3D printer extruders love to extrude at a constant rate for the best extrusion consistency. However, during a print, the extrusion is typically not constant at all. Inifill is usually printed the fastest, perimeters are printed slower and the external perimeter is printed the slowest for the best surface finish and accurate dimensions. Bowden style extruders are especially sensitive to pressure fluctuations, due to the slack in bowden tube, they are not able to reproduce rapid changes in extrusion rate reliably.

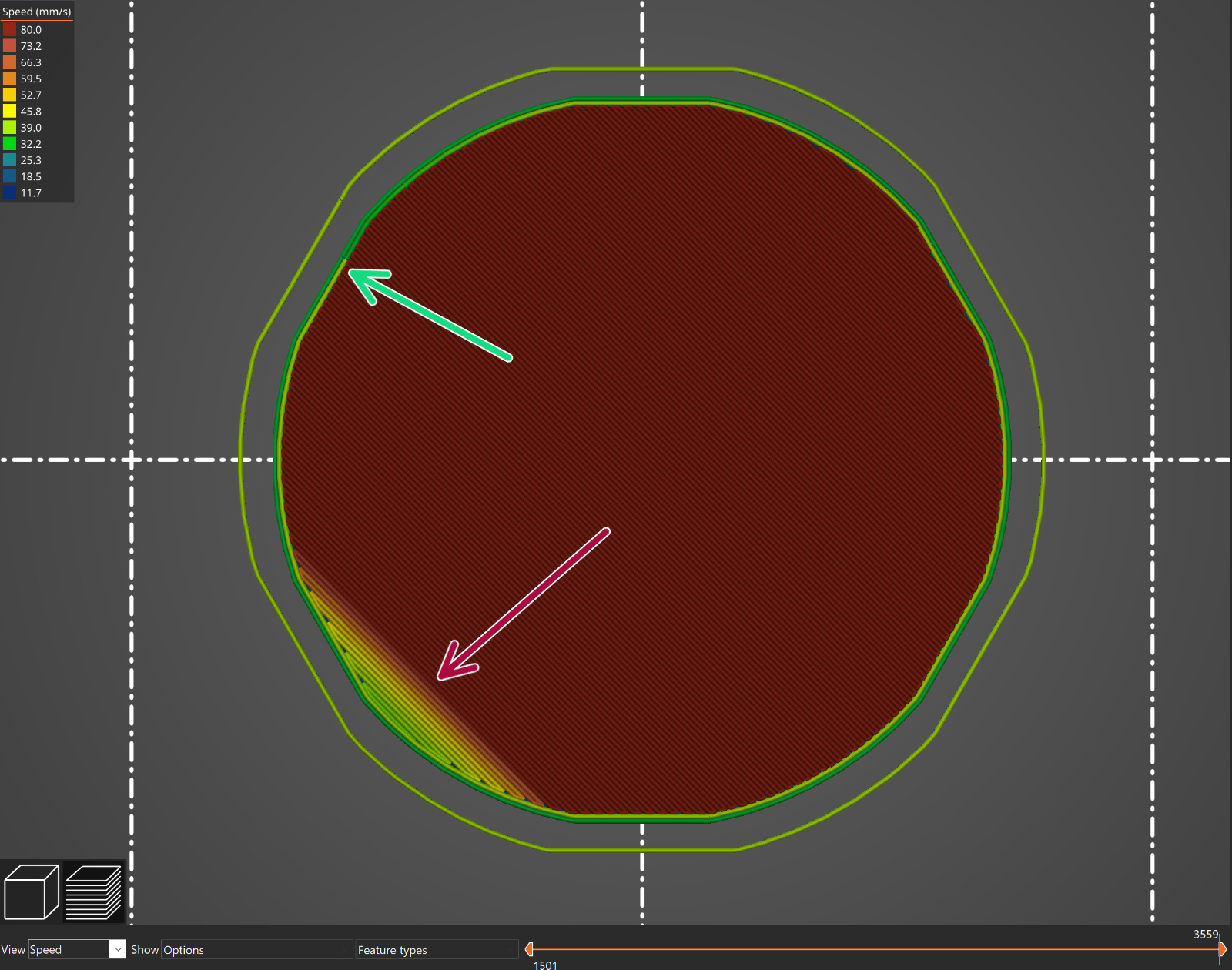

The Pressure equalizer smooths sudden changes in speed between two features (e.g. between printing infill and perimeters).

You can find the Pressure equalizer settings in Print settings - Speed.

The acceleration limit from lower to higher speed (speed up) is called Max volumetric slope positive.

The acceleration limit when going from higher to lower speed (slow down) is called Max volumetric slope negative.

The lower the volumetric sloper value is, the smoother will the transition be. Adding these speed transition will likely increase the print time a little bit. Slowing down infill after perimeter may increase print times excessively, this can be suppressed by setting Max volumetric slope positive to zero.

We suggest using values between 2-10.

Linear Advance vs Pressure Equalizer

The Linear Advance algorithm predicts the pressure build-up in the extruder when printing at higher speeds. The firmware of the printer uses that prediction to decrease the amount of filament extruded just before stopping and decelerating, which prevents blobs or artifacts at the sharp corners. In short, it affects extrusion.

The Pressure equalizer smooths the speed changes when transitioning from printing one feature (e.g. infill, perimeters) to another. In short, it affects print speed.

Both of these features can work together to achieve the same end result - smooth and accurate prints with minimal artifacts. In a way, the Pressure equalizer can make the job of Linear Advance easier, but reducing the number of sudden fast movements.

9 comments

For example I am printing flexibles which already have a low volumetric speed of let's say 2.5 mm³/s setting this to very low values such as 0.0001 mm³/s² seems to be ignored ?