Supports can be hard to remove and leave imperfect surfaces above them. Depending on the shape of the object, there is also the risk of ruining the print in the process. Some geometry is not even possible to print as a single piece using FFF printing.

With the Original Prusa MMU3, MMU2S, and XL multi-tool, it is possible to use water-soluble materials, like PVA+ and BVOH, to print the supports or just the 'interface' between the print and the support structure. However, printing solubles can be demanding and requires some considerations along the way. It is a process more suitable for advanced users.

Which material to use

The first consideration is that the main material and the soluble support material must have similar melting/printing temperatures. PVA+ and BVOH are similar in many ways, but BVOH is absolutely the better (but more expensive) option. It is stiffer and will behave much better than PVA+ when printed. This is why it is better to be printed with PETG.

For PETG you can practically only use BVOH. PLA can be printed with both PVA+ and BVOH.

Slicer configuration

There is a specific configuration for the soluble support materials in PrusaSlicer. Once you have selected the Original Prusa MMU3, MMU2S, or XL multi-tool printer profile, you will find some new options in the 'Print Settings' drop-down menu. For 0.15 mm and 0.2 mm layer height, you now have the additional SOLUBLE FULL and SOLUBLE INTERFACE.

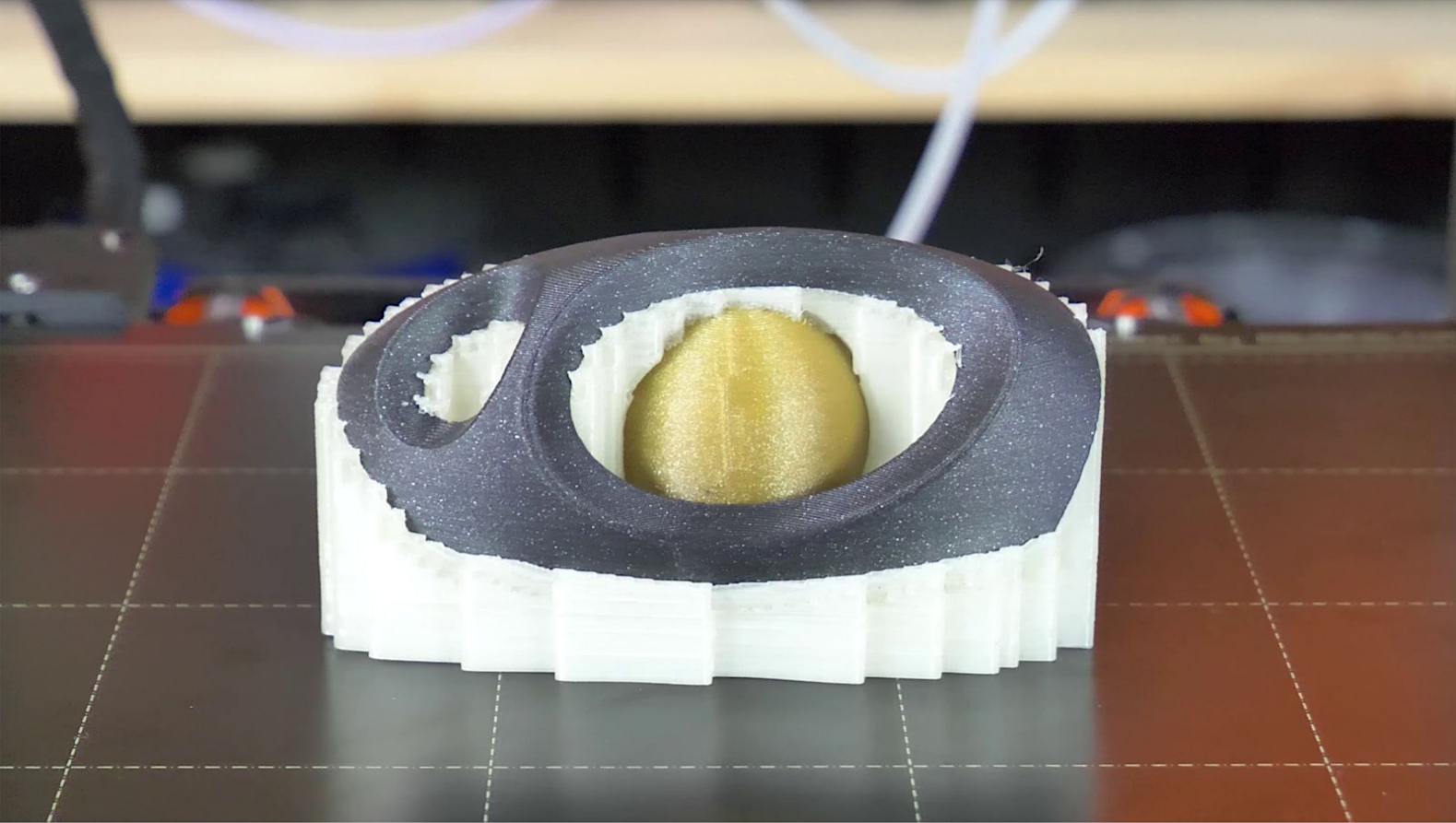

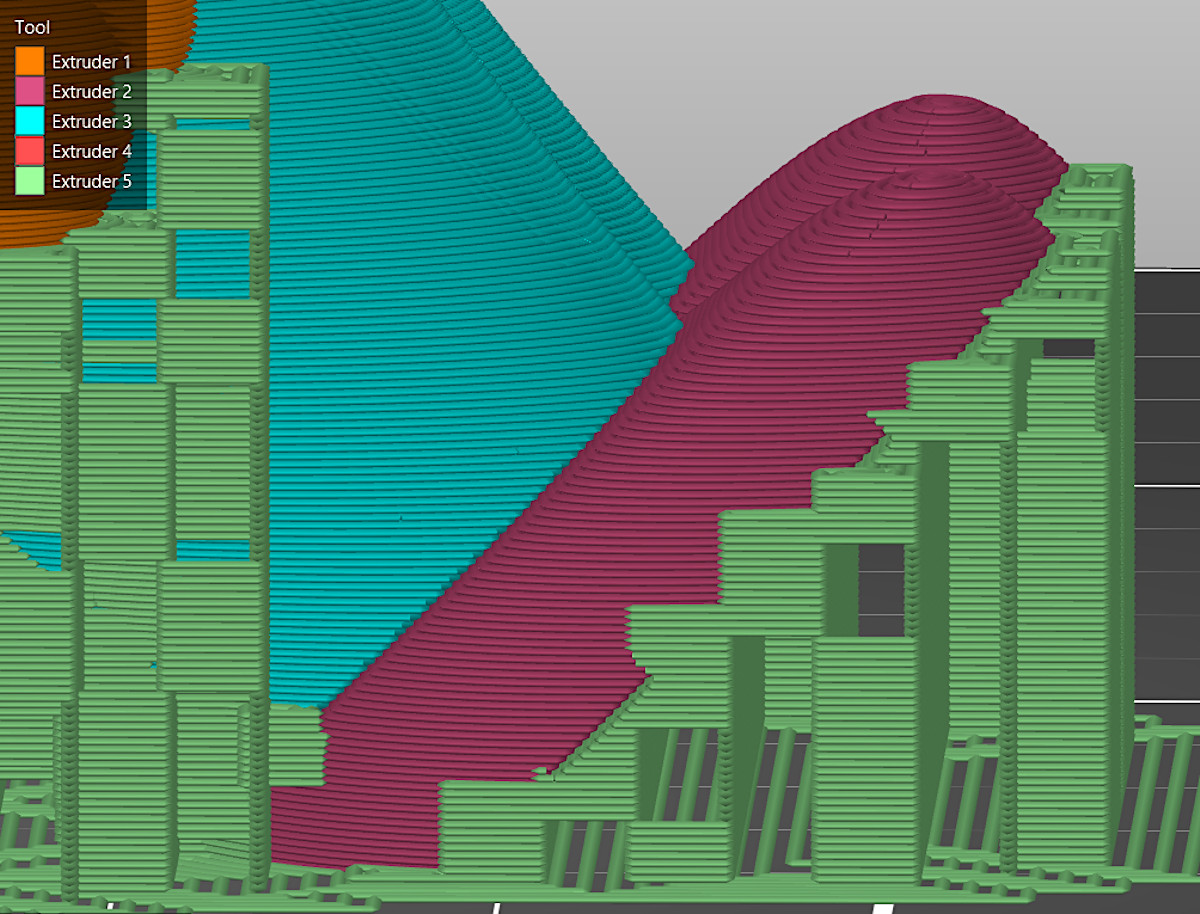

SOLUBLE FULL

This option will use the soluble material for the entire support structure (left picture). This is recommended where you have complex geometry that requires a lot of internal supports only. PVA+ and BVOH adhere poorly to the Smooth PEI or Textured steel sheet but will adhere well when printed directly onto PLA and PETG. If you are printing something with supports on the build plate, we recommend the SOLUBLE INTERFACE preset.

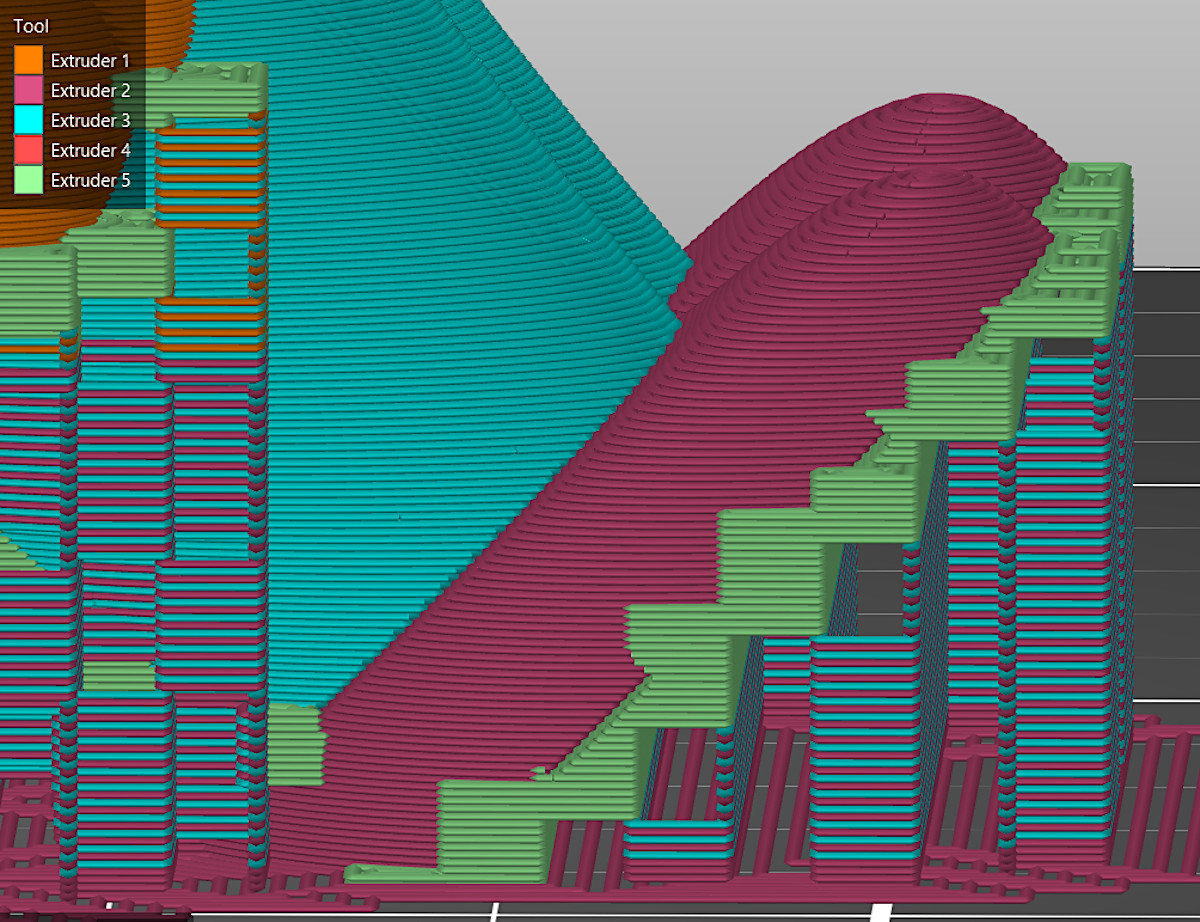

SOLUBLE INTERFACE

This preset applies the soluble material only in the more densely printed layers between the actual support structure and the model (right picture). This allows you to print the support structure with whatever color is loaded and only uses the soluble material where it is needed. This will save soluble material, which is more expensive than PLA and PETG. If you have a print that requires a lot of support directly on the steel sheet, this is the option preset for you.

|  |

| SOLUBLE FULL - Green filament is BVOH | SOLUBLE INTERFACE - Green filament is BVOH |

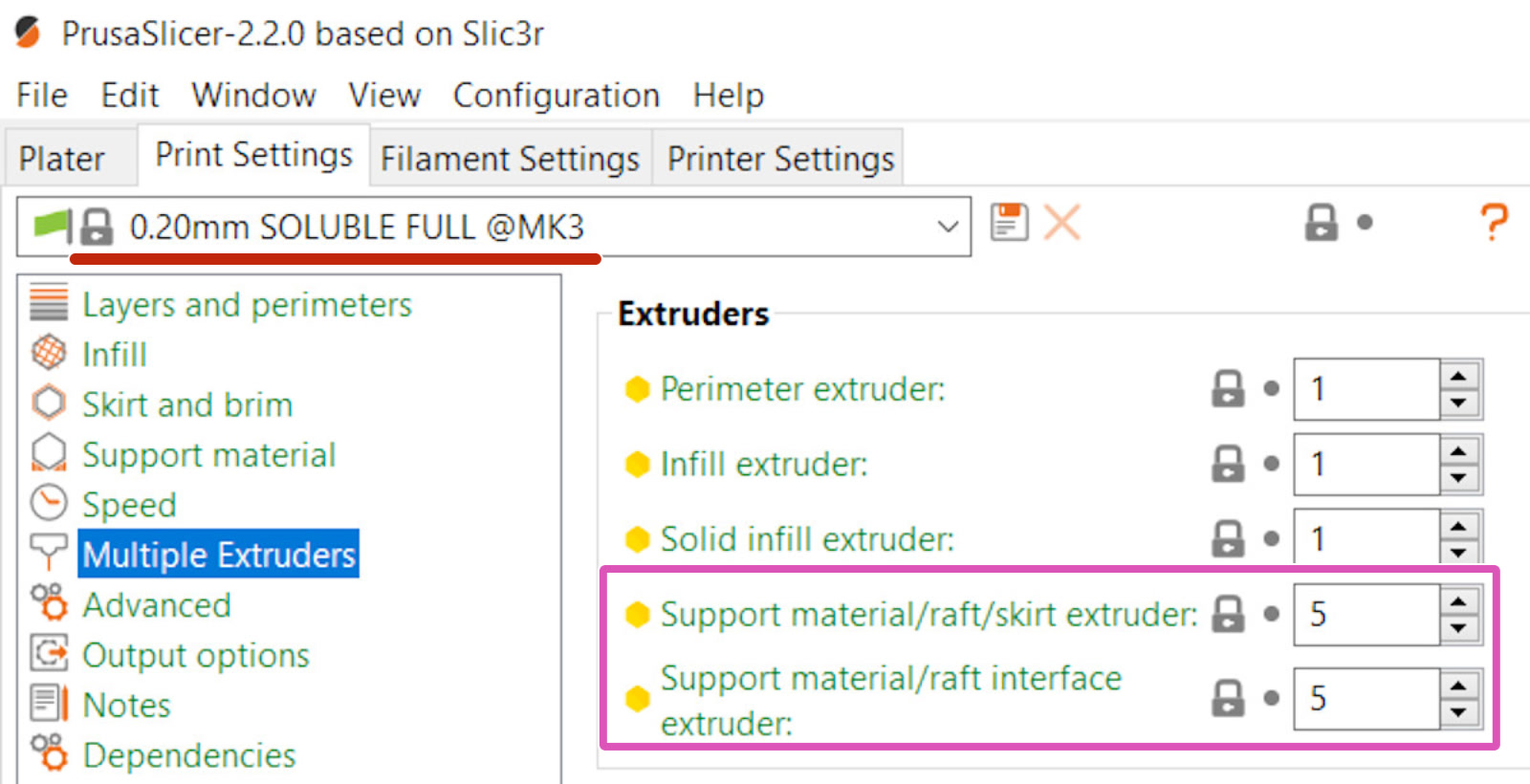

Default tool

PrusaSlicer or the printer will not detect where you loaded the soluble filament.

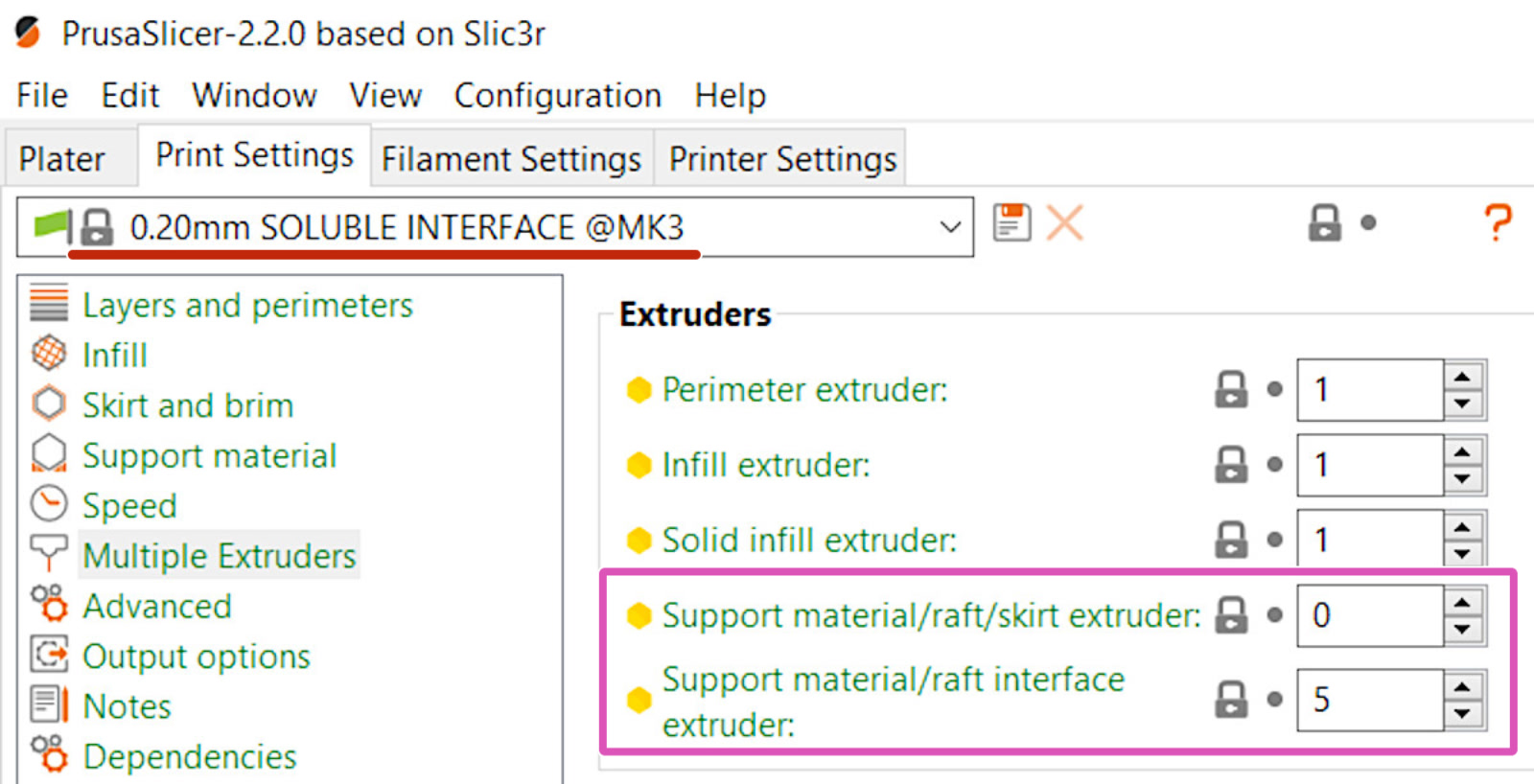

On MMU2S/MMU3, PrusaSlicer will default to assign the support material or interface material to Filament number 5. On XL, PrusaSlicer will assign by default the support material or interface material to Tool 2. You can change this to any other filament/tool by entering another value between 1-5, corresponding to the filament/tool to use.

Setting the value at 0 uses the tool that is available, which is the last one used in that layer.

|  |

'Support material/raft/skirt extruder: 0' will use whatever tool is currently loaded into the extruder.

Purging volumes (MMU3, MMU2S)

By default, 140 mm³ is used for a filament change (sum of unloading and loading). When using water-soluble supports we suggest using at least 200-240 mm³. If you find any residue in your print, increase the amount. A minimum of 240 mm³ for extruder change from PVA+/BVOH may be required.

To access the settings for purging volumes, press the Purging volumes... button. To be able to modify the values, select 'Use custom project-specific settings'.

MMU2S, MMU3 for MK3S/+ configuration

It is essential that you have performed a very precise IR sensor calibration. With the properties of PVA+ and BVOH, their diameter can easily deform with excessive pressure from the idler.

Again, due to their soft properties, the filament tips will inevitably string, so it’s important to keep an eye on them and be ready to intervene and cut them while the main filament is being printed.

The difference in Max Volumetric speed: PLA has a max volumetric speed of 15 mm³/s, while PVA+, and BVOH have 4 mm³/s. This increases the total print time.

Dissolving and removing supports

When the print is complete and before removing the supports, immerse it in warm water (maximum 45 °C) and leave it there for a few hours to overnight. After this, the supports should come off pretty easily but may require some use of tools, depending on your print's geometry. It may help to remove as much of the supports as possible while still dry.

Once the printed object is free from the supports, immerse it in hot water again for 10-20 minutes and then brush it to remove the residual debris of PVA+/BVOH. Using a small tough toothbrush can be an ideal tool for this task.

Unless you are dissolving several kilos of PVA/BVOH per day, you can pour the resulting BVOH/PVA-solution down the sewer.

Handling and storing soluble filaments

As you might have expected, both BVOH and PVA are very hygroscopic (easily absorb water) and should be kept as dry as possible. PVA+ or BVOH should not be exposed to humidity. It must be placed right back in its zip-lock bag right after its usage, and always with one or more bags of silica. Otherwise, it will deteriorate in a matter of a few months and go soft at a much lower temperature, starting trouble already at the loading process.

When deteriorated like this it will quickly cause loading/unloading issues and your hotend to clog. The best approach is to print and store these materials in a Drybox.

7 comments

I wish somebody would make a flexible soluble filament that interfaces well with TPU/TPE.

https://forum.prusa3d.com/forum/original-prusa-xl-tool-changer-assembly-and-first-prints-troubleshooting/trouble-printing-with-soluble-supports-pva-or-verbatim-bvoh/paged/2/#post-782071

TLDR: High extrusion factor (1.18 for me) and low temps (178C).

Hope it helps!

Need .15 and of course its not there, even in your screen shot above its not there. Typical.

Hello. We cannot tell you specific date, but we are working on it ;-)

Will BVOH eventually dissolve completely? The project will not function properly if any support material is left behind.

Hi Tim! Unfortunately, I don't think BVOH would dissolve fully when enclosed in the object with restricted access. Is there a way to split the object in half and then use screws to assemble it together, for example?

Thank you for your reply. The moving part can be "seen" from the build plate, so I will try the build based on that. It would be better to add stability throughout the build, as it takes over 24 hours to print. I will continue to work on the design to optimize for no support internally where the support material cannot be accessed for removal.

I do not yet have the MMU2S upgrade for my MK3S+, so I cannot experiment with BVOH yet. I am trying to determine the best course of action for the project. It seems a dual extruder setup would be better than the MMU2S in this particular case.