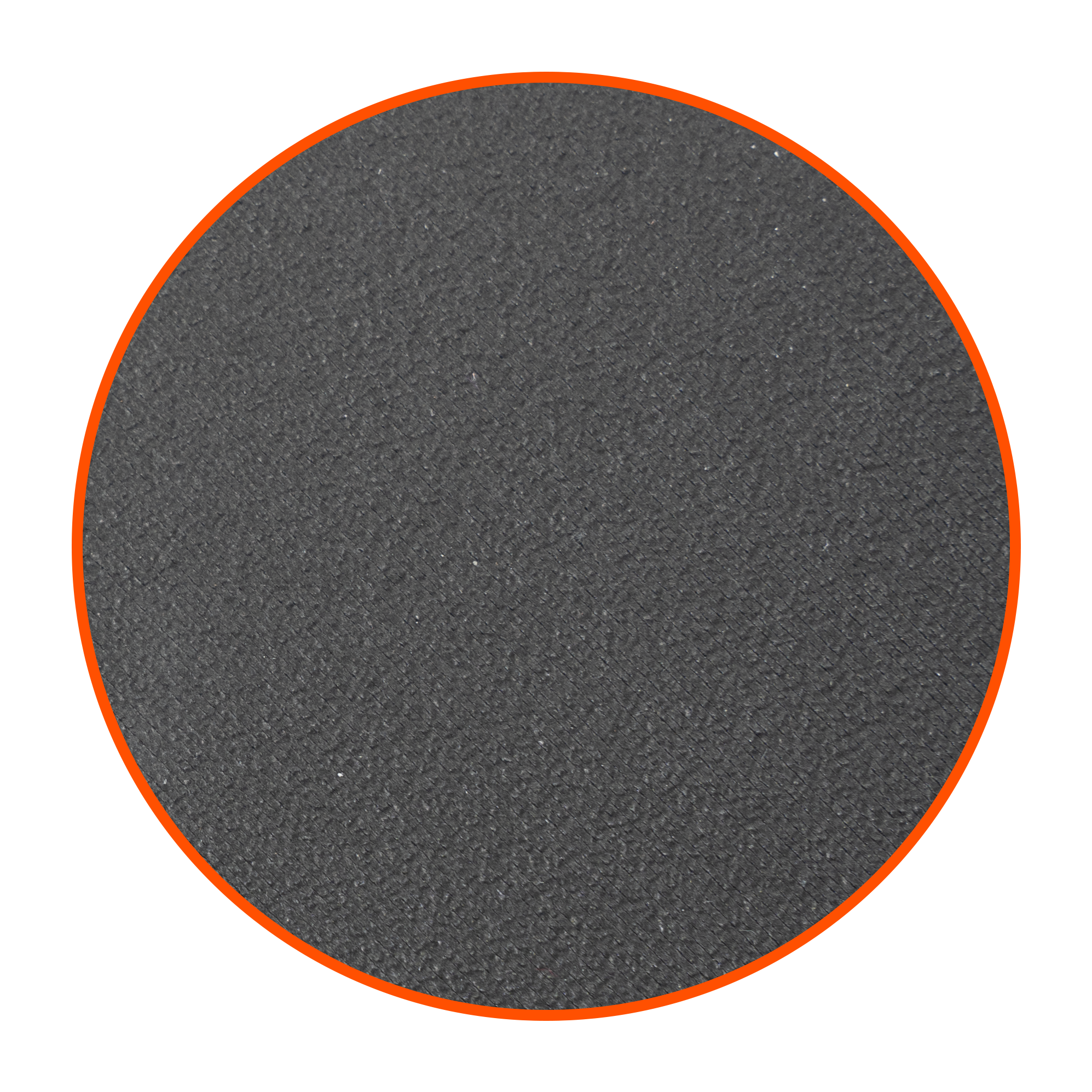

Close-up of a printed Smooth sheet |

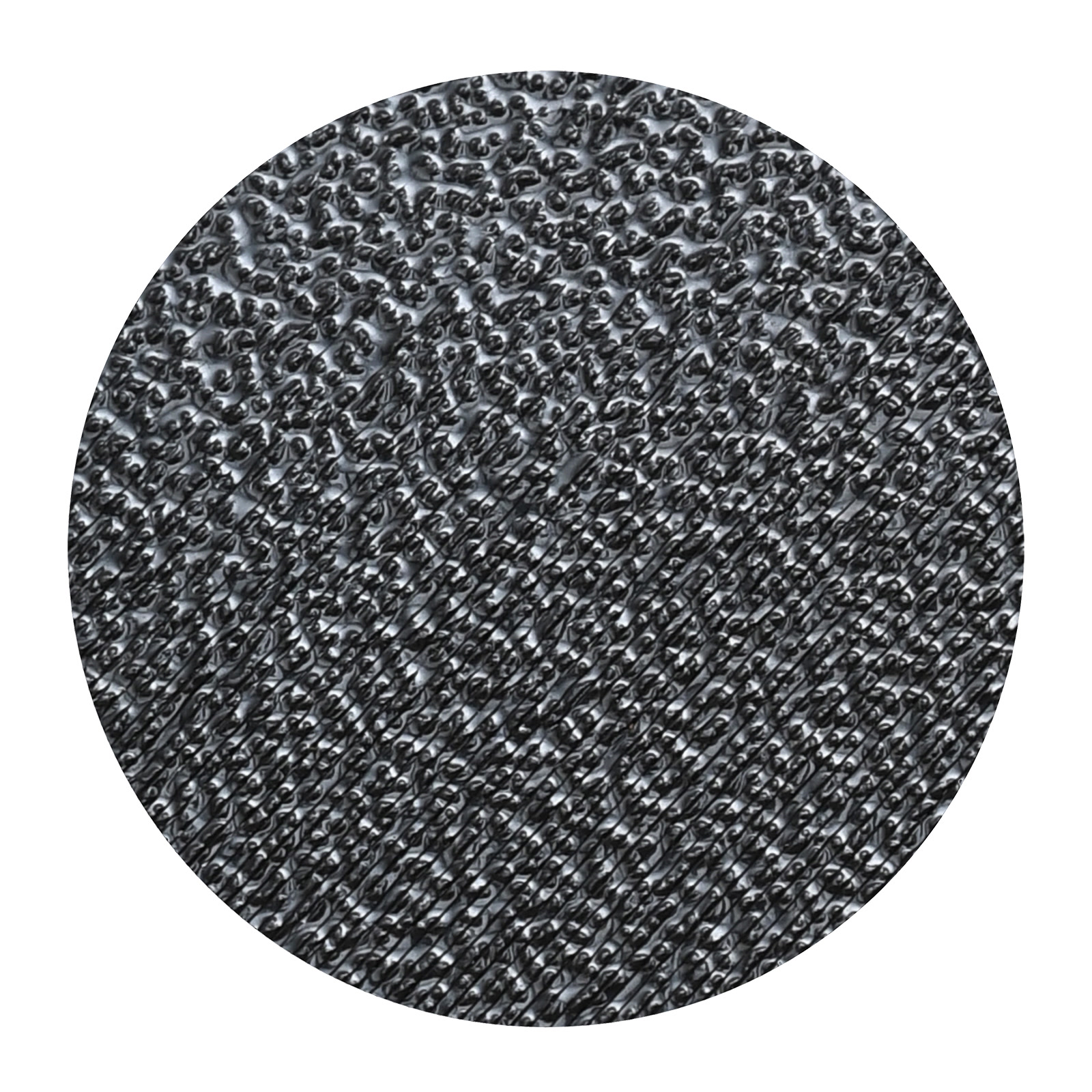

Close-up of a printed Textured sheet |

Close-up of a printed Satin sheet |

Close-up of a printed PP, PA nylon and HighTemp sheets |

Smooth PEI sheet

Both sides of this sheet are covered by a sticker made from smoothed PEI plastic. This is the same time-tested surface type that was used on the older MK2S printers. Prints with a small area touching the print surface or with sharp corners are less likely to detach when printing on a smooth spring steel sheet. Some users also like the smooth and shiny bottom side of their prints. For all details and considerations of the Smooth sheet, please see Smooth Steel Sheet.

Powder-coated textured sheet

The surface of this sheet is covered with a special polymer (Ultem) to ensure perfect adhesion. The powder-coated steel sheets are better for printing objects with materials such as PETG, CPE, or Flexfill (TPU) which tend to adhere too much to a smooth surface, but can be more easily removed from the textured one. For all details and considerations of the Textured sheet, please see Textured steel sheet.

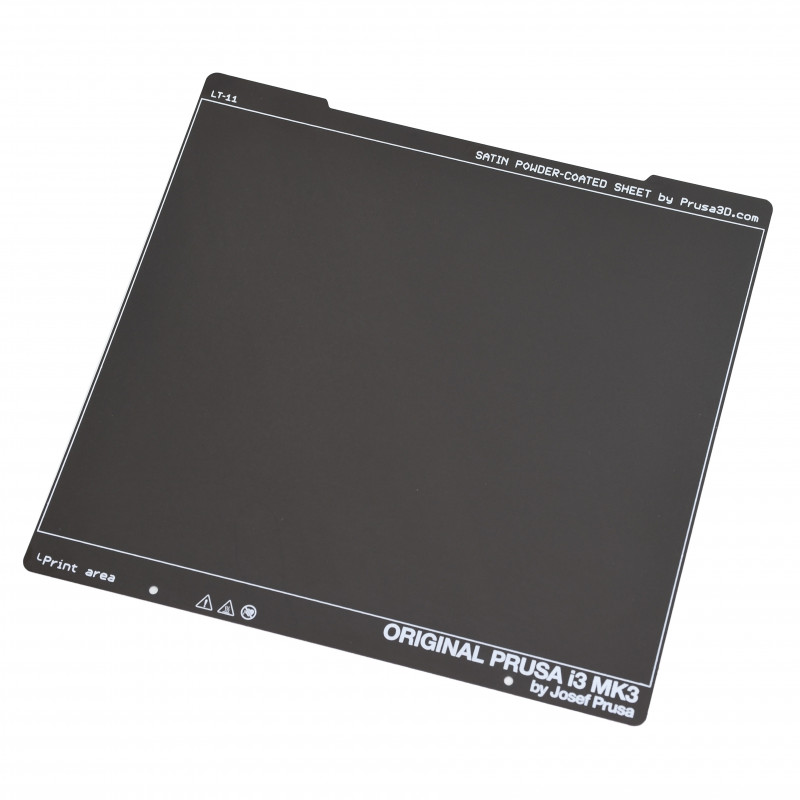

Satin sheet

The Satin sheet further expands our line-up of print sheets. Its powder-coated surface with a lightly textured matte finish offers an optimal level of adhesion and is fully compatible with a wide range of common and less-common filaments. For all details and considerations of the Satin sheet, please see Satin steel sheet.

PA nylon sheet

The special PA nylon sheet is made for printing polyamides (Nylon) since their adhesion to standard PEI sheets is generally very poor. The sheet comes with a matt texture, similar to the satin steel sheet with a PEI surface. The sheet is compatible with most polyamides and PETG, other materials may have insufficient adhesion and should be printed on our standard PEI sheets. For all details and considerations of the PA nylon sheet, please see PA nylon sheet.

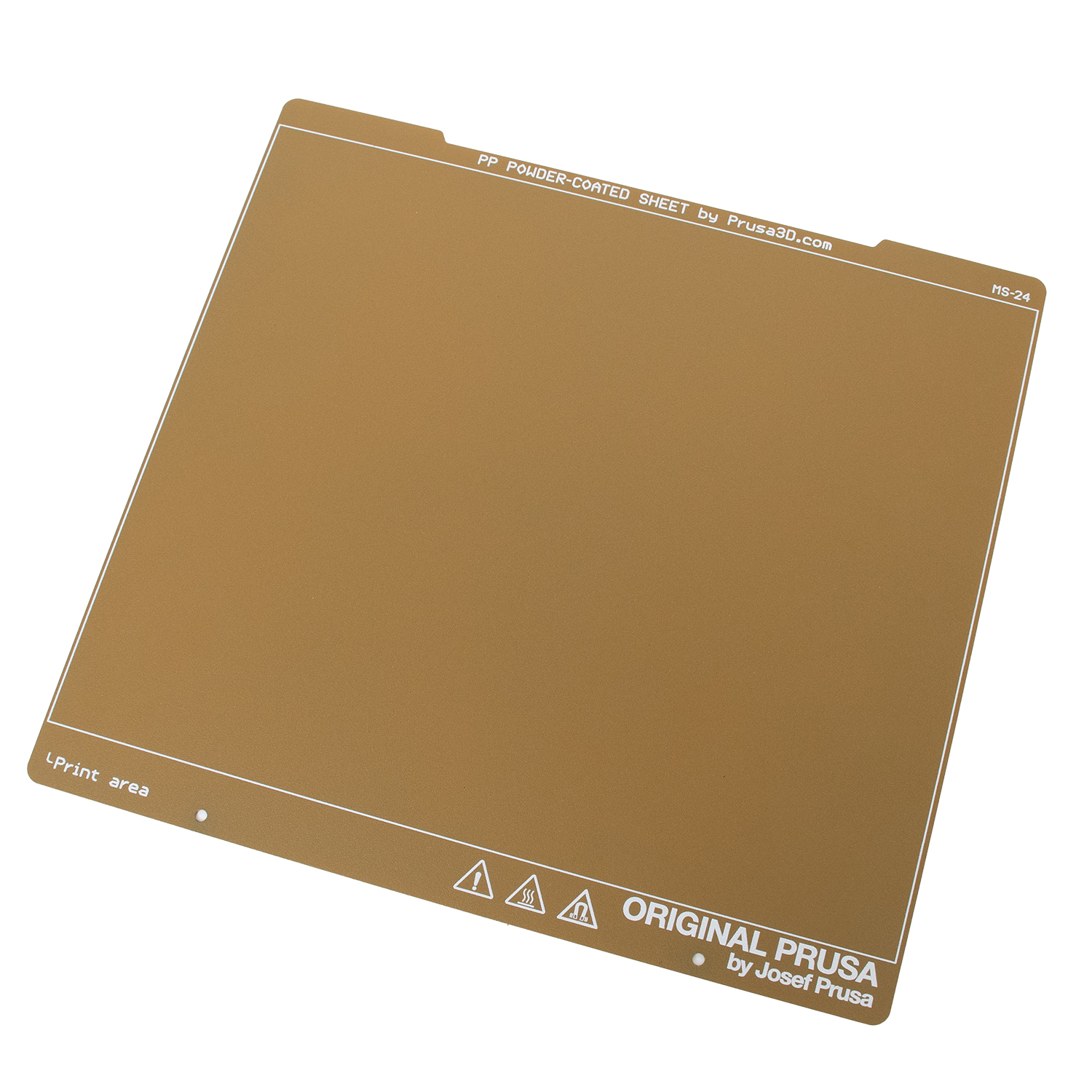

PP sheet

This print sheet is specially designed to print polypropylene-based filaments, especially the Prusament PP Carbon Fiber Black. The PP-type materials have generally a lower adhesion on textured or satin print sheets. This sheet has a special surface finish that increases the adhesion and is perfect for Prusament PP. The PP sheet has a lightly textured surface finish similar to the Satin Powder-coated Steel Sheet. For all details and considerations of the PP sheet, please see PP sheet.

HighTemp sheet

The HighTemp print sheet is intended for printing with special high-temperature materials, such as PEEK, PEEK-CF, PEI, PEKK, and PPSU, which may otherwise have poor (or too strong) adhesion on standard steel sheets. Basic materials such as PLA or PETG do not adhere very well, as this print sheet was developed for high-performance, high-temperature materials. This sheet is made for the Prusa Pro HT90 printer only. For all details and considerations of the HighTemp sheet, please see HighTemp sheet.

Prints don’t stick

If your print surface is perfectly clean and all grease has been removed by wiping it as in the guidelines for your steel sheet type, and if the first layer height is set up perfectly, yet your print still does not adhere reliably to the print surface, check out First layer issues.

17 comments

Suggestion2: Print the sheet type on the sheet *near the front* so I can confirm sheet type with sheet type setting before starting a print.