Basic info

Description

CPE is a copolyester based on terephthalic acid. Thanks to its mechanical properties somewhere between PETG and ABS, and good layer adhesion, it’s good for printing prototypes of mechanical parts. CPE excels in its chemical and mechanical resistance and dimensional stability. Unlike with ABS, there is no strong odor or warping issues. CPE is a chemically and high-temperature resistant material (resistance up to 75 °C). The tensile strength of CPE is similar to ABS. It’s suitable for printing thin-walled models due to its translucency. CPE is good for making visual and functional prototypes, mechanical parts, etc.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ Good mechanical resistance |

✖ Hygroscopic material |

|

✔ Good layer adhesion |

✖ Too strong print surface adhesion |

|

✔ Good temperature and chemical resistance |

✖ Stringing issues similar to PETG |

Best use

The best use of CPE is for printing technical parts requiring good chemical and mechanical resistance. CPE is good for making visual and functional prototypes, mechanical parts, etc.

Tips for successful printing

Most of the print settings are similar to PETG.

Use a textured print sheet

Make sure the print surface is clean, as described in our dedicated article. It is advisable to use one of the powder-coated print sheets. Do not print on the smooth PEI sheet as the adhesion may be too strong! If you decide to use the smooth PEI sheet anyway, apply a glue stick on it before printing.

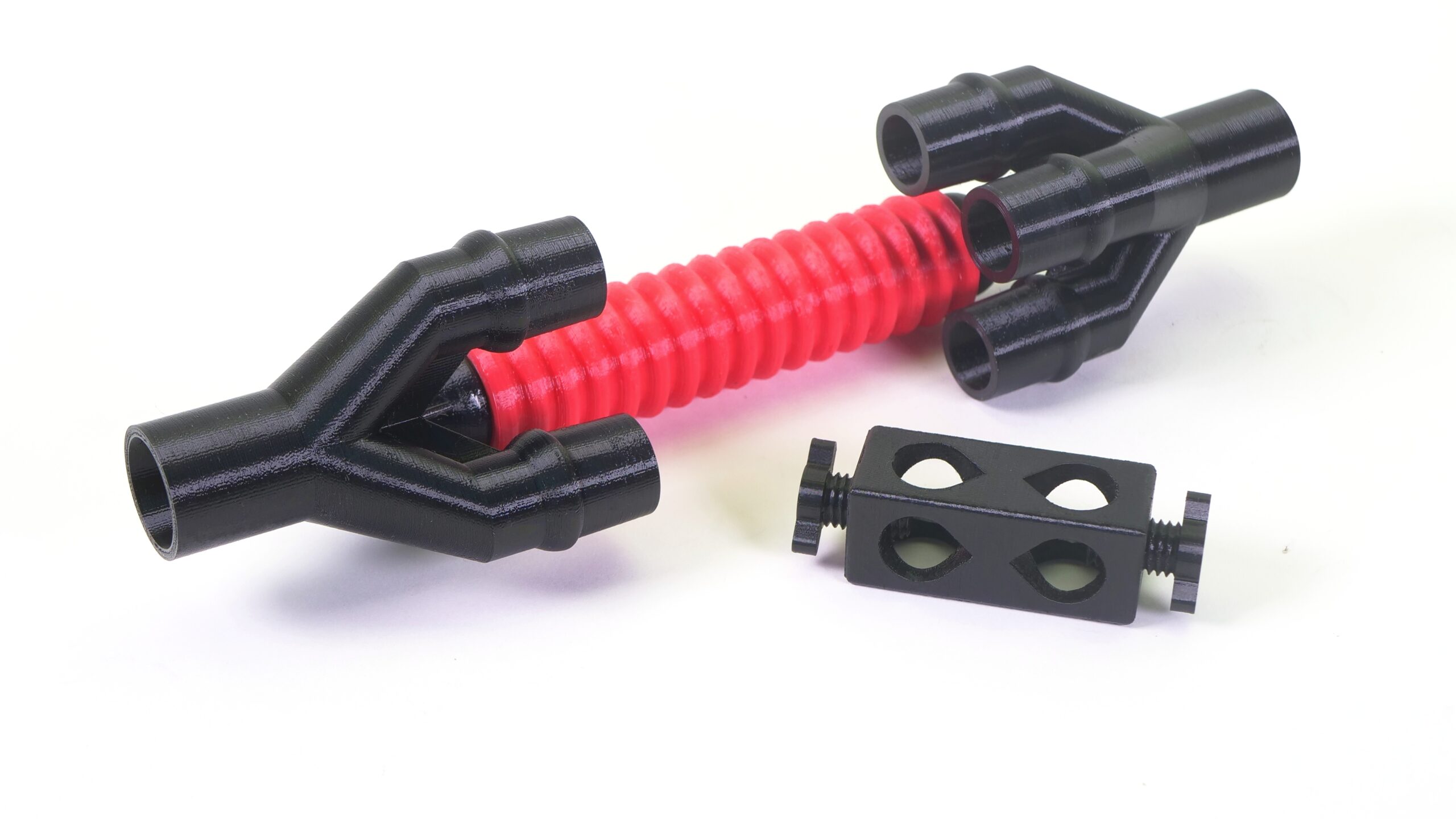

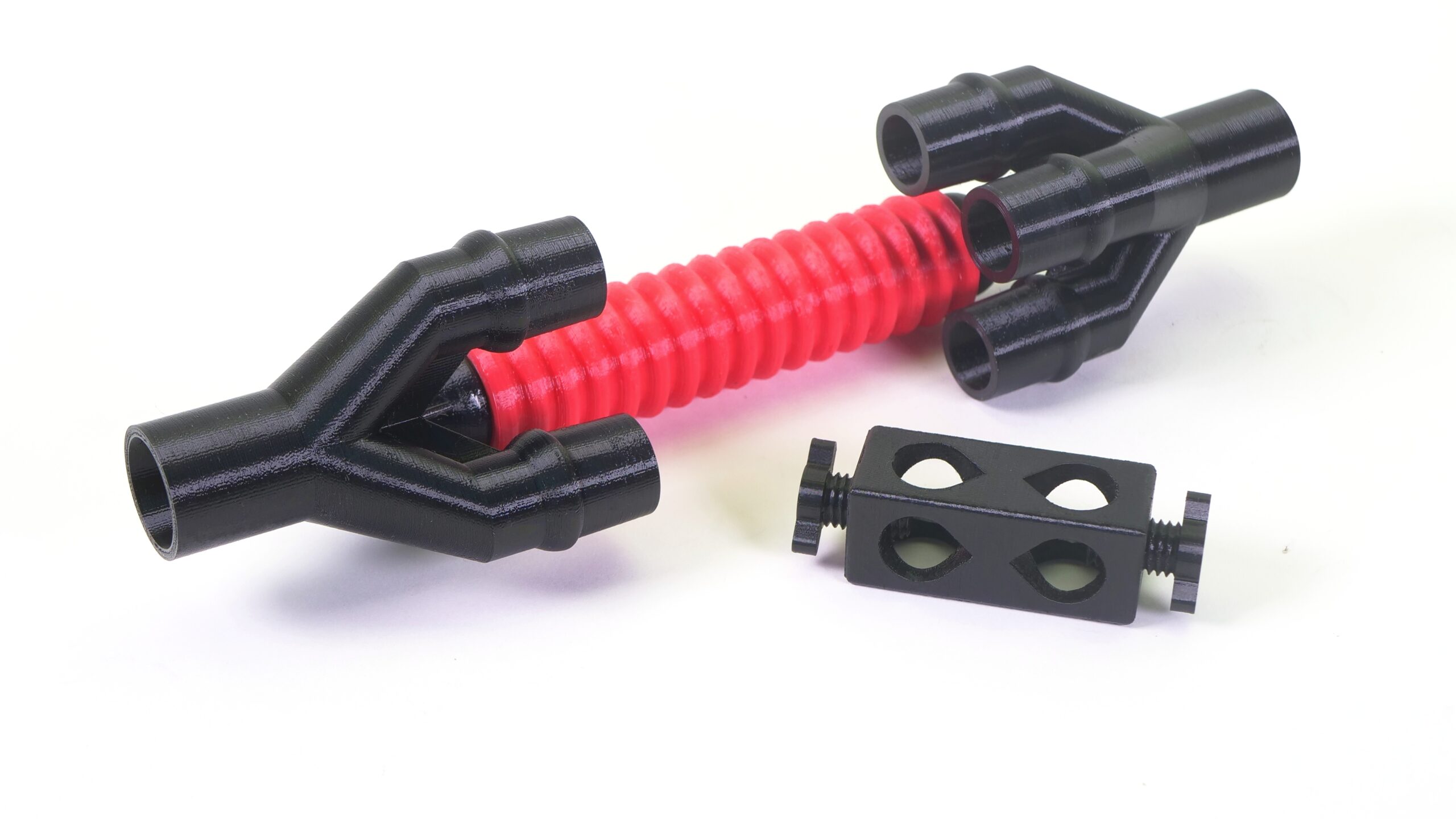

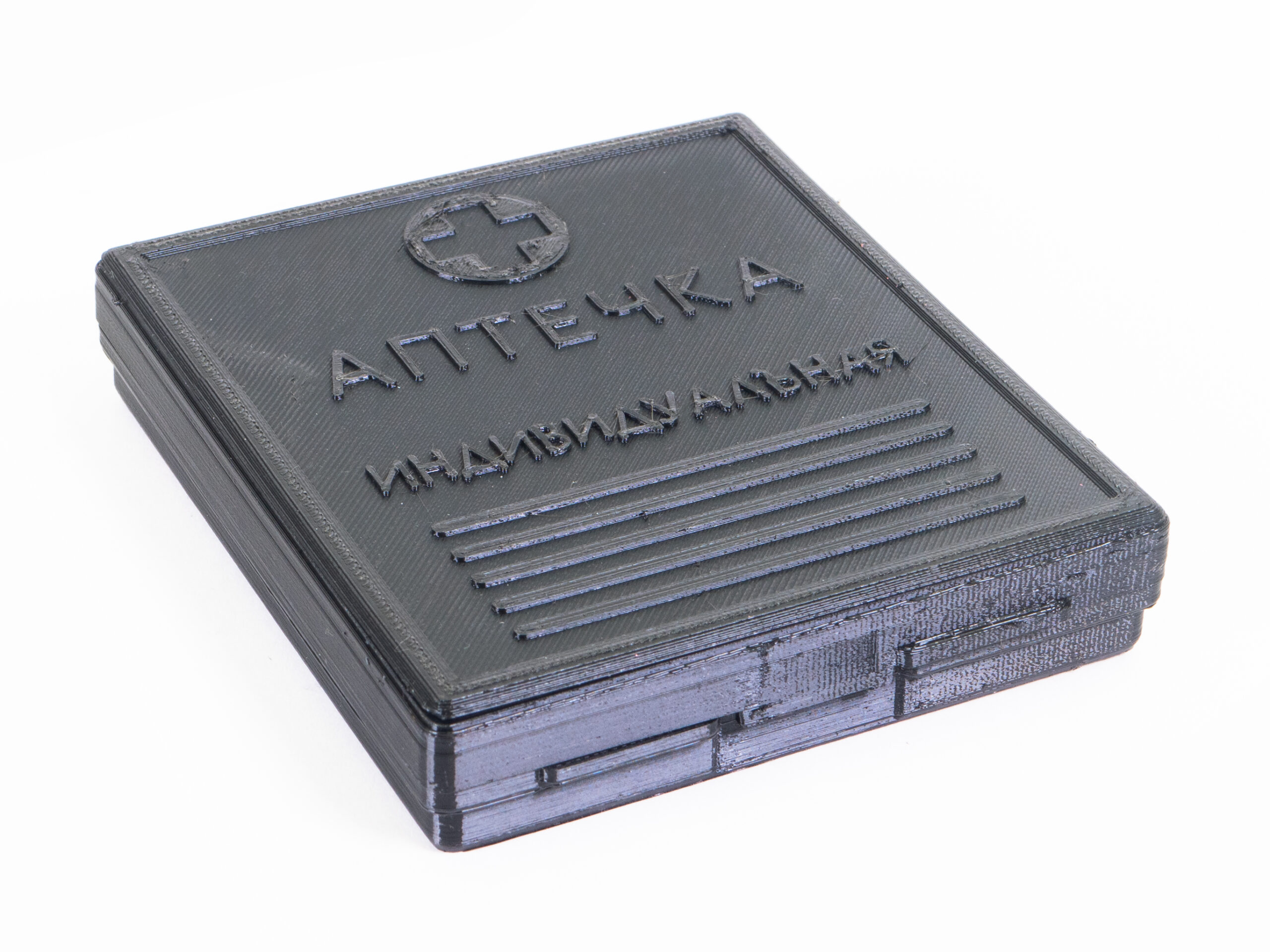

Sample prints

|  |

| Chemically and mechanically resistant parts | Various boxes |