Basic info

LW PLA is a filament that can expand during printing. It is useful for parts that need to be light.

Description

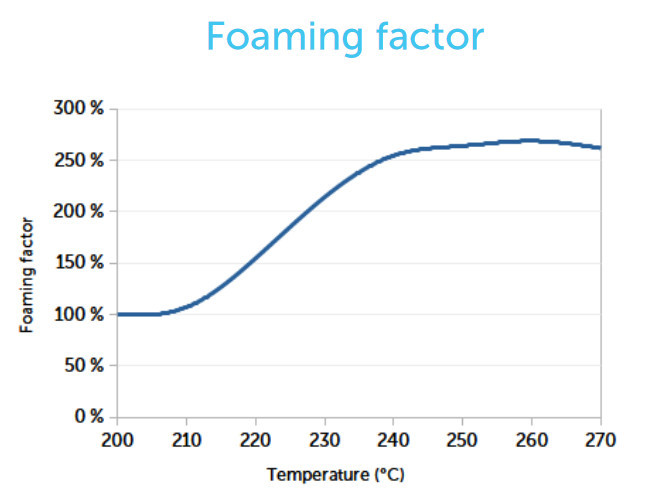

LW PLA (Lightweight PLA or PolyLight 1.0) is an active foaming material that can expand from 2.3 to 3 times the original material size when printed. The expansion depends on the print temperature and speed of the print.

The LW PLA can be used with standard PLA settings. It will behave in general as PLA, but still have a lot of oozing.

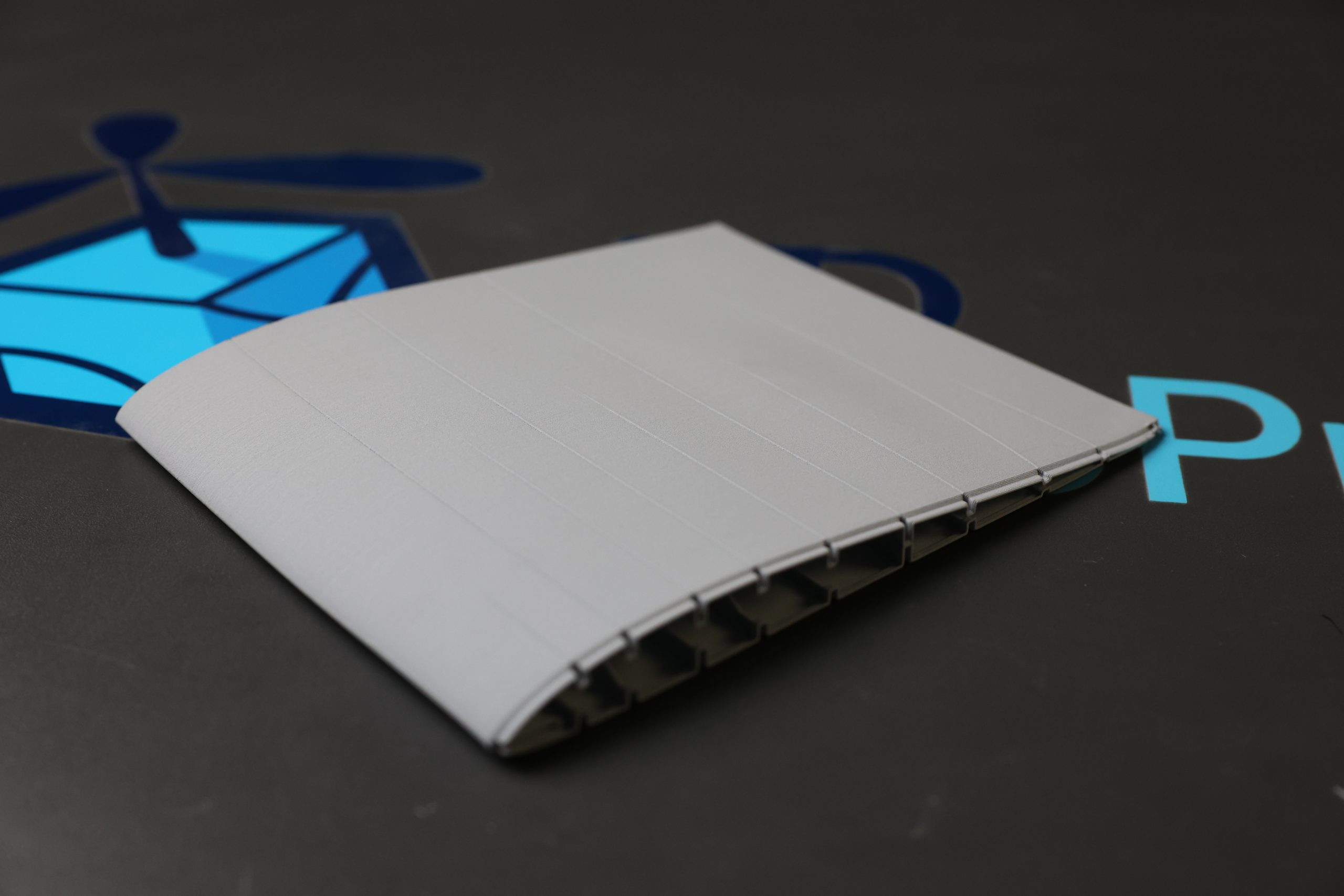

This filament is also useful to print models with thin walls and internal structures, like the 3DLabPrint planes. We have prepared a config bundle with all the necessary settings for that, including the "Even-odd" Slicing mode, in our e-shop.

3DLabPrint also has a general config bundle for the parts in their website.

|

Pros |

Cons |

|---|---|

|

✔ Reduced weight by 65% |

✖ Less stiff than PLA |

|

✔ Increased volume by 270% |

✖ Lower glass transition temperature |

|

✔ Cost-effective |

✖ Oozing during travel moves |

|

✔ Strong inter-layer adhesion | |

|

✔ Heat-activated foaming | |

|

✔ Easy to glue with CA | |

|

✔ Less visible layers |

Best use

The best use of LW PLA are models that need low weight, such as model airplanes and cosplay wearables.

Tips for successful printing

Sample prints

|  |

| Part of 3DLabPrint airplane models | Part of 3DLabPrint airplane models |