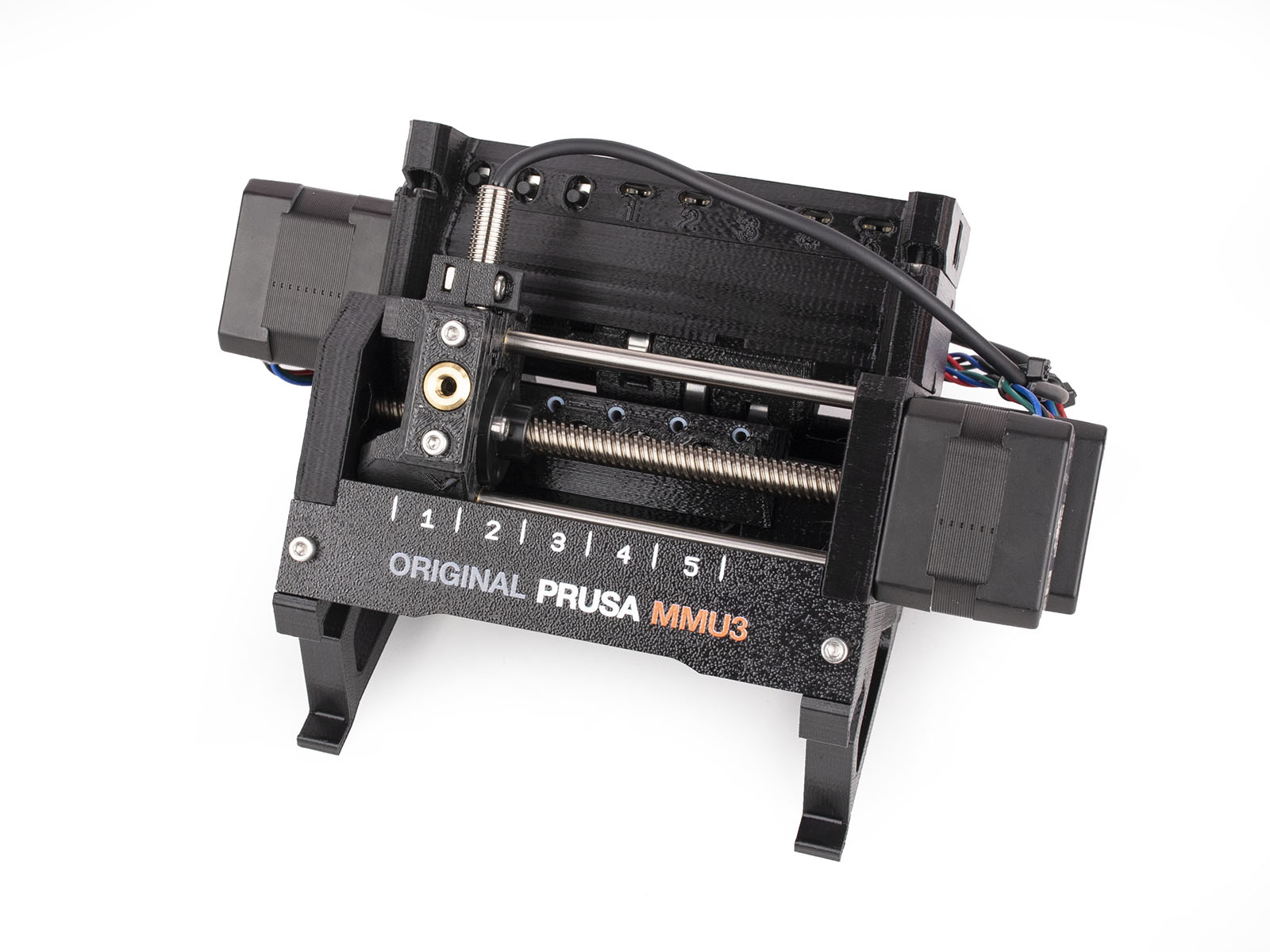

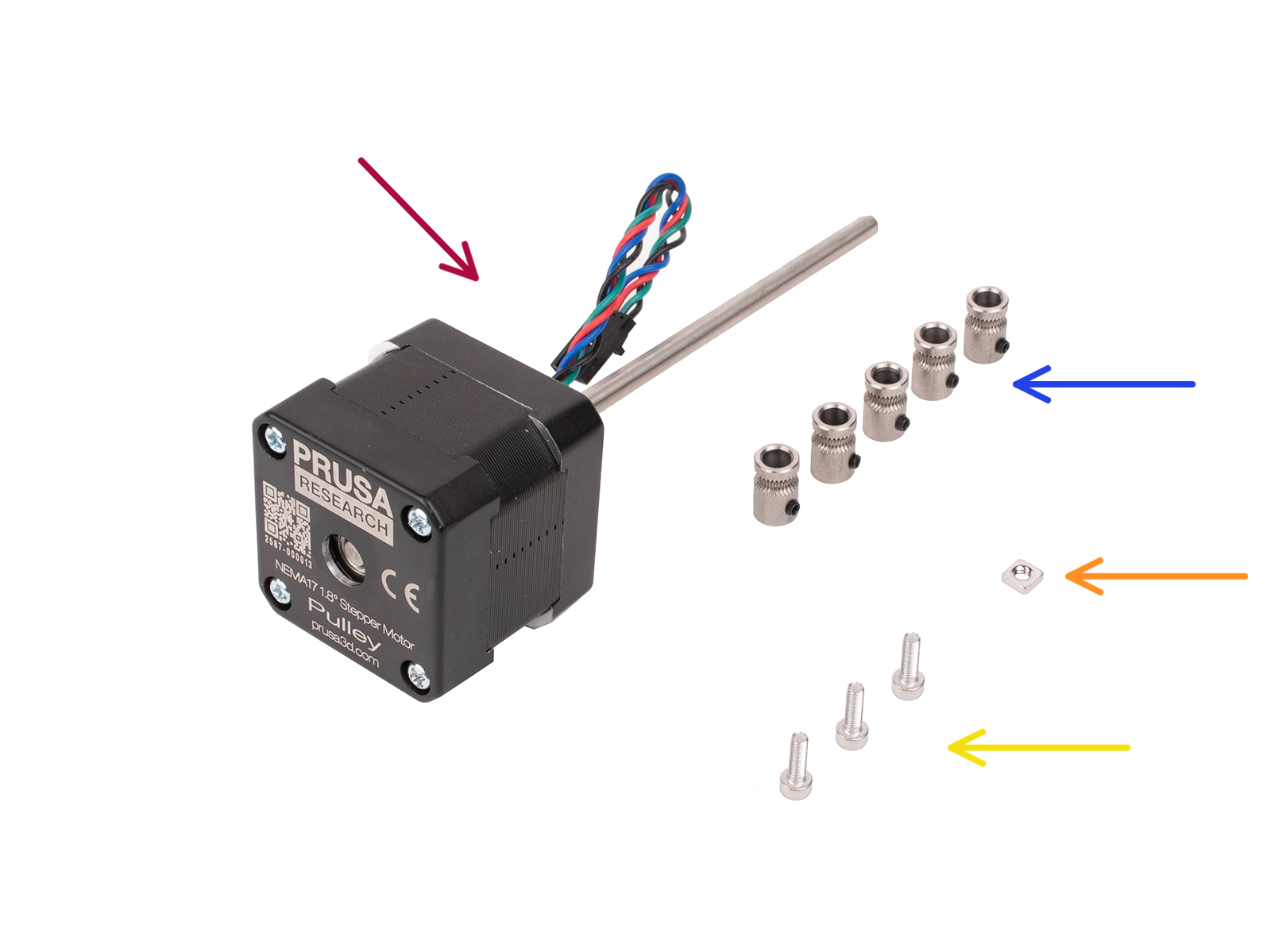

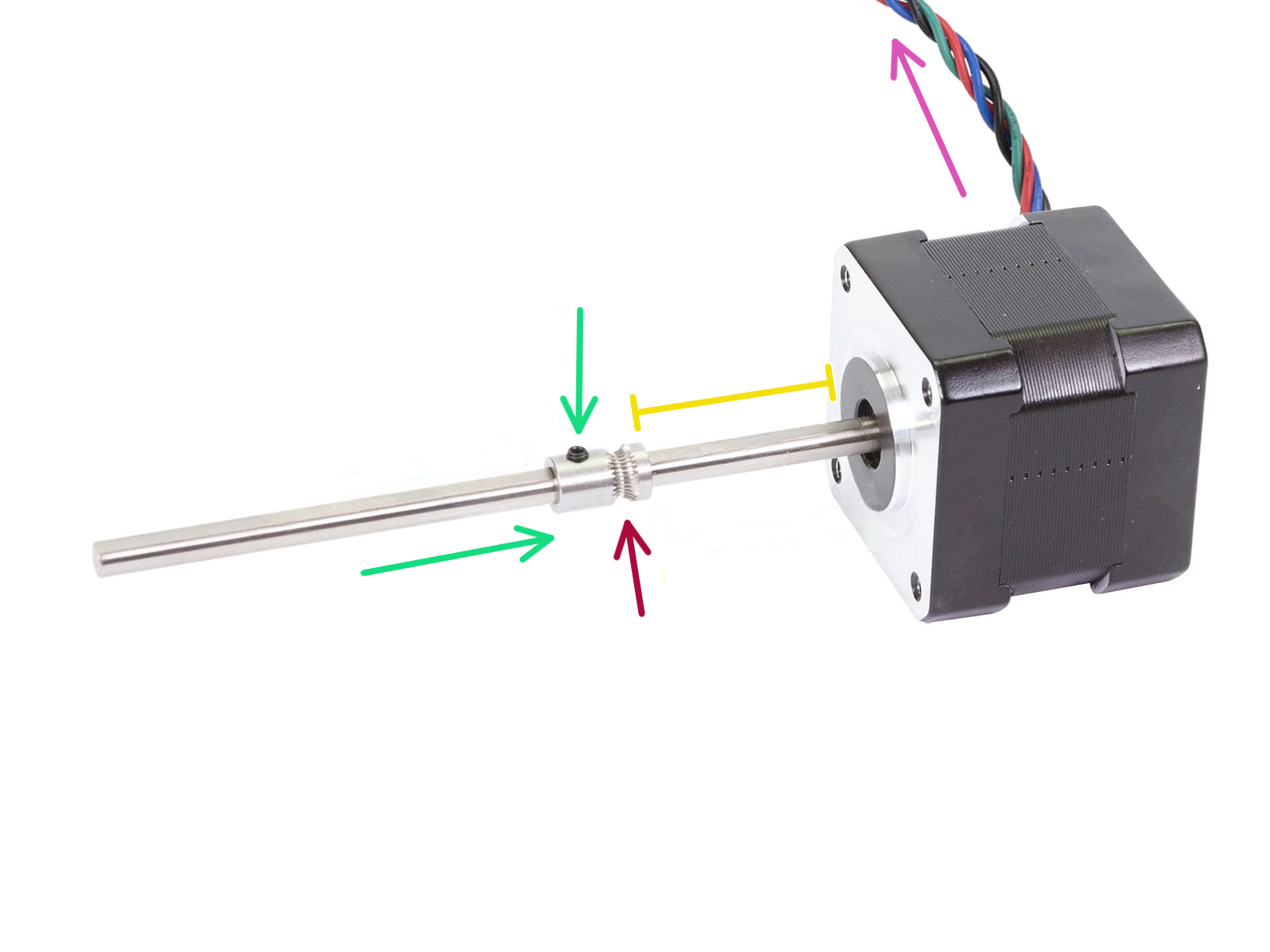

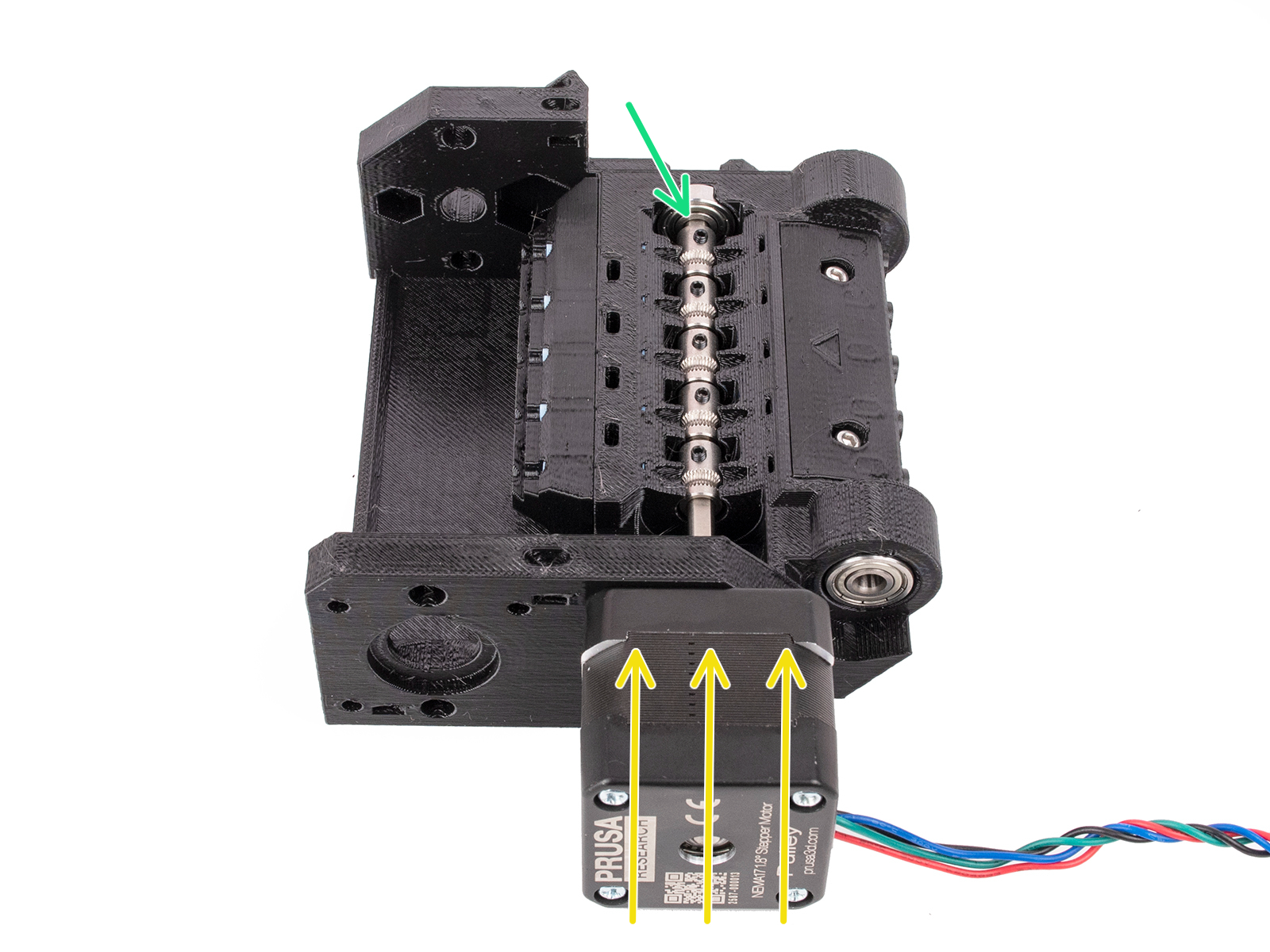

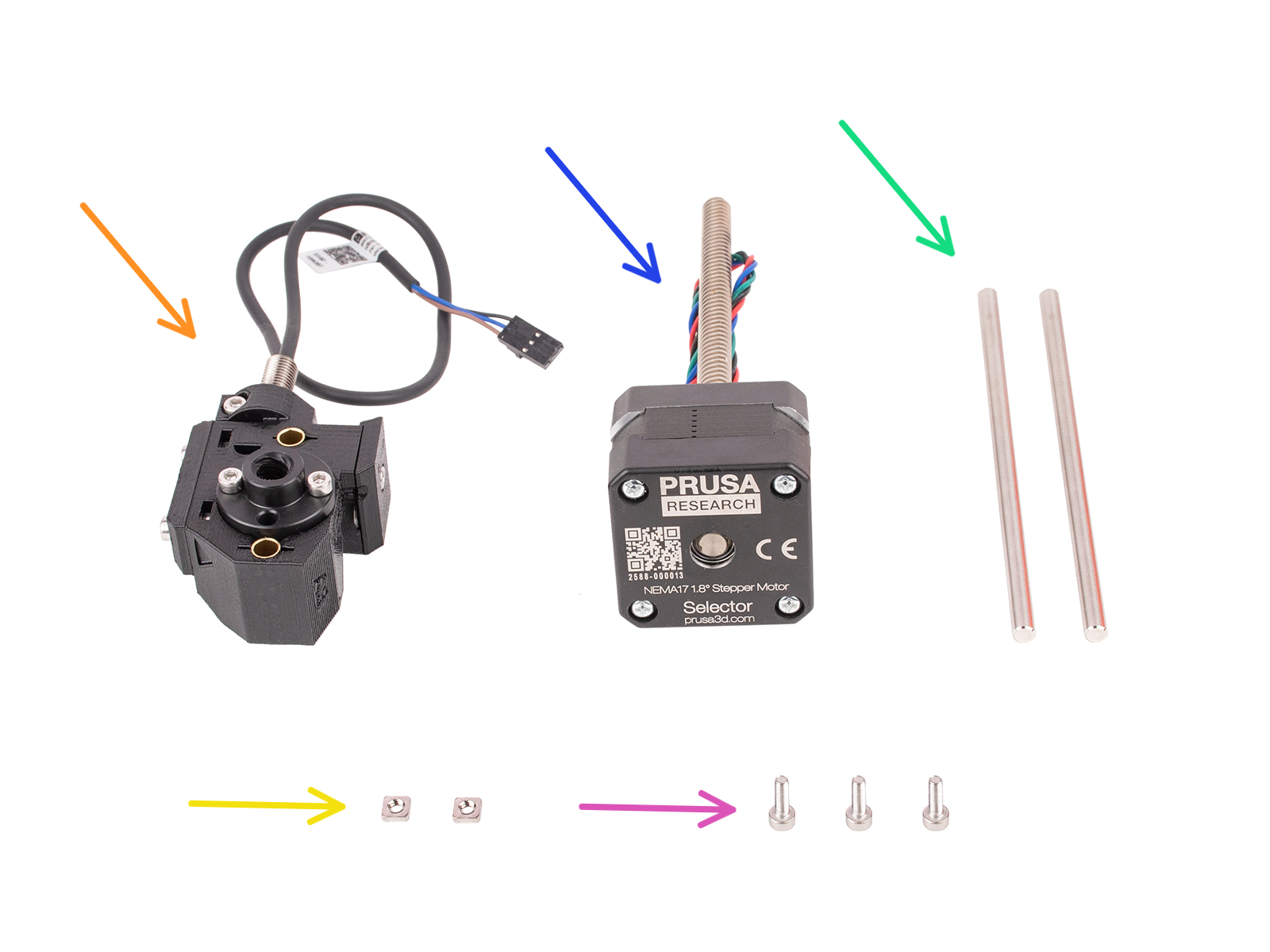

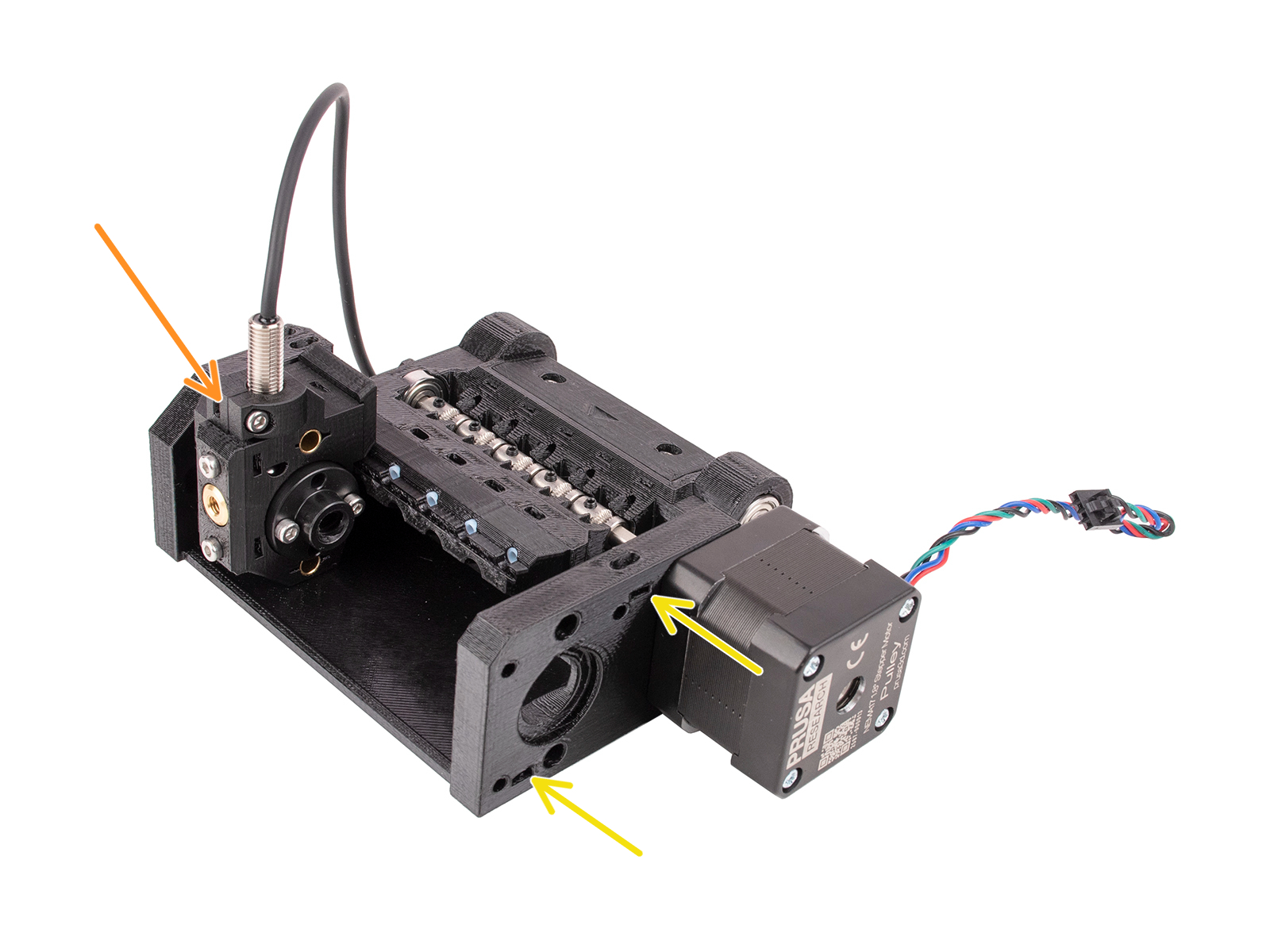

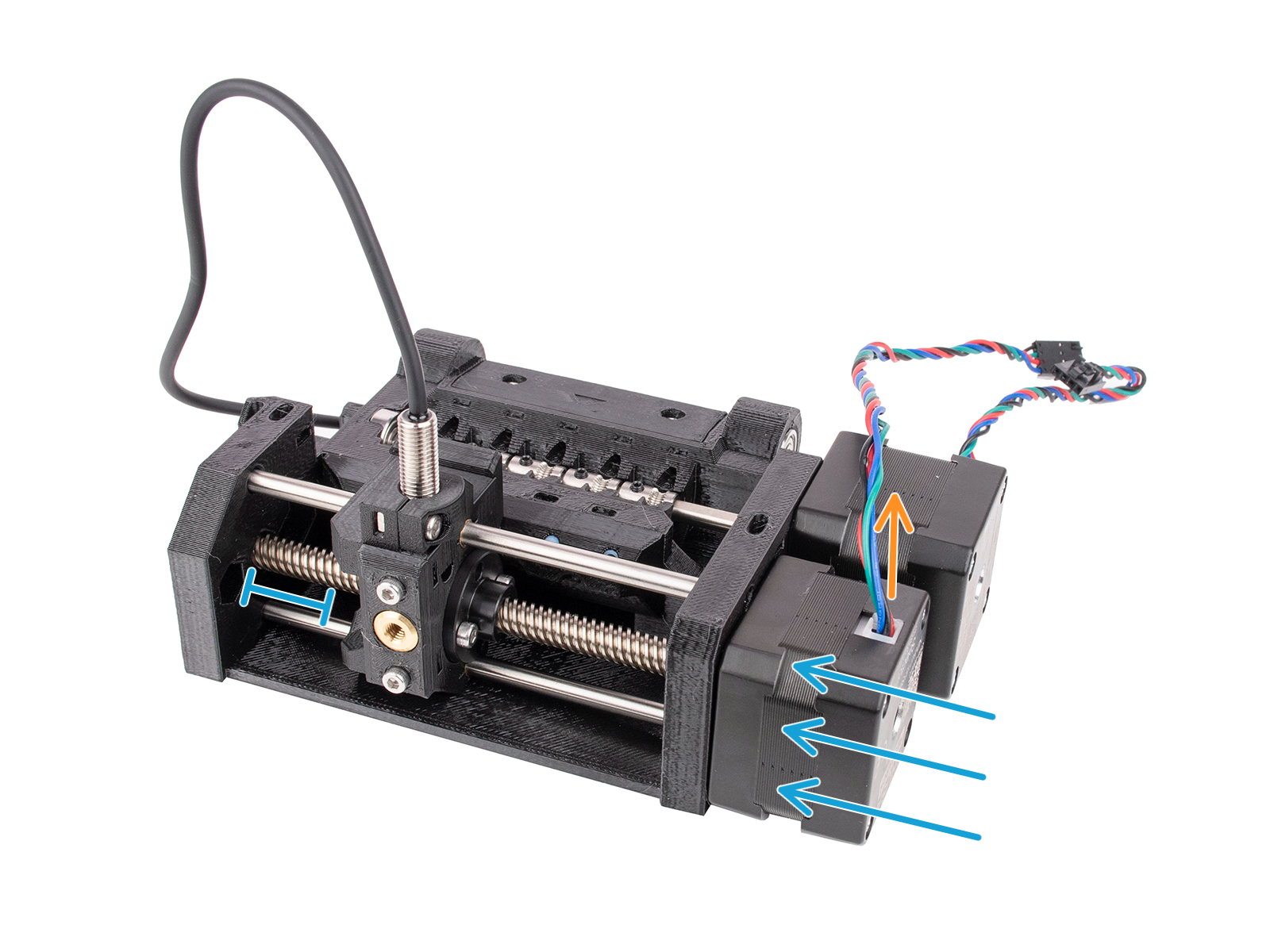

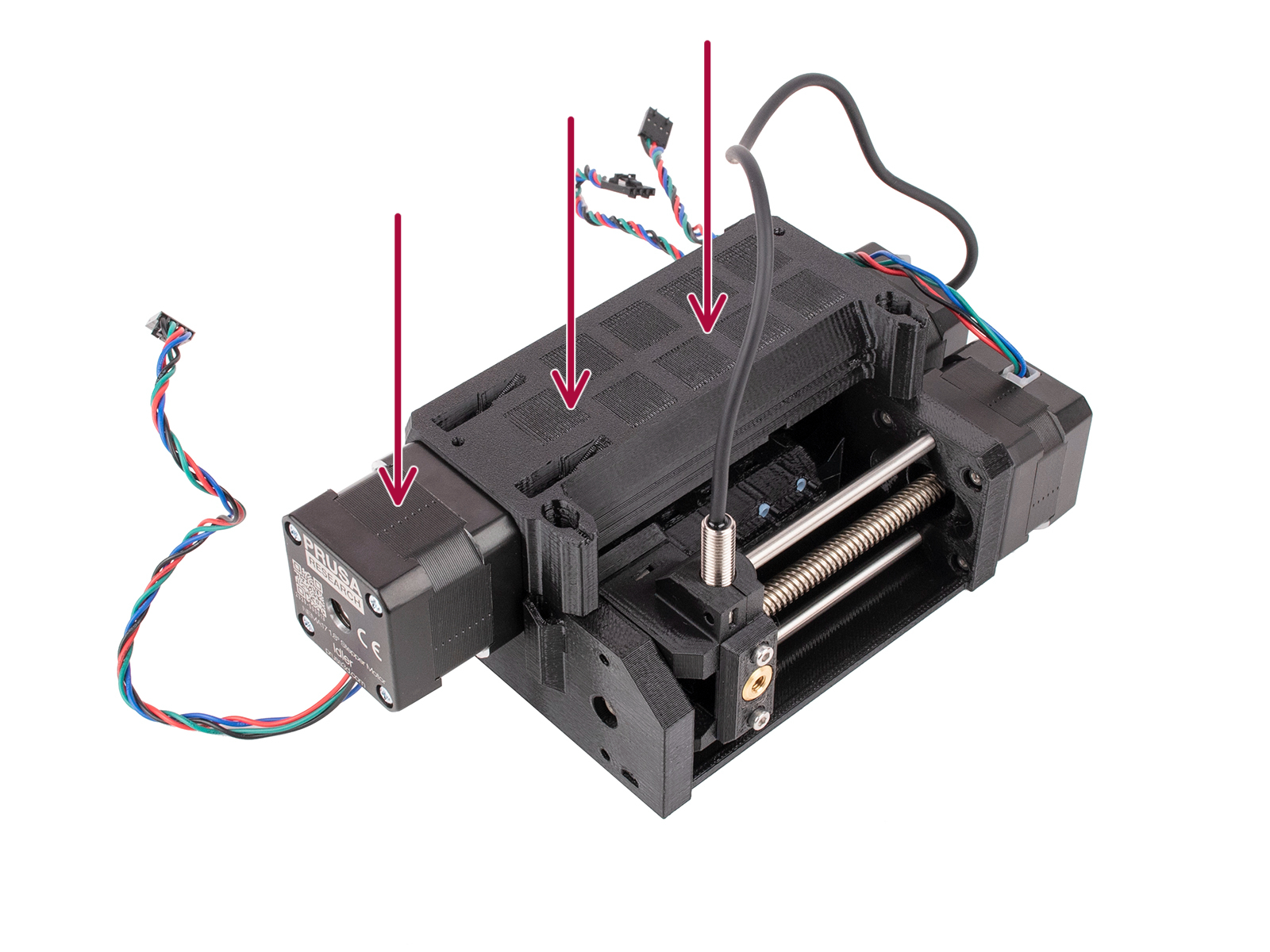

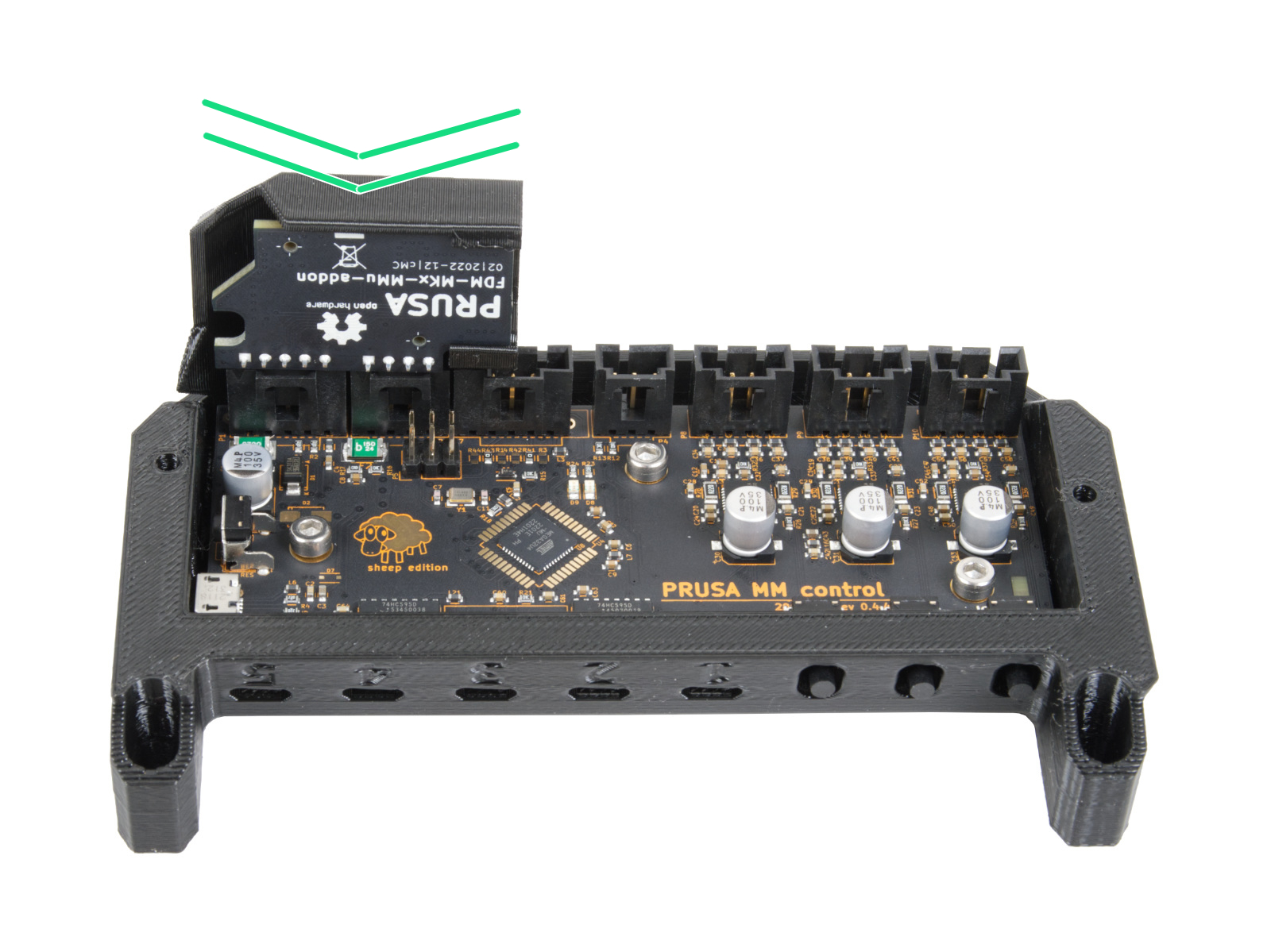

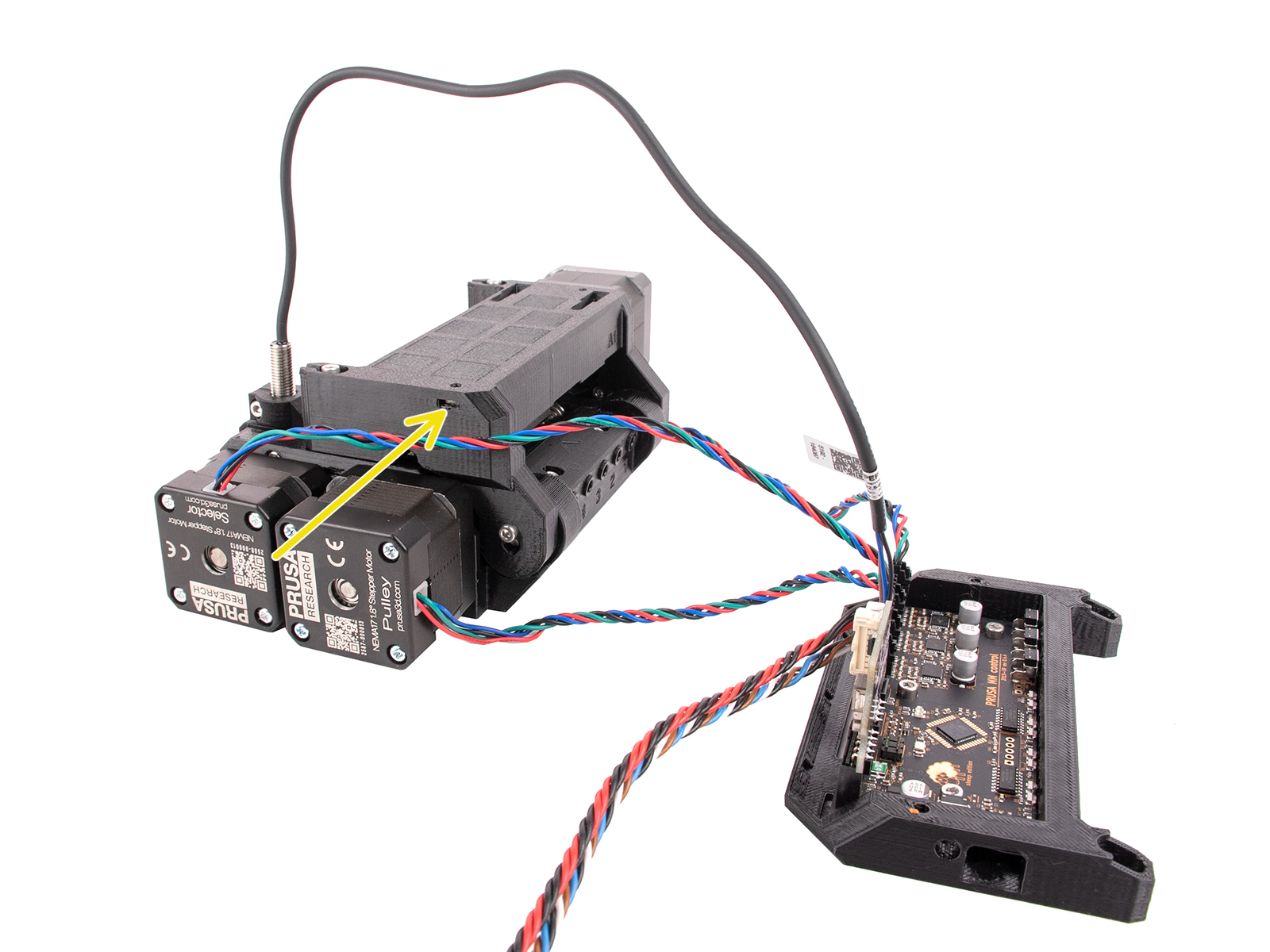

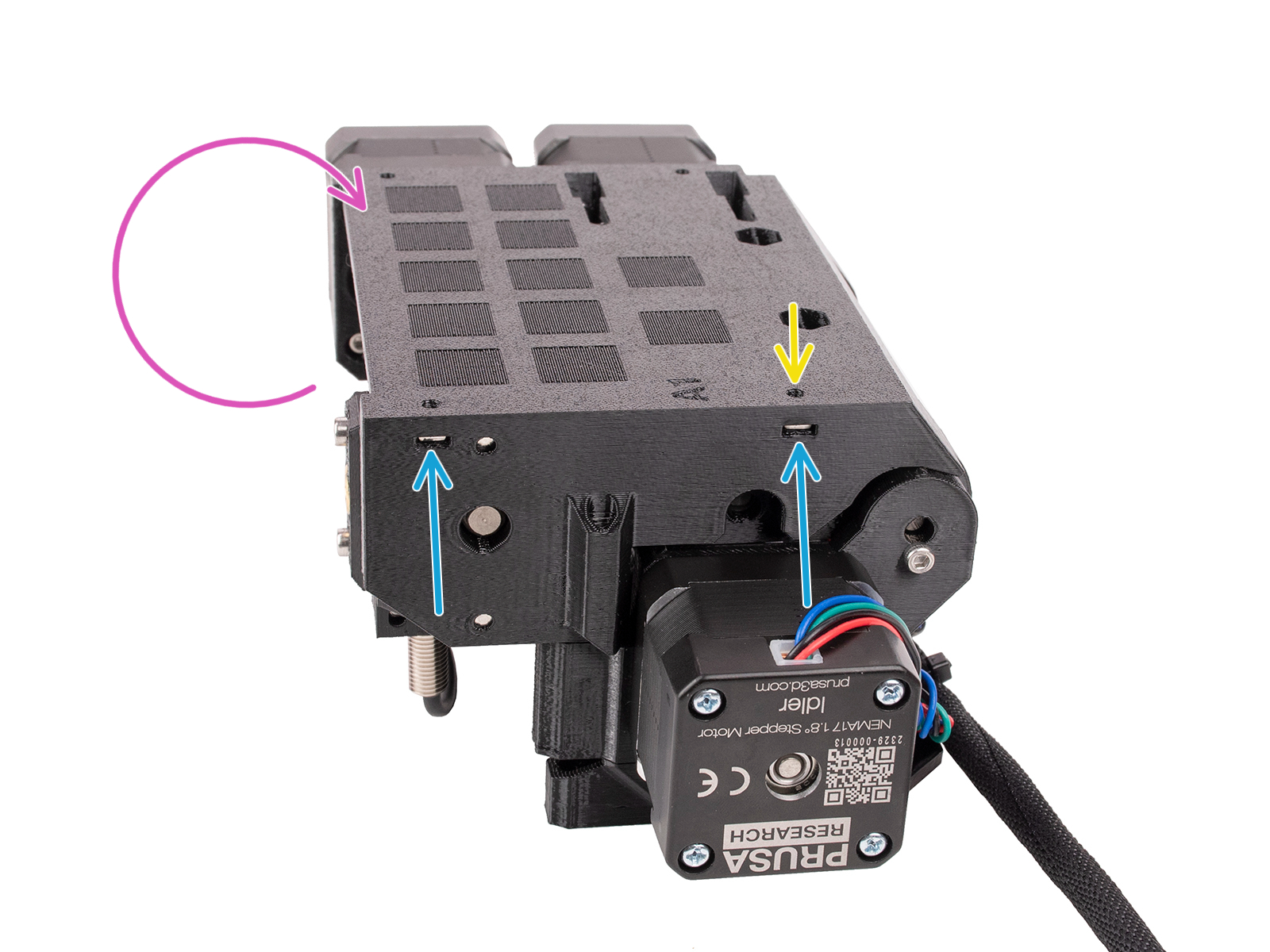

Pulley motor (1x)

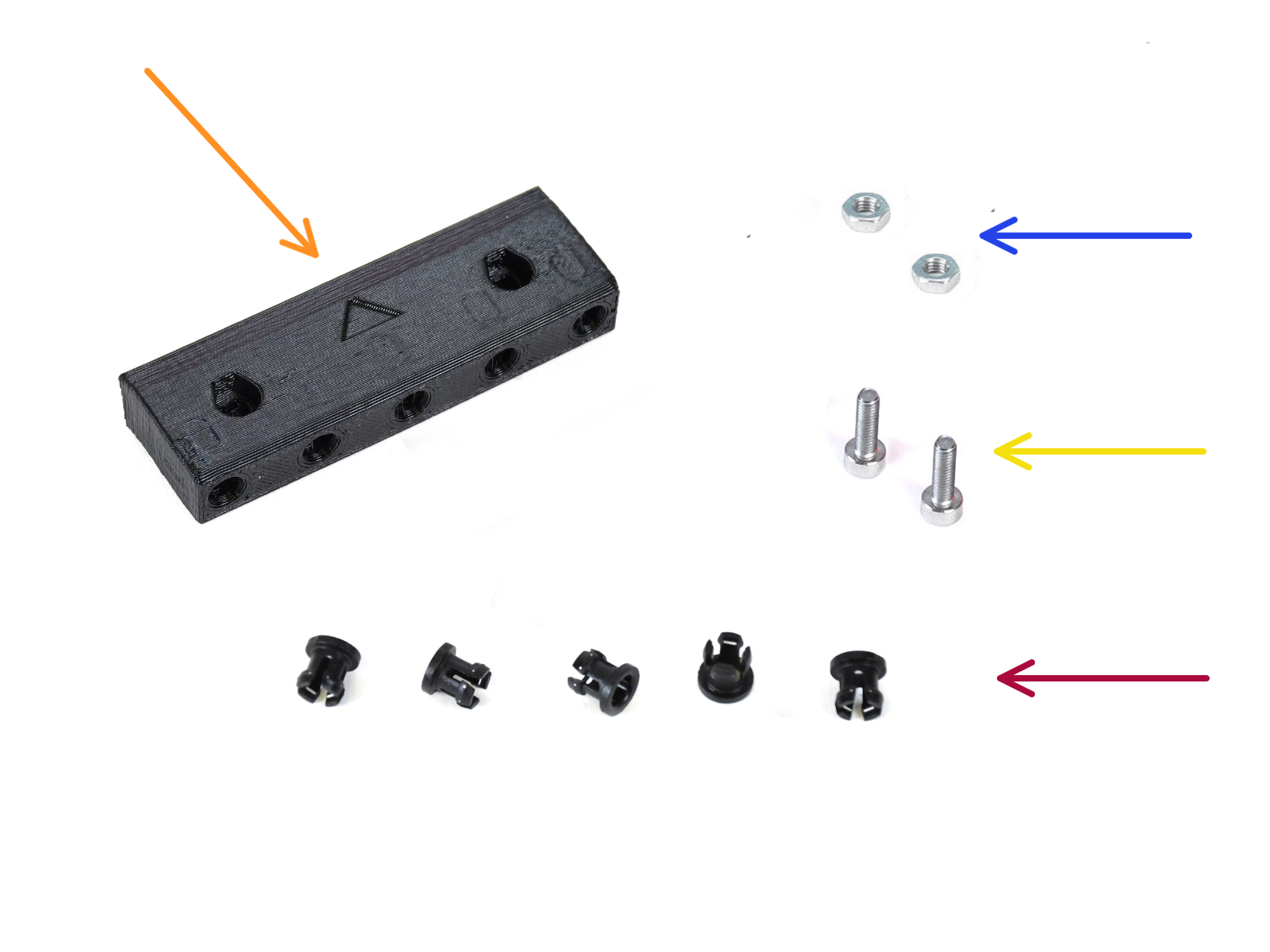

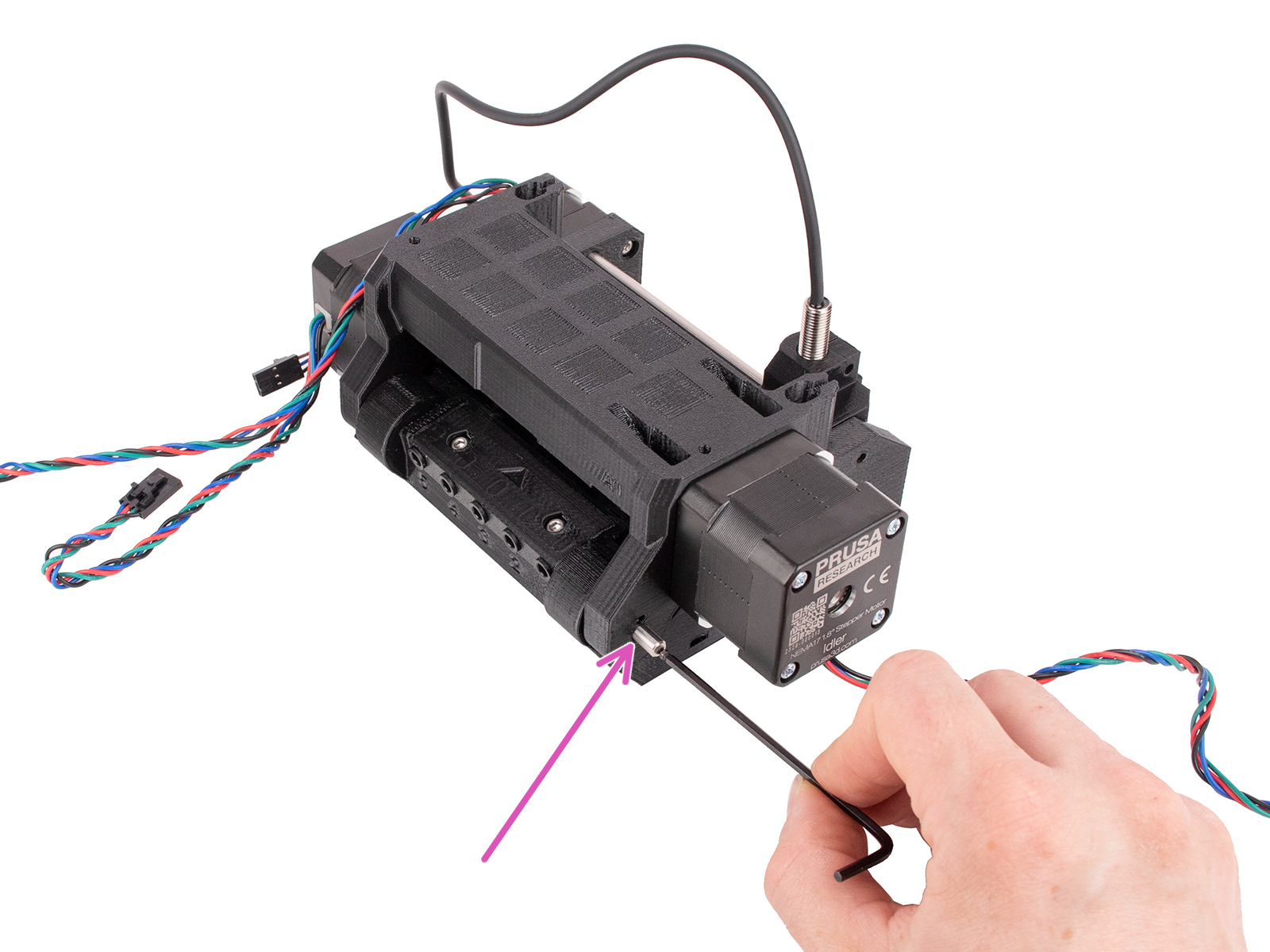

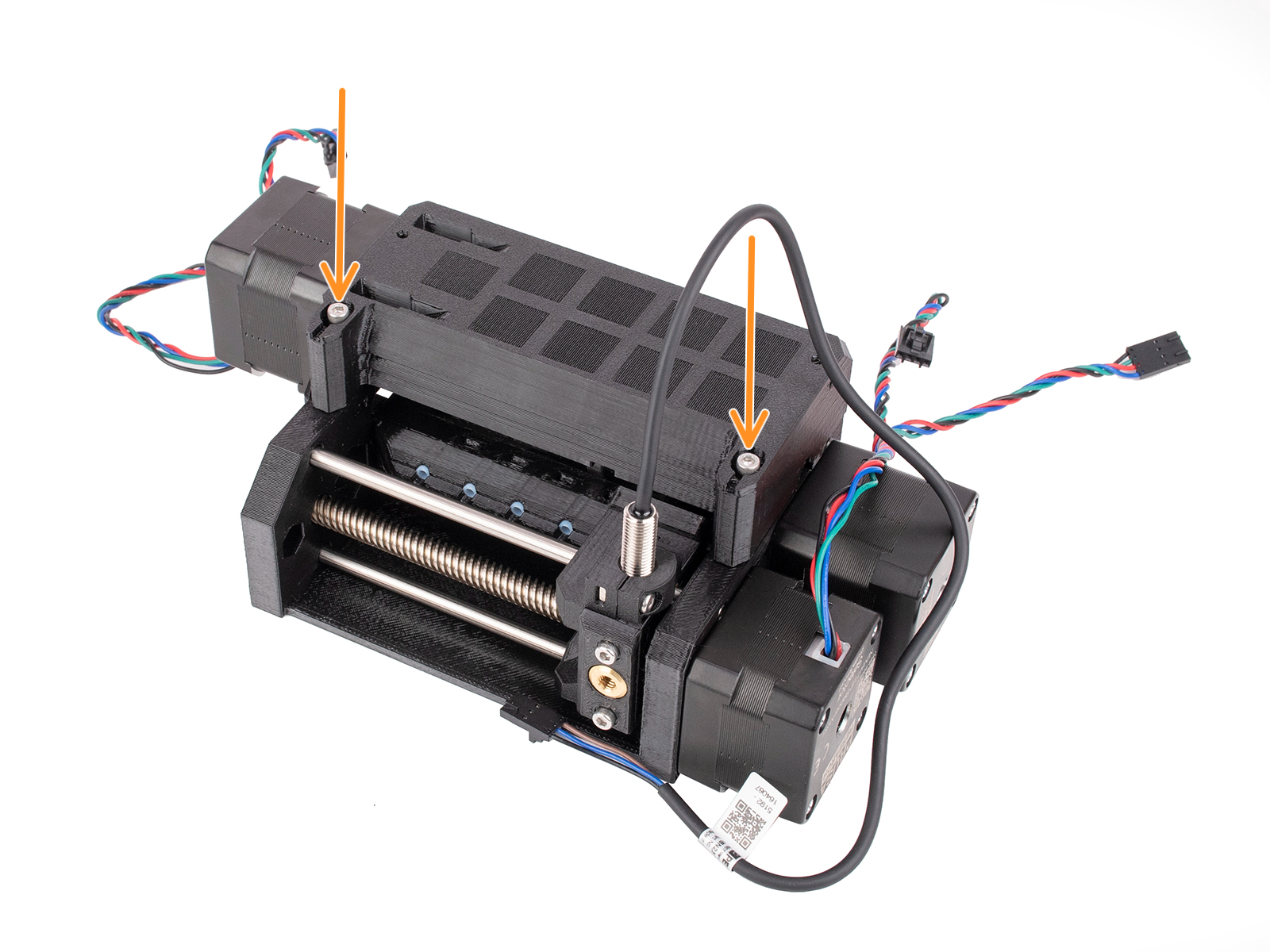

Attach the motor with one M3x10 screw on top.

Just start the thread so that it holds in, don't tighten it up yet!

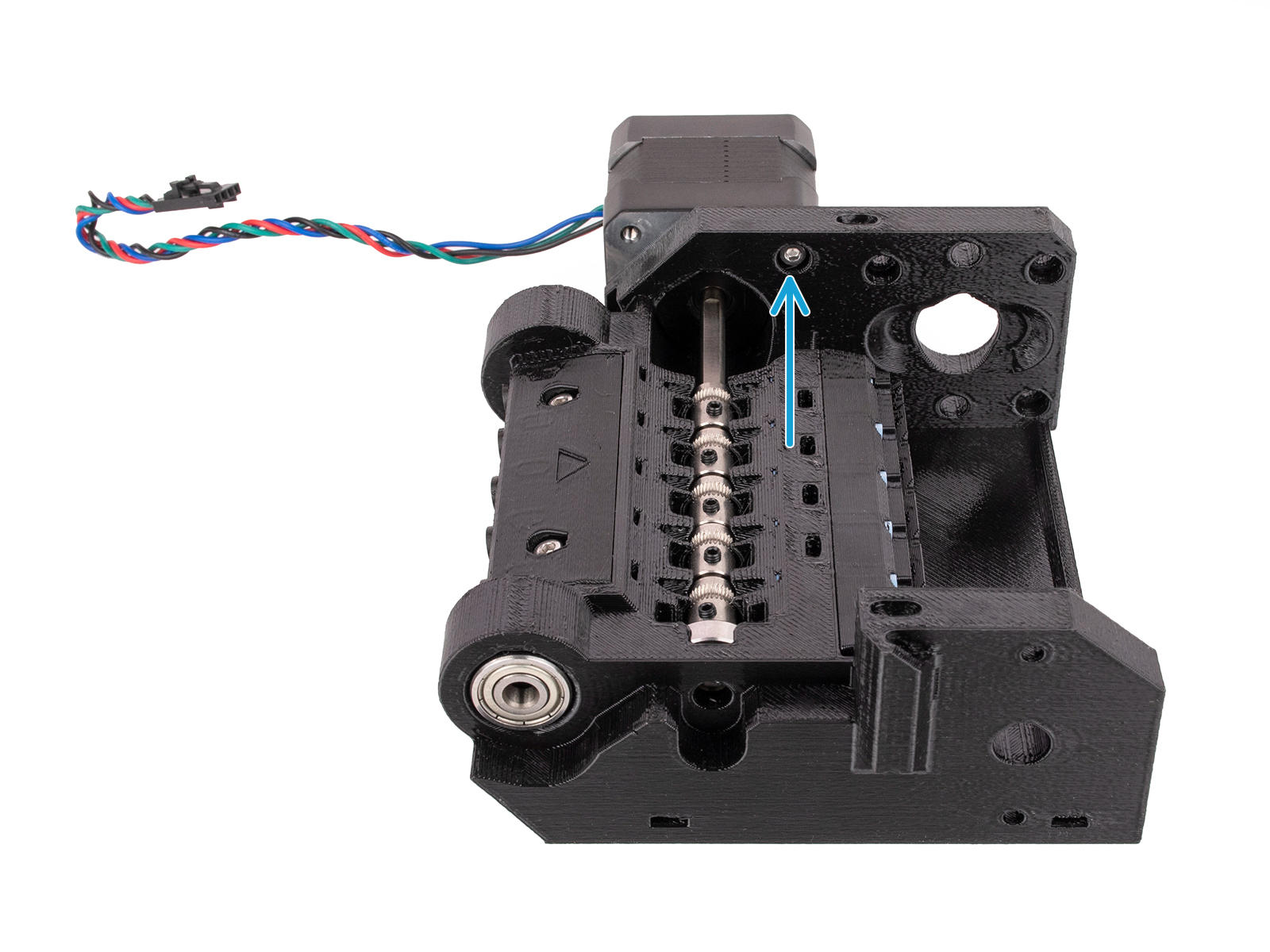

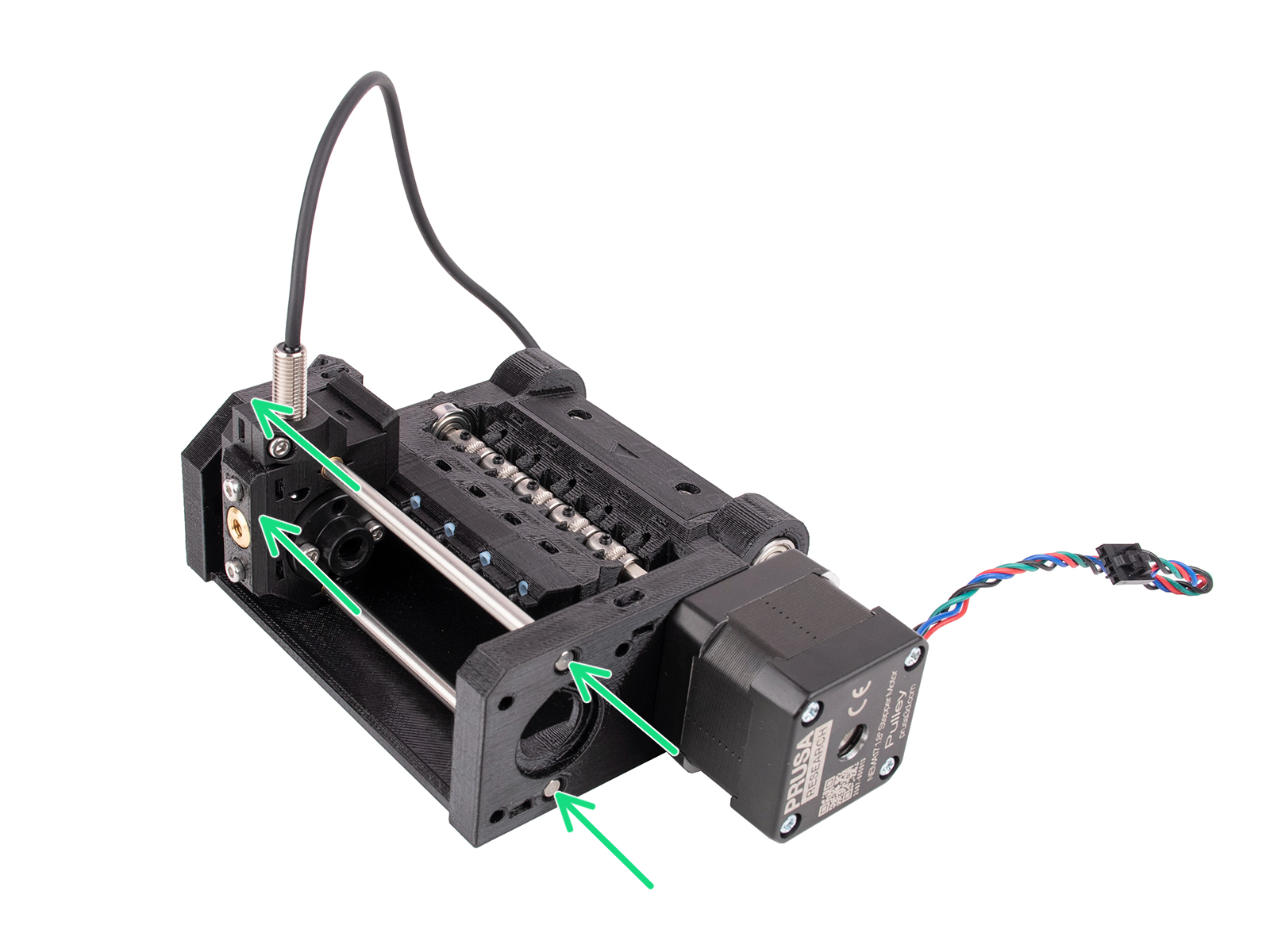

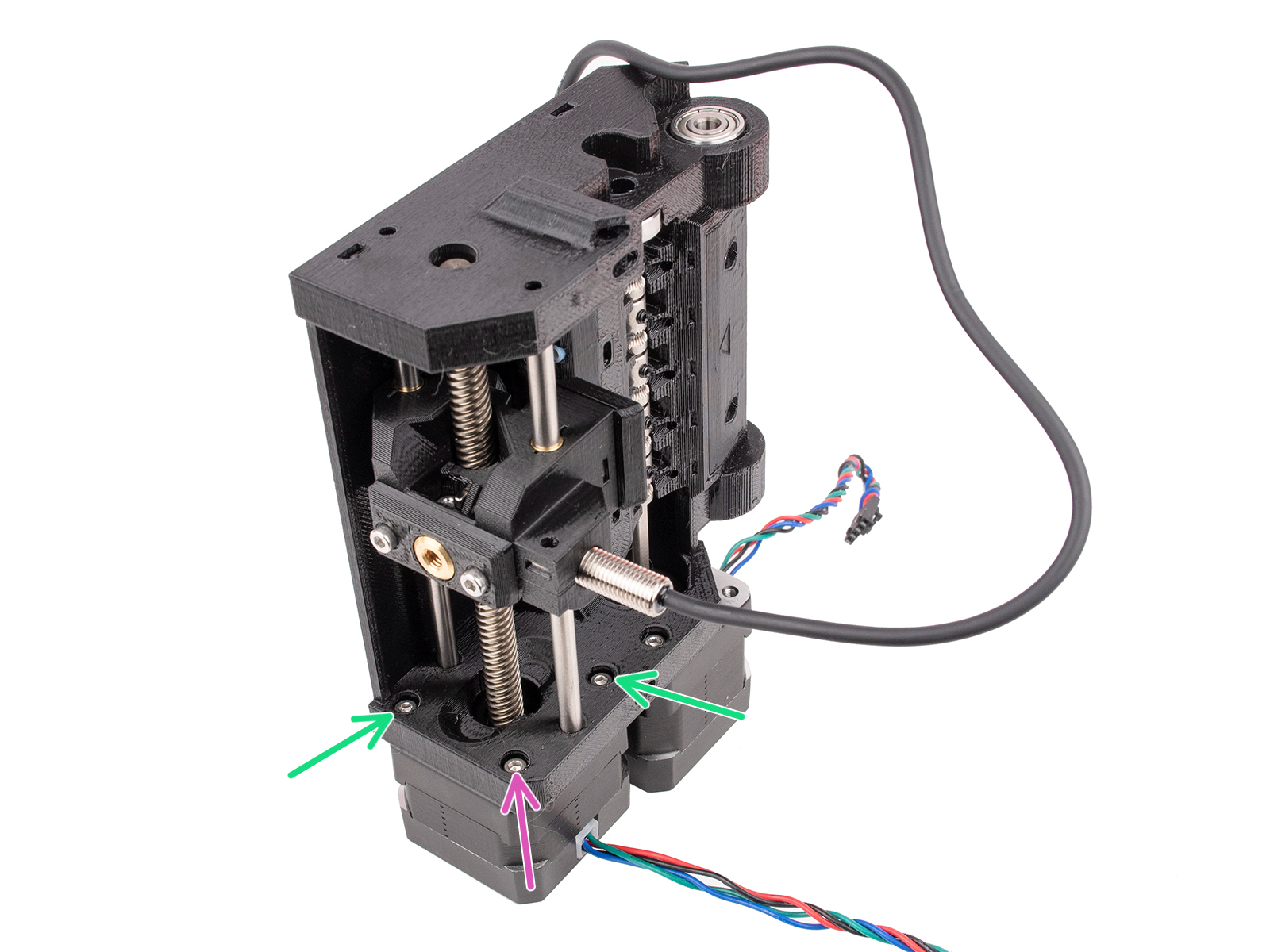

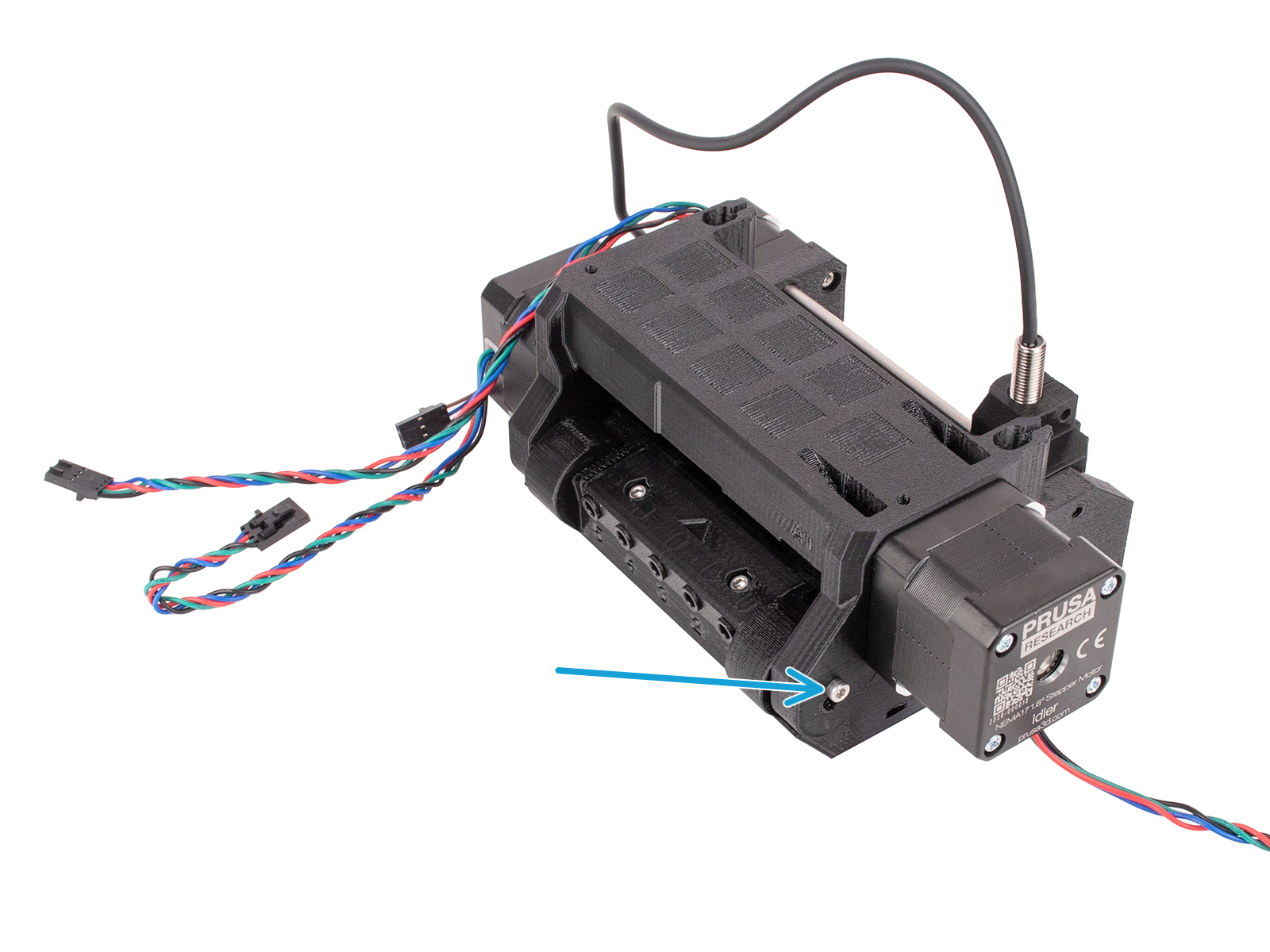

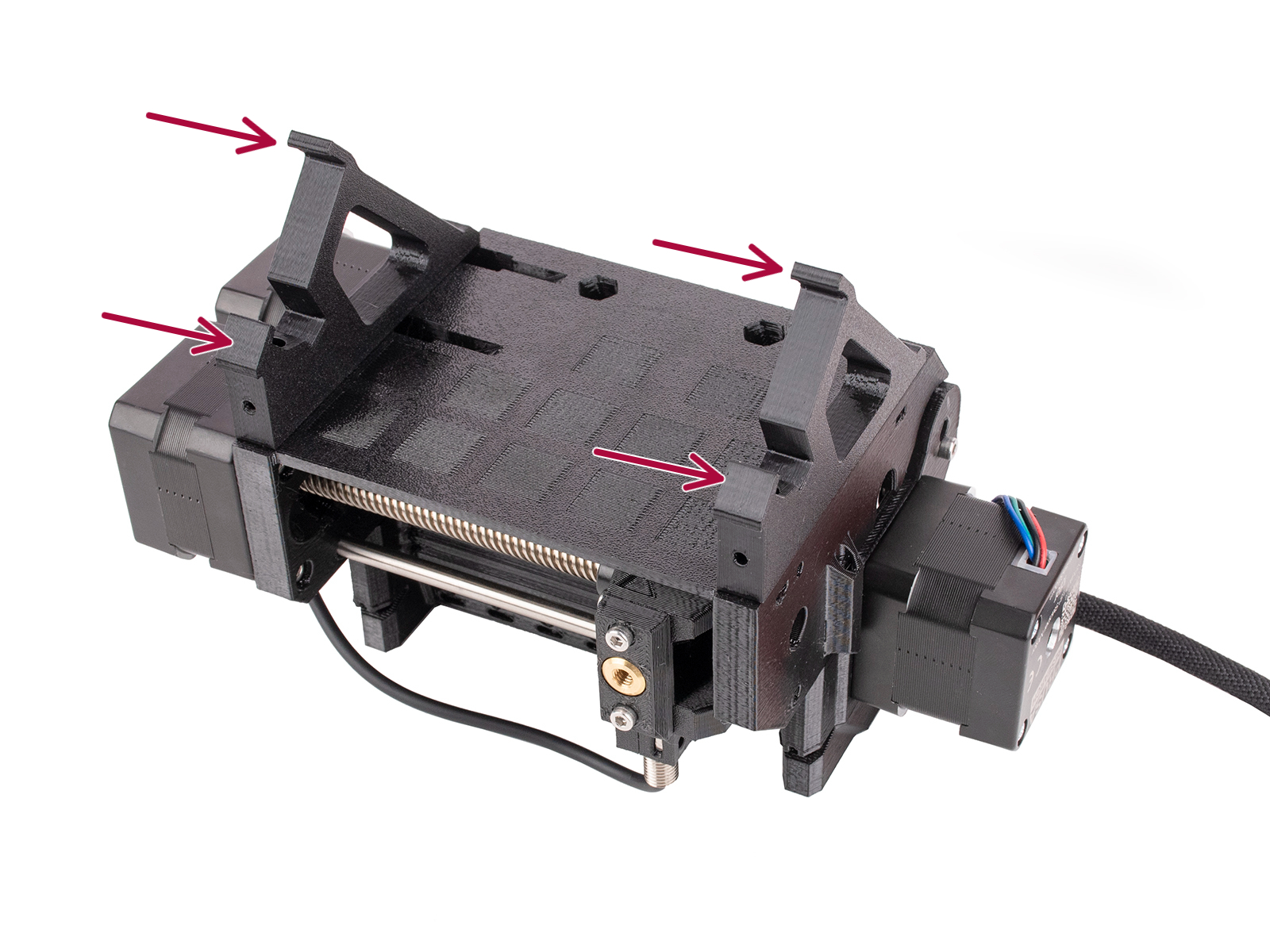

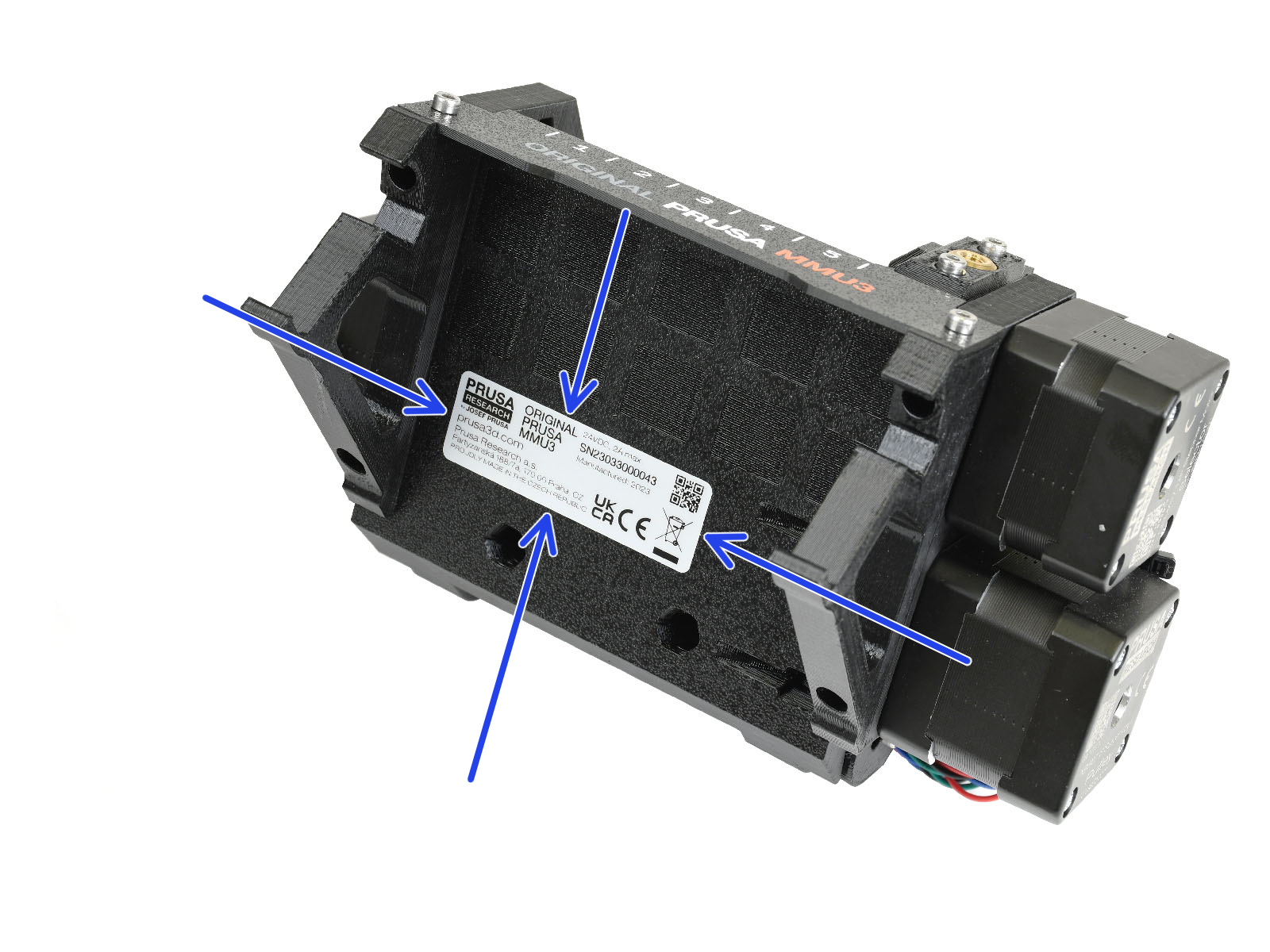

Turn the unit around and attach the motor with the other two M3x10 screws at the bottom. Use the ball-end 2.5mm Allen key at an angle to tighten up the screws fully.

Make sure, the screw is perfectly perpendicular to the motor while tightening. If it is hard to turn, release the screw fully, re-align it, and start tightening it from the beginning to avoid cross-threading it.

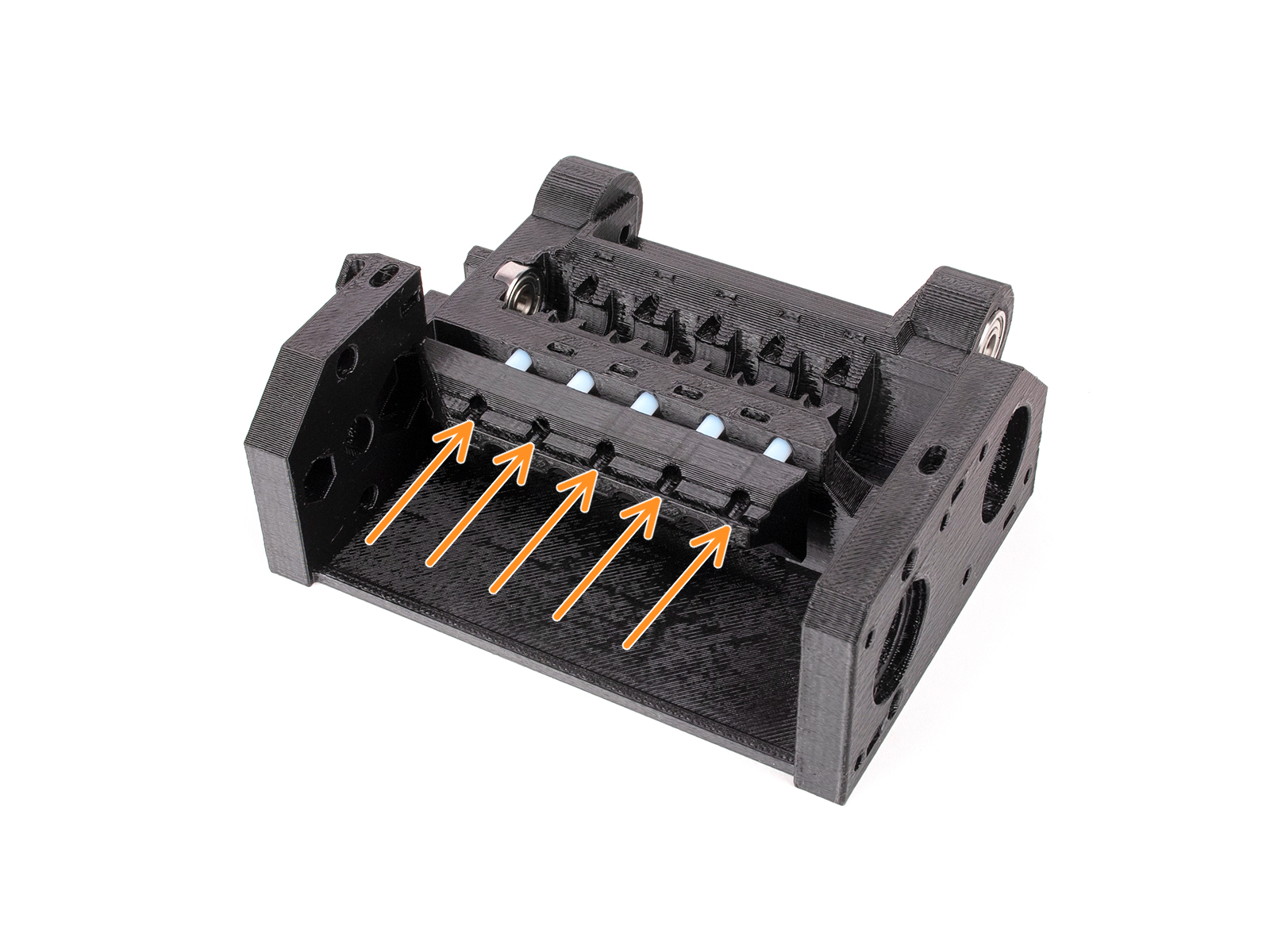

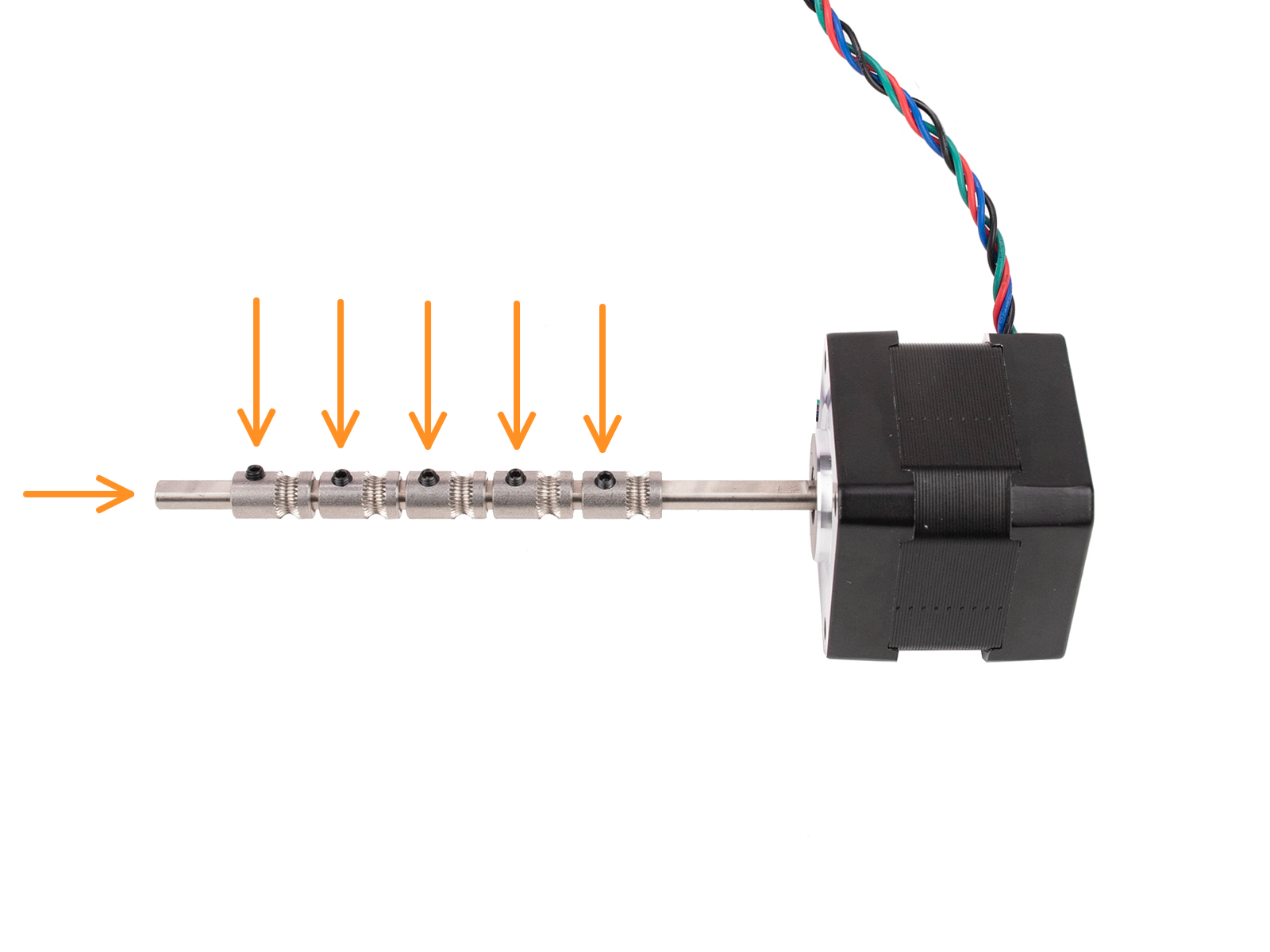

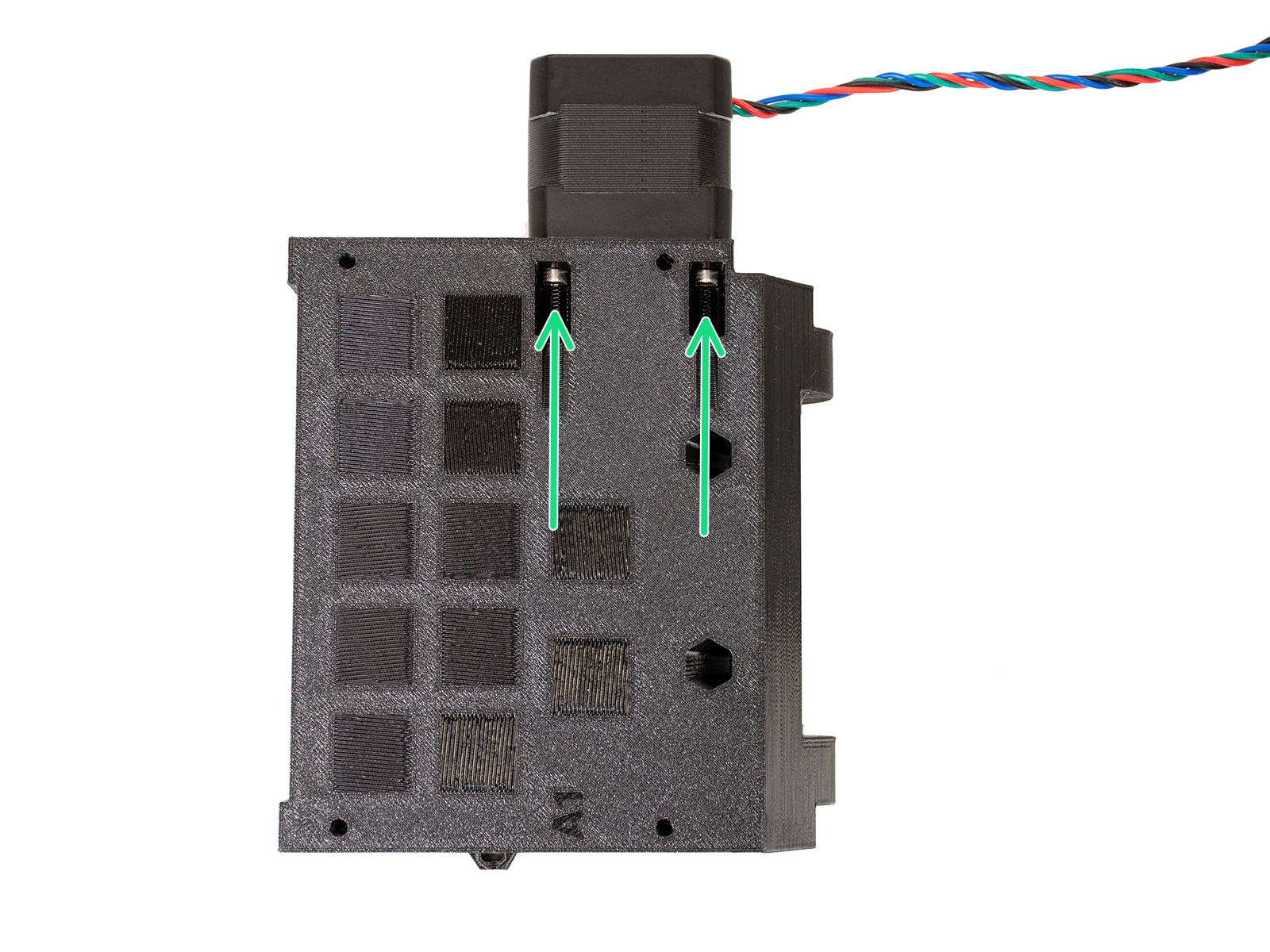

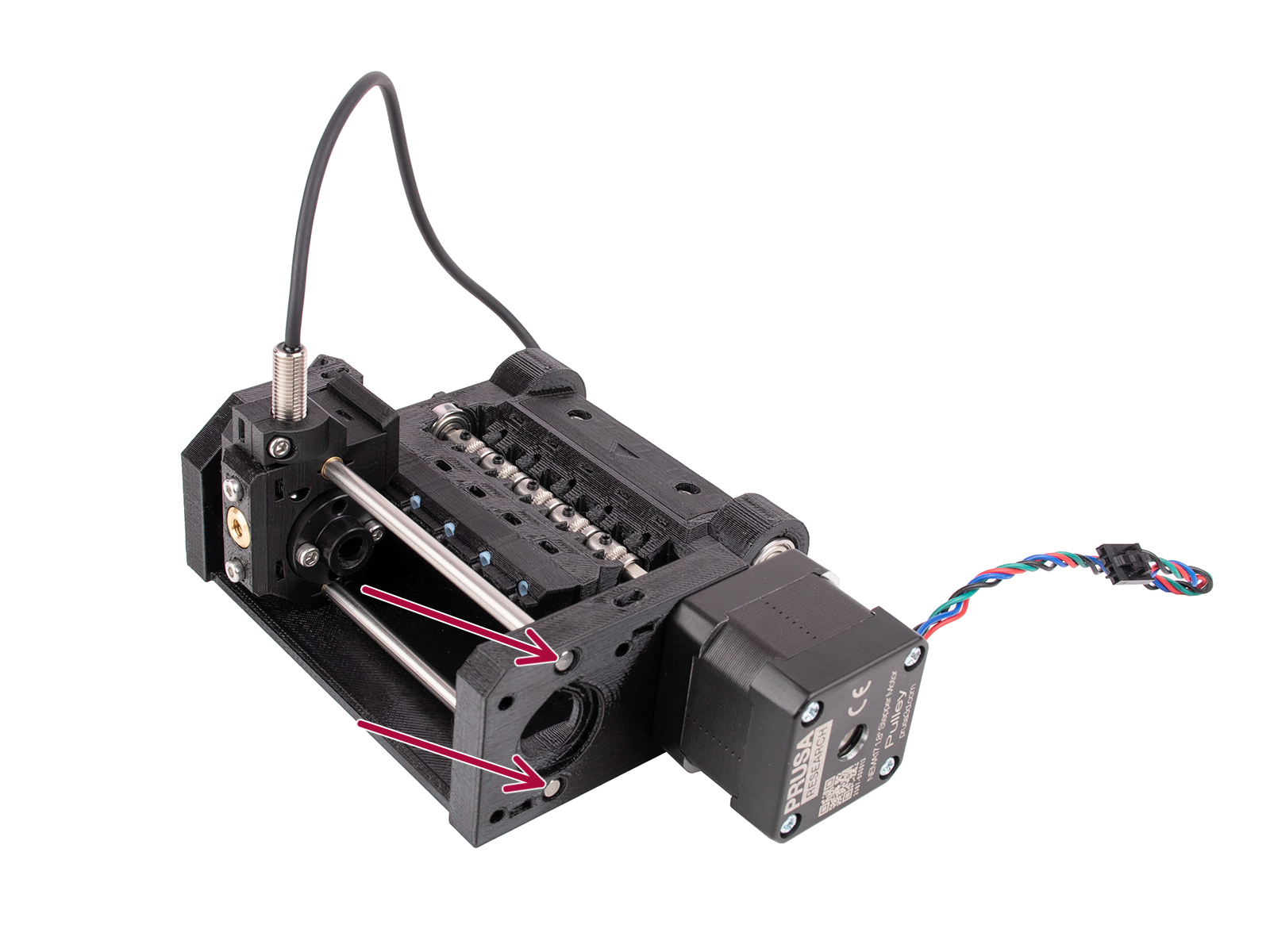

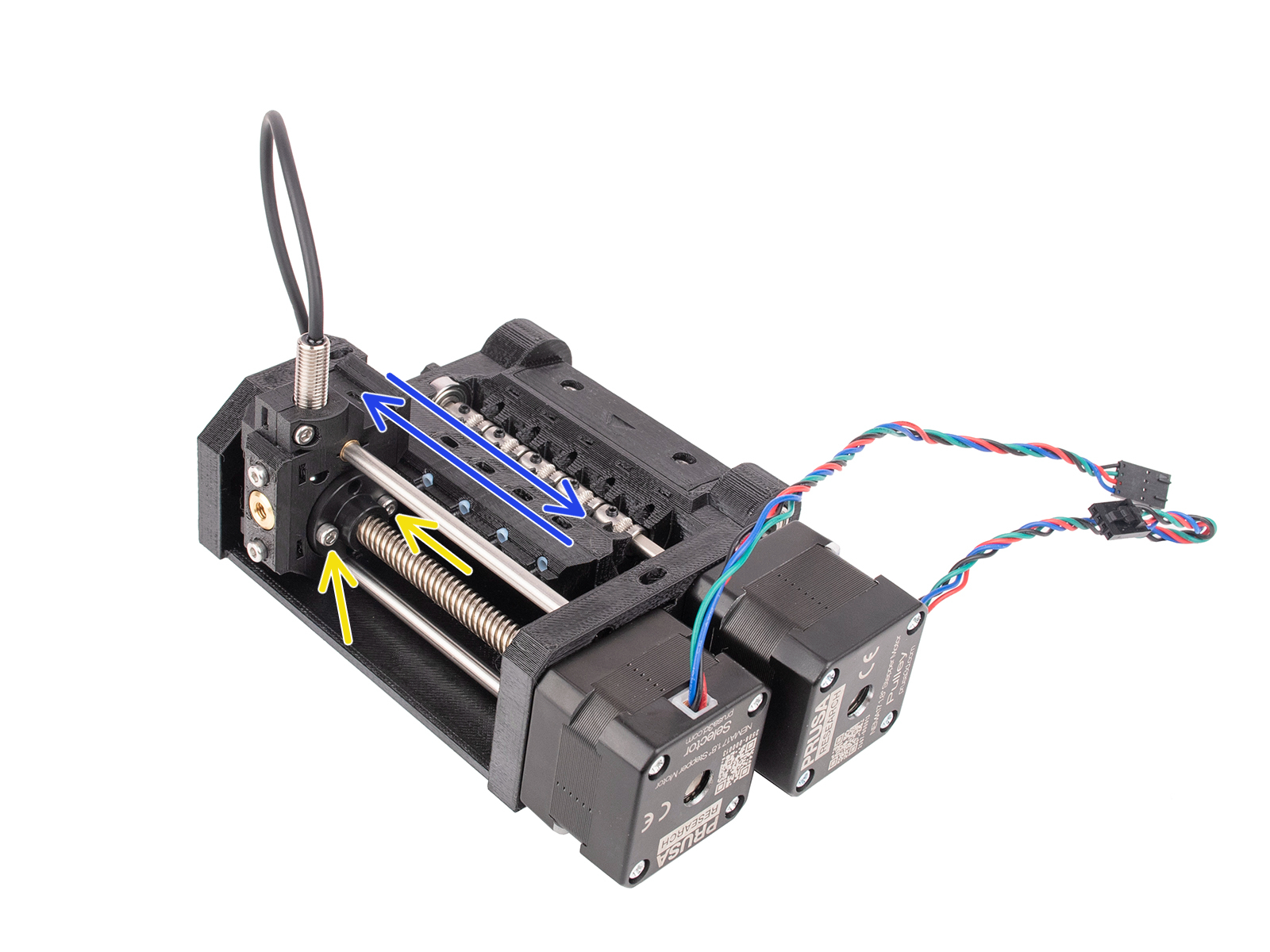

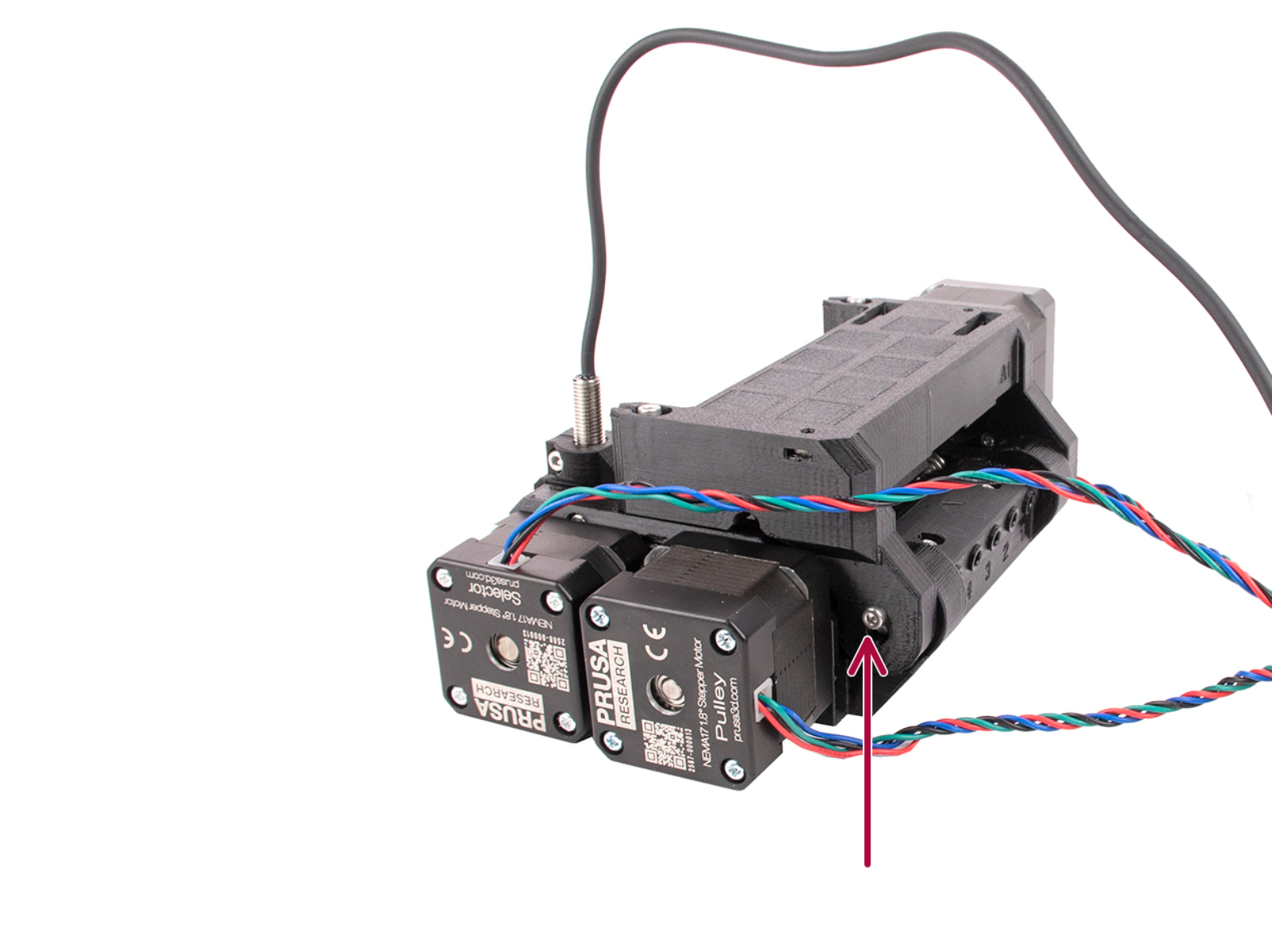

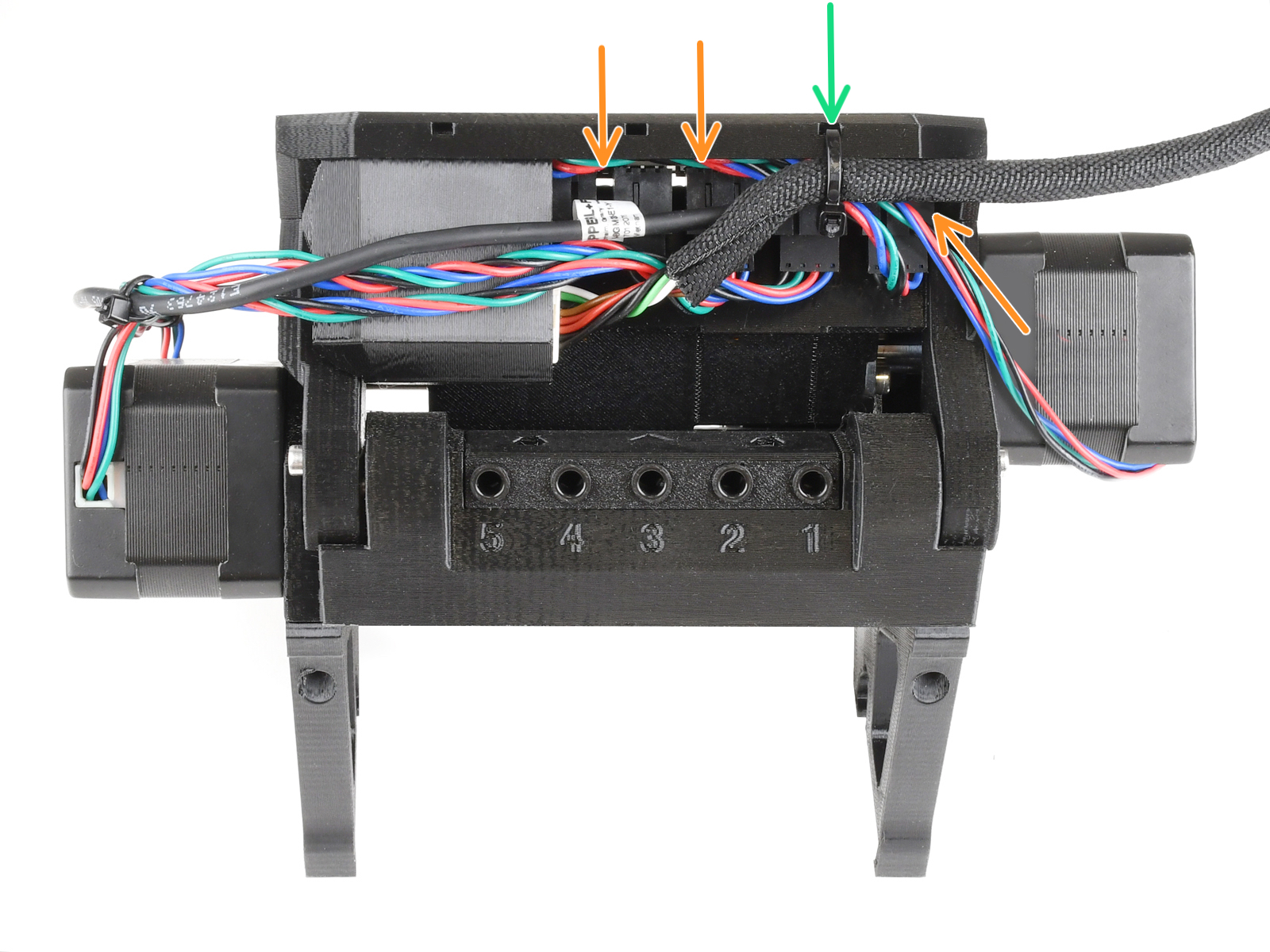

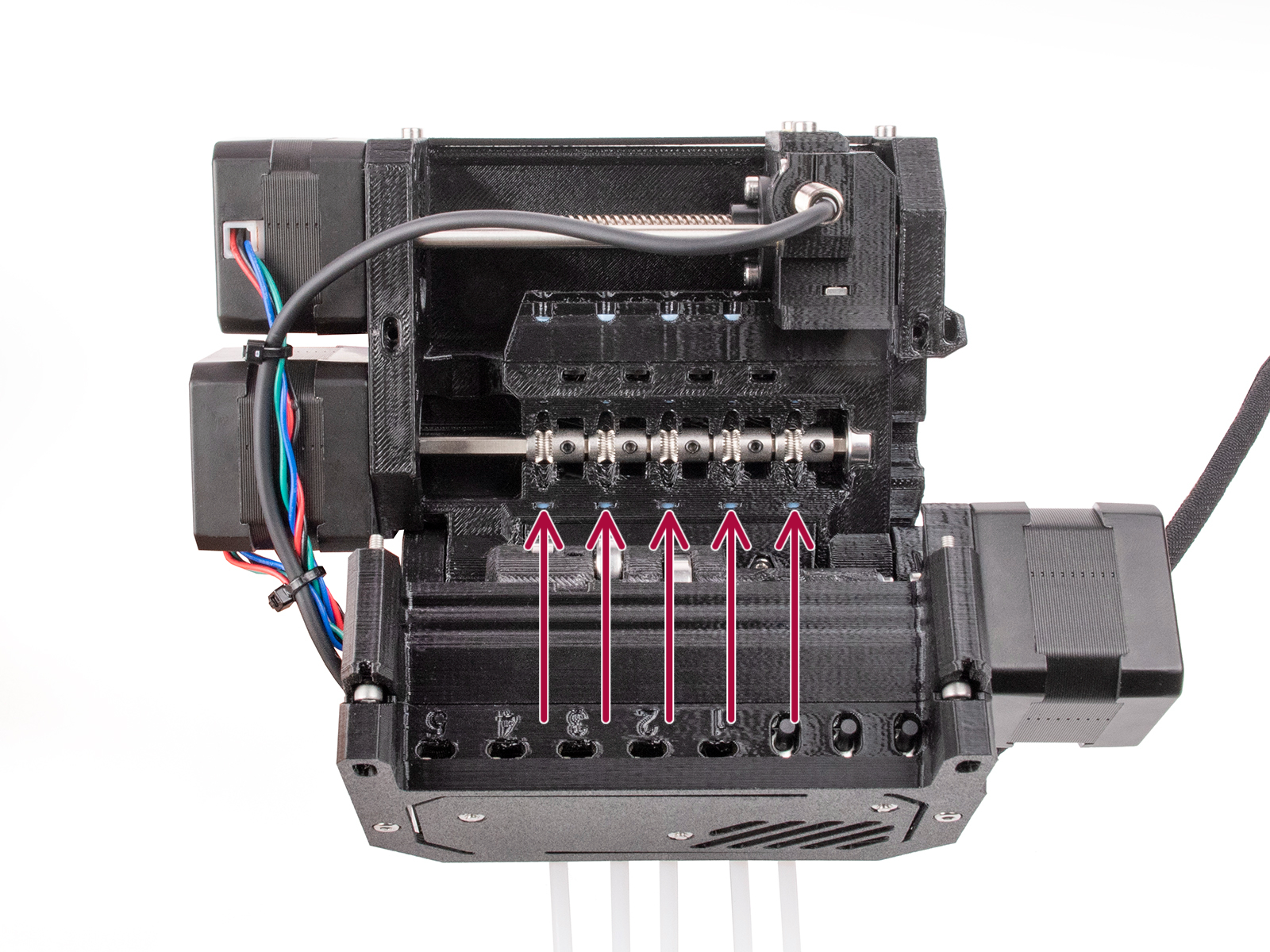

The groove inside the pulley must be perfectly aligned with the filament openings in the pulley body.

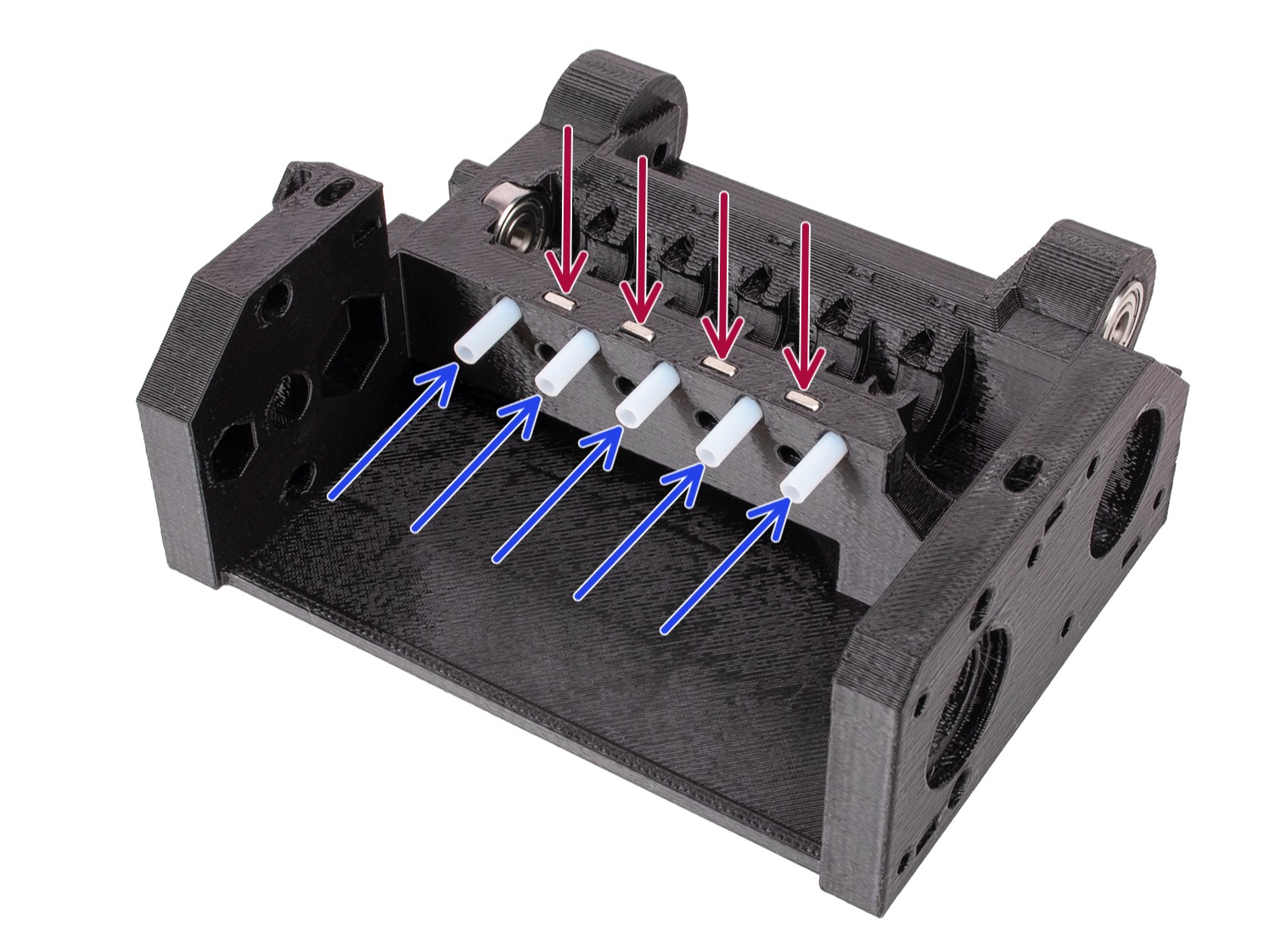

Align the pulleys one by one.

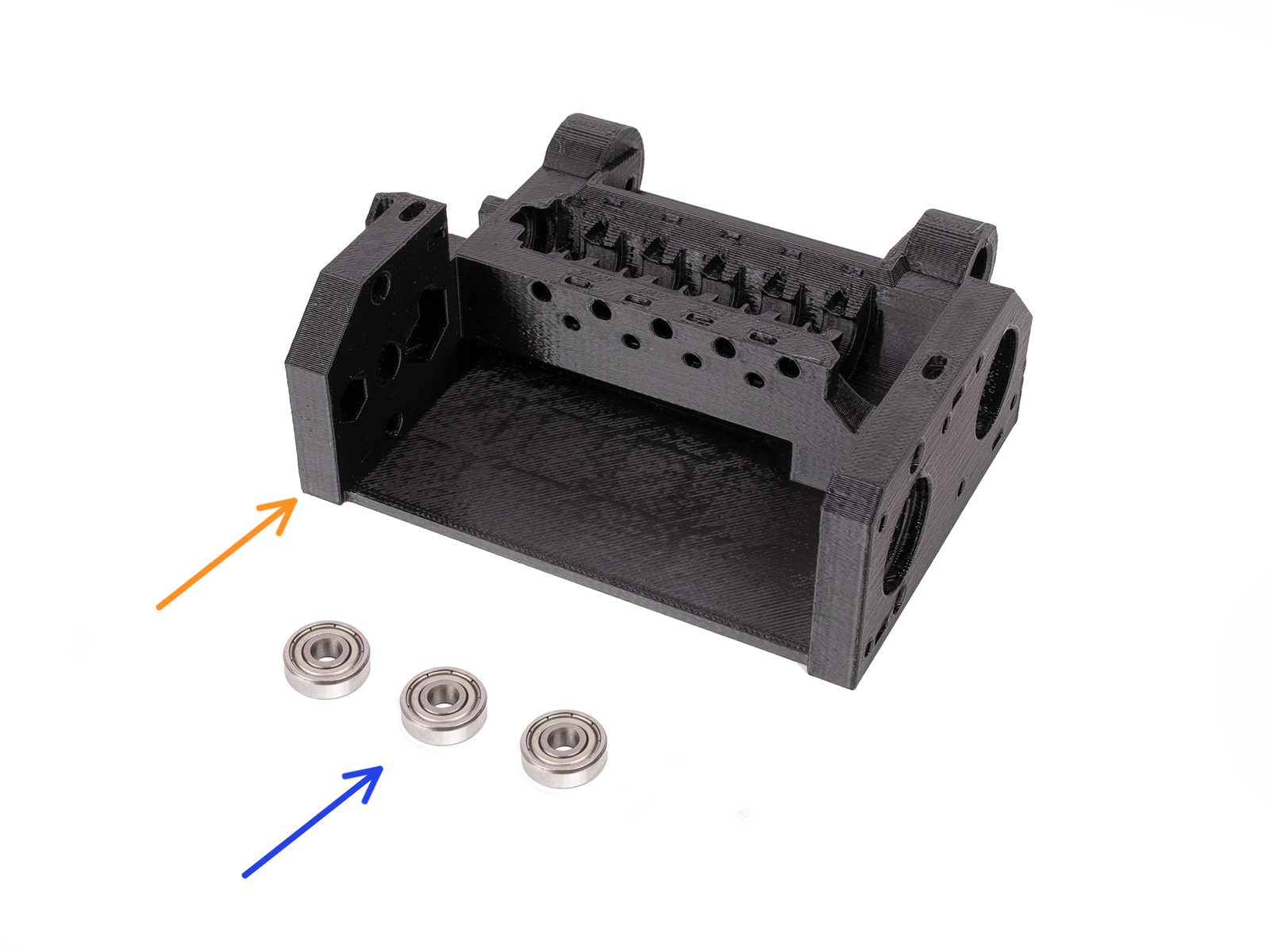

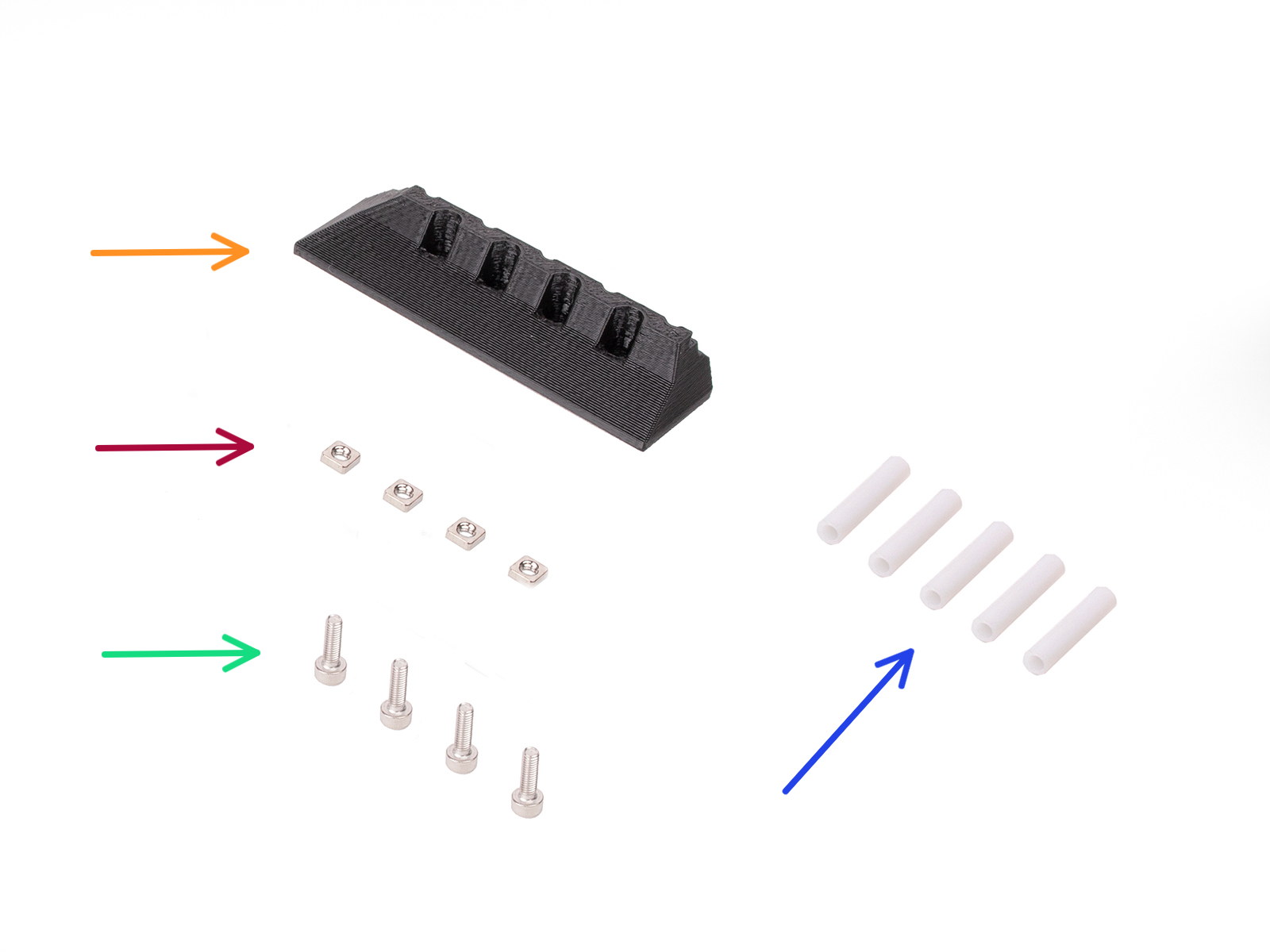

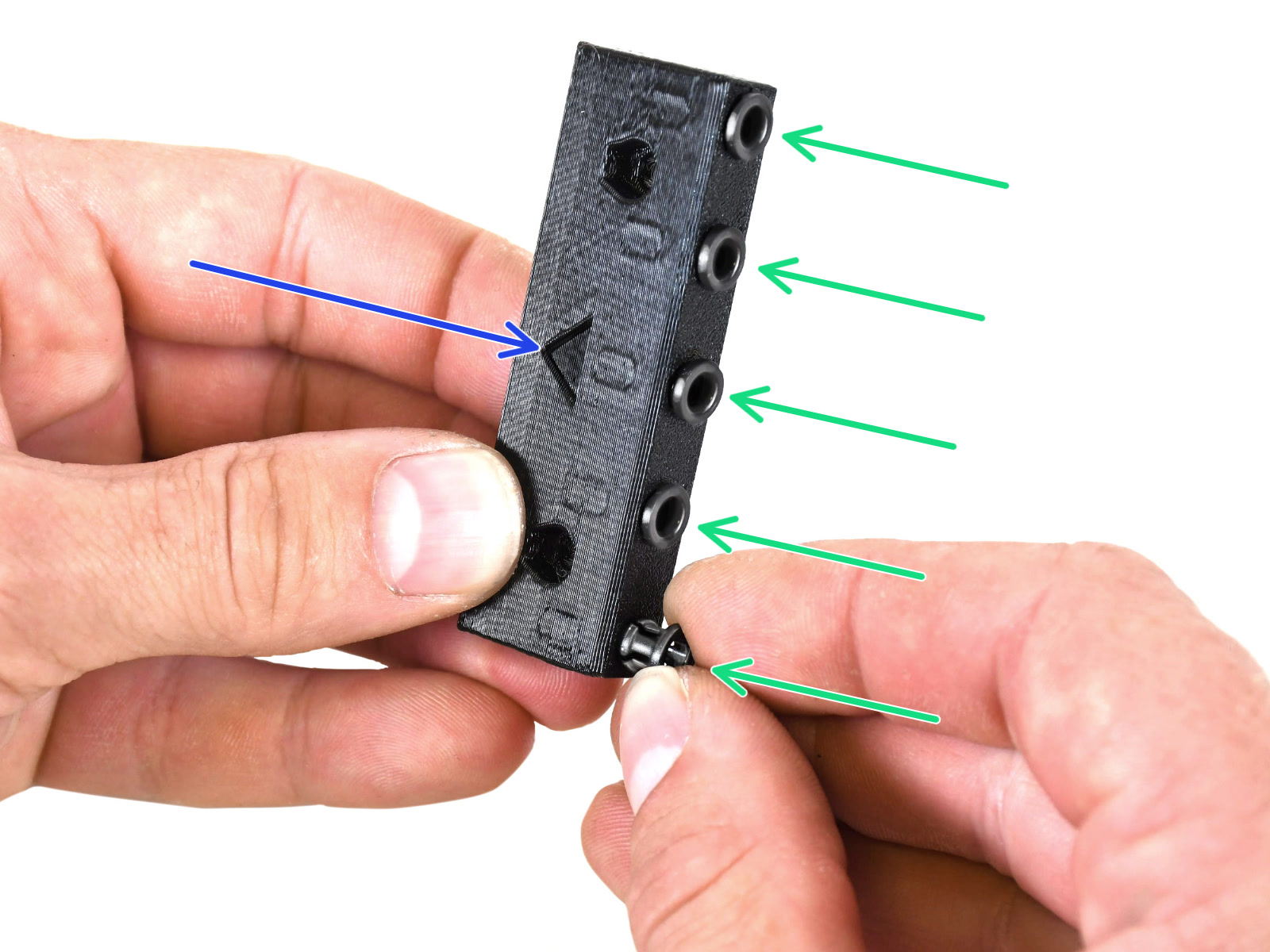

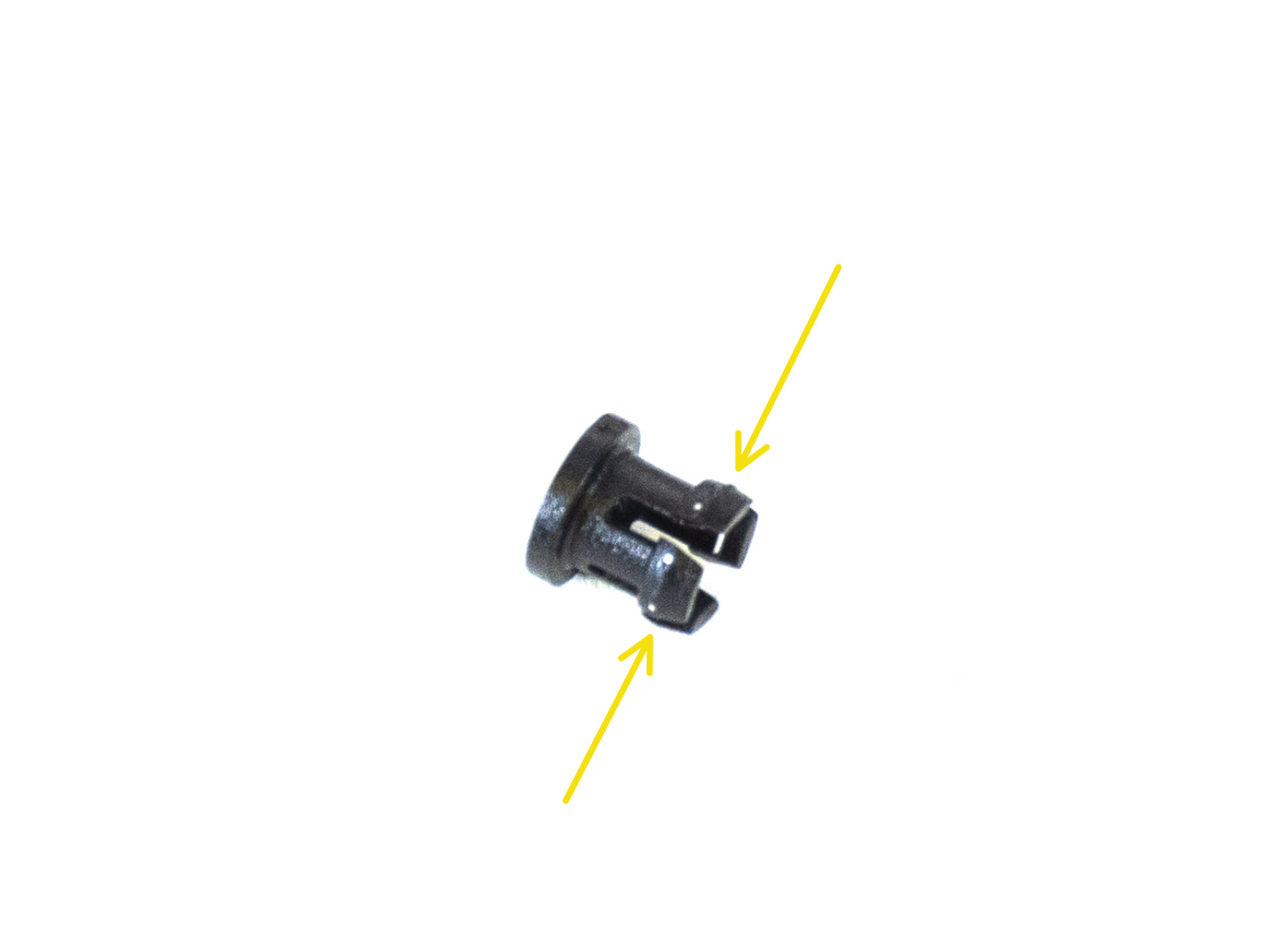

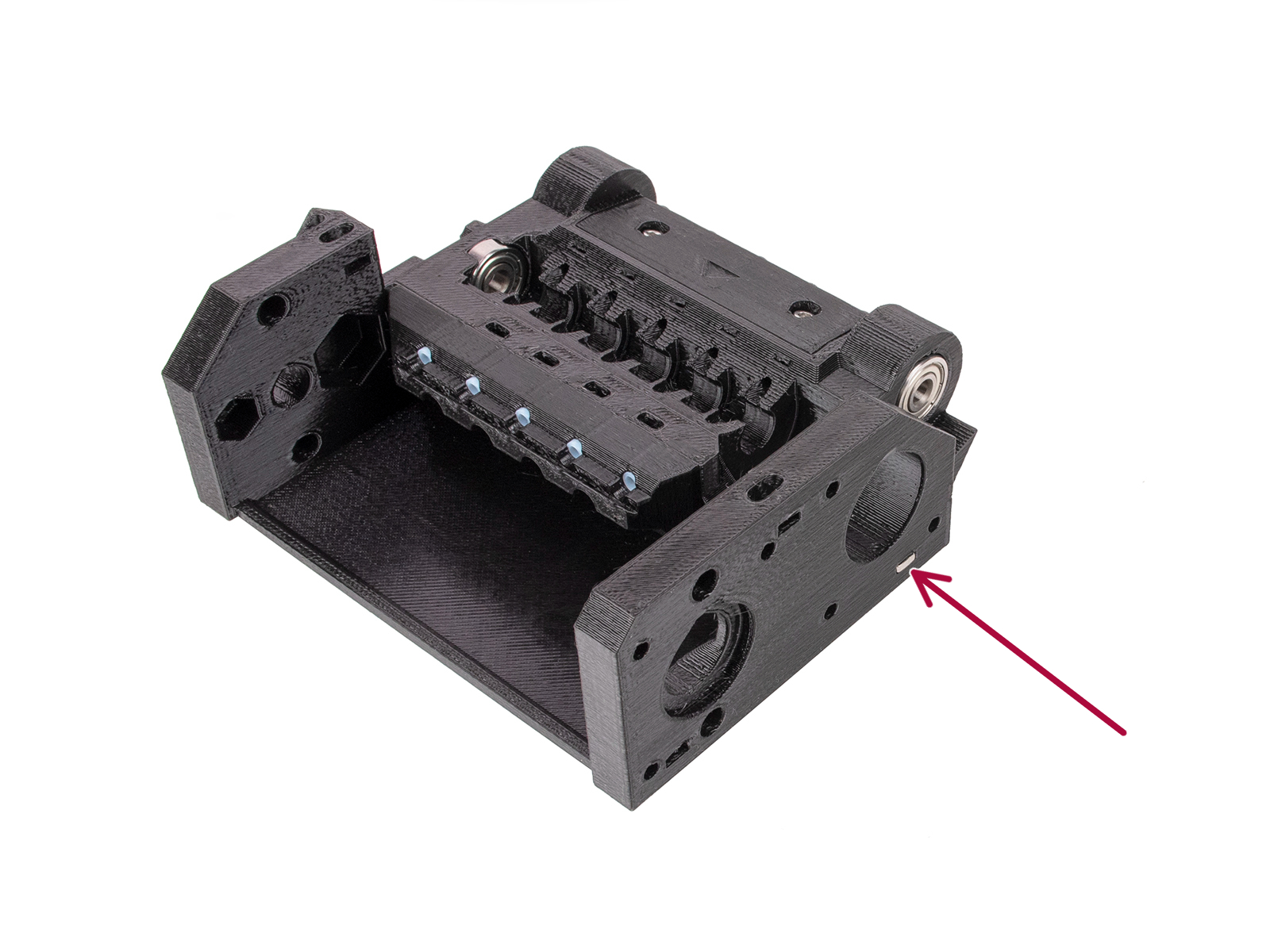

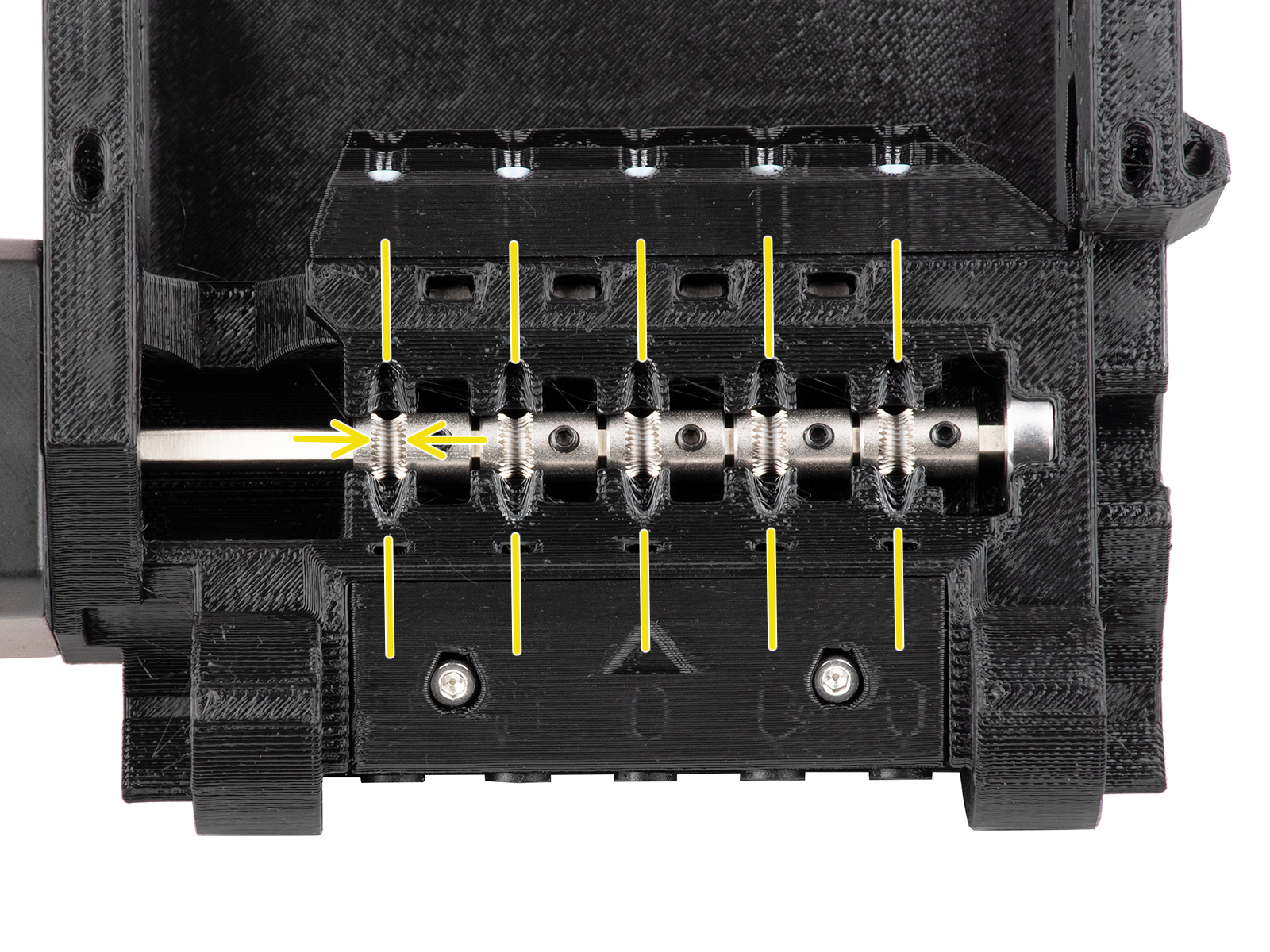

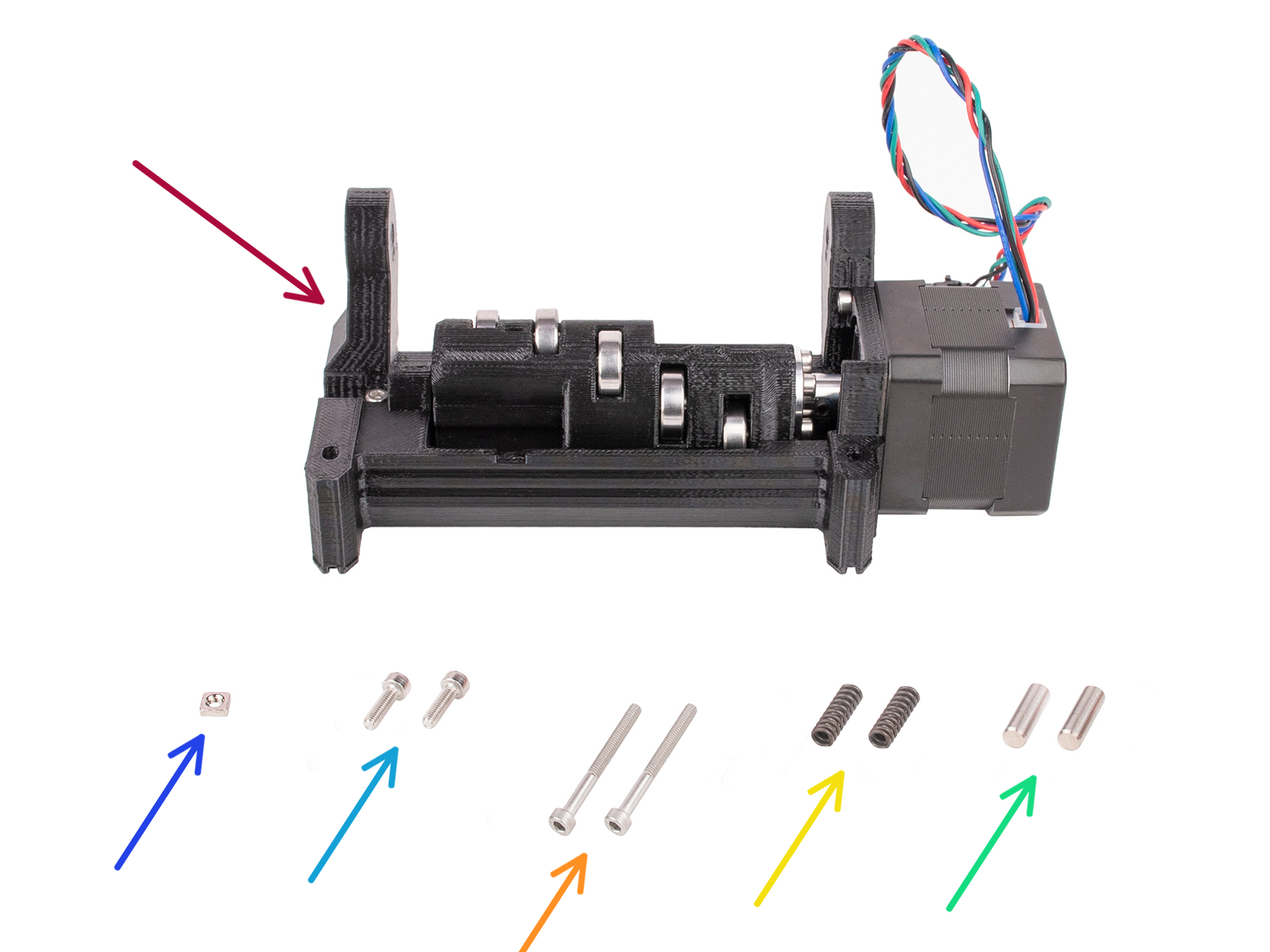

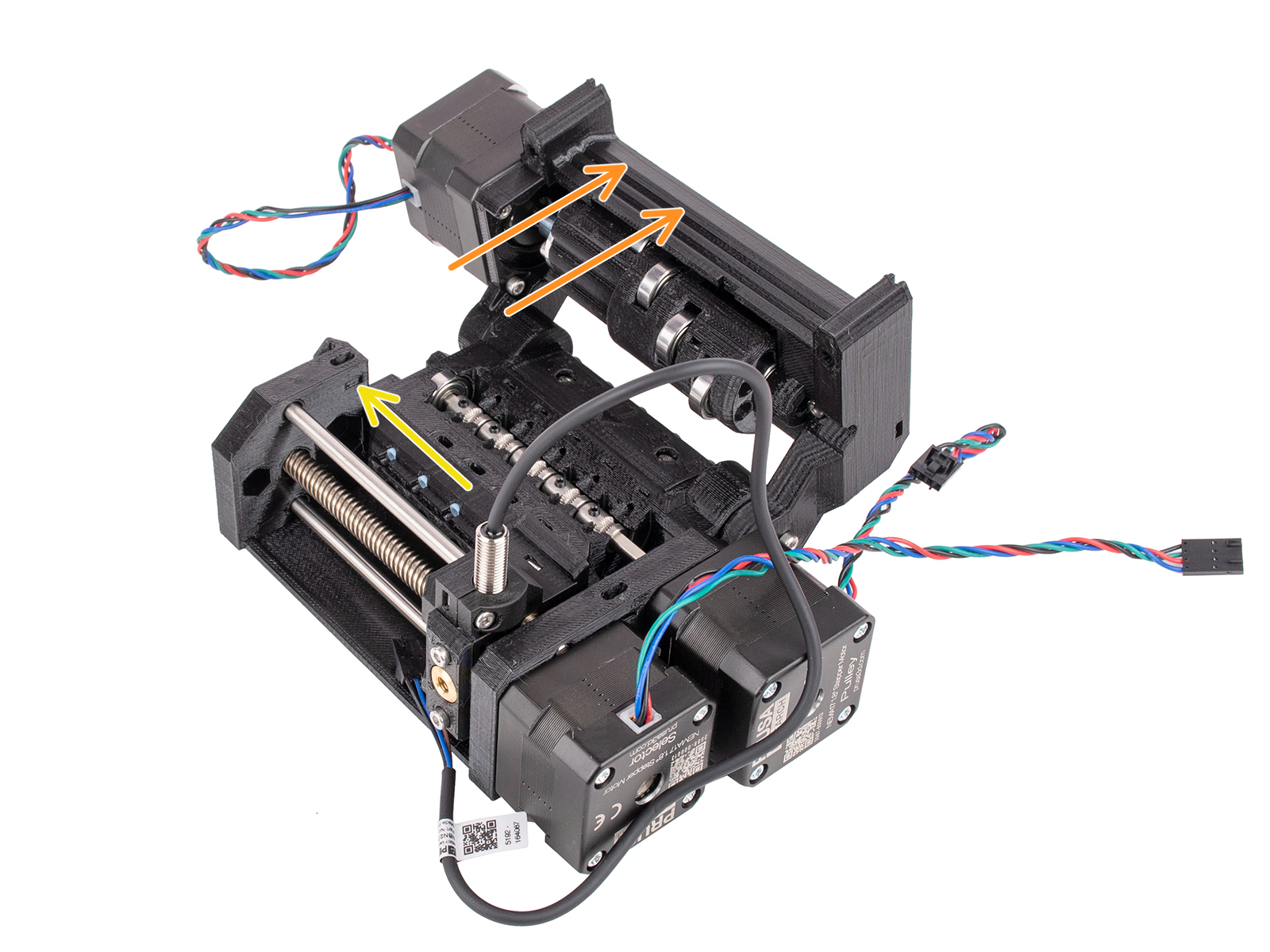

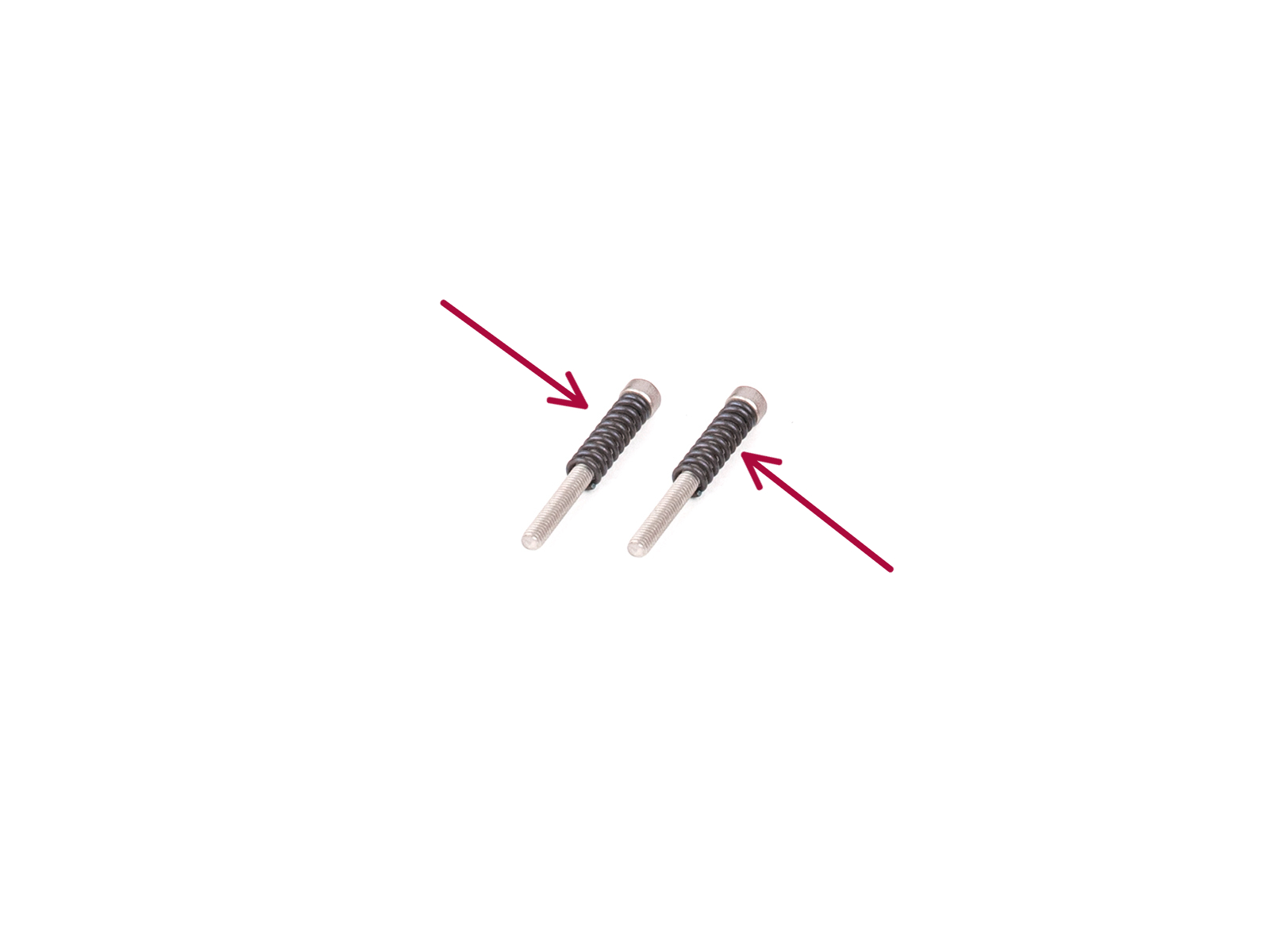

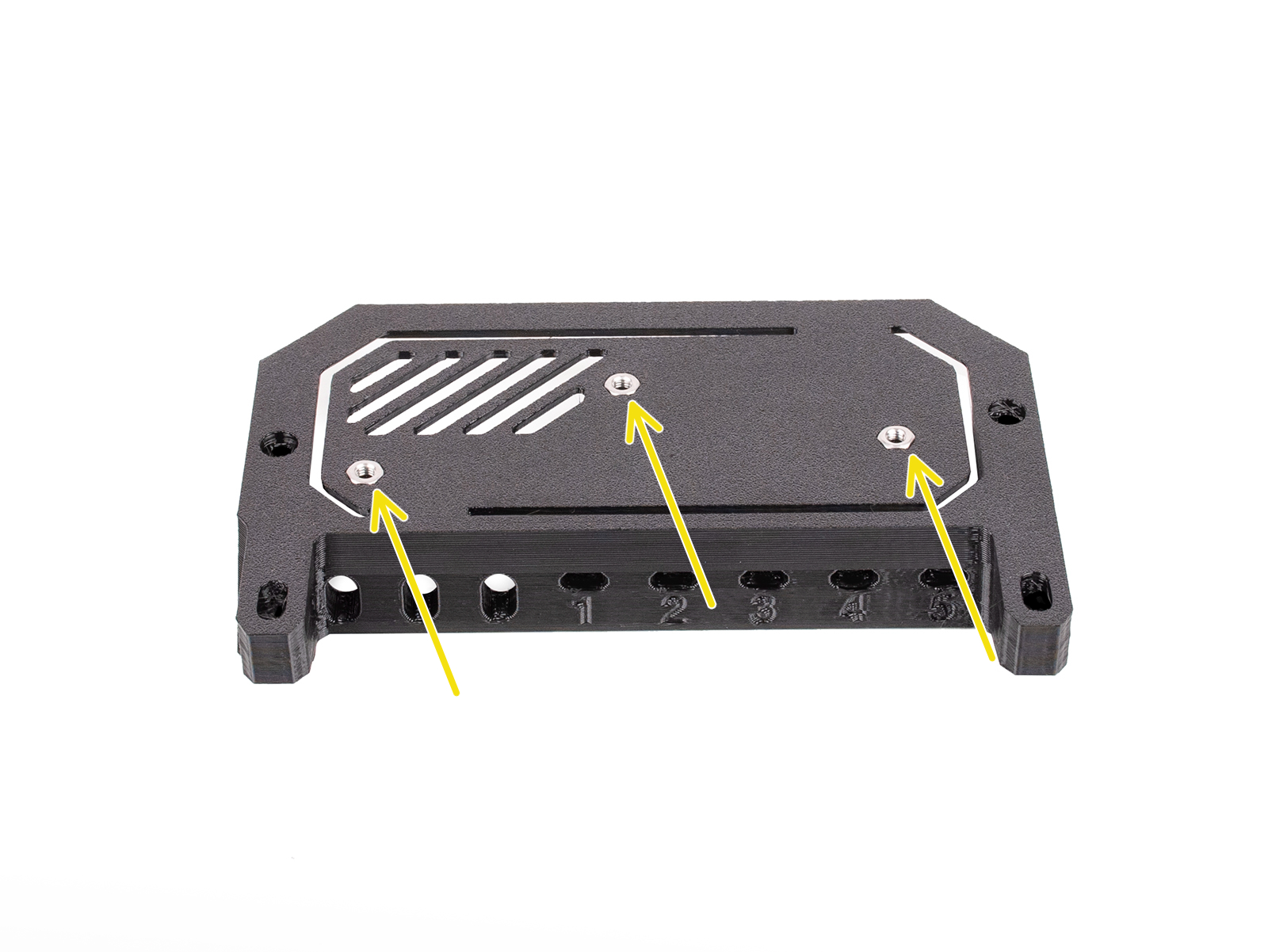

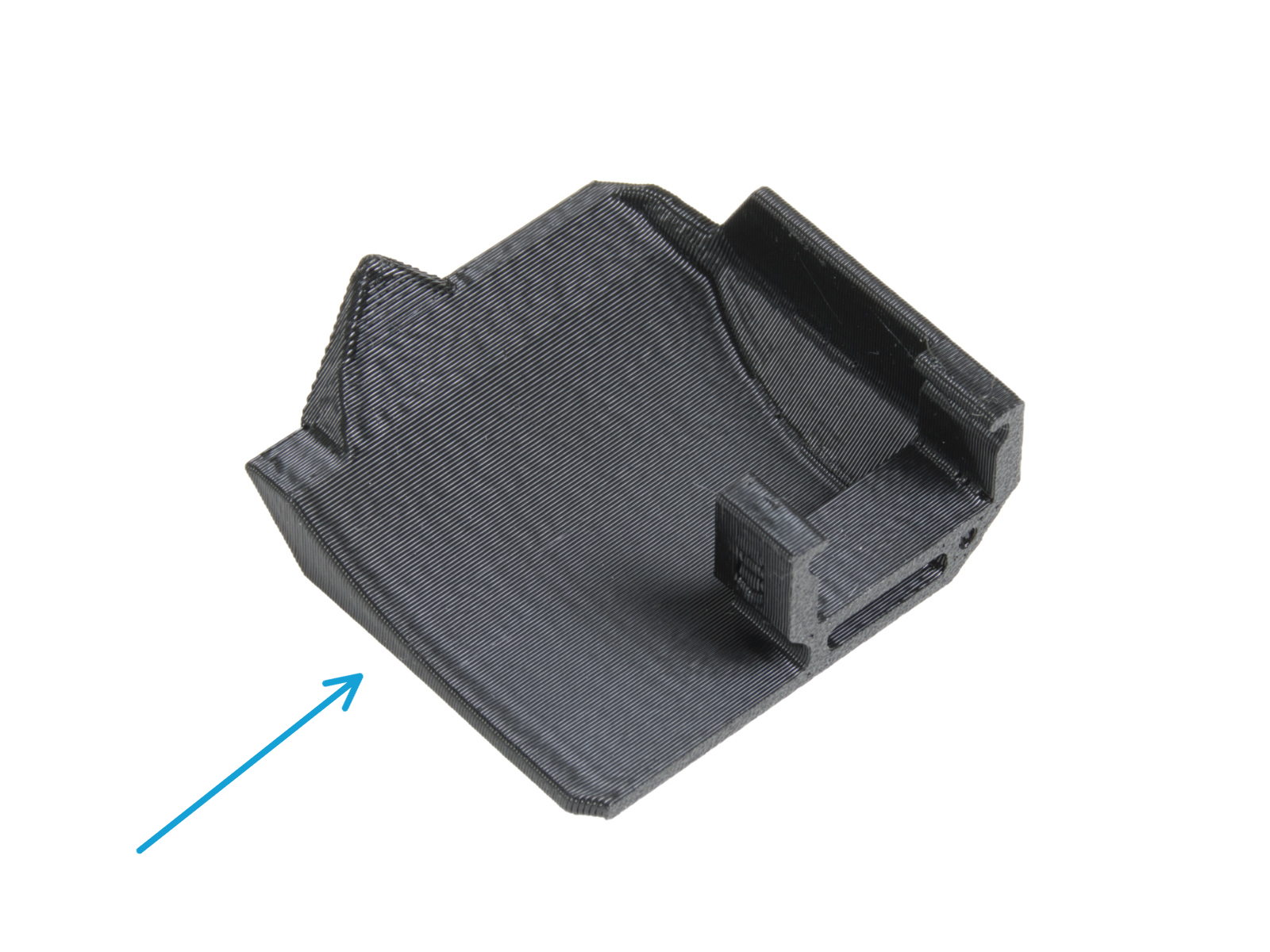

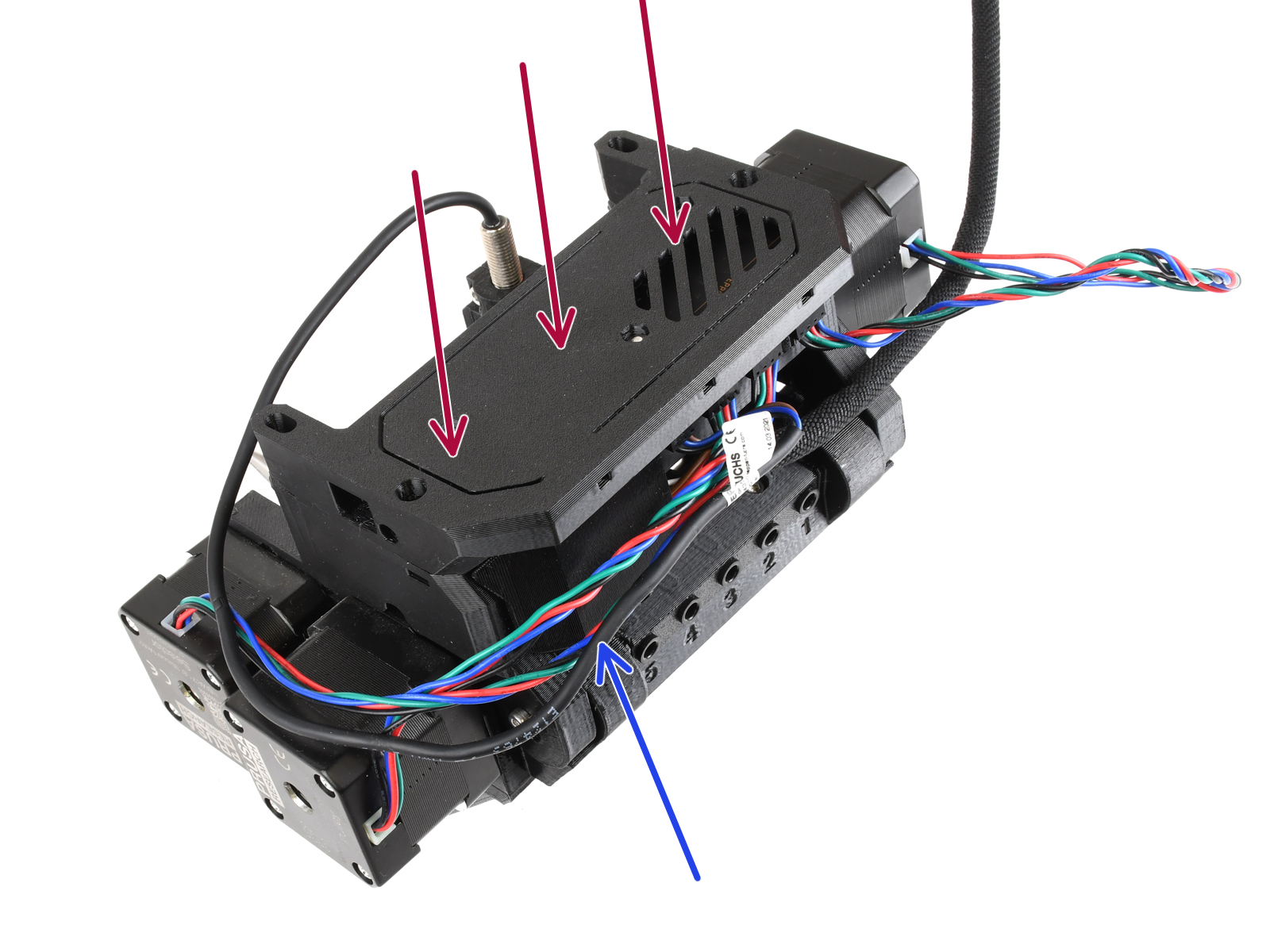

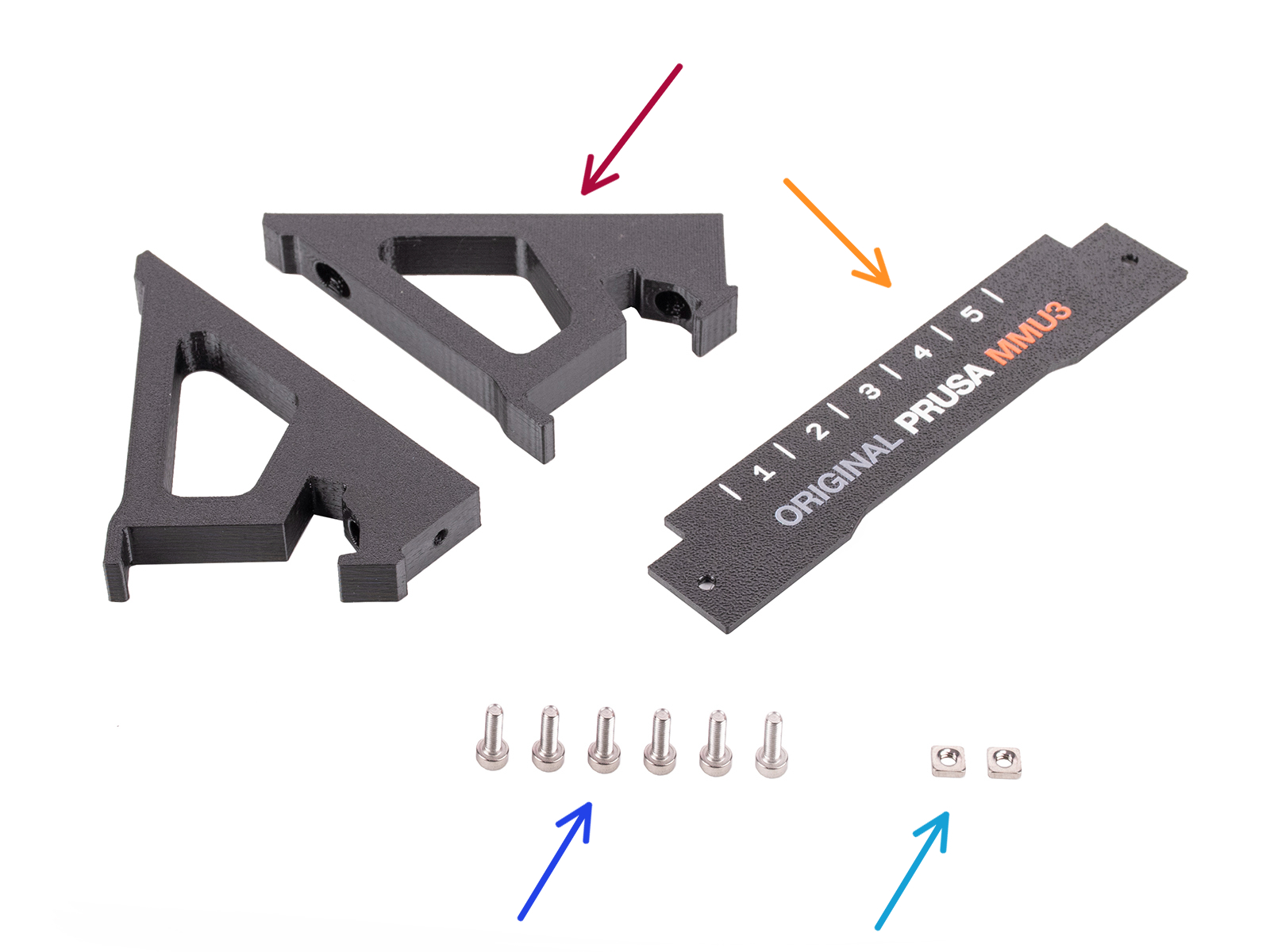

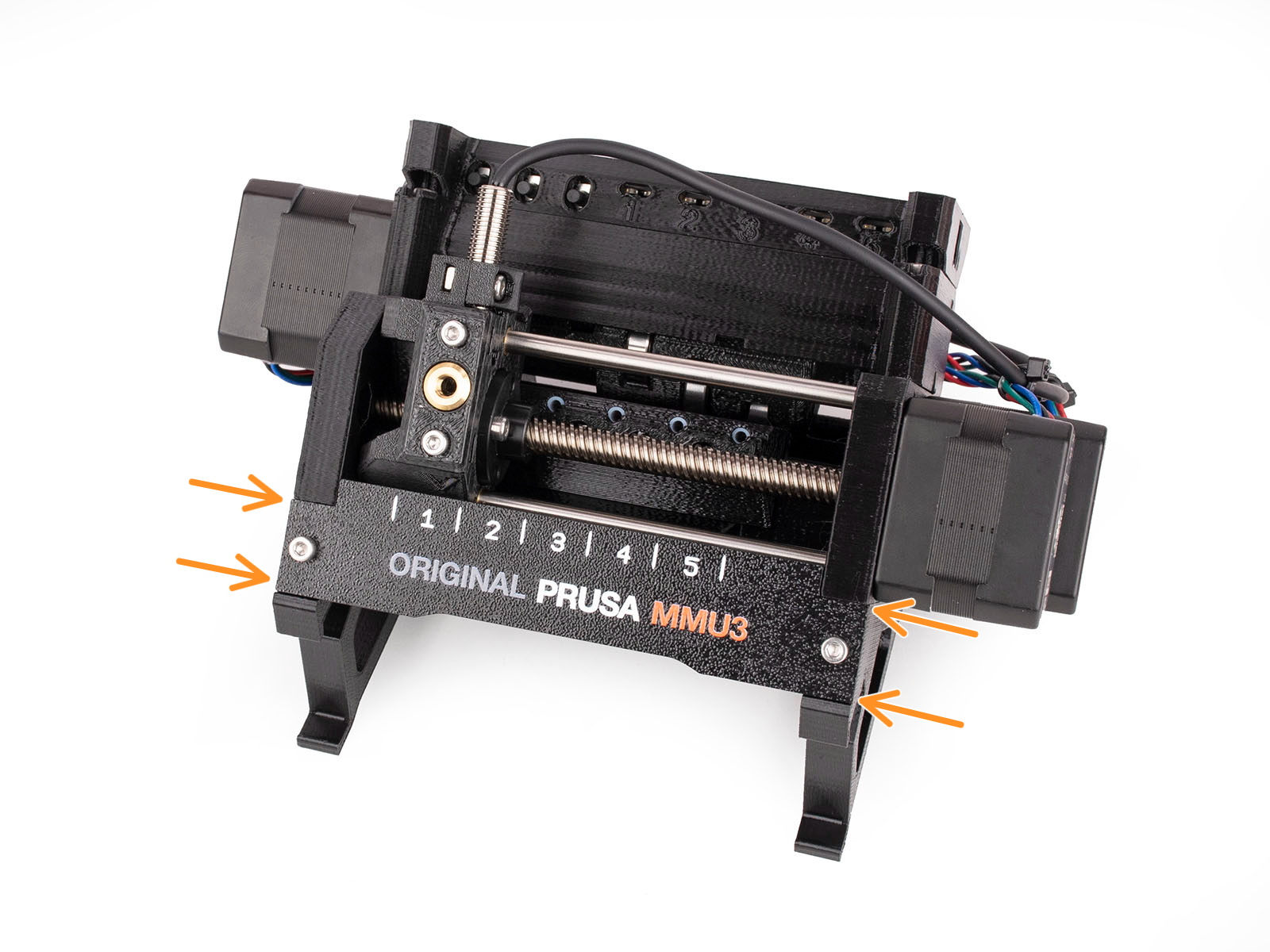

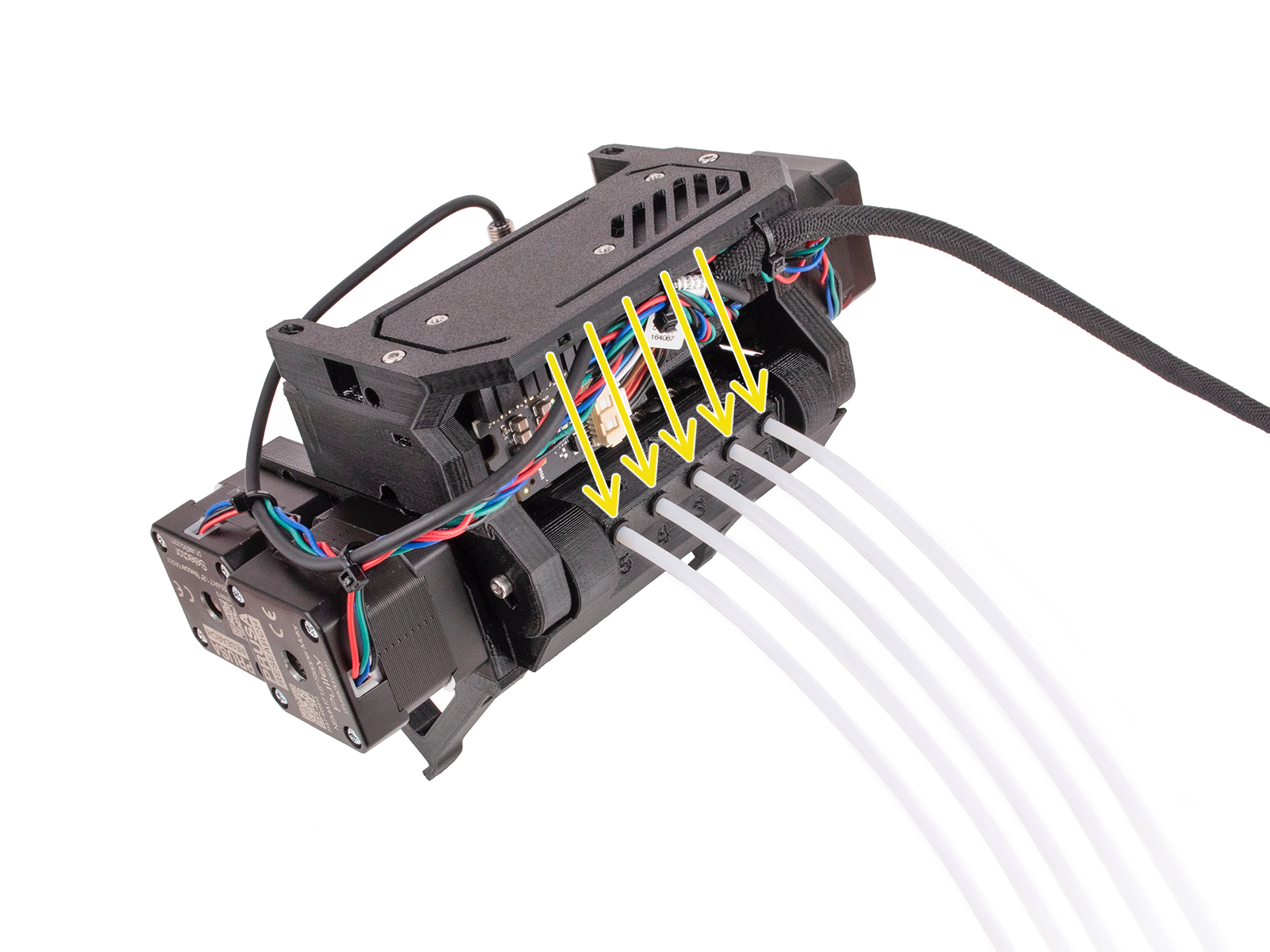

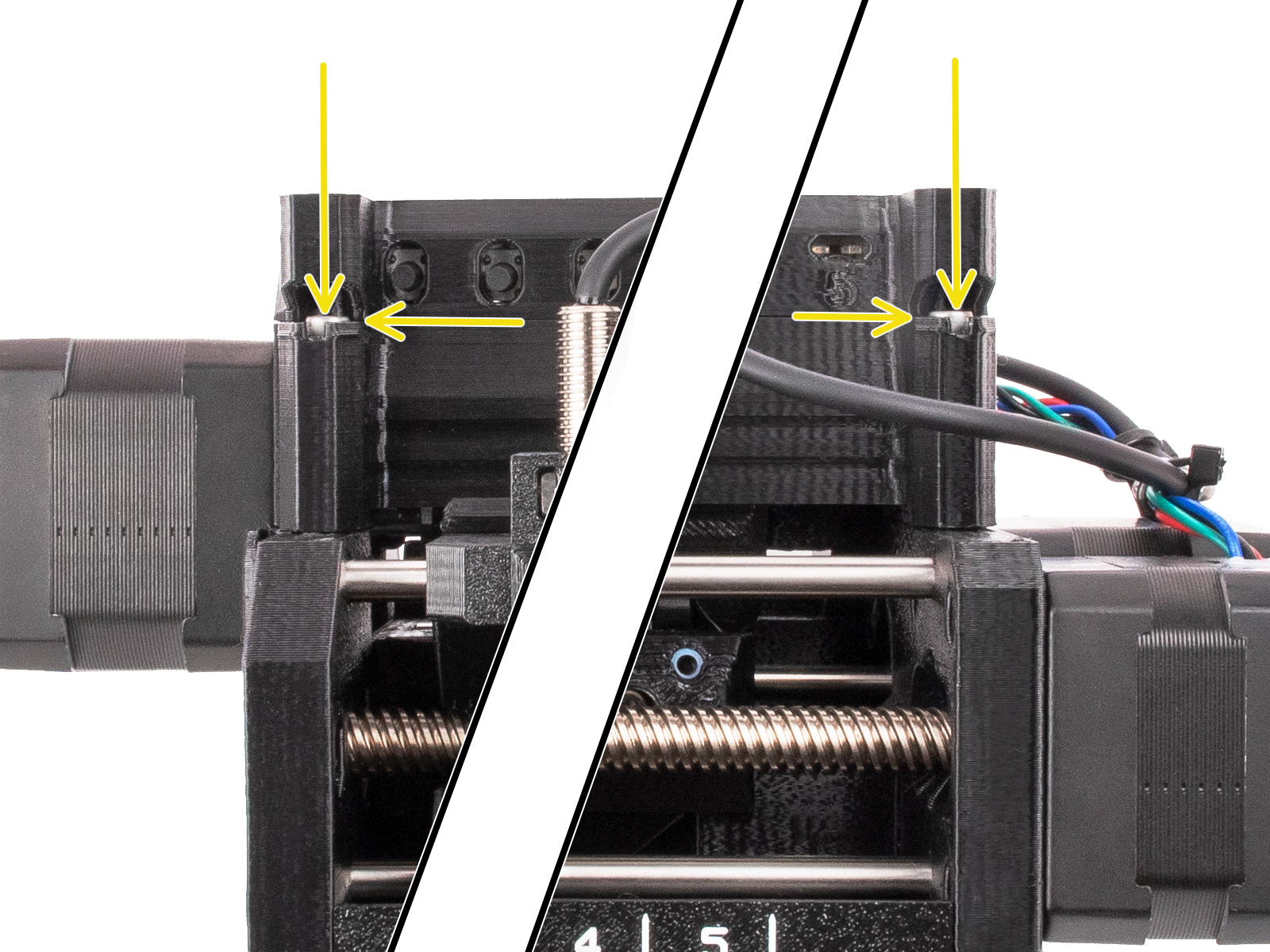

Insert two M3nS nuts into the marked openings in the pulley body. Push the nuts all the way in.

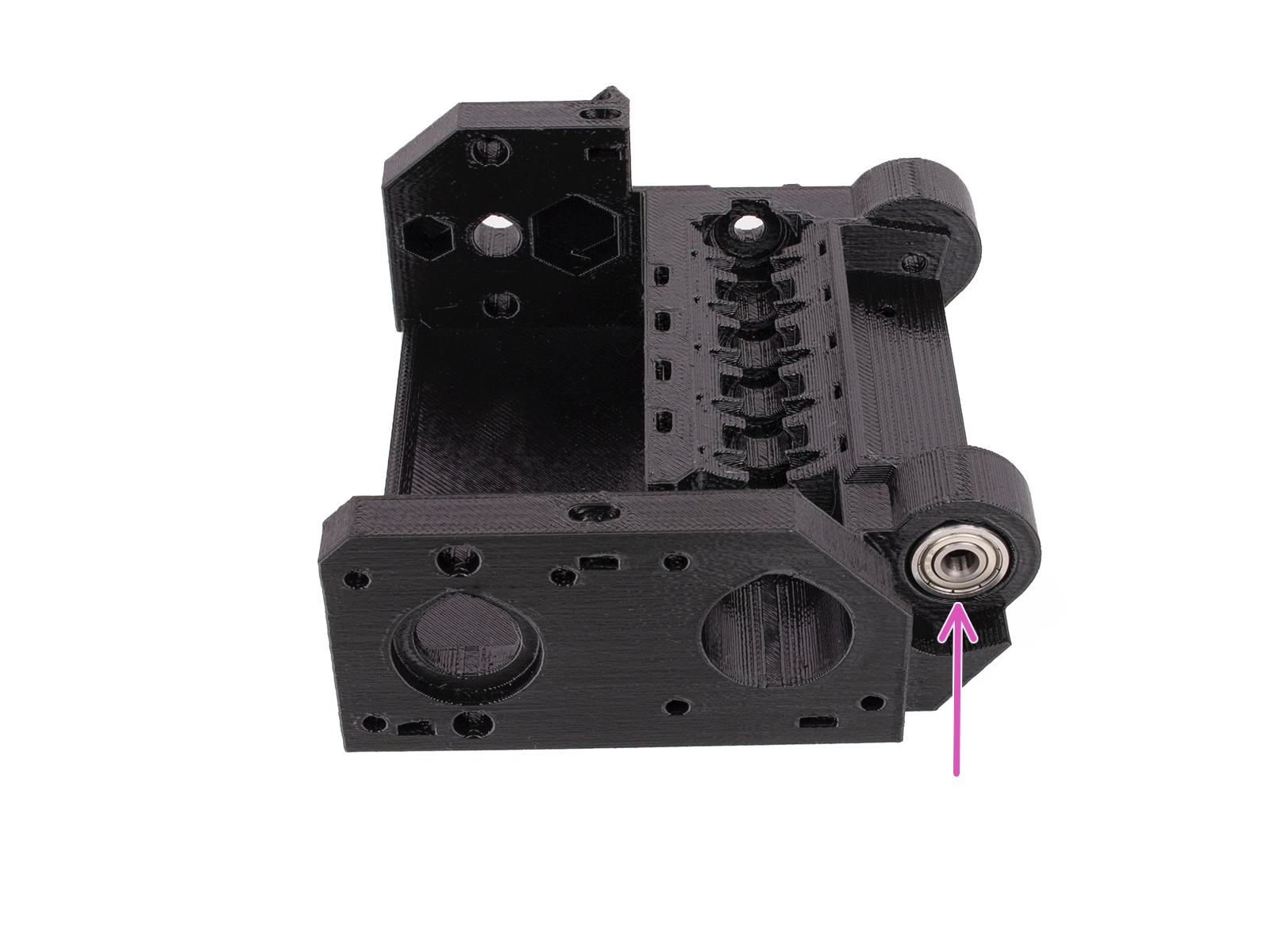

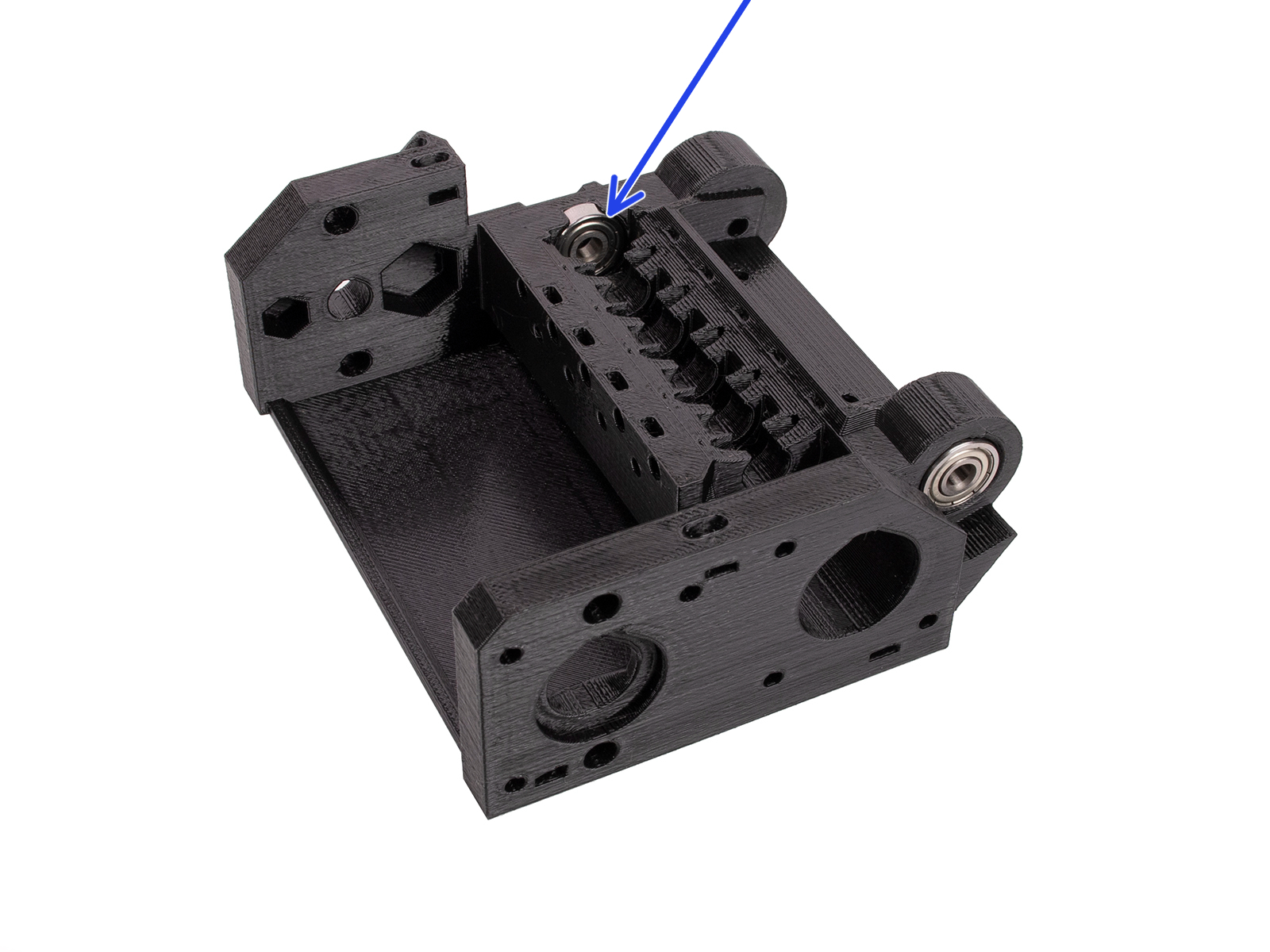

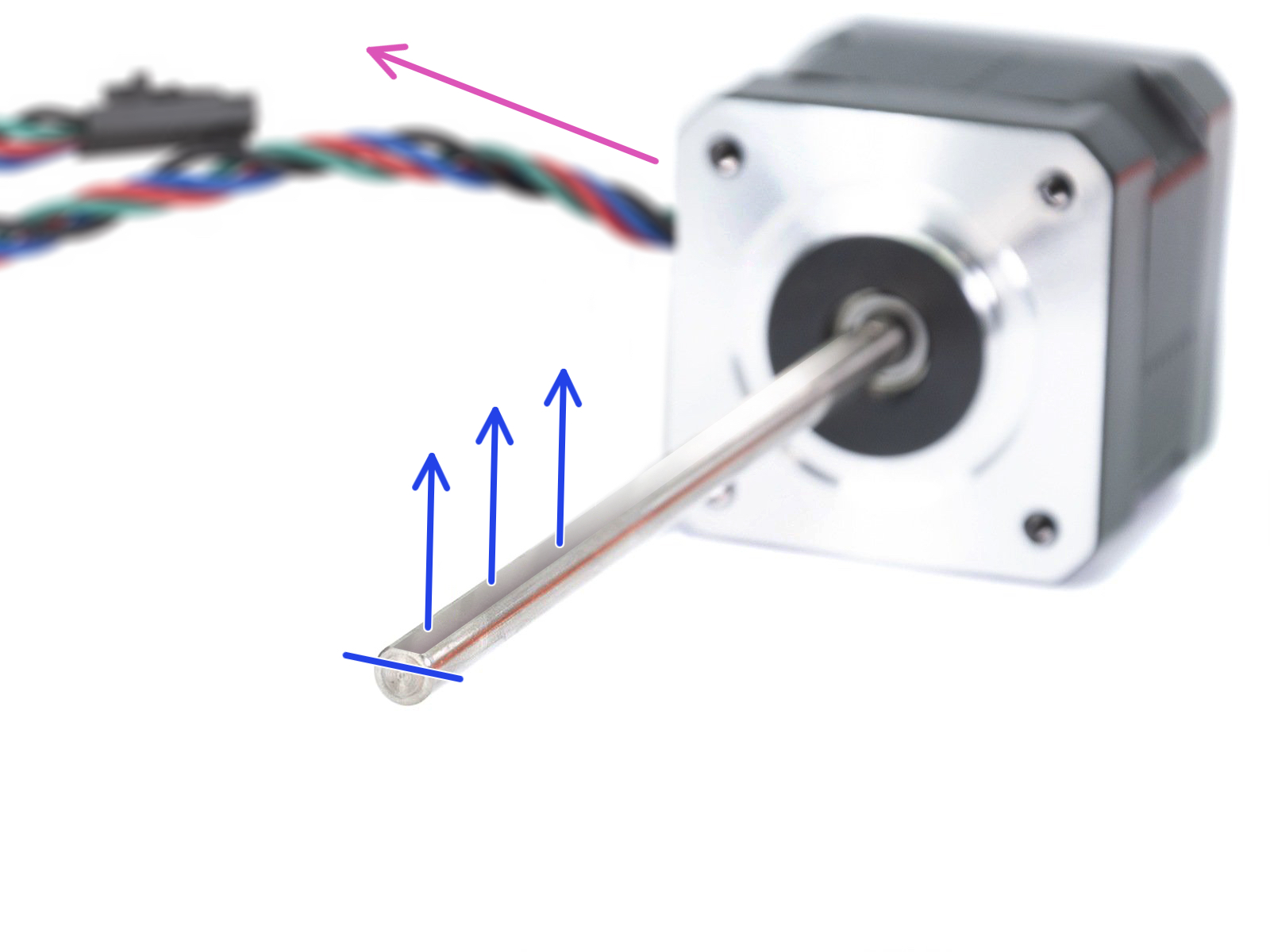

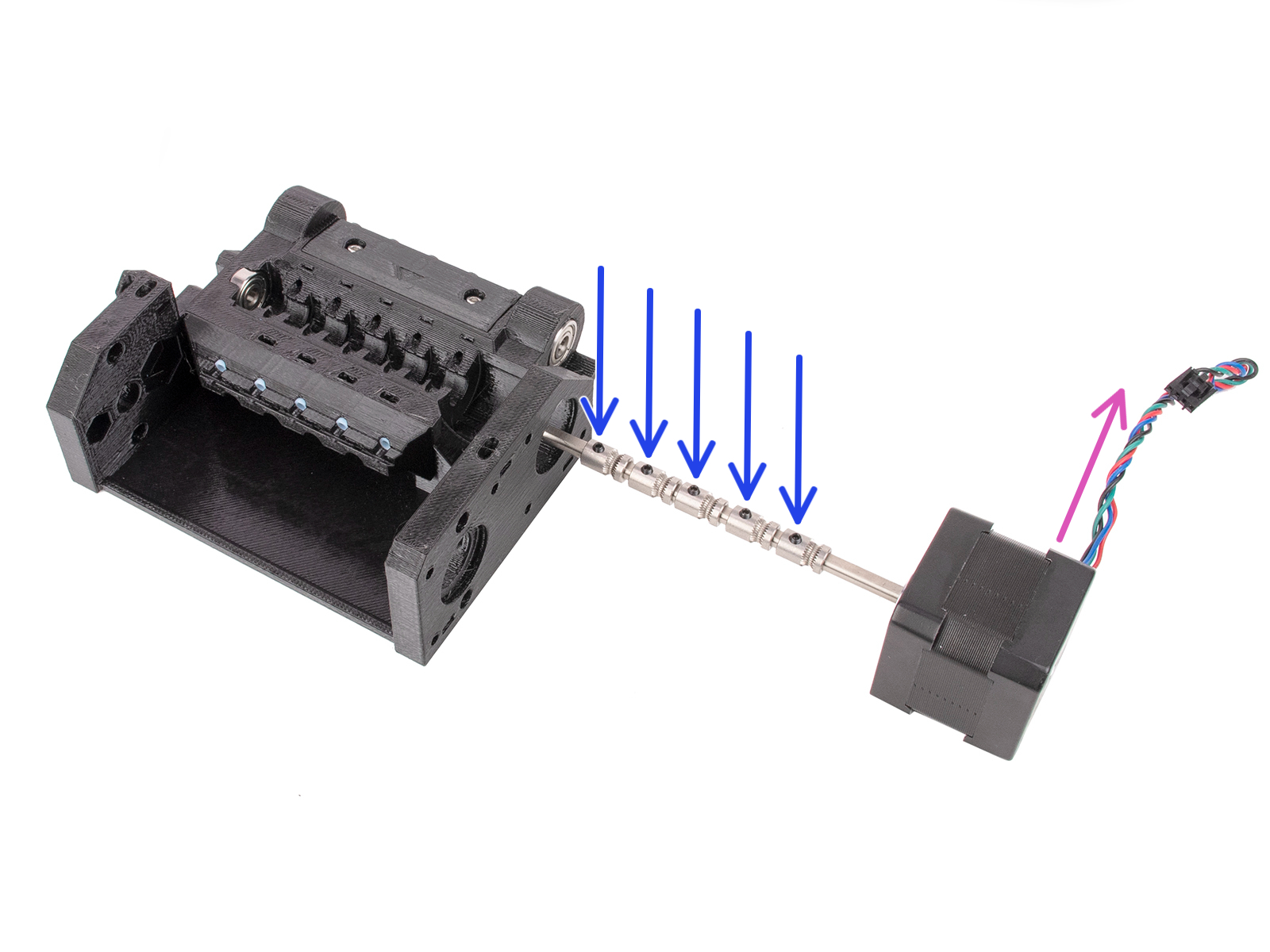

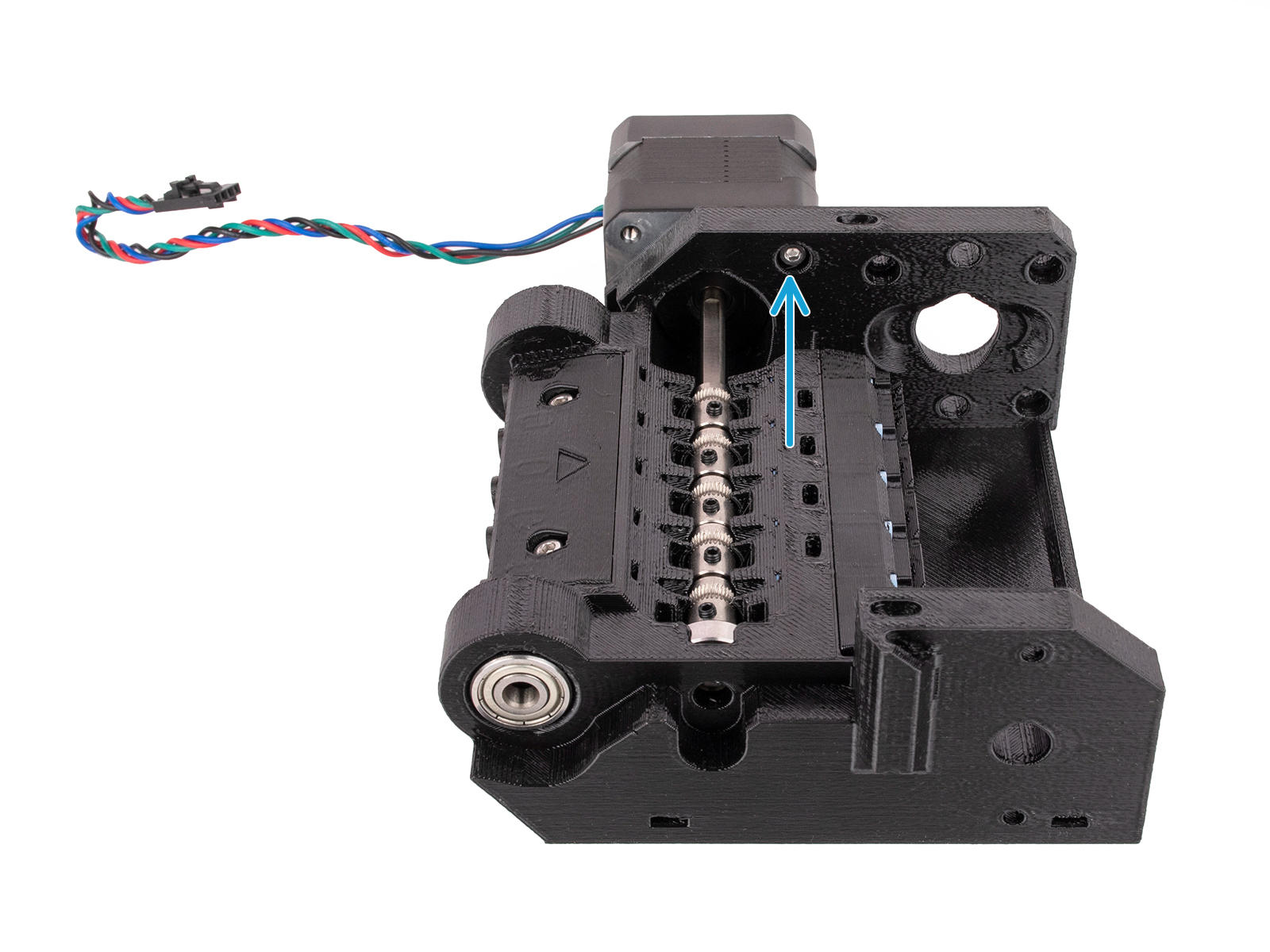

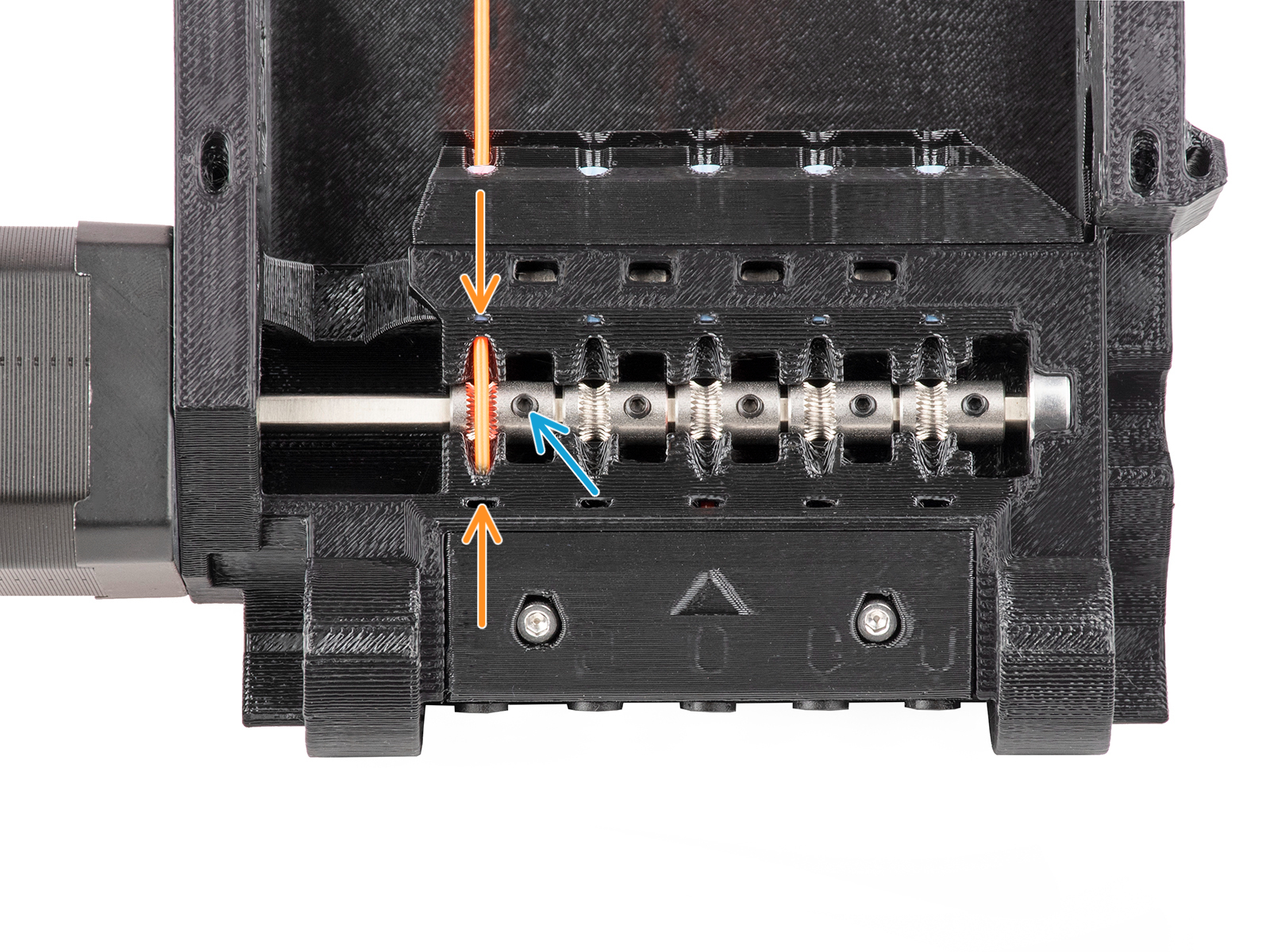

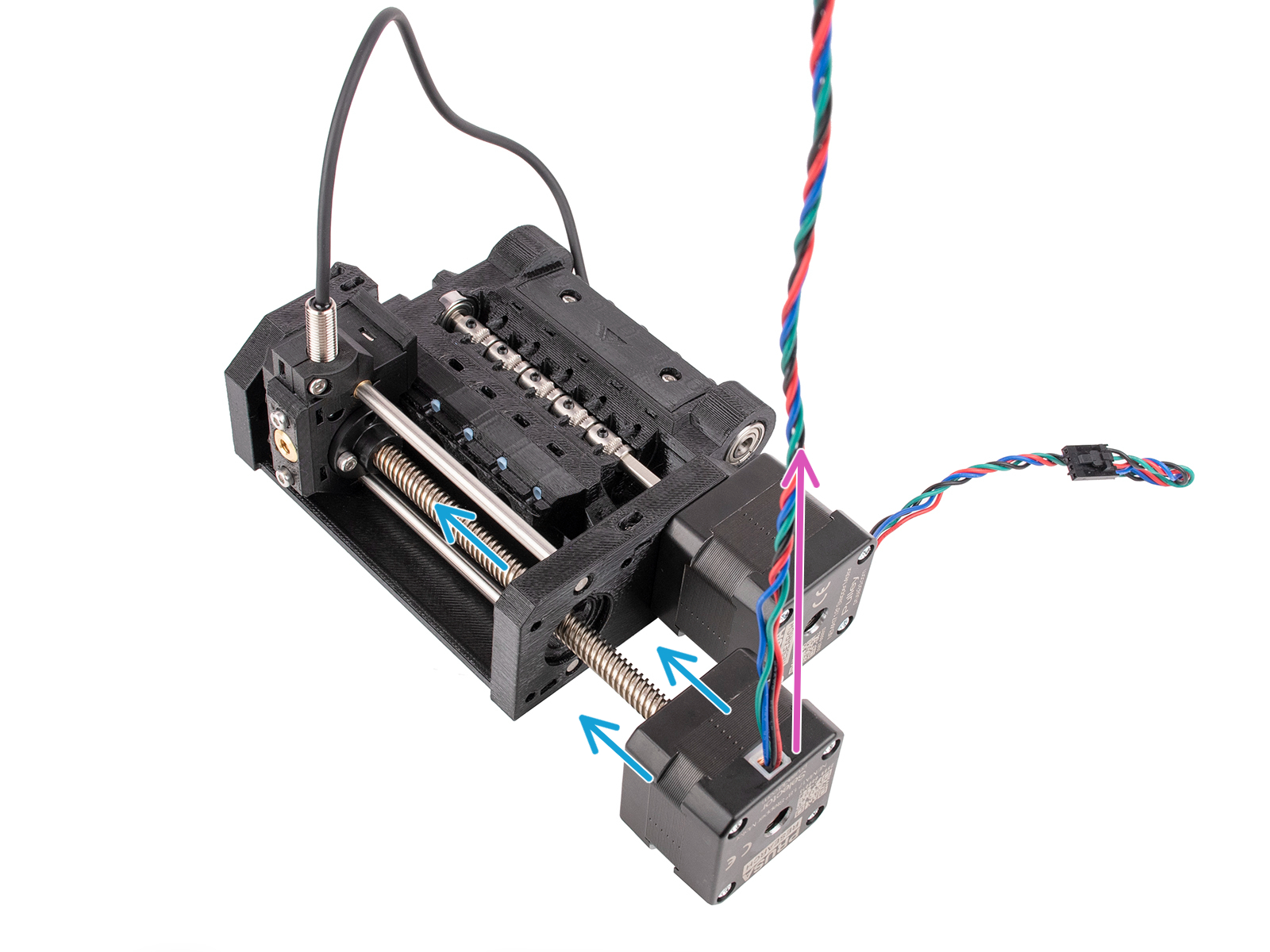

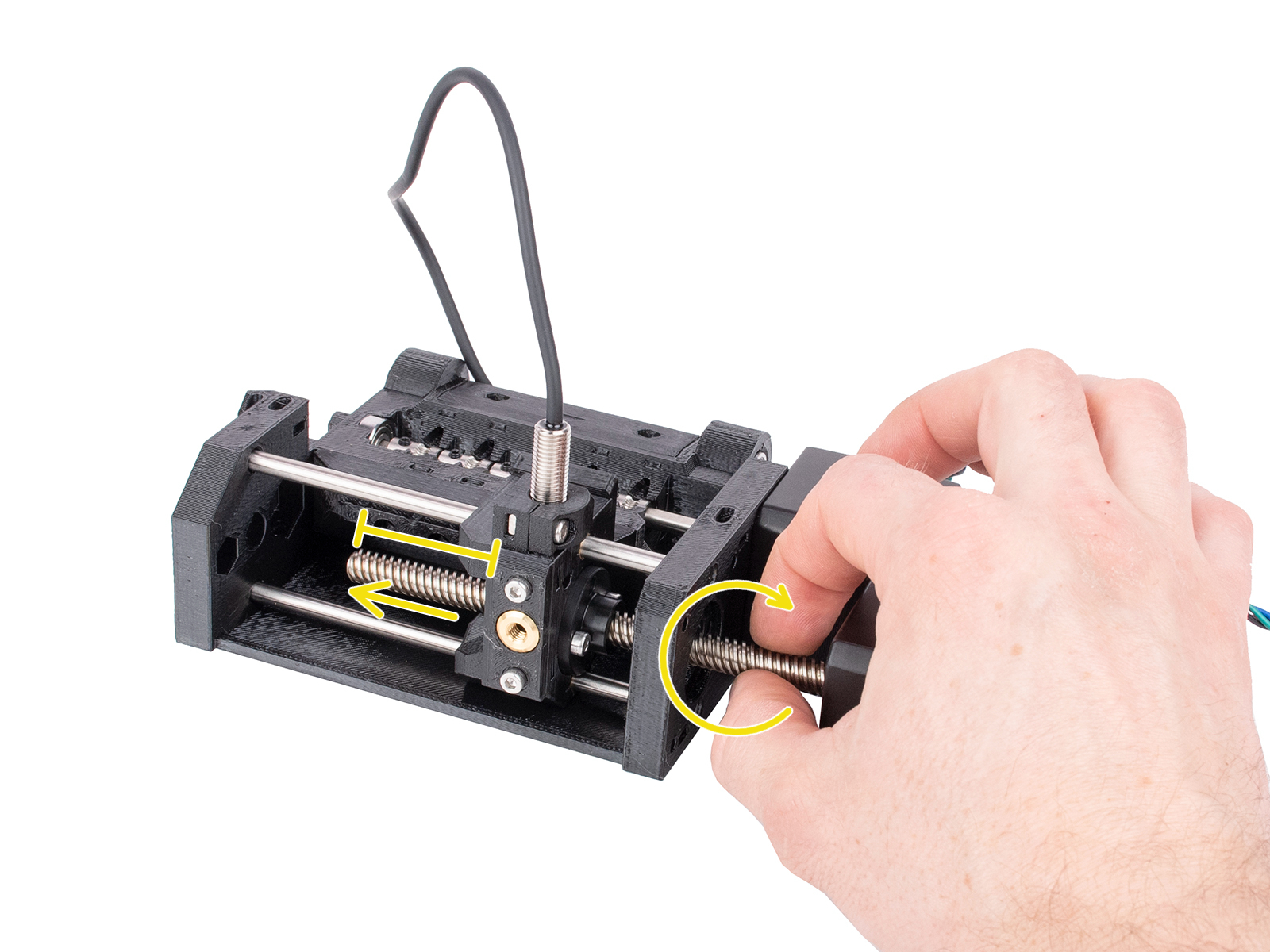

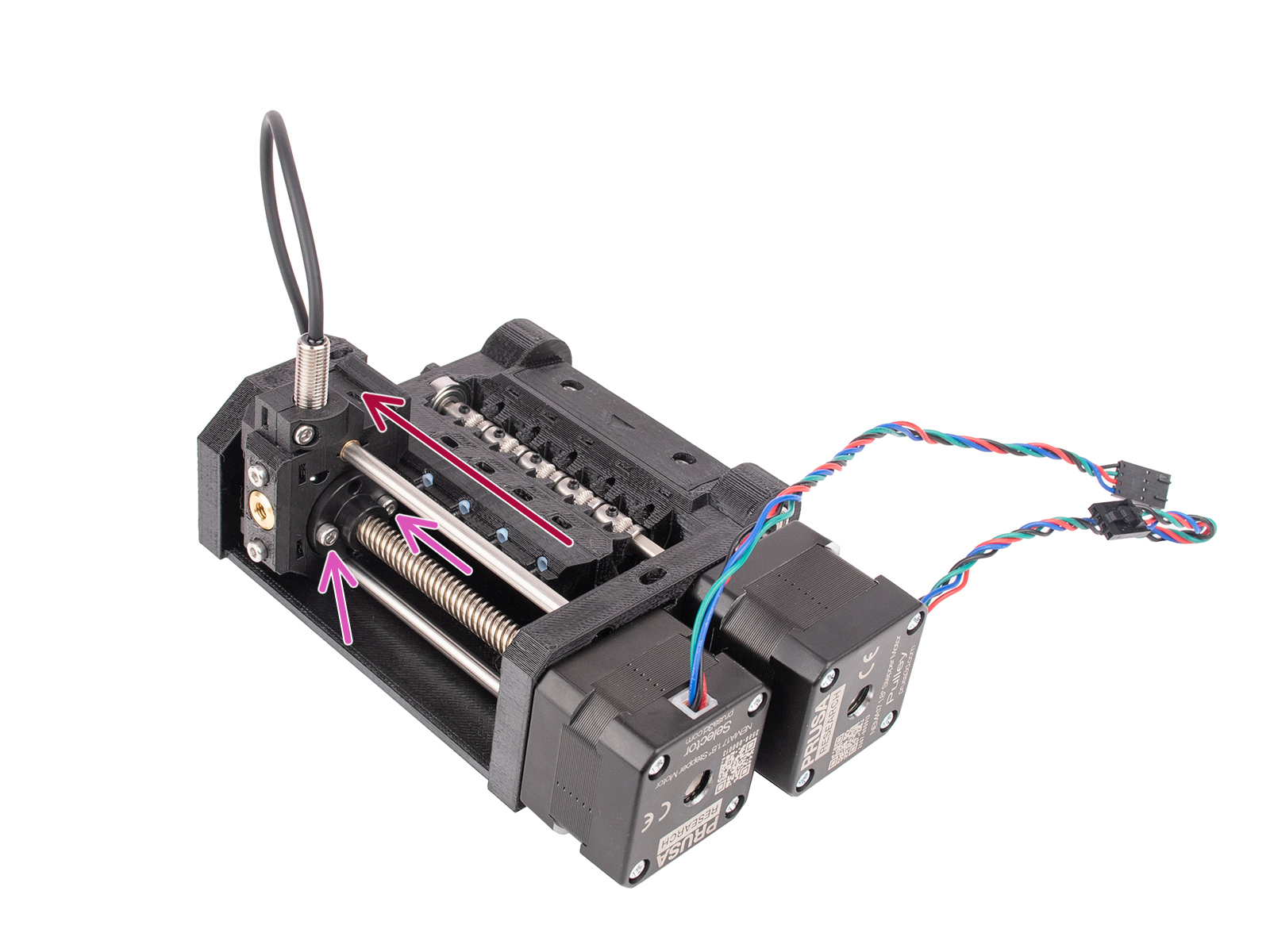

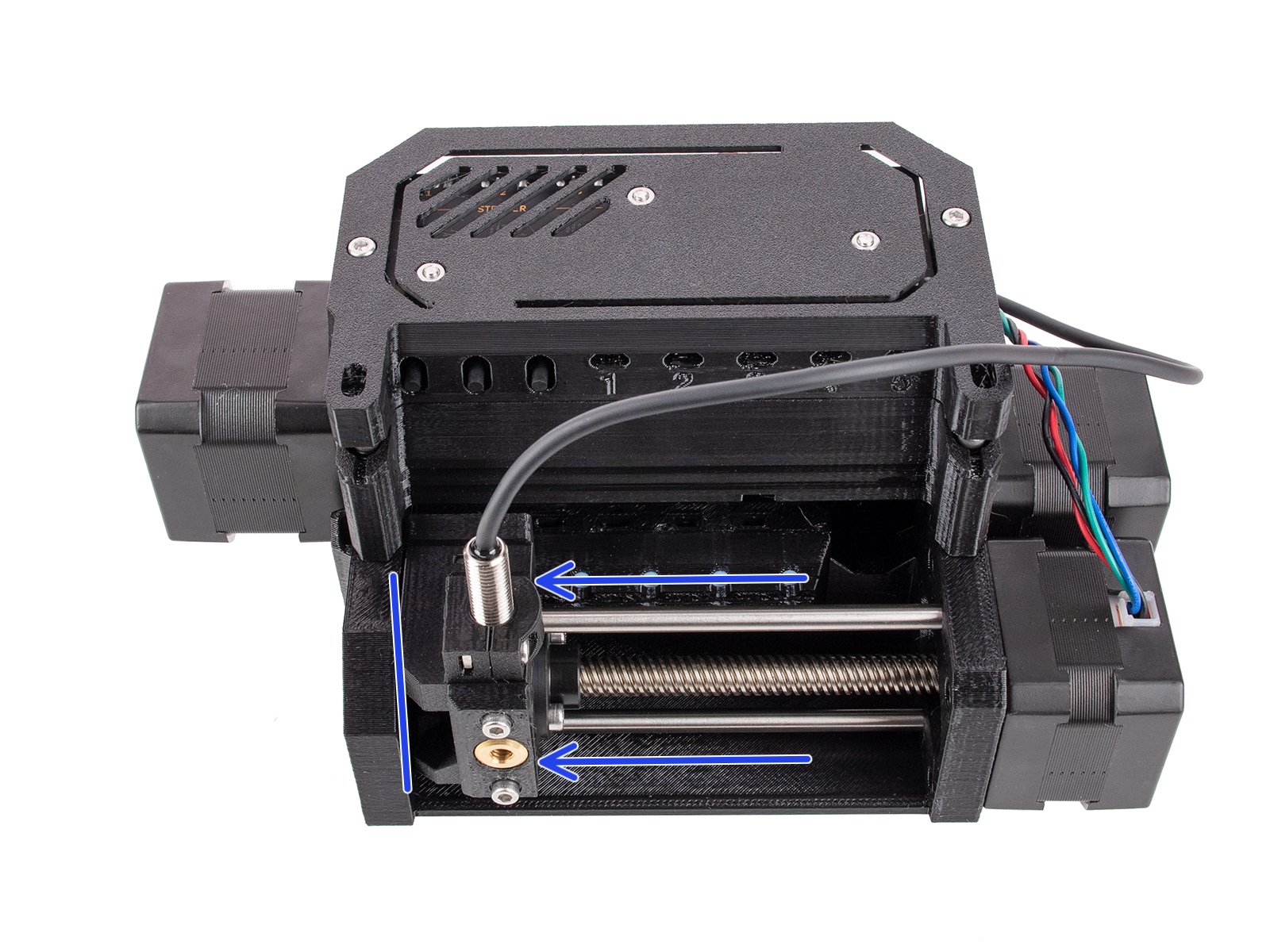

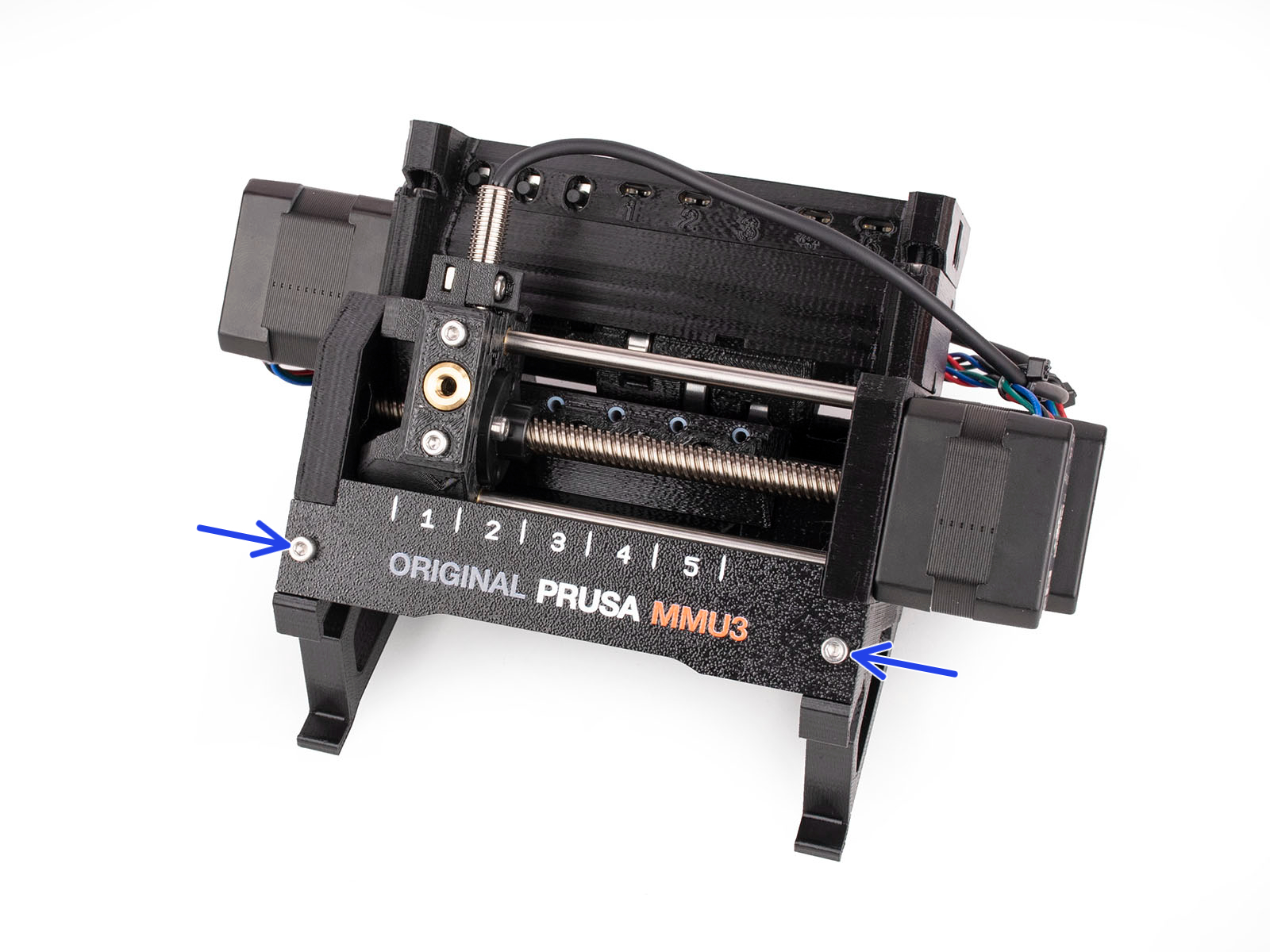

Rotate the threaded rod while pushing it towards the selector to engage it into the trapeze nut.

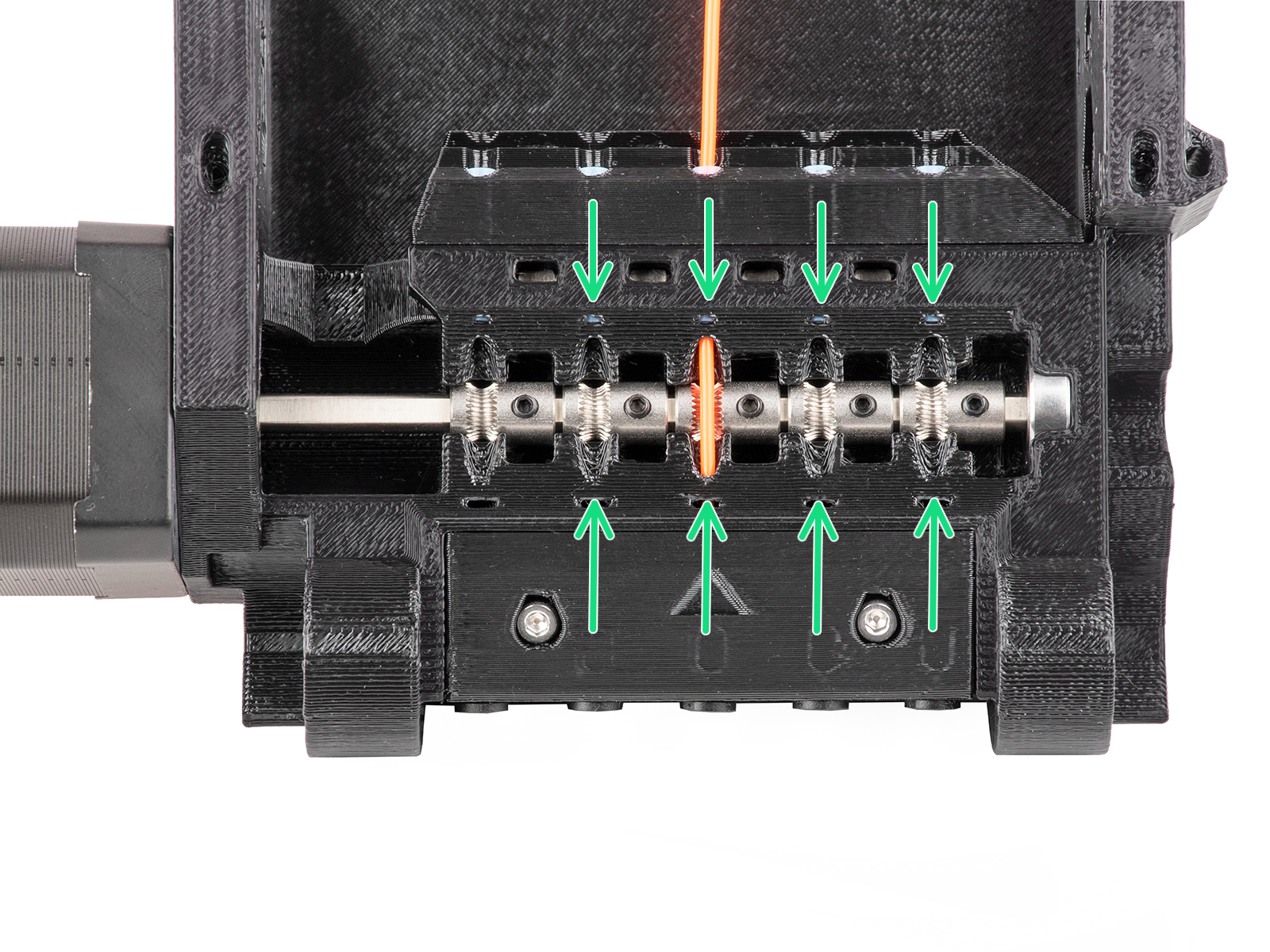

Continue rotating the rod until it passes entirely through, leaving around 2cm / 1in. of the shaft exposed on the left side of the selector.

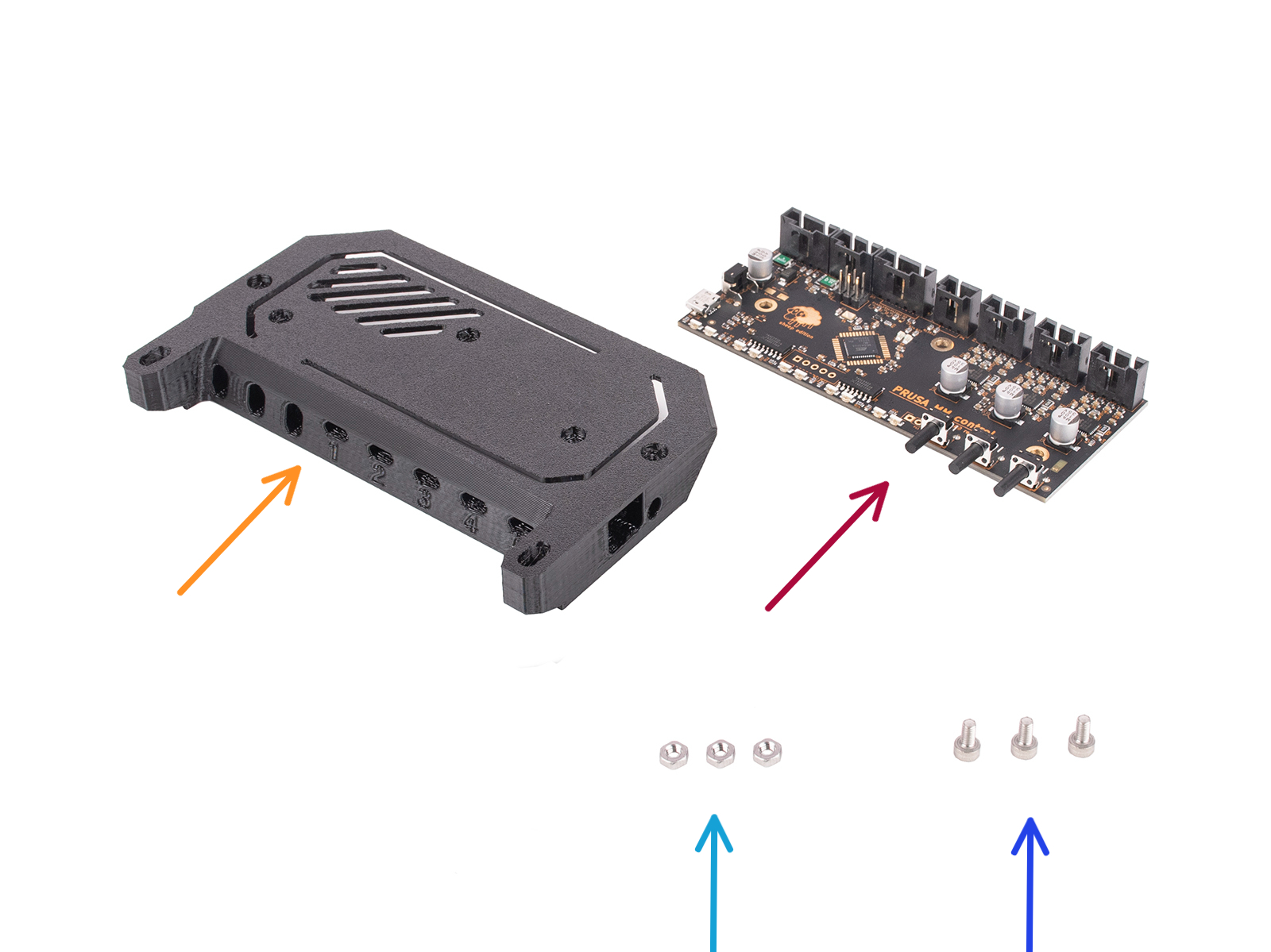

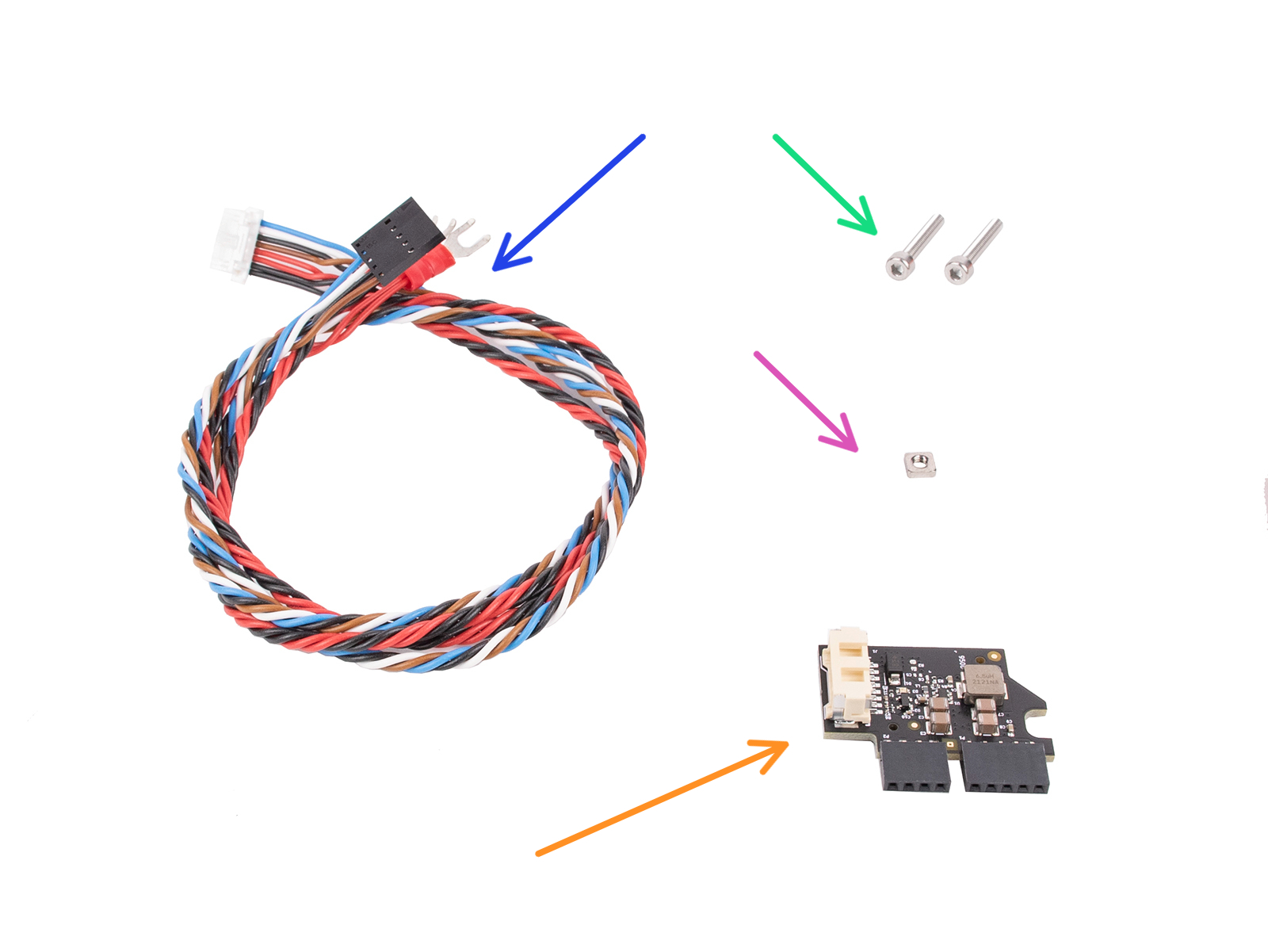

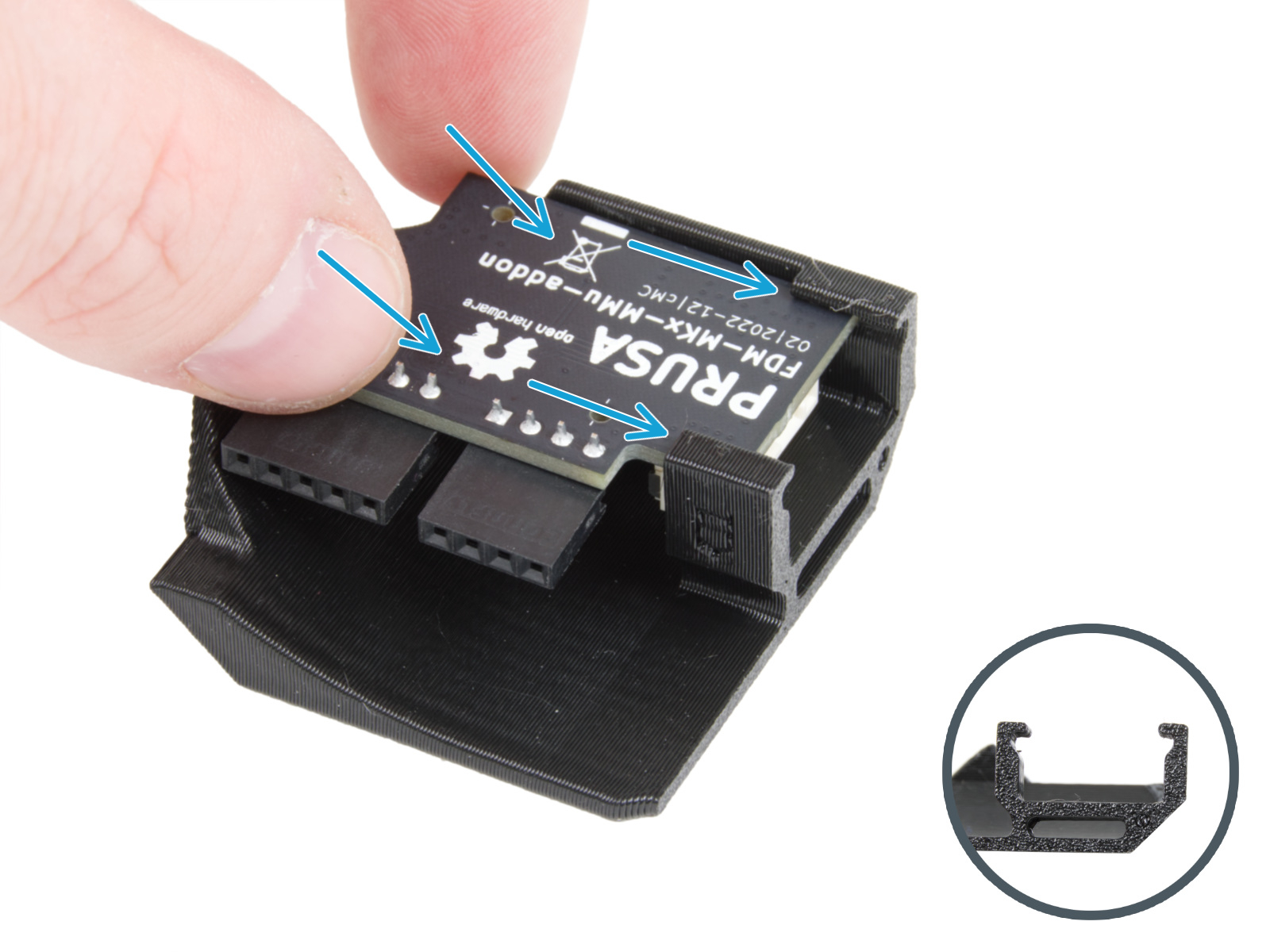

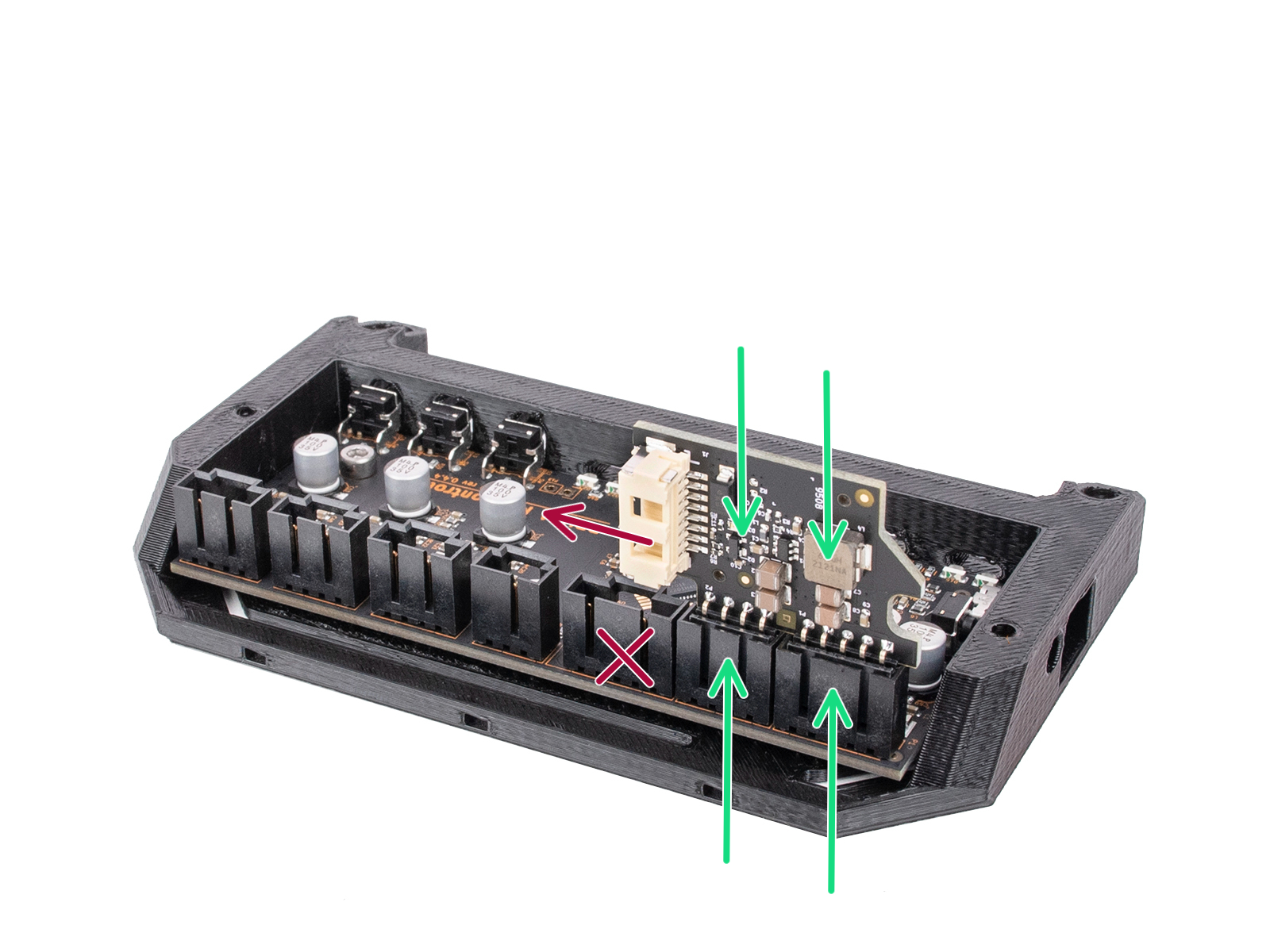

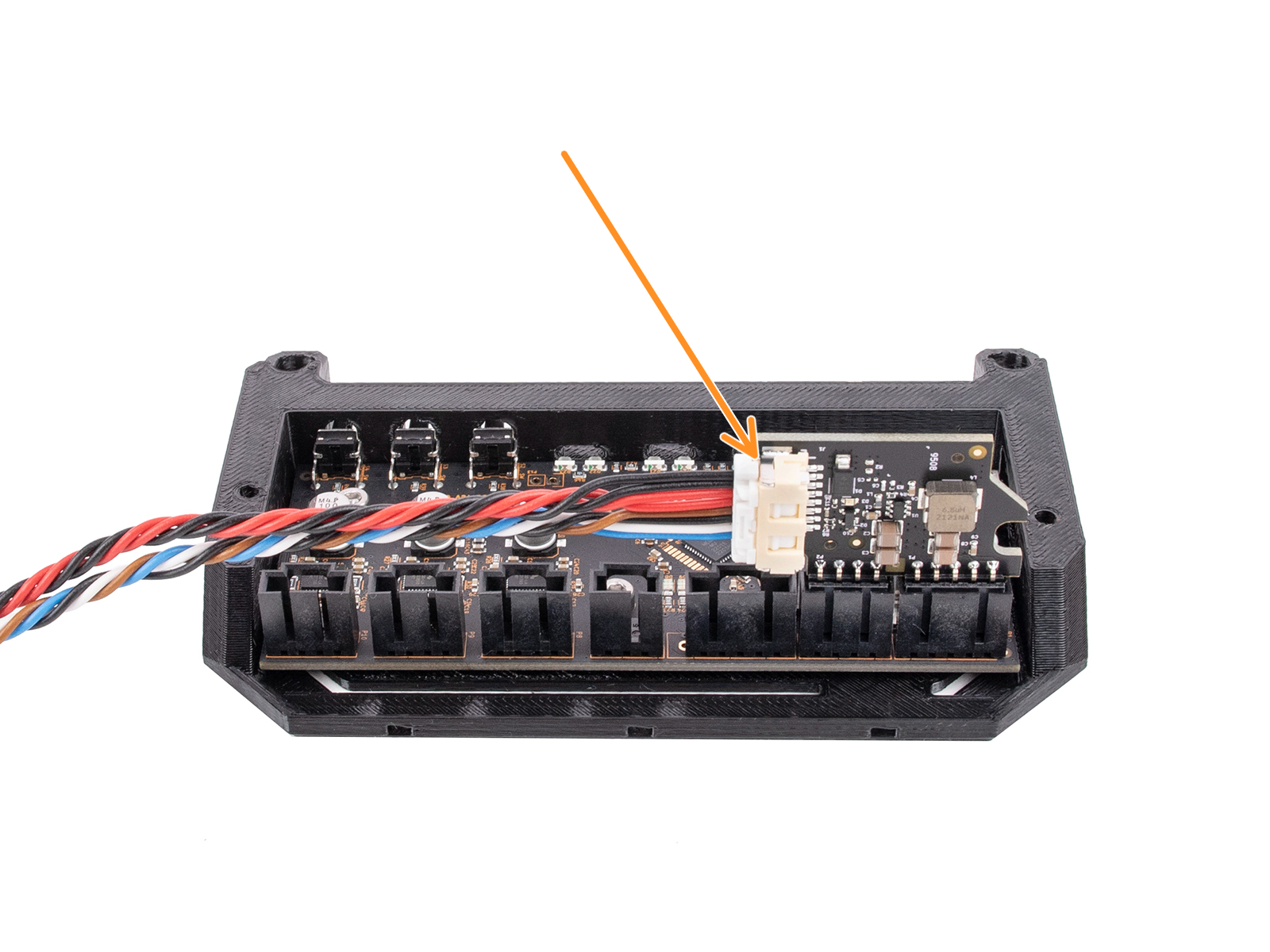

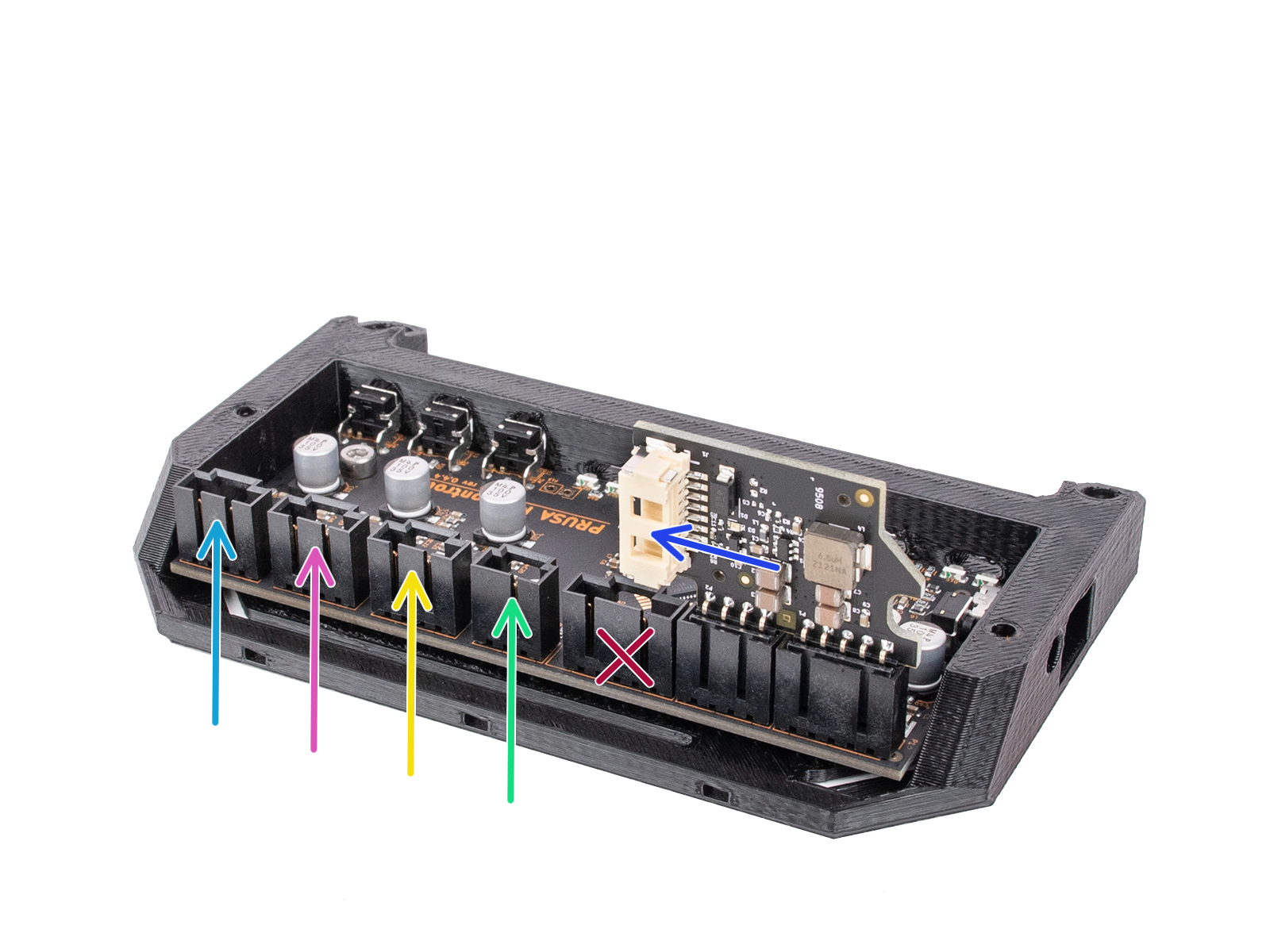

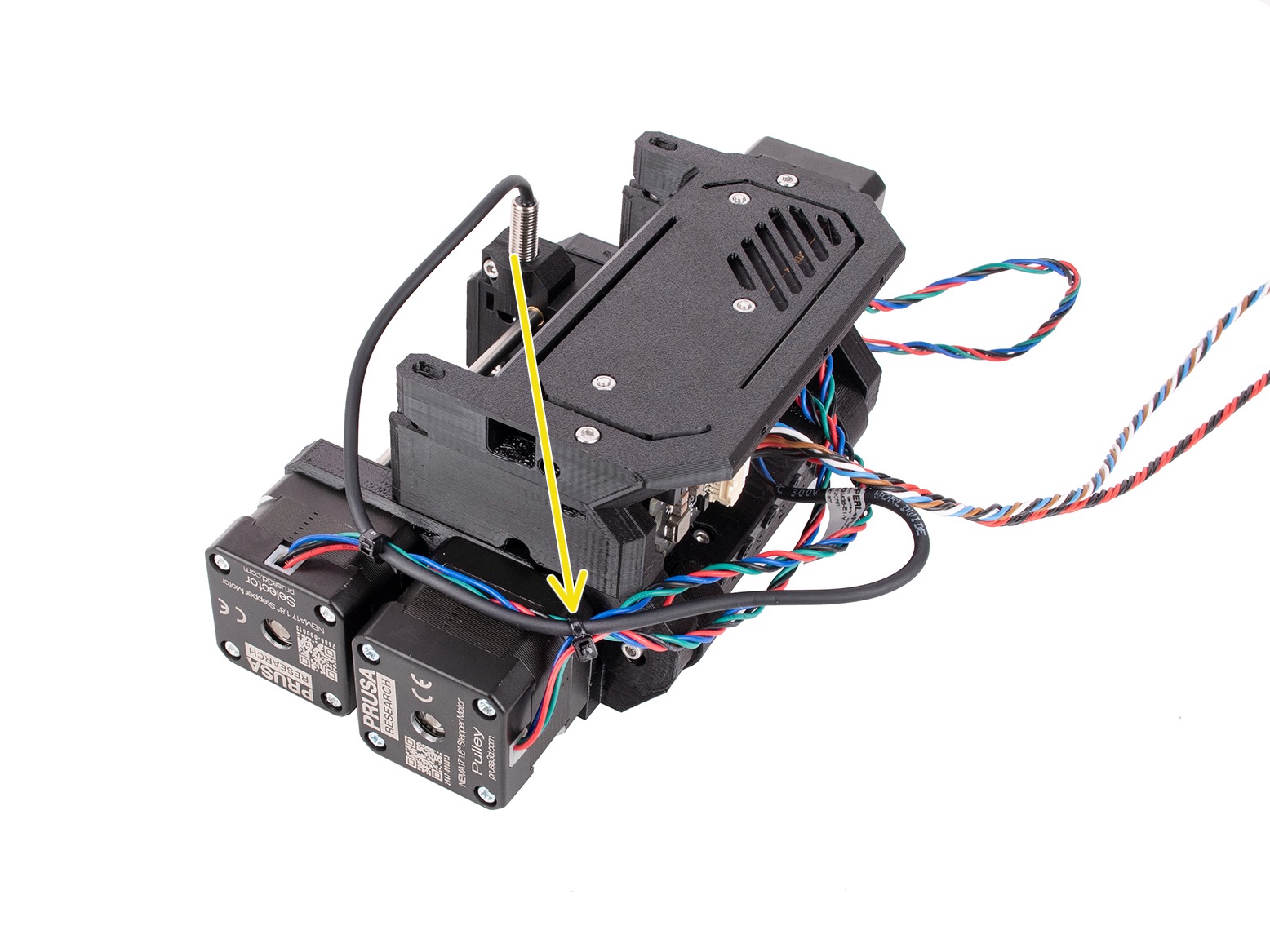

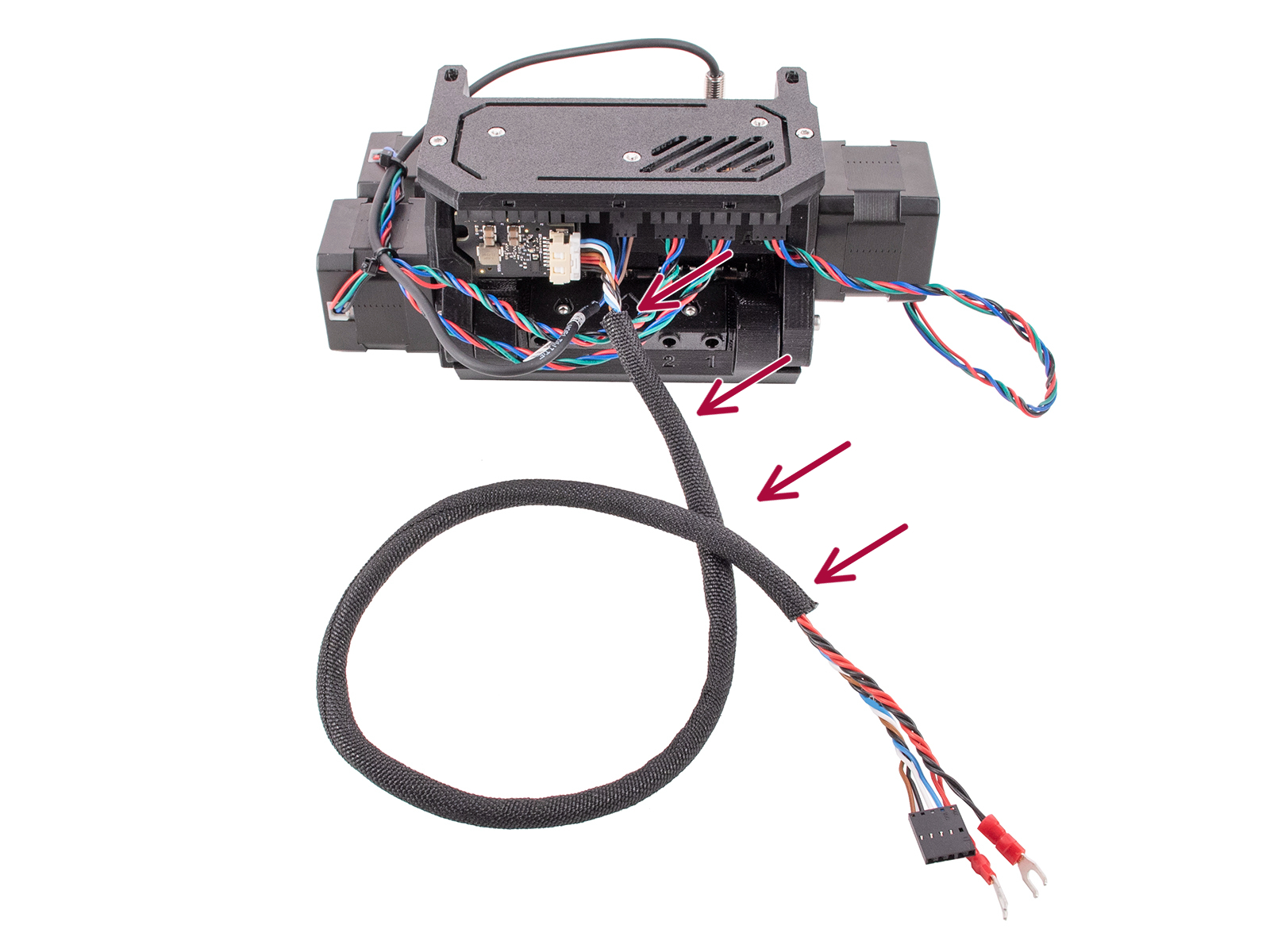

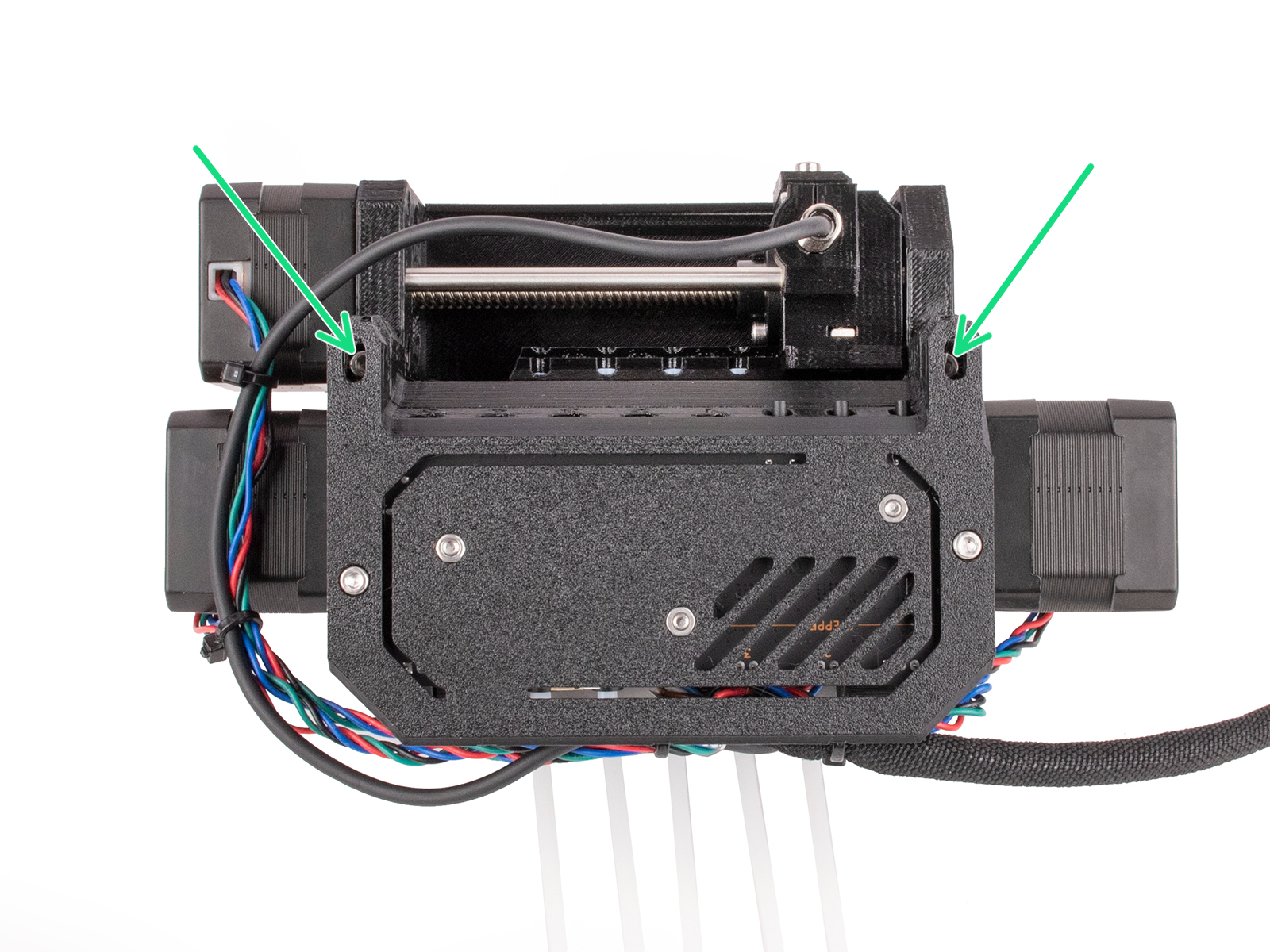

Make sure the PD-board is connected the exact same way as seen in the picture.

If you plug in the PD-board incorrectly, you will damage the electronics. Any damage caused to the printer due to an incorrect electronics assembly is not covered by warranty.

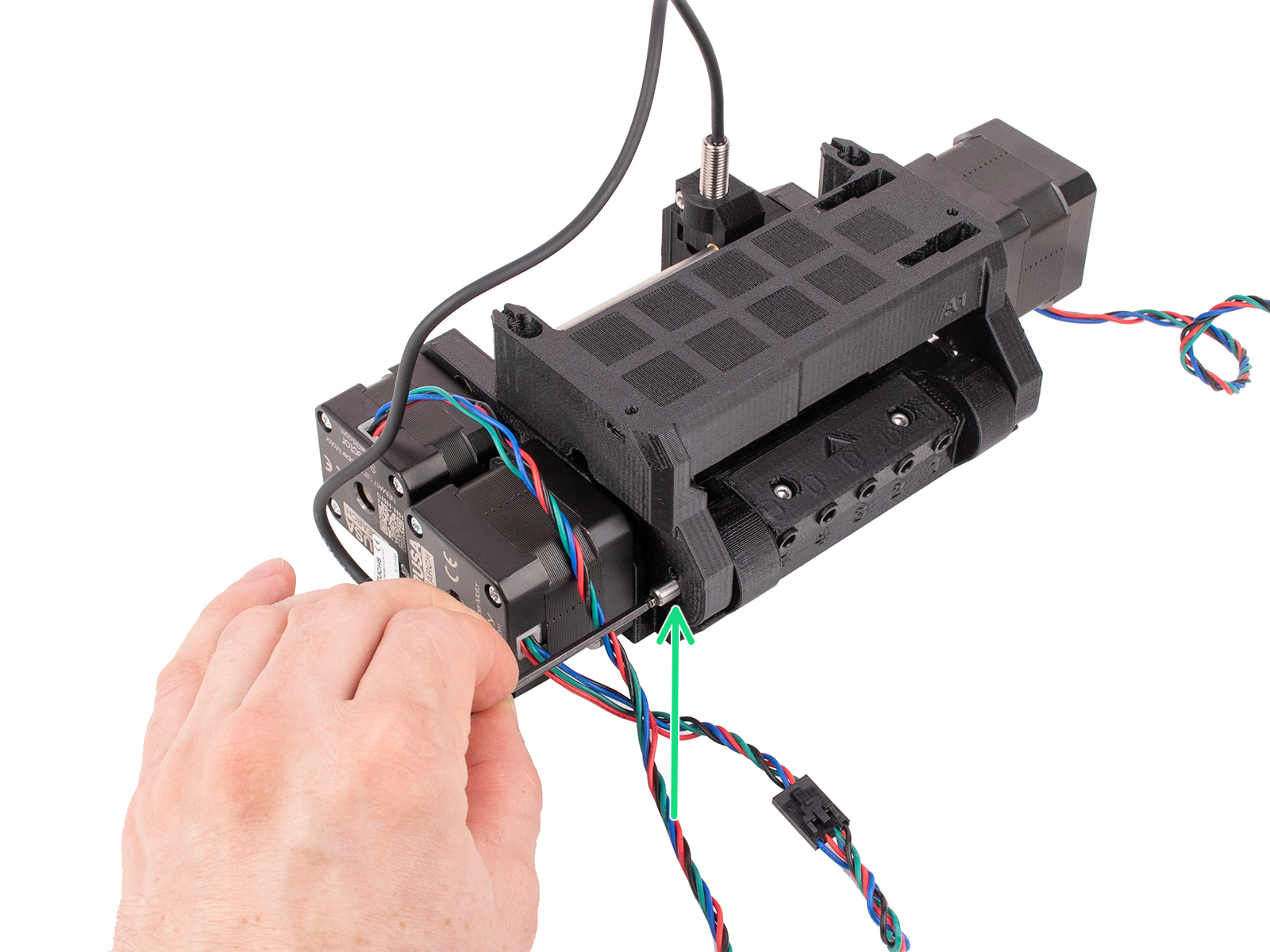

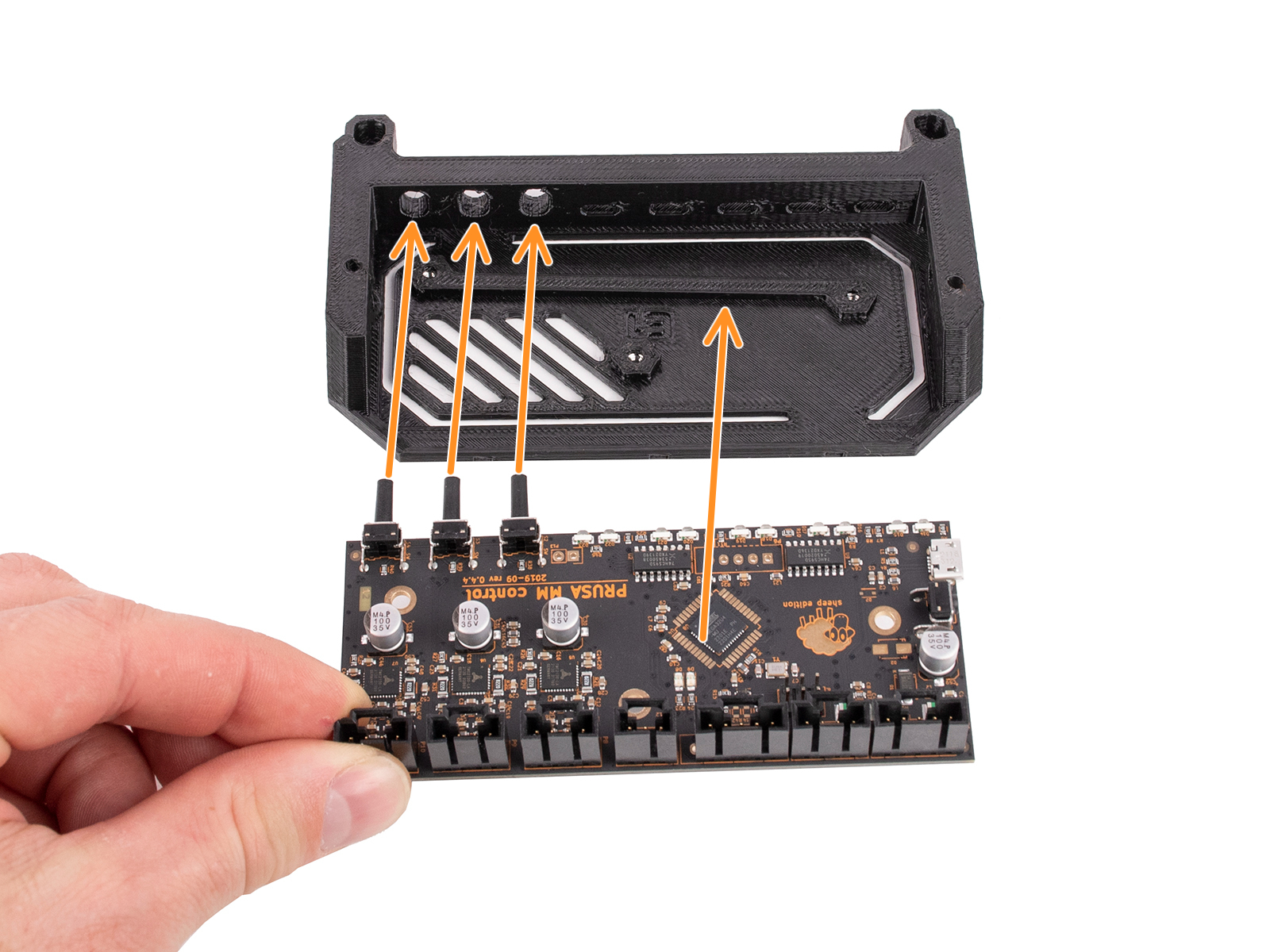

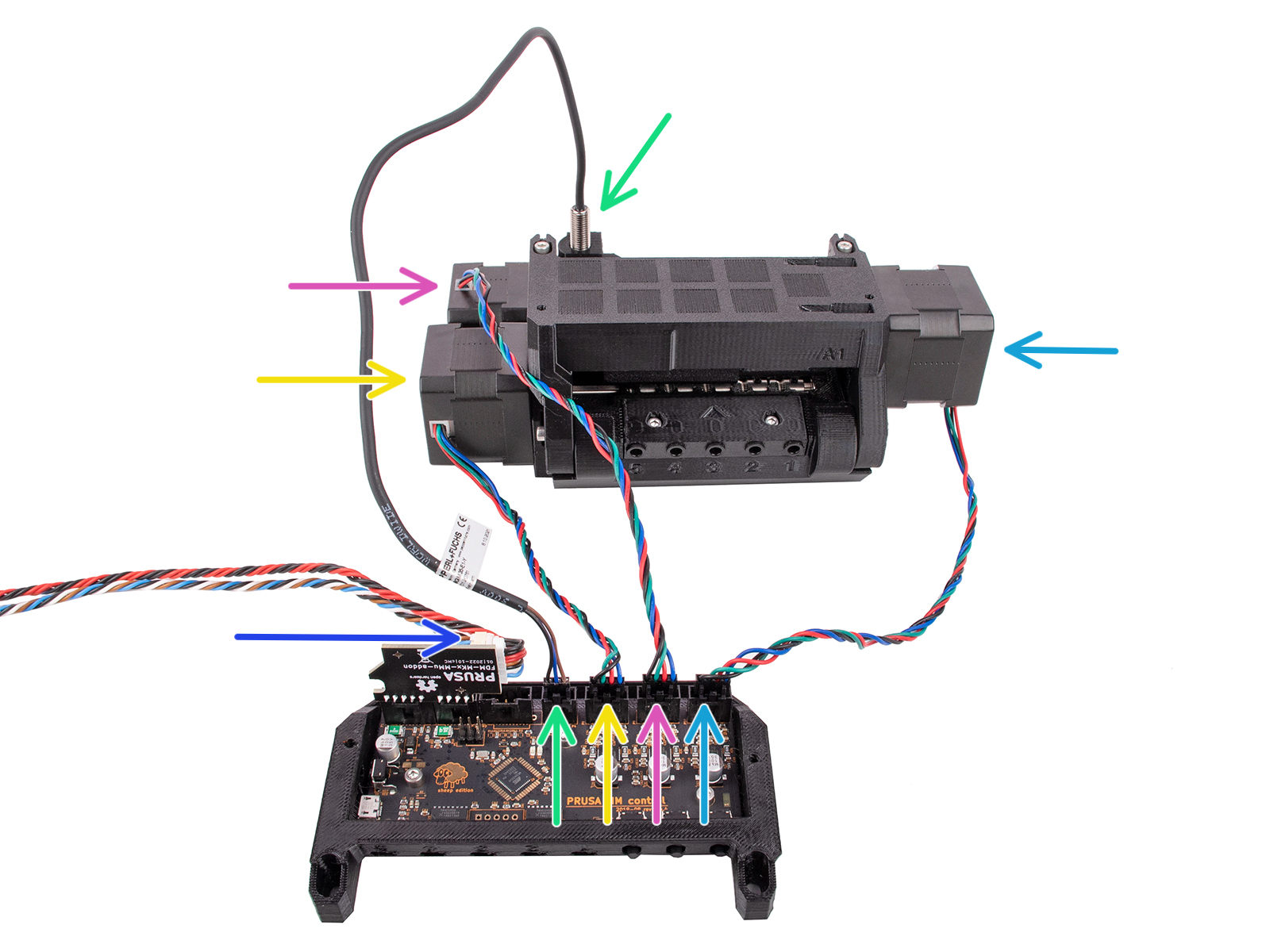

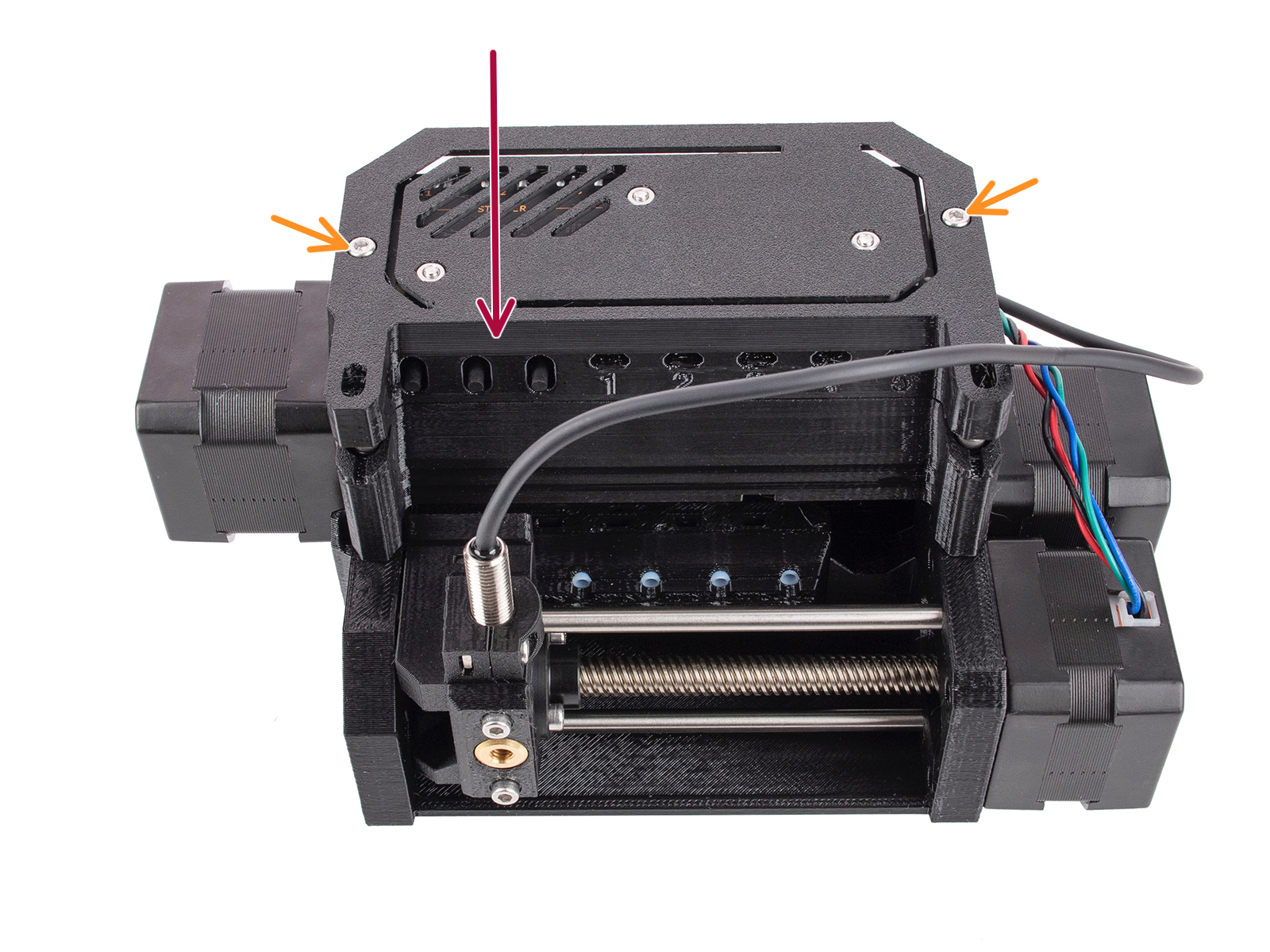

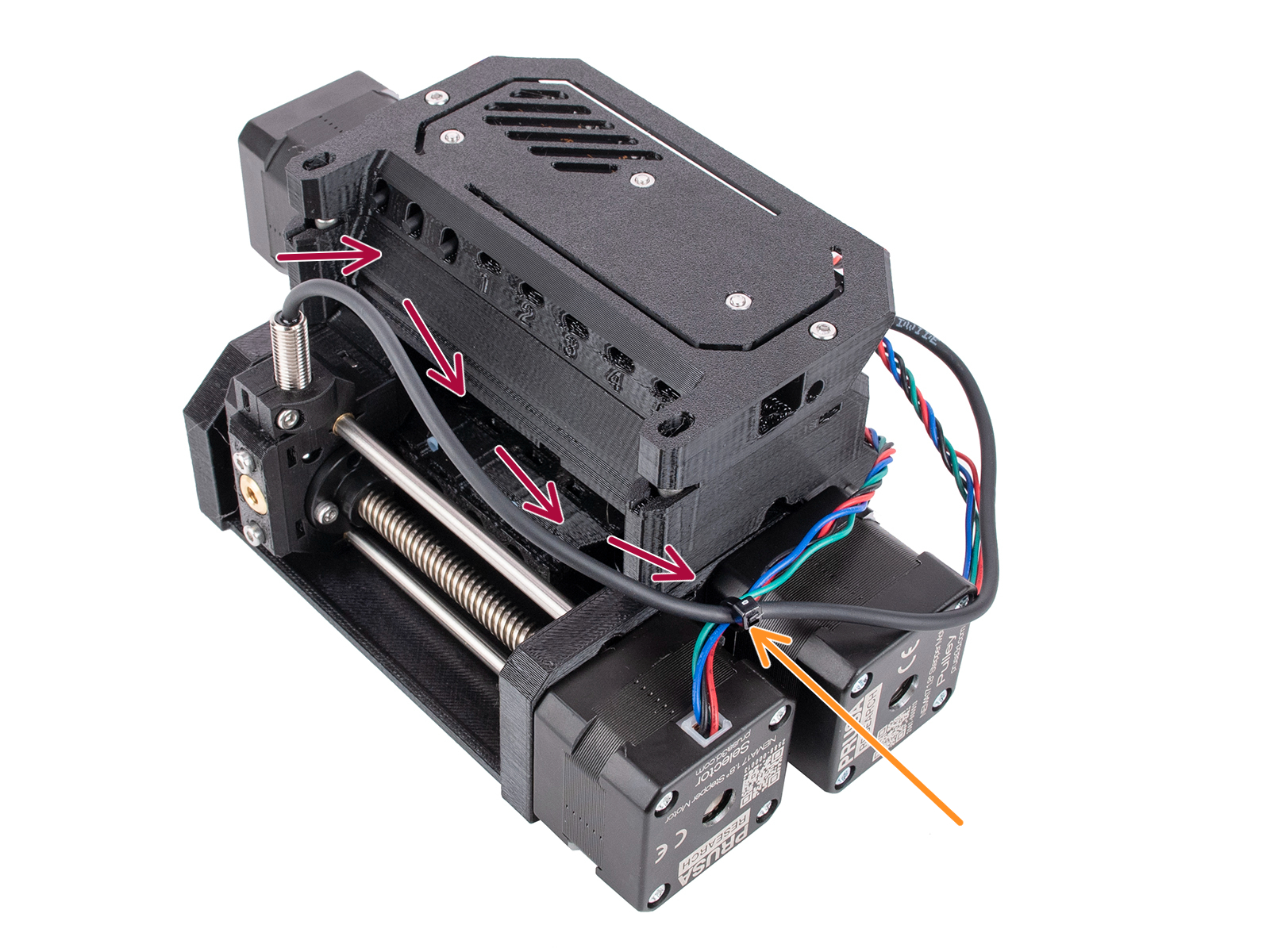

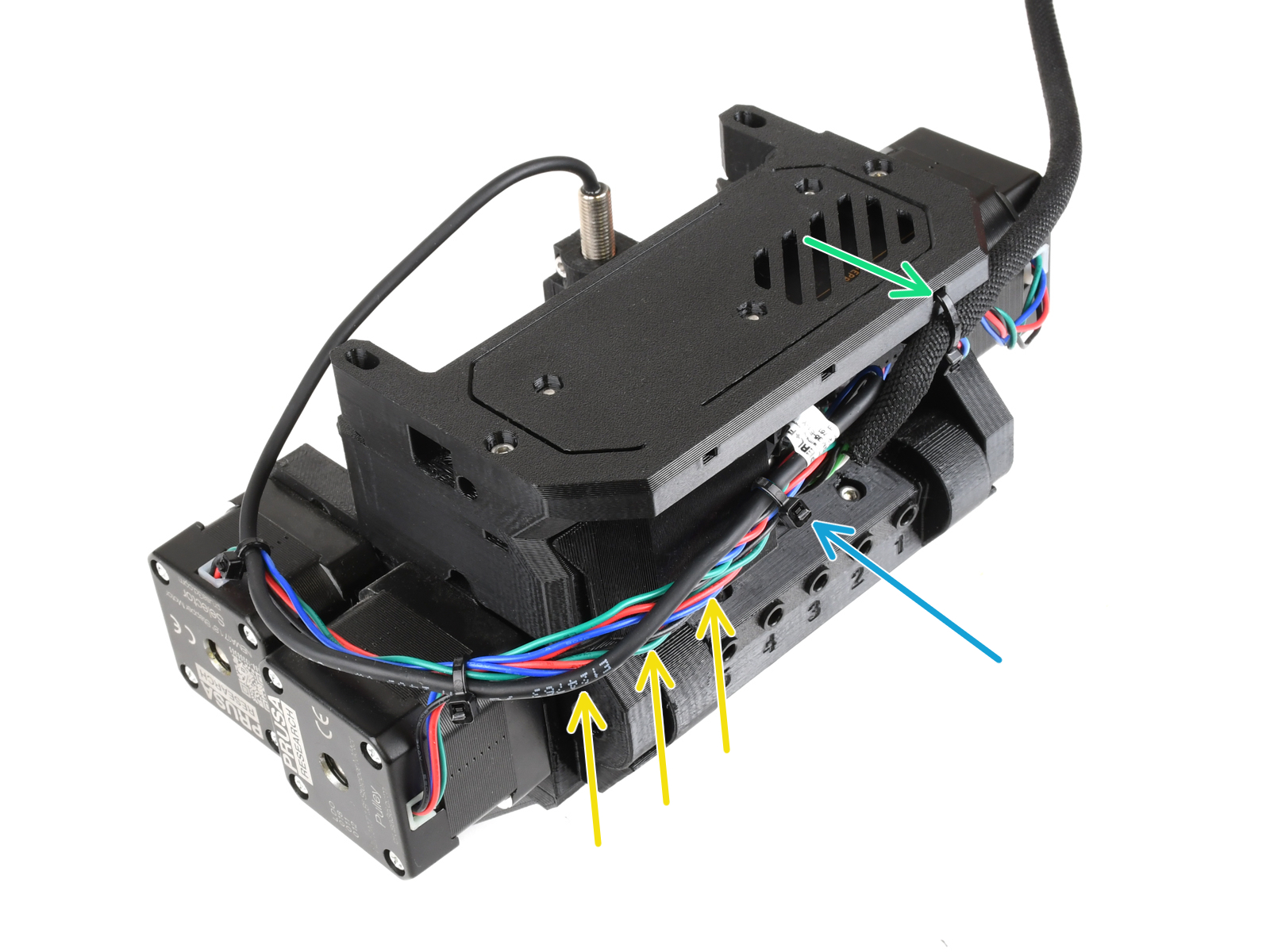

Attach the electronics assembly to the MMU unit.

Make sure the side with the buttons is pointing to the front.

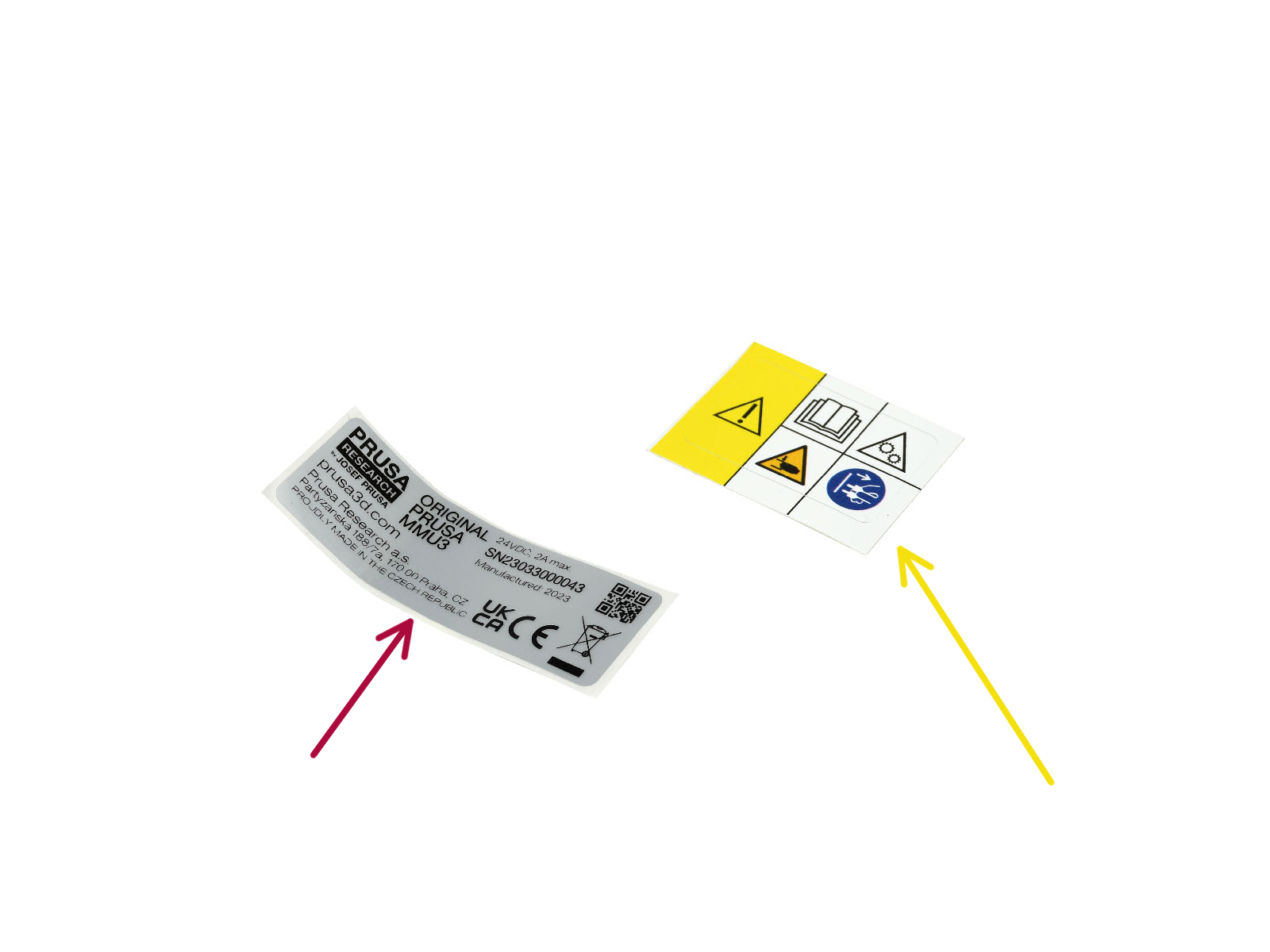

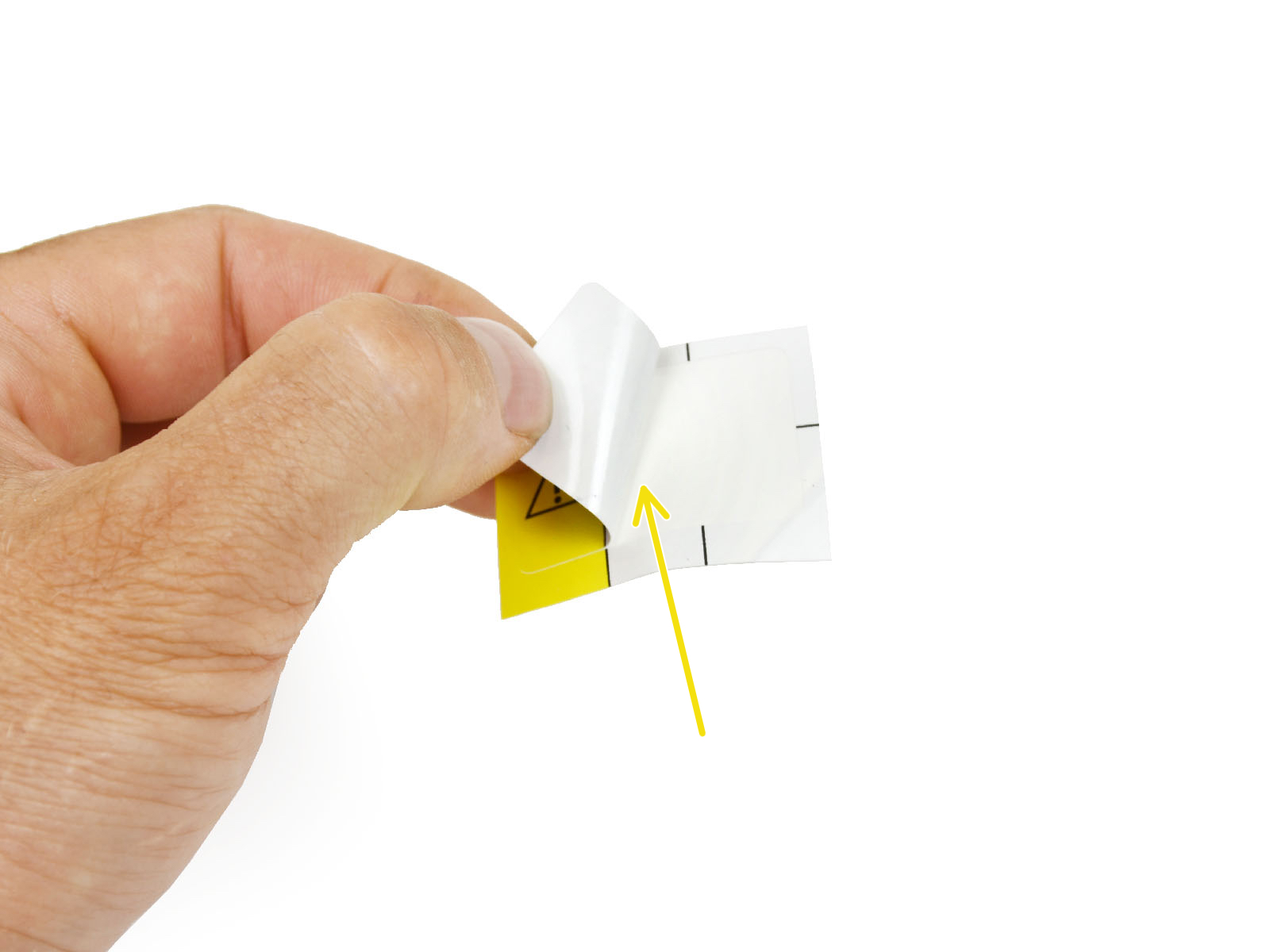

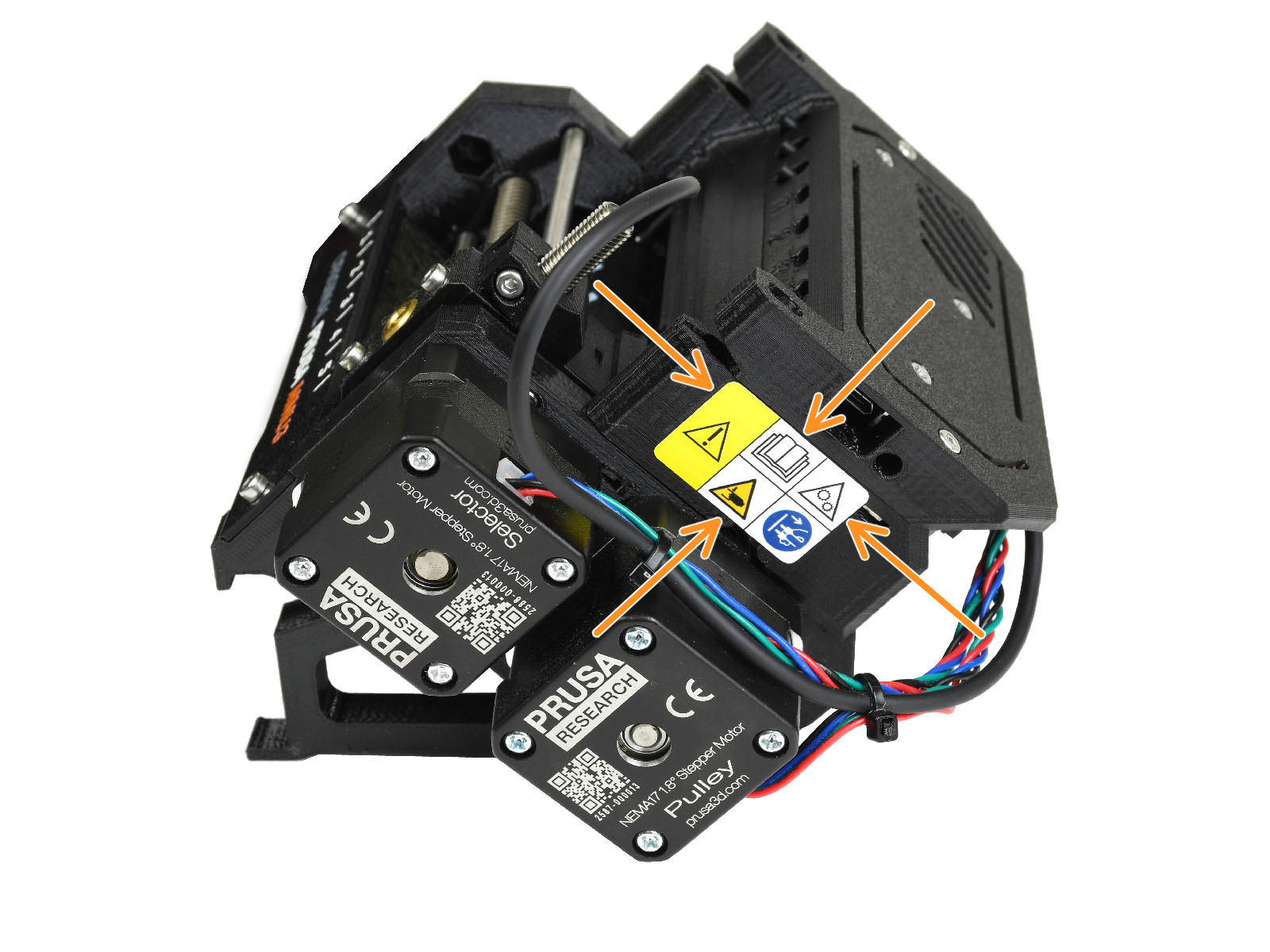

Apply the safety sticker onto the right side of the MMU3 unit. The correct position is depicted in the second picture.

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.