All induction proximity probes alter the sensing distance with increased temperature. This might affect the quality of the first printed layer. P.I.N.D.A. v2 probe, included in the MK3S/MK3/MK2.5S/MK2.5, has an embedded thermistor inside its body to measure the temperature and fully compensate for the drift. A pre-calibrated data table is stored in the printer and the temperature calibration is active by default.

However, it can drift out of calibration over time, and you may also find this calibration helpful when weather and temperatures change in the spring and autumn.

The calibration is fully automatic, but we will lead you through it so you know it went OK.

- Start by taking off the Flexible steel sheet.

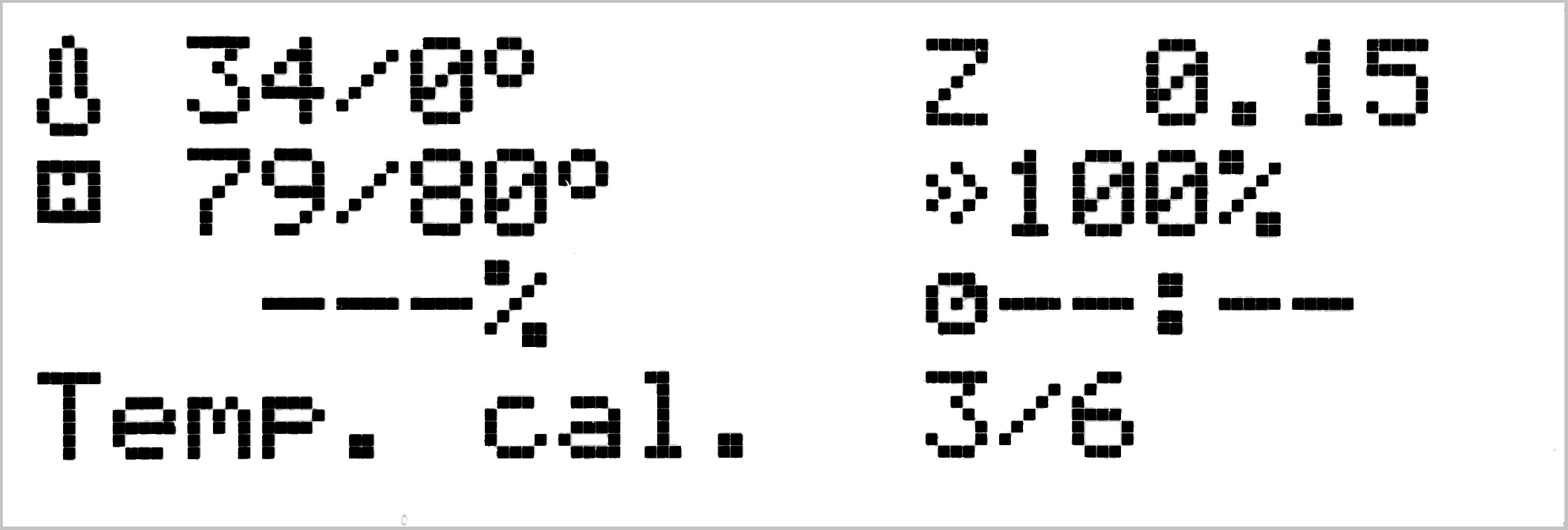

- Navigate the LCD-menu to Calibration -> Temperature calibration. Once selected, the printer will home all axes in order to ensure the correct initial position, and warn you it needs an ambient temperature from 21-26 °C (70 - 80 °F) and a stable surface, then ask if the Steel sheet is on the bed. Make sure it is not on and Select "NO".

- The extruder will move in over the bed-surface, stop, and with the pinda positioned over the bed, heat up the bed from 75 - 110 °C (167 - 230 °F), across six parts, while checking the readings given by the stationary PI.N.D.A. sensor.

This calibration can take 15-20 minutes to go through. The temperature-calibration has to run after a completed XYZ-calibration, and it can be recommended to run PID-calibration beforehand, should you receive any errors, like "Thermal Runaway", when running the calibration.

11 comments

Also, for anyone reading: my MK3 ran through the first 5 stages relatively quickly, but the 6th is lagging. I suspect that I messed up the measurement by walking by the machine quickly enough to cause a breeze. Not sure, but something to look out for.

Just run it again. I think it indicates it is finished, but since neither you nor I saw it it is hard to say. A breeze/draft or cold environment can slow down the process.

mk3s

My Printer It is having problems using textured sheet, nothing can be printed on that. So Far I am able to print PLA on Smoth sheet. Tried PTEG, and do not print well, neither on Smooth or Textured. It seem to have issues sticking to the bed (both, smooth with Glue or textured)

I compared the temperature on the Bed as reflected on the LCD upon preheat and during operation with the lecture that picks a Laser Thermometer and the bed is 5-6 degrees lower than what the LCD shows.

Since this is the MK3S+, there is no temperature calibration on the Menu. but even after Hardware reset, flashing again the same firmware, and full Wizard - brand new shining calibration - The bed temperature is 5-6 degrees lower than what 2 different lasser thermometers shows and still I am not able to use textured bed with any material.

What should I do?

Hi! This calibration is meant to correct PINDA v2 offset at different temperatures. It is not needed for MK3S+ with SuperPINDA. What you are describing concerning the heatbed temperatures, is normal behavior. If you are experiencing bed adhesion issues, try cleaning the print sheet with IPA or a dish soap with water first, then calibrating Live adjust Z.

[id=1804|title=See this article]