What happened?

If, during the filament load-to-nozzle process, the extruder's filament sensor is not triggered, the printer will display an error.

How to fix it?

Assembly

- Remake the filament sensor calibration.

- Make sure that the PTFE tube is fully pushed into the Festo fitting on the extruder and the MMU unit, and that the fitting is fully tightened, with no gap.

- If you use an alternative MMU-to-Extruder PTFE tube, make sure it is not excessively long. The original tube is 360mm long. The MMU can adapt to tubes between 350 mm to 380 mm.

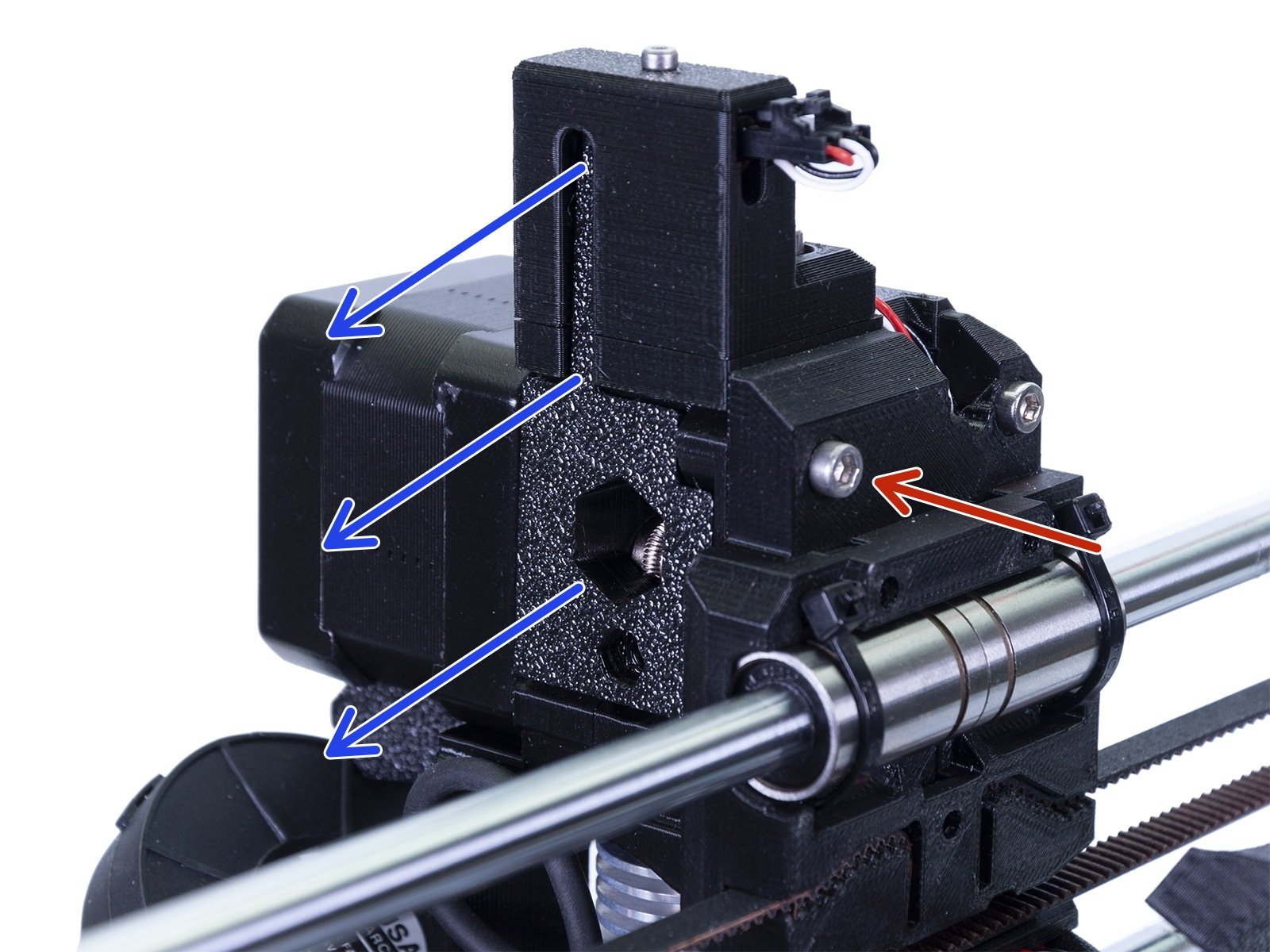

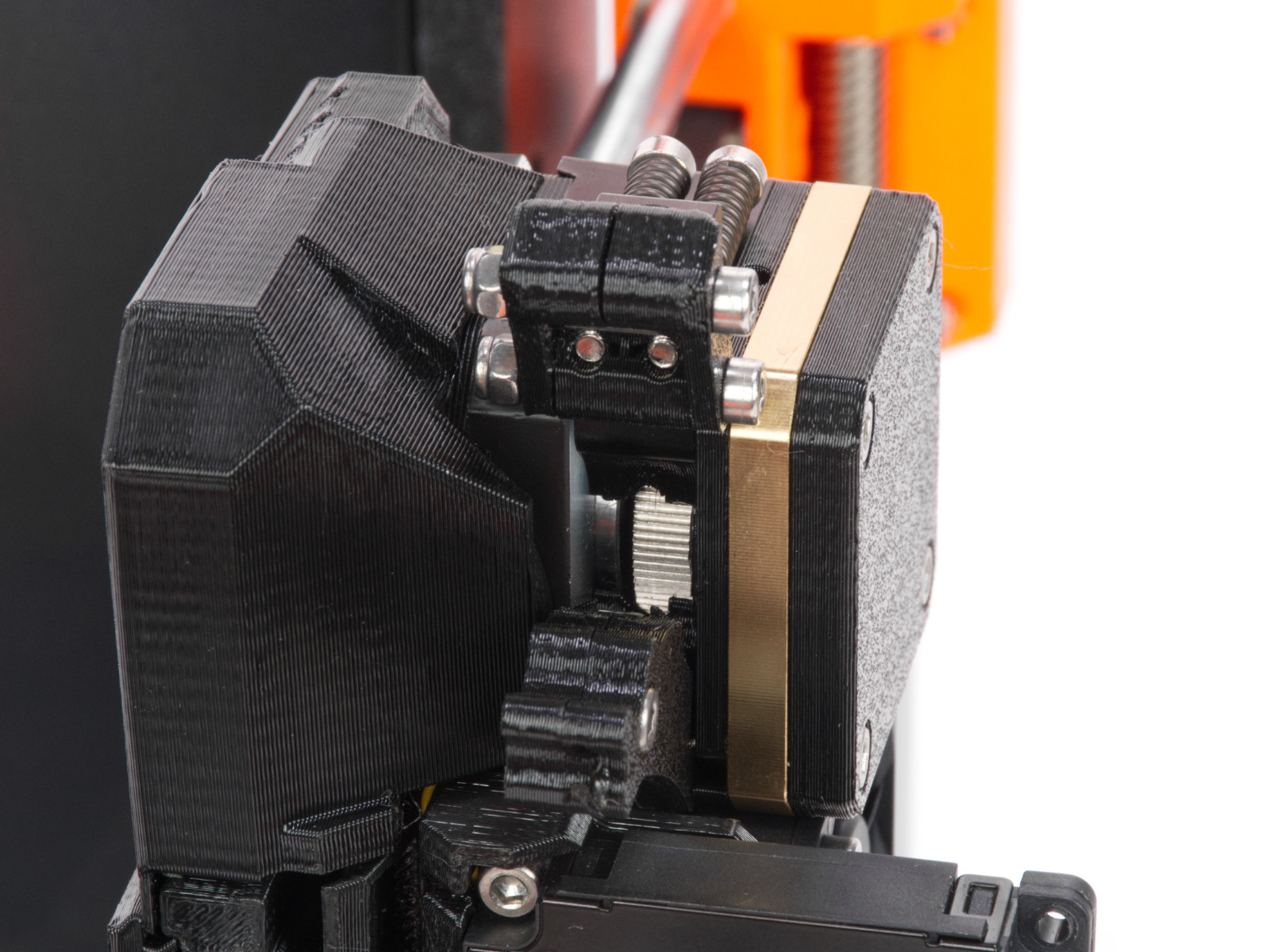

- Open the extruder idler and make sure there is no leftover filament blocking the new filament from loading.

|  |

| MK3/S/+, MK3.5/S | MK4/S, MK3.9/S, CORE One |

Filament

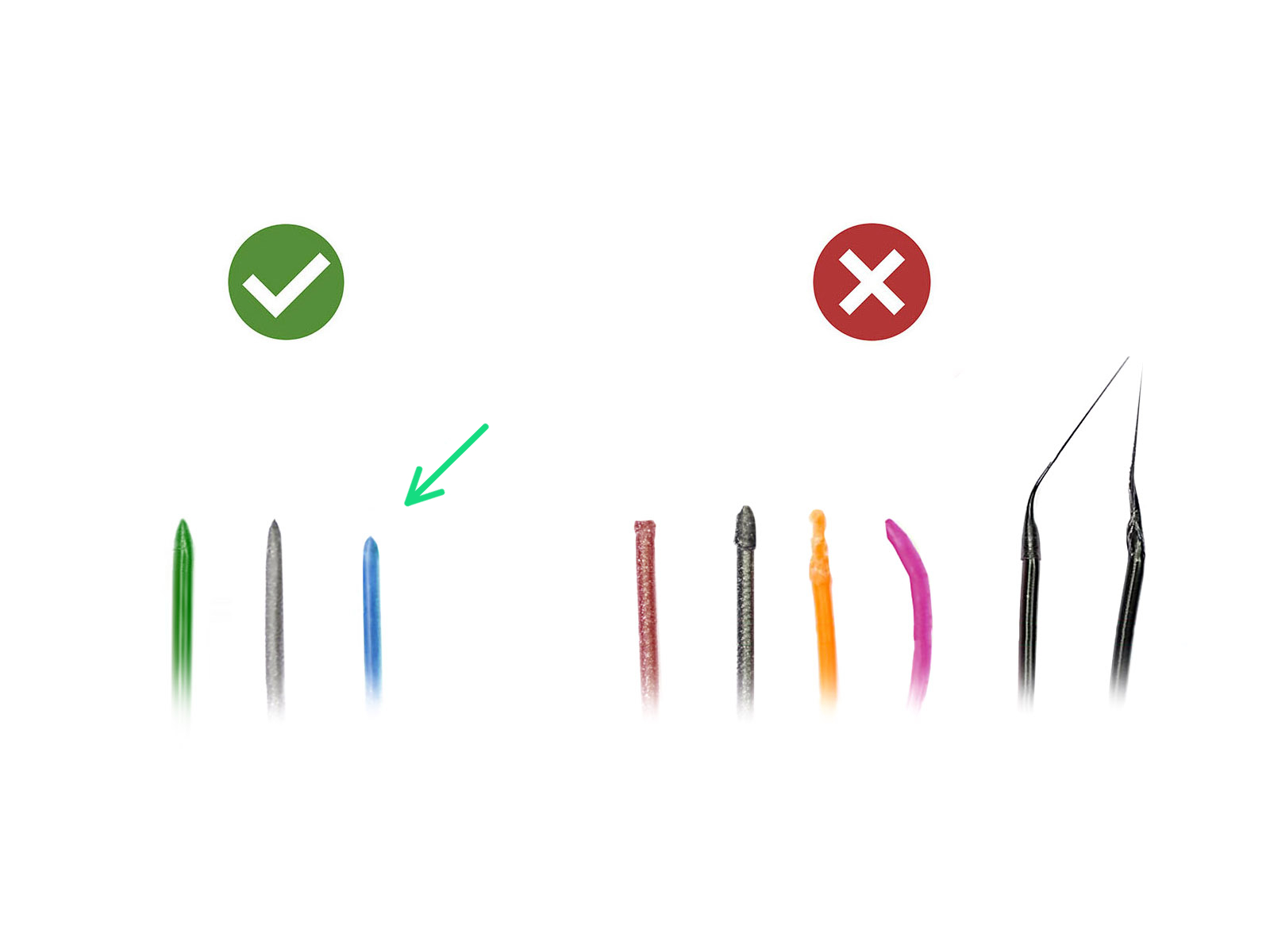

- The filaments must have a sharp tip to load properly into the printer. If the tip is deformed, bent, or larger in diameter, cut it off.

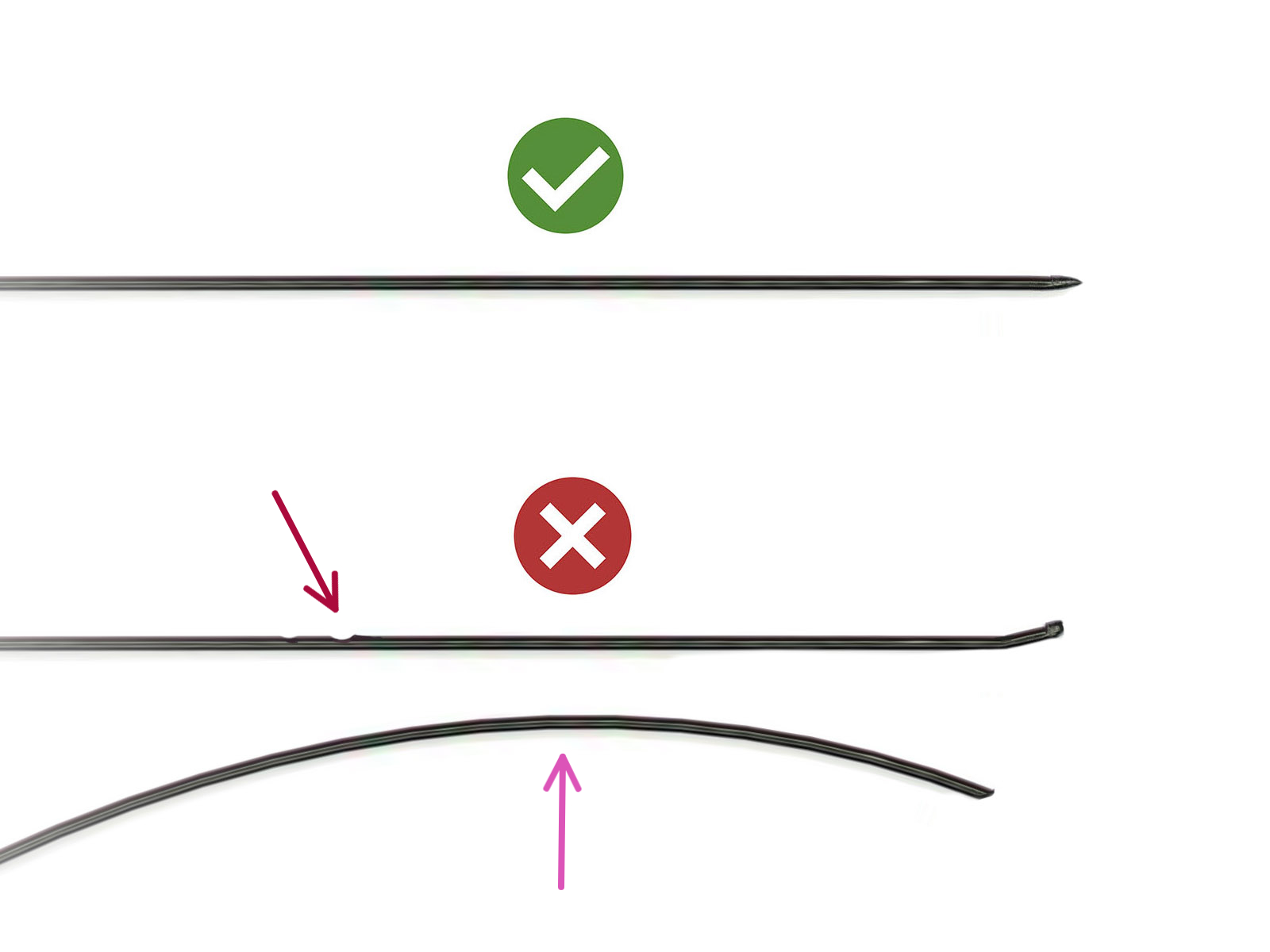

- Inspect the last 40cm (15") of each filament to make sure there are no dents.

- If the filament is still not being pulled, check the assembly.

|  |

Was this article helpful?

This action is available only to registered users. Please log-in.

5 comments

Just tightened them back to the indicated recess.

Also doesn't cover scenarios when slots 1-3 load fine (so the sensor is fine), but 4-5 fail to load (when filament tips are fine as the first three).