What happened?

On the multi-tool versions of the Original Prusa XL, the offset of the tools compared to the first is calibrated through the Tool Offset Calibration. If the offset of one of the tools deviates too far from the expected range, the printer will show the following message: "Tool %d offset %c: %.3f is out of bounds [%.3f, %.3f]".

Error name: Tool offset out of bounds

Error code: #17104

How to fix it?

Filament unload

Make sure that the filament is unloaded before the calibration process.

Nozzle position

On single-tool XL, after removing the x-carriage cover, hold the heater block (make sure that the nozzle is not heated!), and use the Torx TX8 key as shown in the picture to tighten the set screw. Do not use extra force while tightening, it may damage the hotend tube. The nozzle must be approximately at a 35°-40° angle to avoid damaging the hotend cables.

|  |

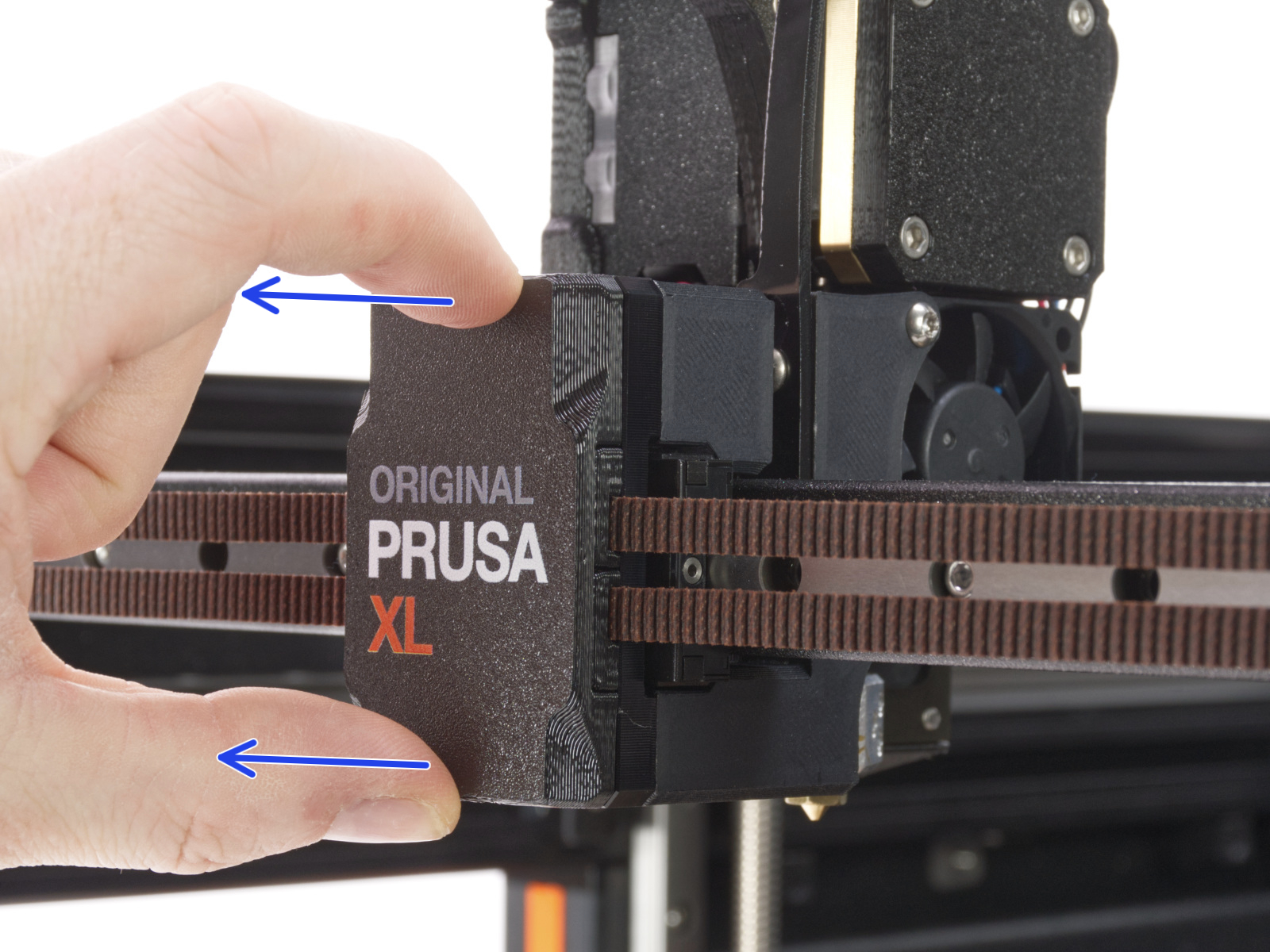

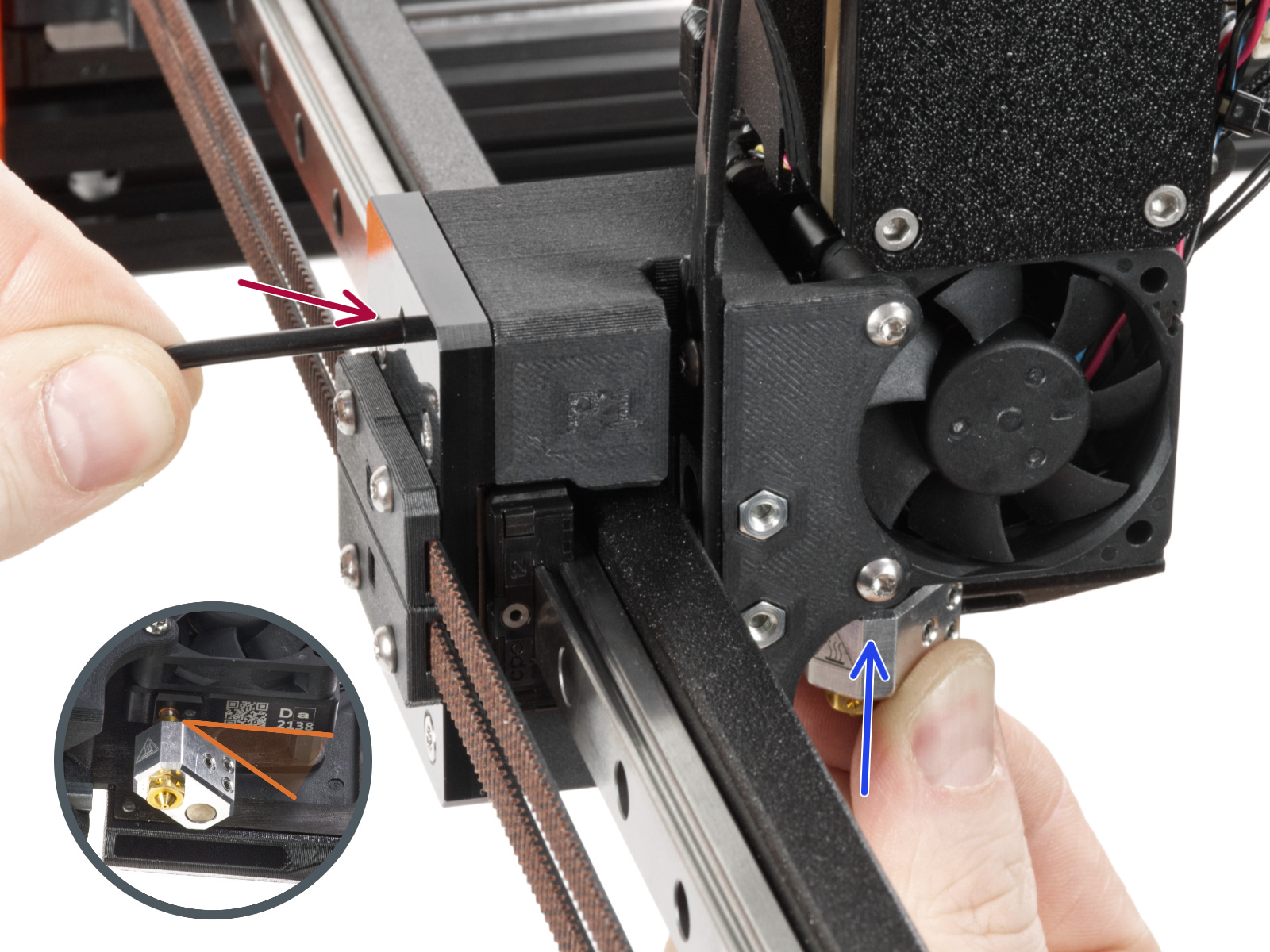

On multi-tool XL, identify the tool that has the nozzle to be checked, and park it. Hold the heater block (make sure that the nozzle is not heated!), and use the Torx TX8 key in the part shown in the picture to tighten the set screw. Do not use extra force while tightening, it may damage the hotend tube. The nozzle must be approximately at a 35°-40° angle to avoid damaging the hotend cables.

Nozzle cleaning

Use a small brass brush to clear away any old plastic stuck on the nozzle and heaterblock. Avoid contact of the brush with the hotend cables, as this could cause a short circuit.

Swap the hotend

If the points above did not solve the issue, swap the hotend of the failing tool with one of the hotends from a tool that passes the calibration.

If the error moves with the hotend, please contact our customer support with this information.

Dock calibration

If the error message does not follow the tool where the hotend was swapped, it is possible that the issue derives from the dock or its calibration.

Recalibrate the dock corresponding with the tool that displayed the error message. To do so, navigate to LCD Menu -> Control -> Calibrations & Tests -> Dock Position Calibration.

Reduce vibrations

Any form of vibration propagated to the surface under the printer, or a not fully stable surface under the printer might cause a false reading on the loadcell, causing the homing error to trigger.

For example, a printer that is in operation next to your Original Prusa XL can cause vibrations that are propagated to it, potentially causing a tool offset calibration fail. In that case, stop any printers next to your XL, and reattempt the calibration.

A possible solution to dampening the noise and vibration of a printer is to add some additional padding underneath the printer.