What happened?

While the MMU unit was unloading a filament, the SuperFINDA sensor inside the selector stayed triggered/detecting a filament, while it shouldn’t.

How to fix it?

Check if the filament has been unloaded or not.

If the filament has been unloaded, but the superFINDA is still triggered, open the Festo fitting connected to the selector, and check if there is anything stuck in the selector (e.g. broken filament, string).

Also, make sure that the superFINDA is working: FINDA setup and troubleshooting.

|  |

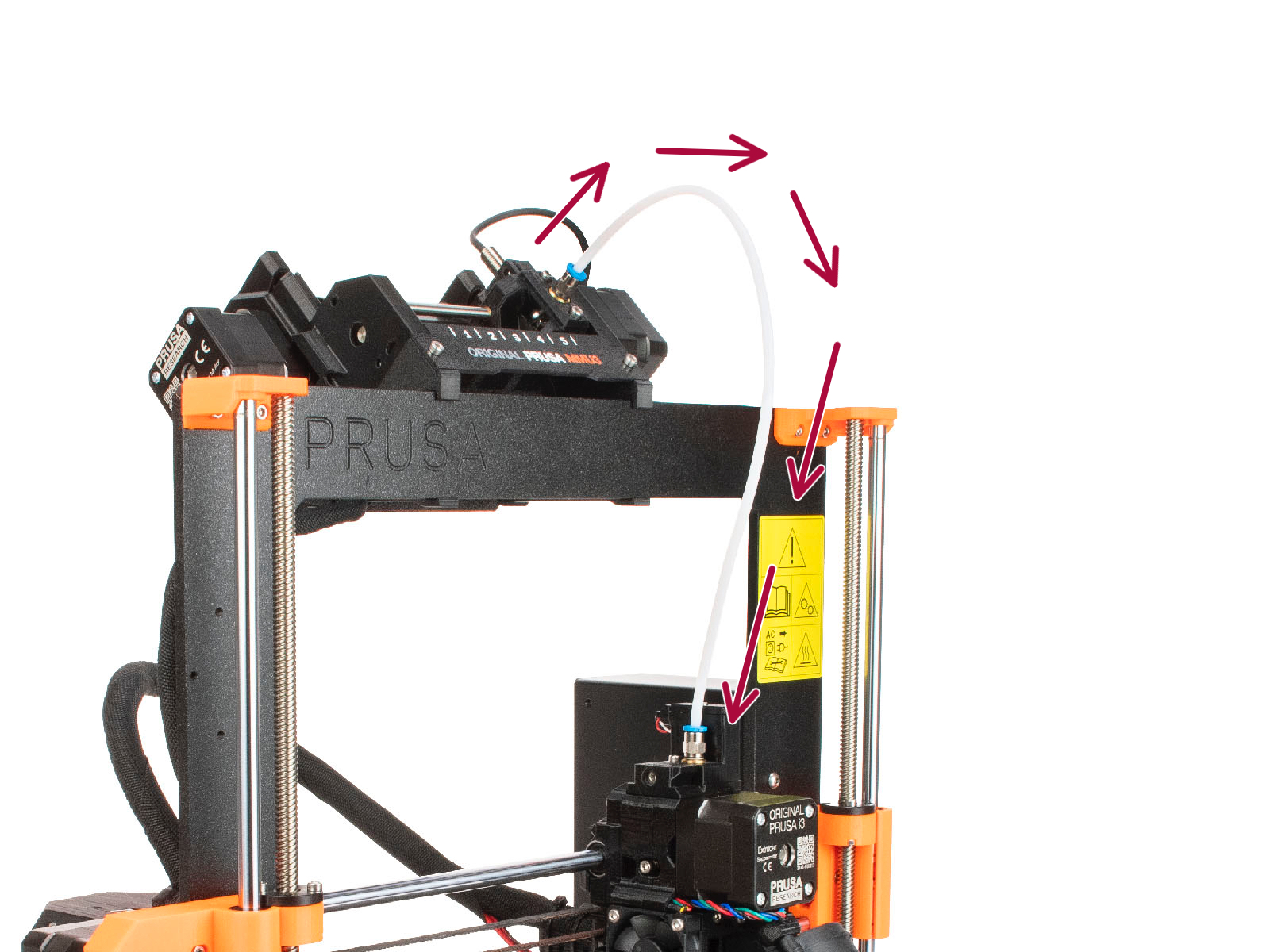

In case the filament is stuck between the MMU unit and the extruder, remove the PTFE tube from the FESTO fitting. Remove any debris that might be stuck in the PTFE tube. pull out approx. 40cm of filament and inspect it for indents. If there are any, cut off the damaged part of the filament, re-install the PTFE tube, and hit Retry.

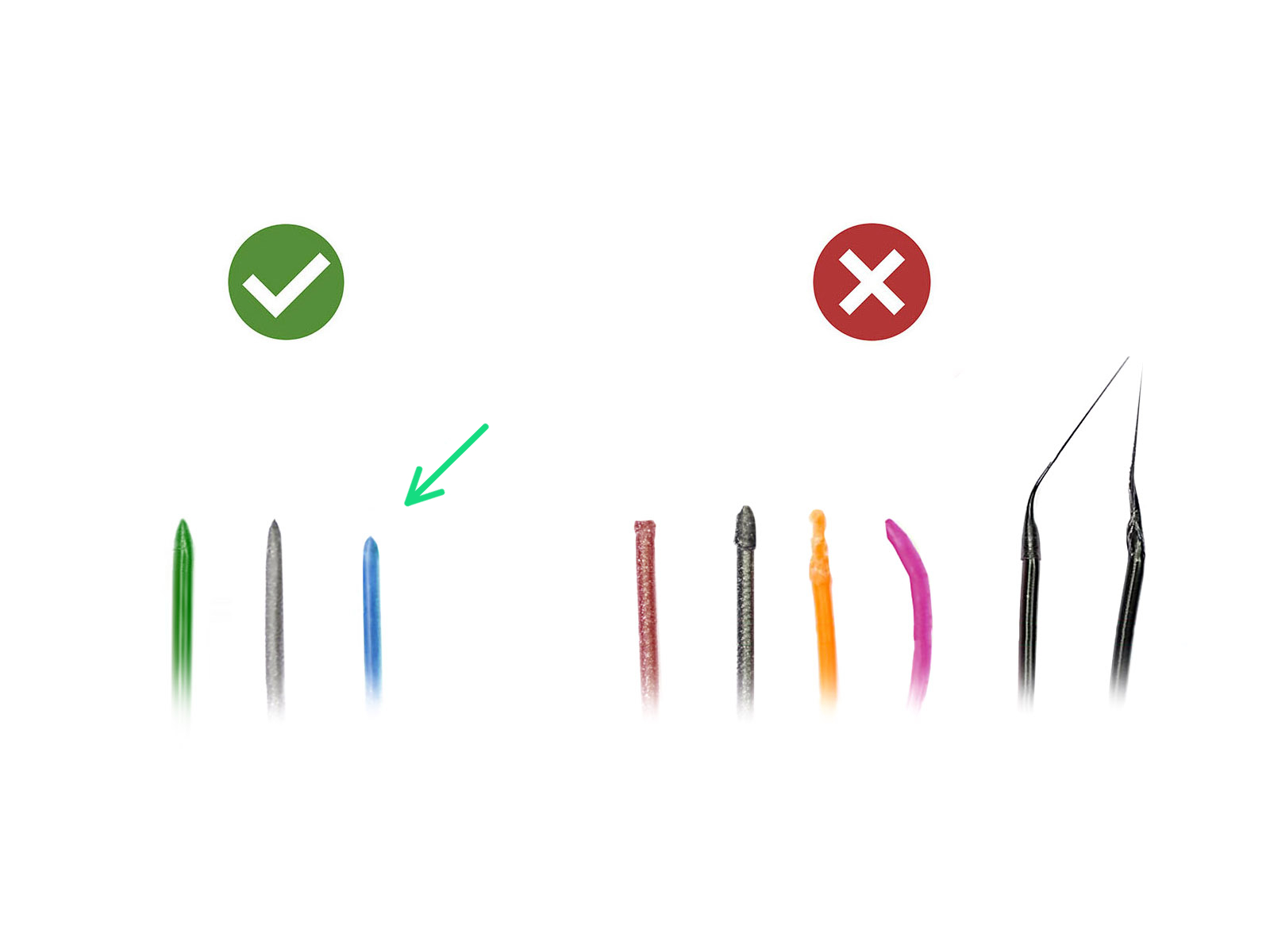

Make sure that the tip of the filament is sharp, and not stringy or expanded so that the issue does not happen again.

If there is any debris or broken pieces of filament inside the selector, it can be cleared up using the 1.5mm Allen key, if you remove the FESTO fitting and move the selector all the way to the right. If the SuperFINDA sensor was triggered due to debris / broken filament, the actual filament might be far behind the pulley wheel and might need pushing into the MMU from the back, while retrying the loading operation.

Multi-material operation is sensitive to proper temperature settings. Check that you are using the correct settings for the given material in Slicer. Incorrect nozzle temperatures will cause issues with filament load/unload. Note that with MMU, some 3rd party filaments might behave differently than during the single-material operation even with the same settings.

Some filaments sensitive to moisture might need to be dried out before use. Moist filaments are usually more stringy and this might cause the filaments to jam. You can read more about how to lower the stringing in our Stringing and oozing article.

It is recommended to use only high-quality filaments. Certain poor-quality filaments or very specific filament types won’t work correctly with the MMU. In this case, change the slicer settings according to the manufacturer's instructions.

11 comments

das Filament wird beim Laden in die MMU3 beschädigt. Es kann weder geladen noch entladen werden. Der Finda reagiert ordnungsgemäß. Das konnte ich testen.

Was könnte ich falsch gemacht haben beim Zusammenbau?

Das Filament ist erst kurz vor dem Versuch zu laden, ausgepackt worden. PLA von eSUN

OrderNr. 1733431480

[email protected]