It is recommended to take some time to maintain your Original Prusa MK4/S and MK3.9/S regularly. This should be done even if the printer is working perfectly.

Useful tools

Besides the usual tools, such as Allen keys, needle-nose pliers, and IPA (Isopropyl Alcohol) + paper towels, you might need:

- Compressed air: also known as canned air. Be sure to not hold it upside down while spraying - otherwise, you could damage any electronic components while trying to clean them.

- Brush: a small brass brush is useful for cleaning the heaterblock. If you don't have a brass brush any brush with hard bristles will do the job.

- Prusa Lubricant: used for lubricating the smooth rods and linear bearings.

Frequent maintenance

The following points should be checked before every print.

Keeping the printer clean

After several hours of printing, various kinds of debris may start to accumulate around the printer parts or under the heatbed - pieces of filament, dust, scraps, broken supports, etc. Always make sure that the parts of the printer are clean. You can use a brush, a small broom, or a vacuum to remove debris.

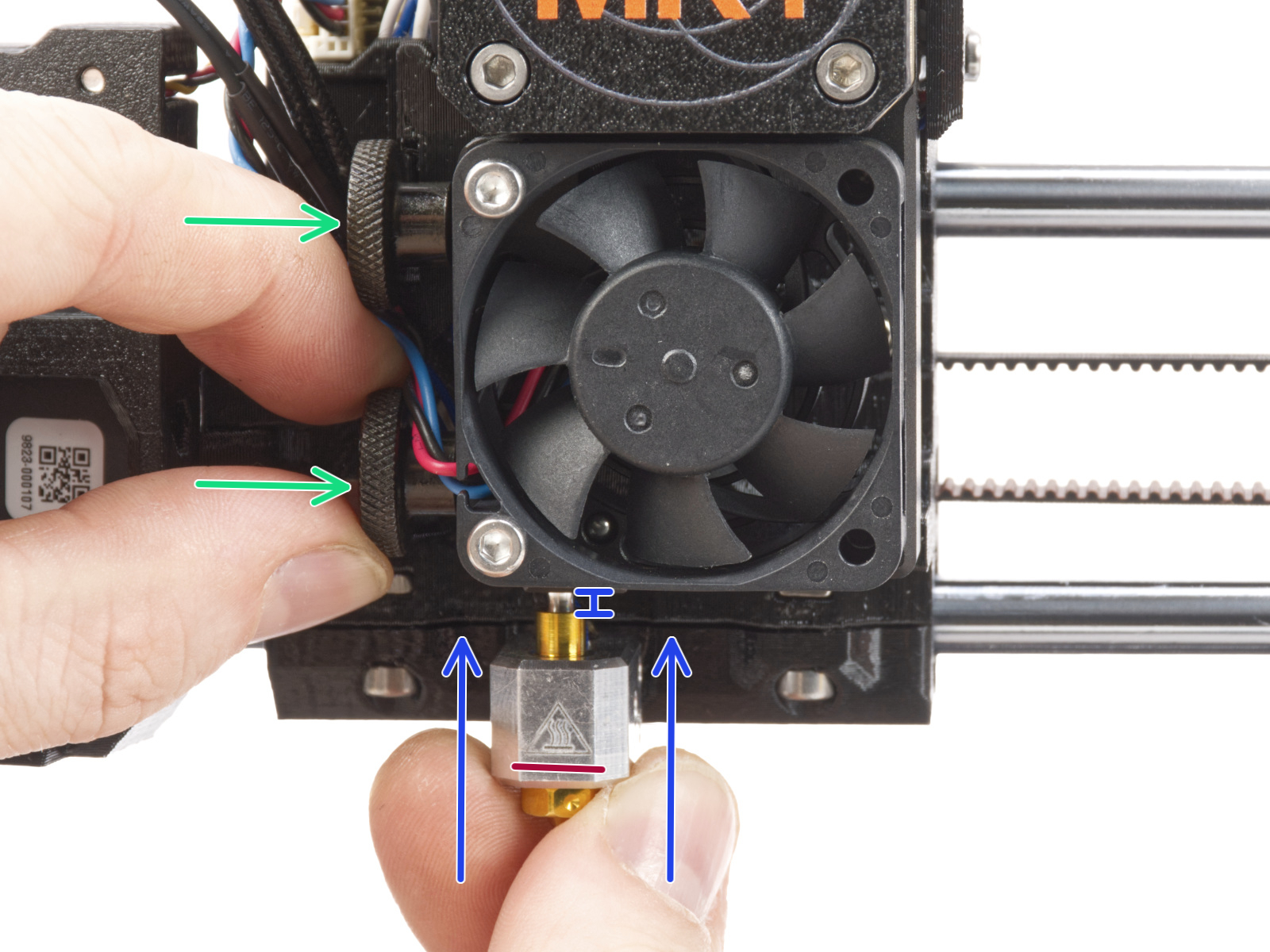

Hotend cleaning

It is fundamental for the hotend to be clean. Debris on the nozzle or heaterblock can cause printer failures, for example with the residue falling onto the printed model while the print is in progress.

To clean the nozzle and heaterblock, heat the nozzle for three to five minutes at 250 °C, as the remains of the filament must be warmed up slightly so that they can be removed more easily.

Use a small brass brush to clear away any old plastic stuck on the nozzle and heaterblock.

Avoid contact of the brush with the hotend cables, as this could cause a short circuit.

Caution: the printer is still at a hot temperature! Wait until the hot parts are cooled down to ambient temperature. It takes approximately 10 minutes. Do not touch it! Always check the values on the display.

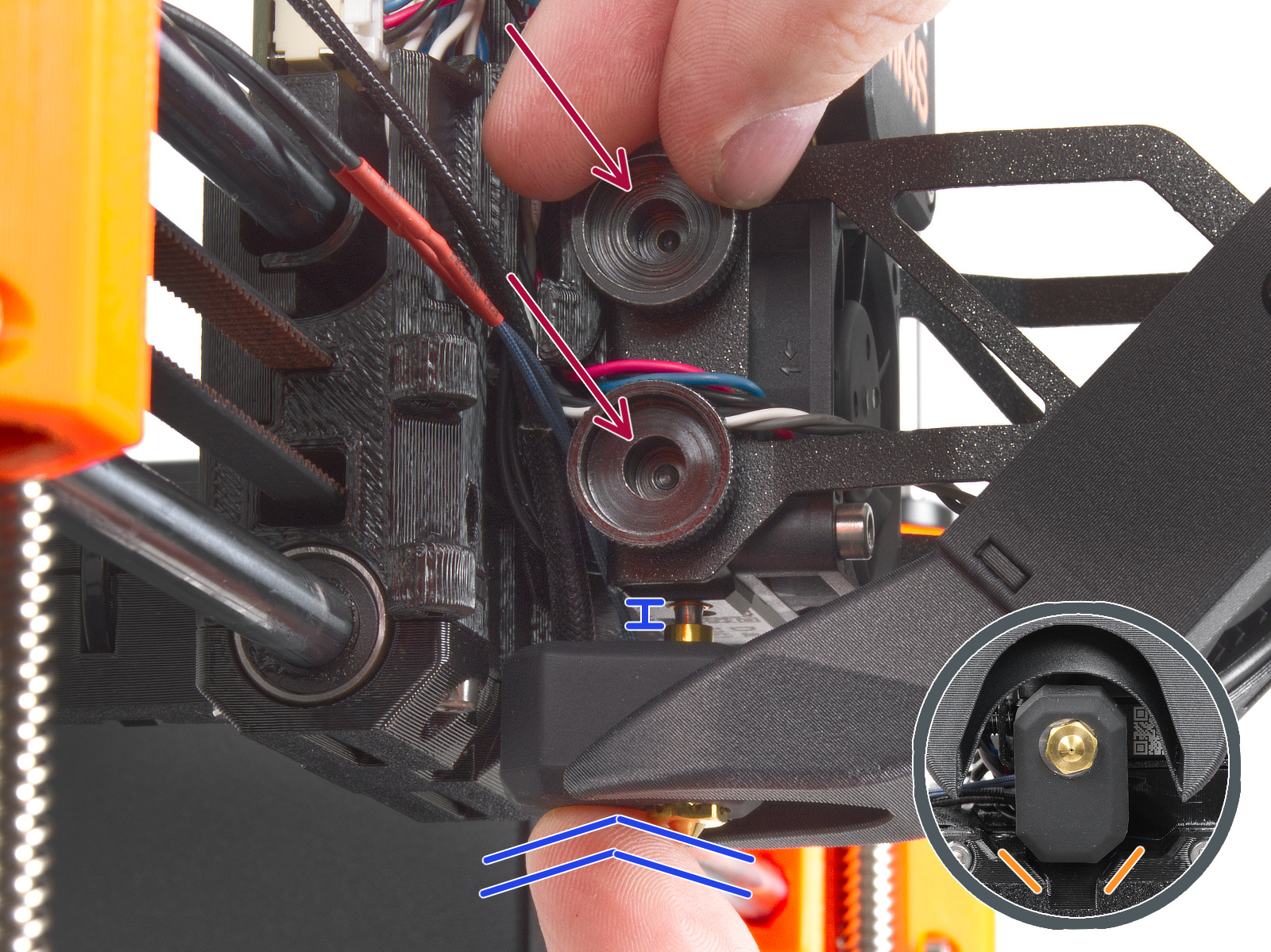

Hotend thumb screws and nozzle position

Ensure the printer is cold and off before this procedure.

On the side of the heatbreak, check the thumb screws. Tighten them just by hand, do not use any tools. After tightening the thumb screws, try moving the hotend to the sides and make sure it does not move.

If you have a Nozzle Adapter, check the installation again to make sure that the nozzle has not been lowered or loosened with the installation of the adapter.

With the thumb screws correctly tightened, the nozzle should not have any vertical play, and the heater block should not have any rotational play.

|  |

| MK4S, MK3.9S | MK4, MK3.9 |

Flexible steel sheet

Never clean the special PA Nylon sheet with acetone, IPA (isopropyl alcohol), or other alcohol-based solvents (window cleaners, Windex, etc.)! This will damage the surface.

All flexible steel sheets should be cleaned regularly to ensure adhesion, but the exact methods and washing solutions can differ depending on your type of sheet.

You can find more information on how to take care of your flexible steel sheet in this article.

Sporadic maintenance

The following checks should be done every 200 hours of printing time.

Axes check

- Smooth rods: scratches/grooves - take each rod between two/three fingers and move them slowly from one end of the rod to another, while rotating the fingers around the rod. If you notice any scratch, verify it with your fingernail.

- Smooth rods and Bearings: Clean the smooth rods with a clean paper towel, and lubricate them using a small amount of Prusa Lubricant.

Only in case you feel the axis is not running smoothly anymore even after recently cleaning and lubricating the smooth rods, bearings can be taken out, cleaned with alcohol, and greased on the inside, still using a small amount of Prusa Lubricant. - Belt pulleys: any debris around the belt pulleys and belts should be immediately removed to ensure smooth operations. Also, check if the set screw of the belt pulley is firmly secured on the flat side of the motor shaft.

- Belts: Both of the belts should be tight enough to sound like a low bass note when plucked.

Fans

The RPM (revolutions per minute) of both fans is constantly measured. This means that the printer will report an error if the fan suddenly slows down, for example, due to a piece of filament stuck in it.

In such a case, check and remove any dirt from the relevant fan. Do not try to bypass the RPM check, as this could damage the printer!

Both fans should be checked and cleaned after every few hundred hours of printing. Dust can be removed with compressed air in a spray can, small plastic threads can be removed with tweezers.

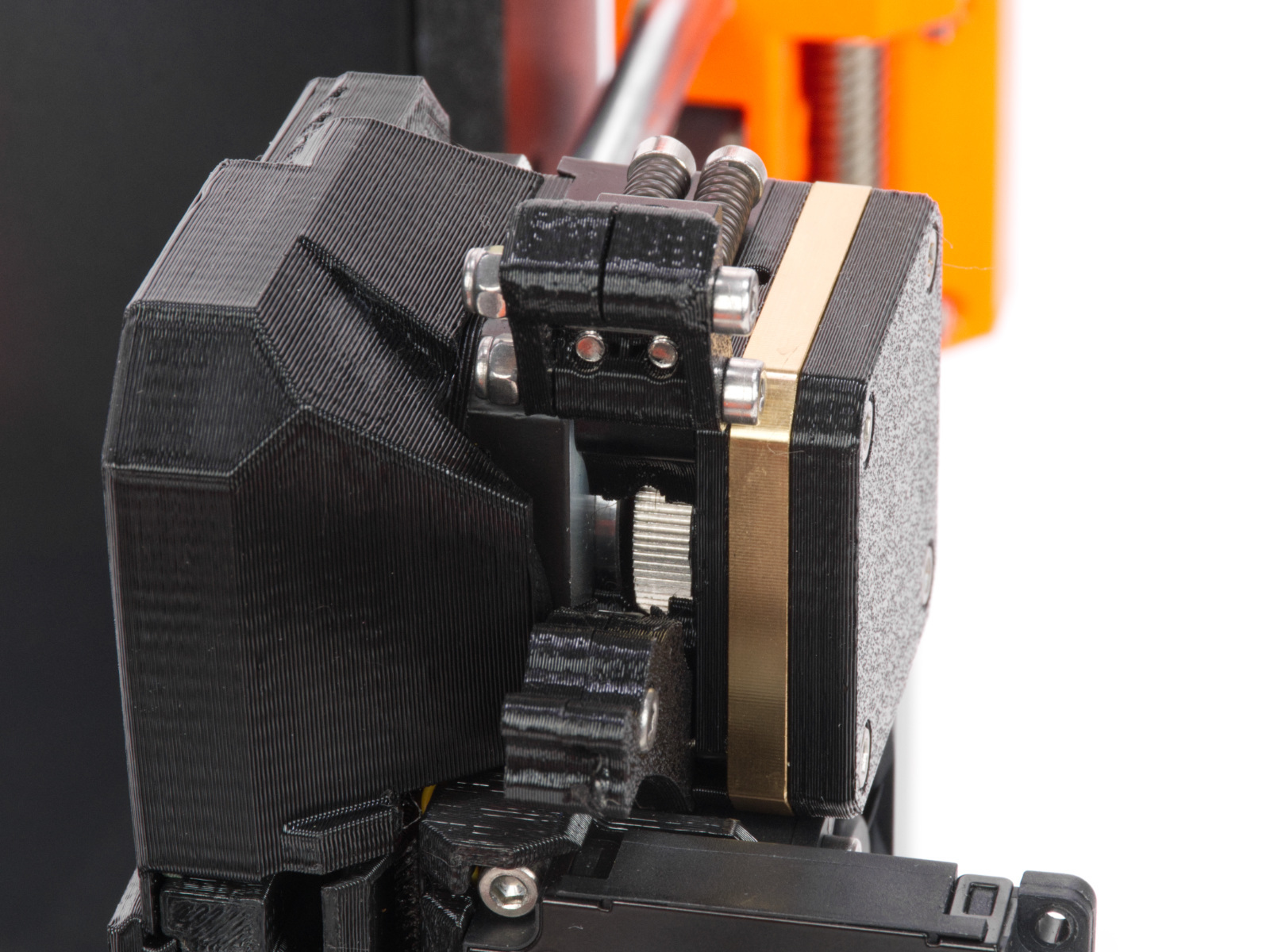

Nextruder

The primary gear and the bearings attached to the Idler Shaft in the extruder do not need any lubricant. Over time, a deposit of filament debris can form in the grooves of the primary gear, which then causes insufficient filament extrusion. Access the extruder by lifting the Idler Nut, and then moving the Idler Shaft. You can blow away the dirt with compressed air, or use a brass brush or an ordinary toothpick. Use the access hole on the side of the extruder.

Annual maintenance

Electronics

It is a good practice to check and optionally reconnect the electrical connectors on the xBuddy board, Loveboard, heatbed, PSU, and xLCD every 600-800 hours of printing.

In particular, ensure that the screw-attached connectors are fully tightened, and the Molex-attached connectors properly connected.

CAUTION: for Molex-attached connectors, it is necessary to press the latch before disconnecting. Otherwise, the connector may get damaged.

10 comments

Greetings!