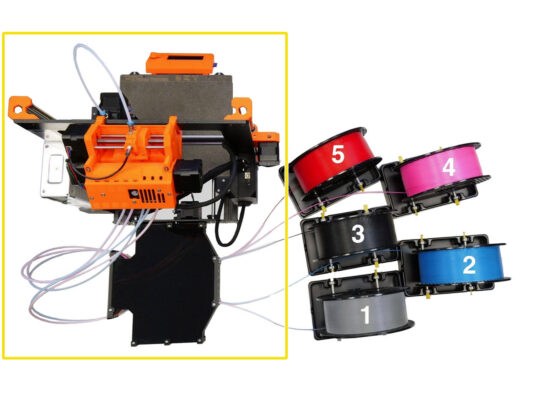

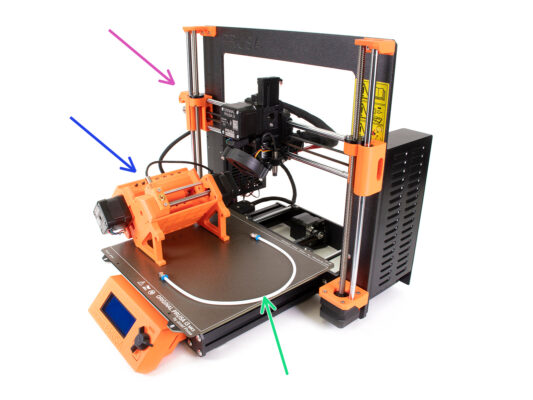

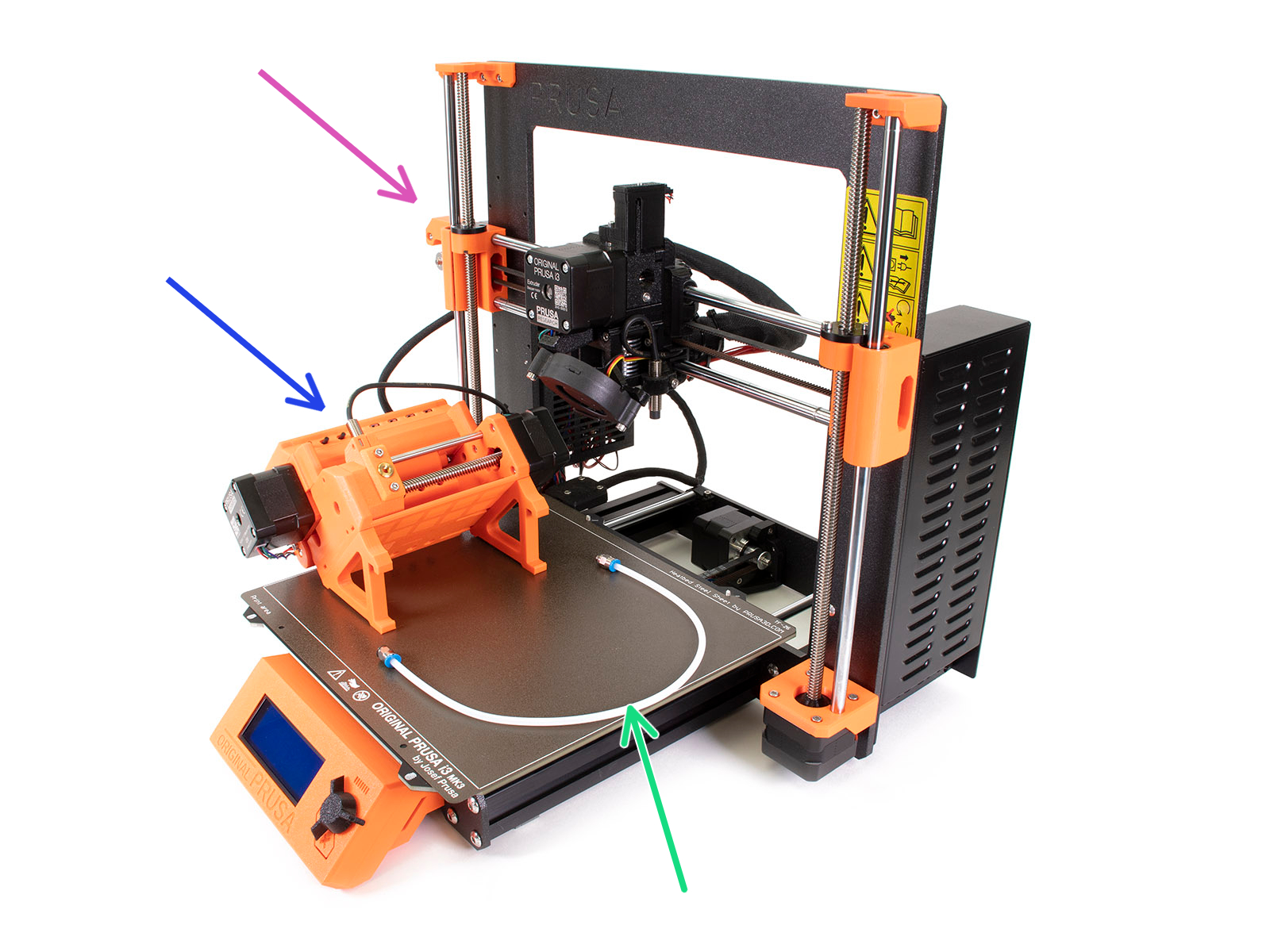

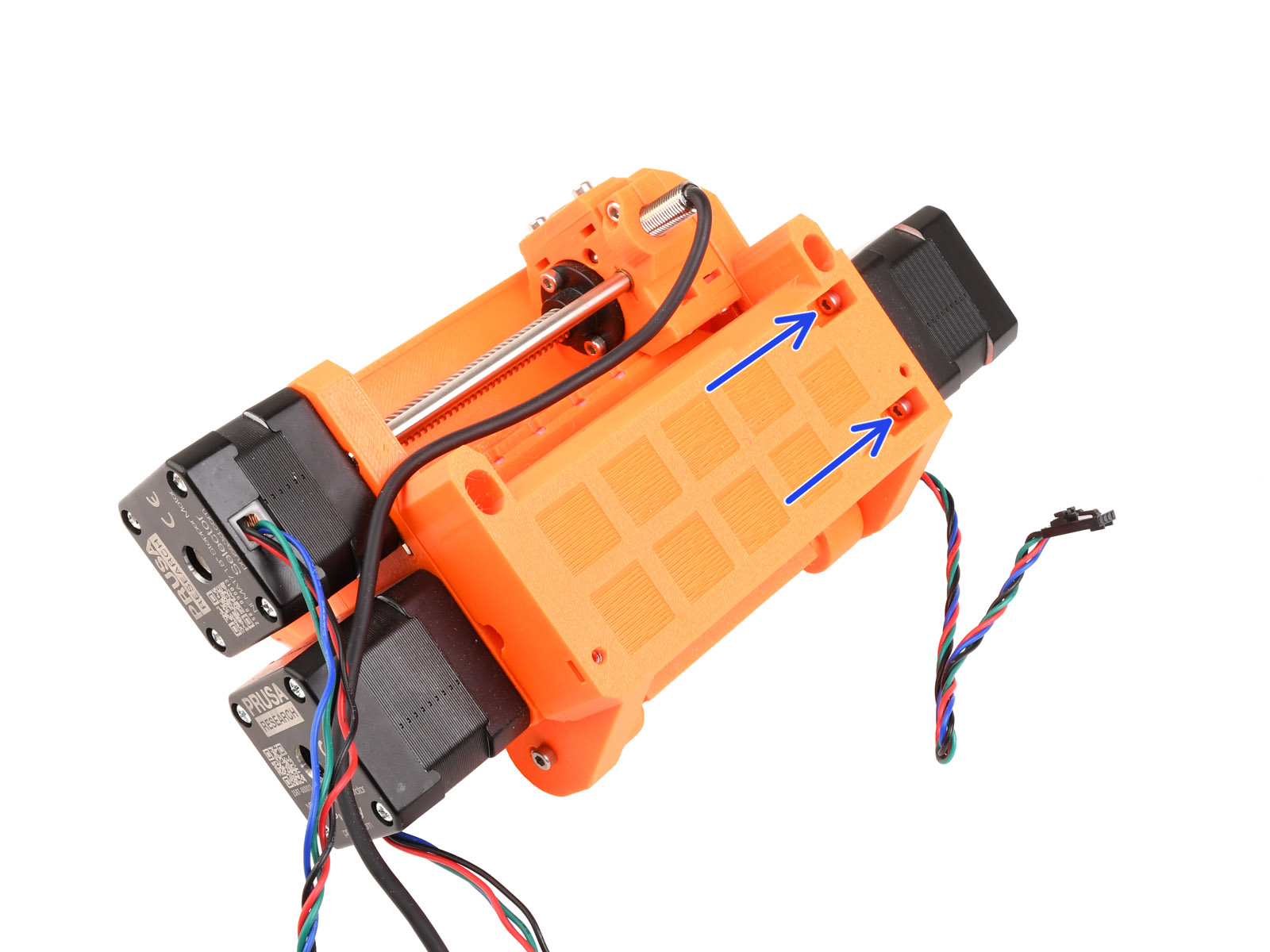

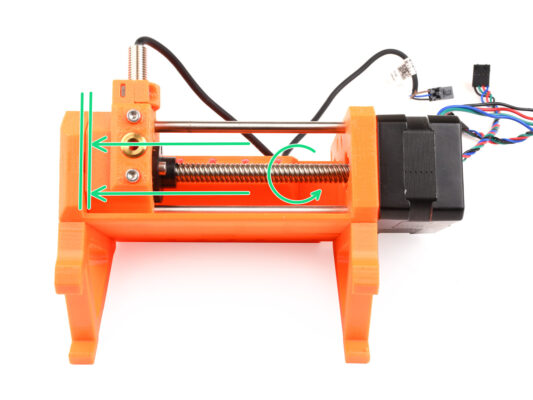

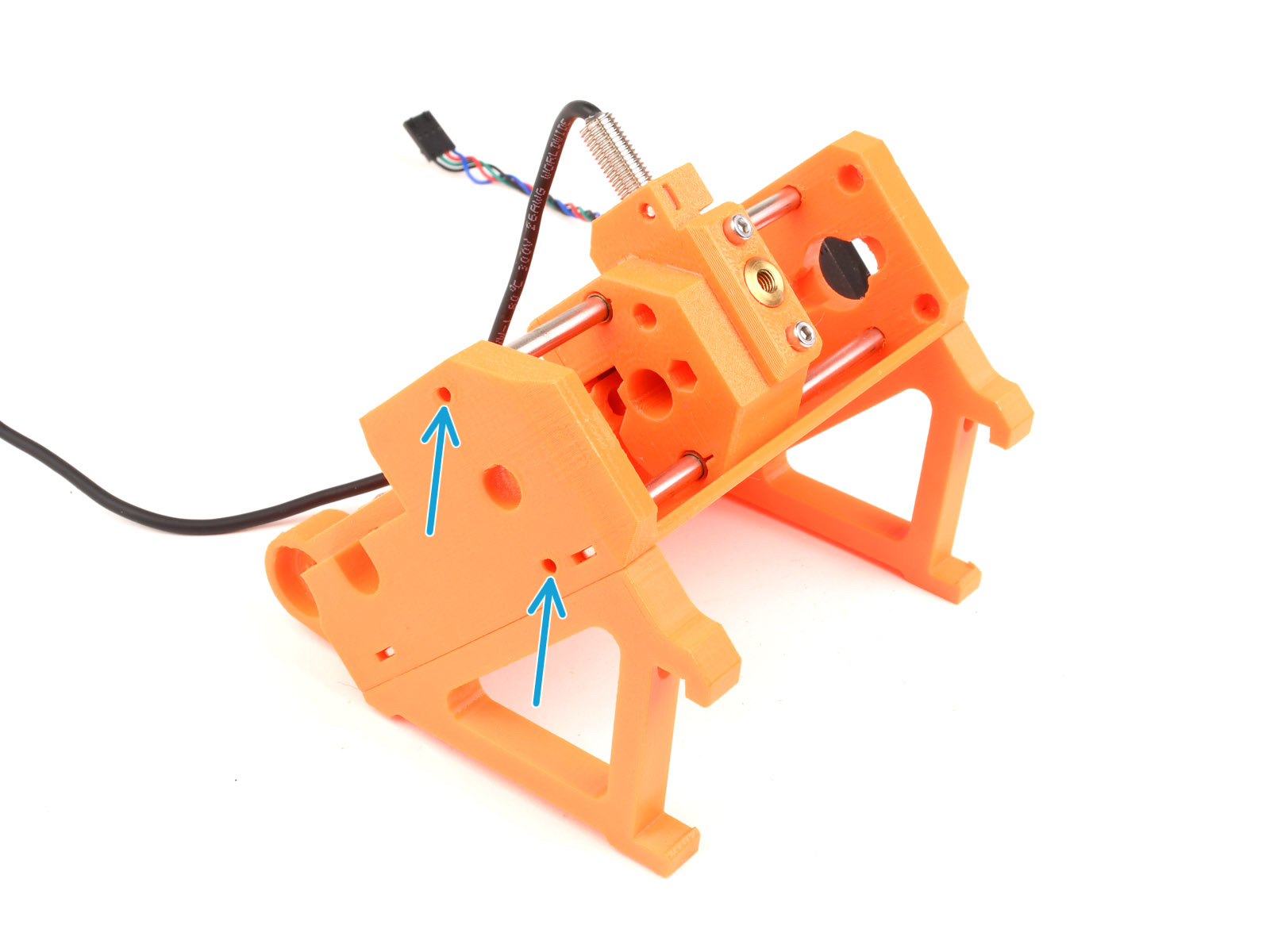

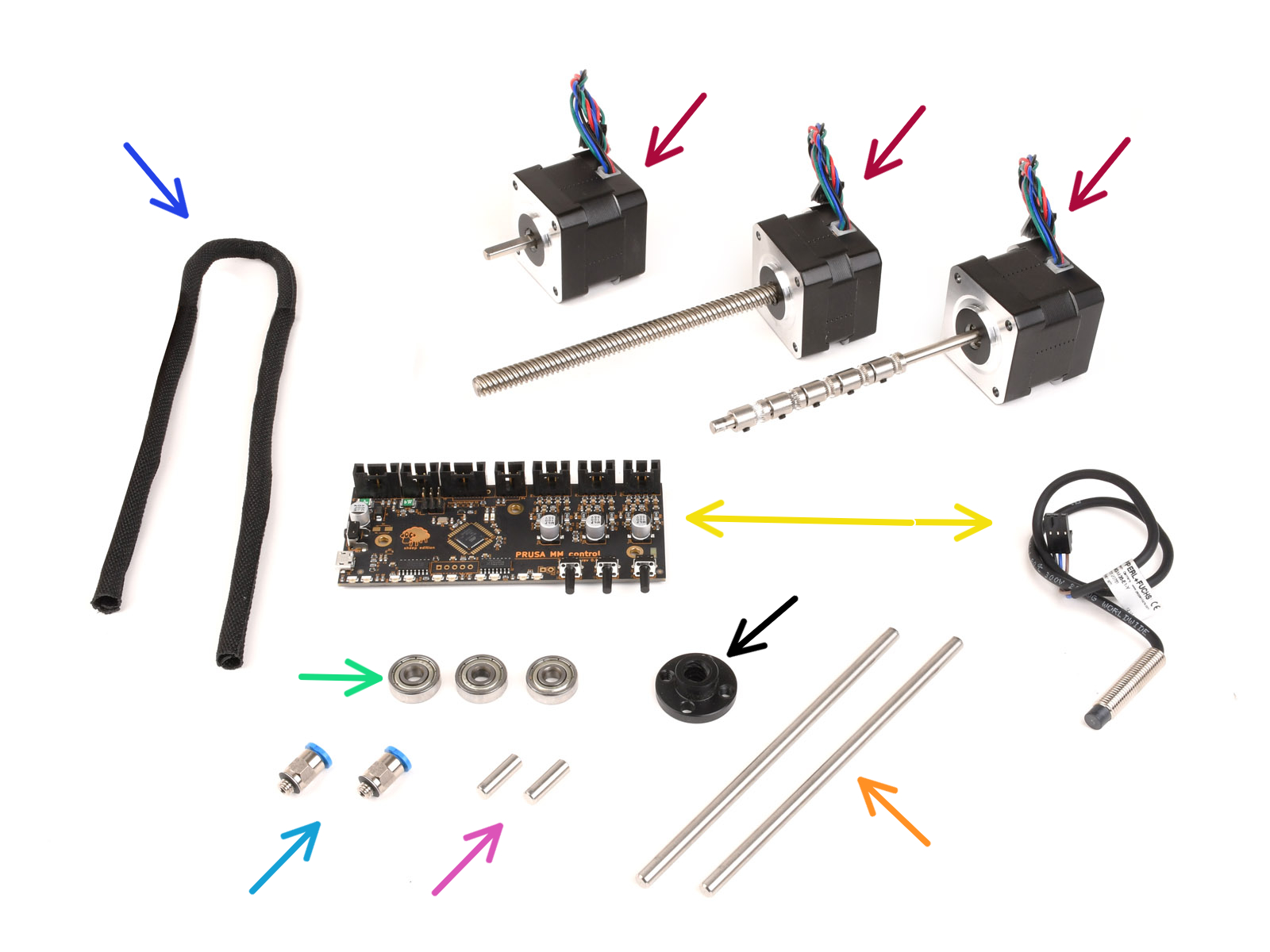

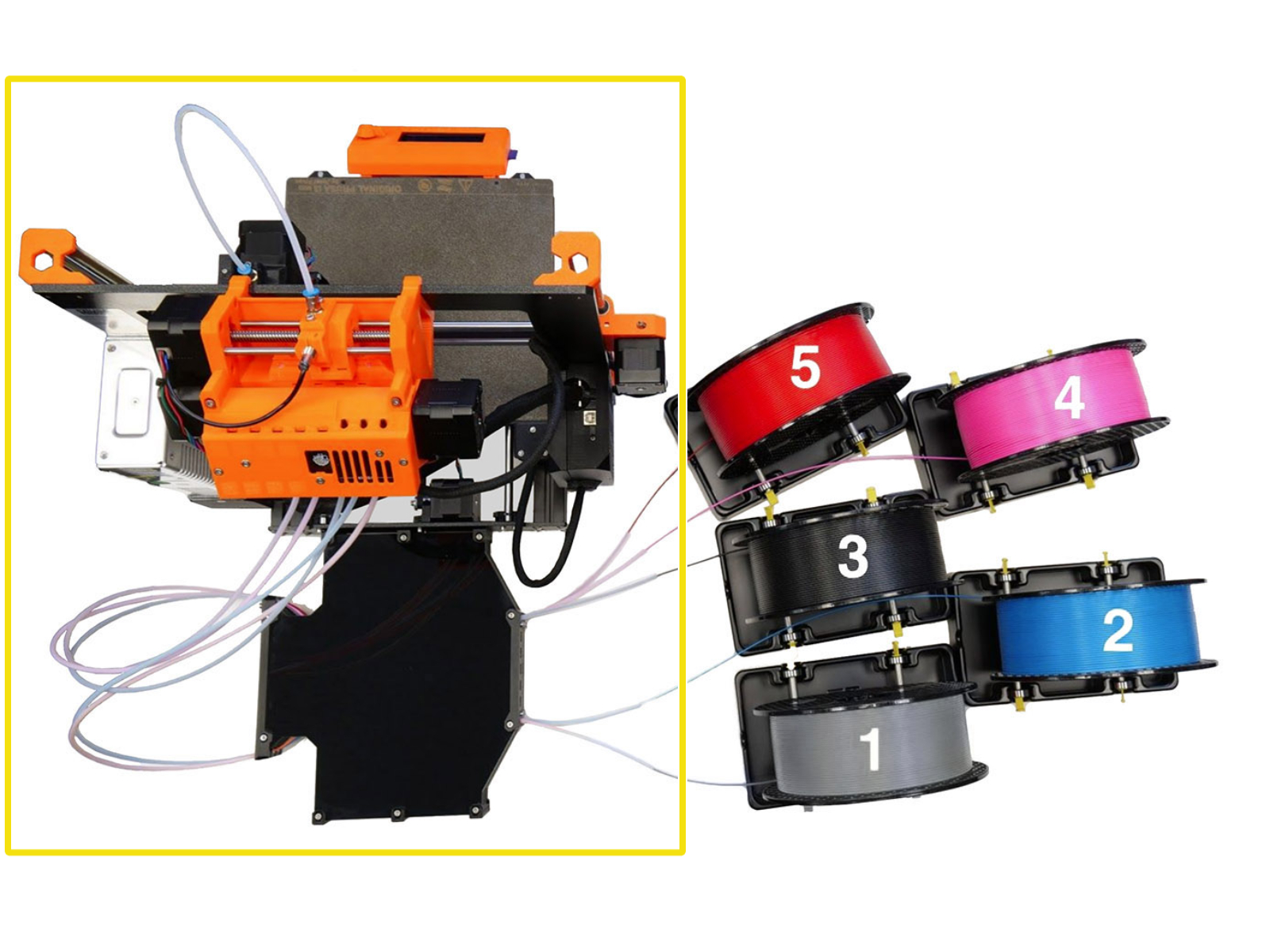

⬢In this chapter, we will partly disassemble the MMU2S unit and harvest a few key parts to be used for the MMU3 build.

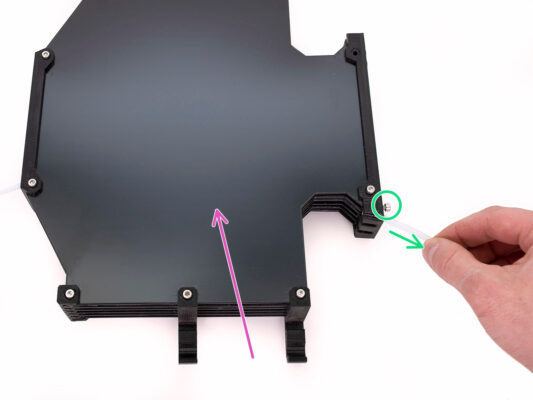

Ensure your MMU printer is powered off and disconnected. Unload all filaments from both the printer and the MMU unit.

⬢If there is a filament loaded in the extruder, use the Unload filament function in the menu.

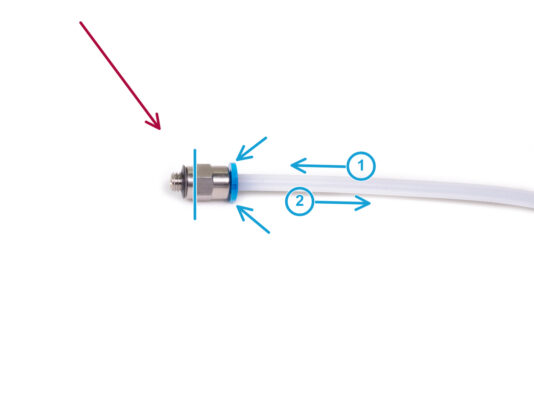

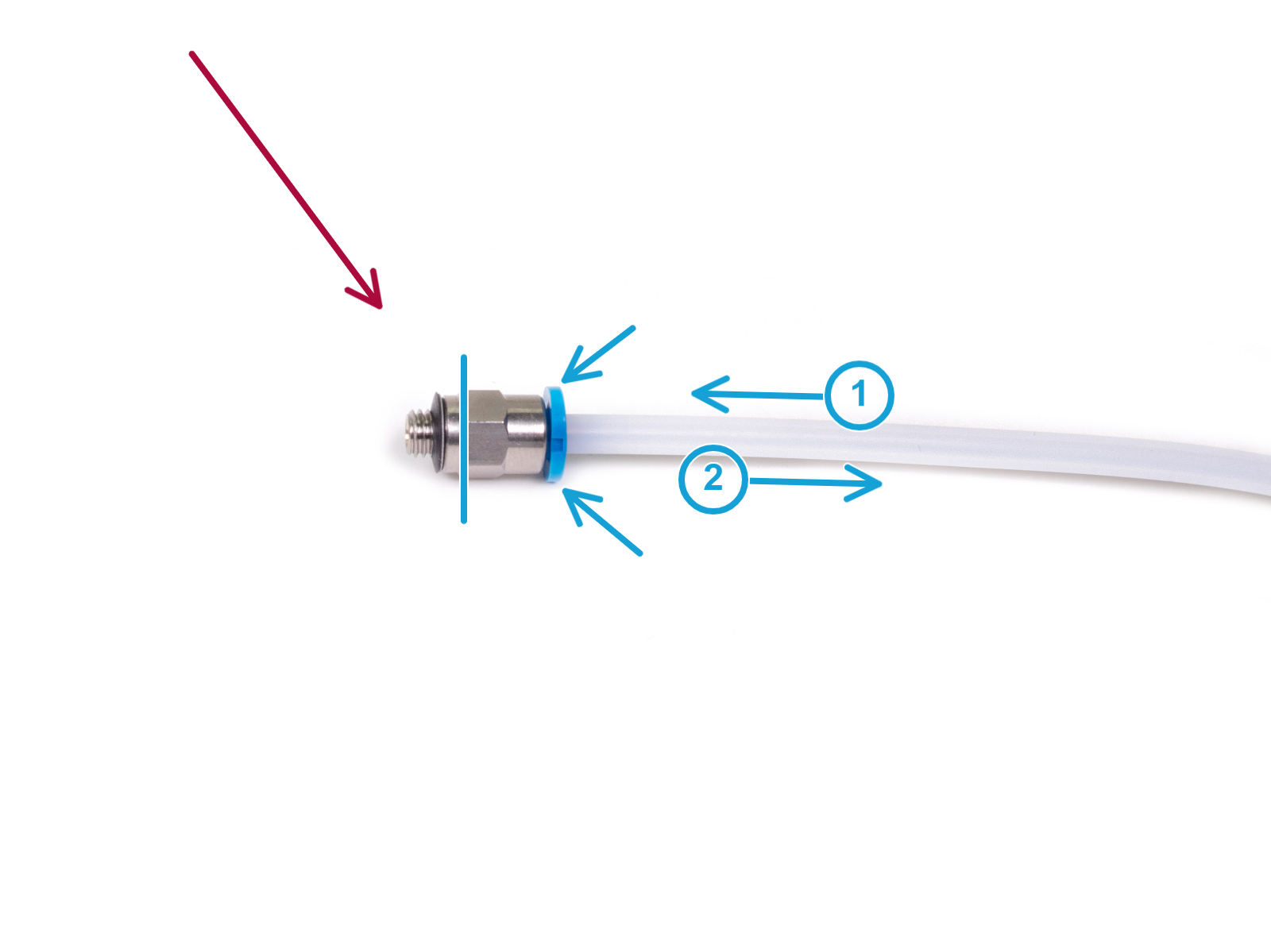

⬢

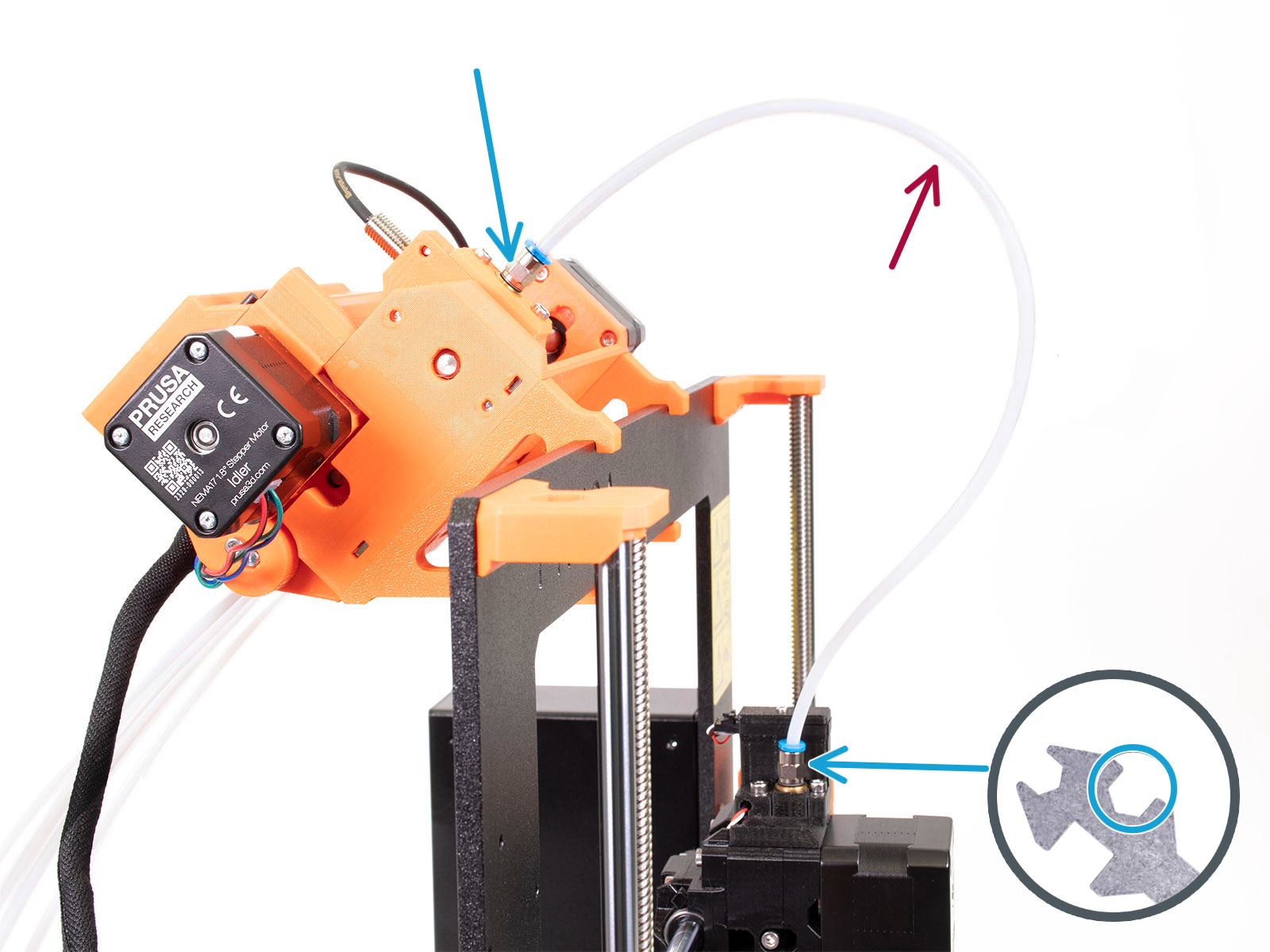

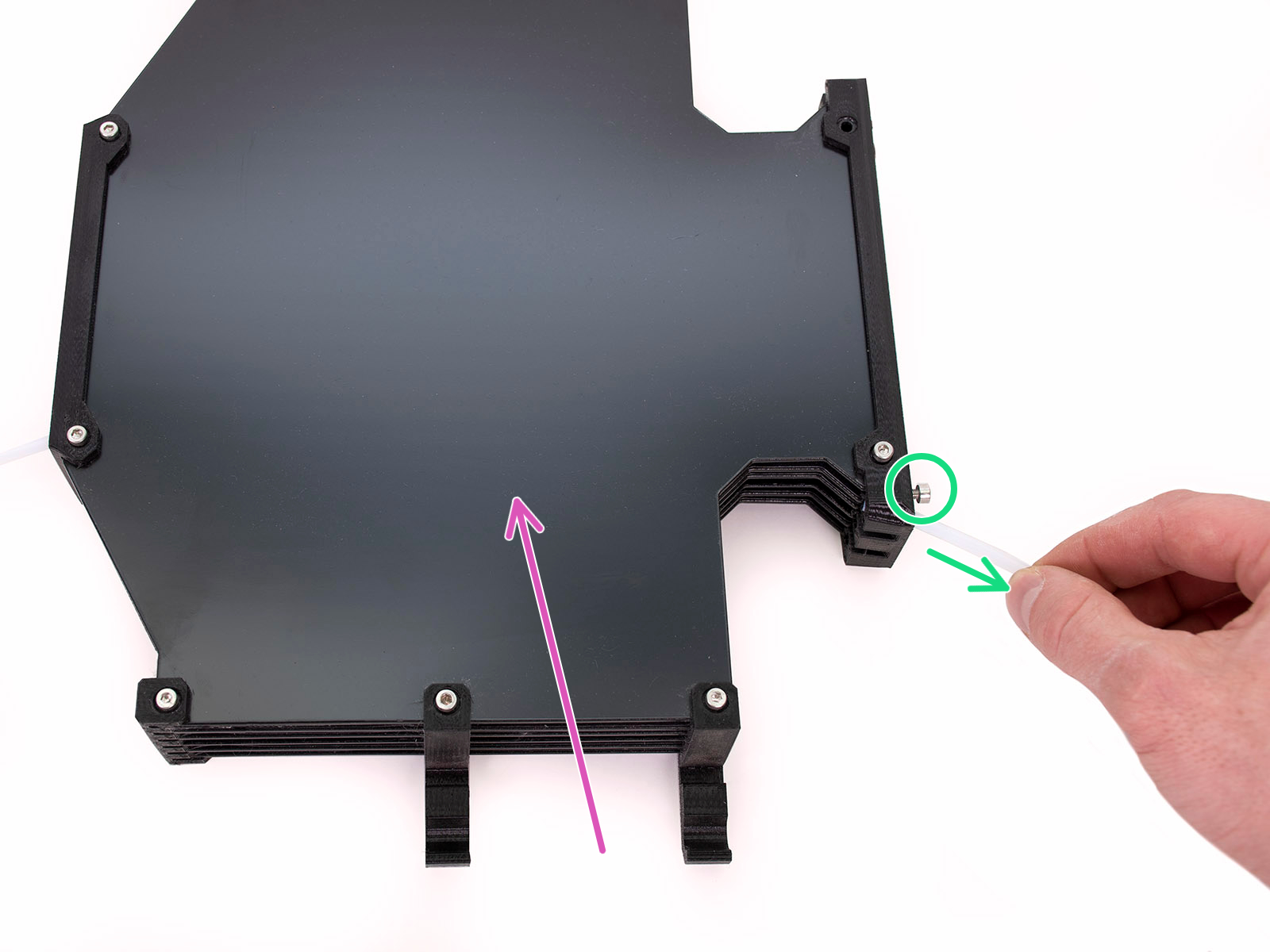

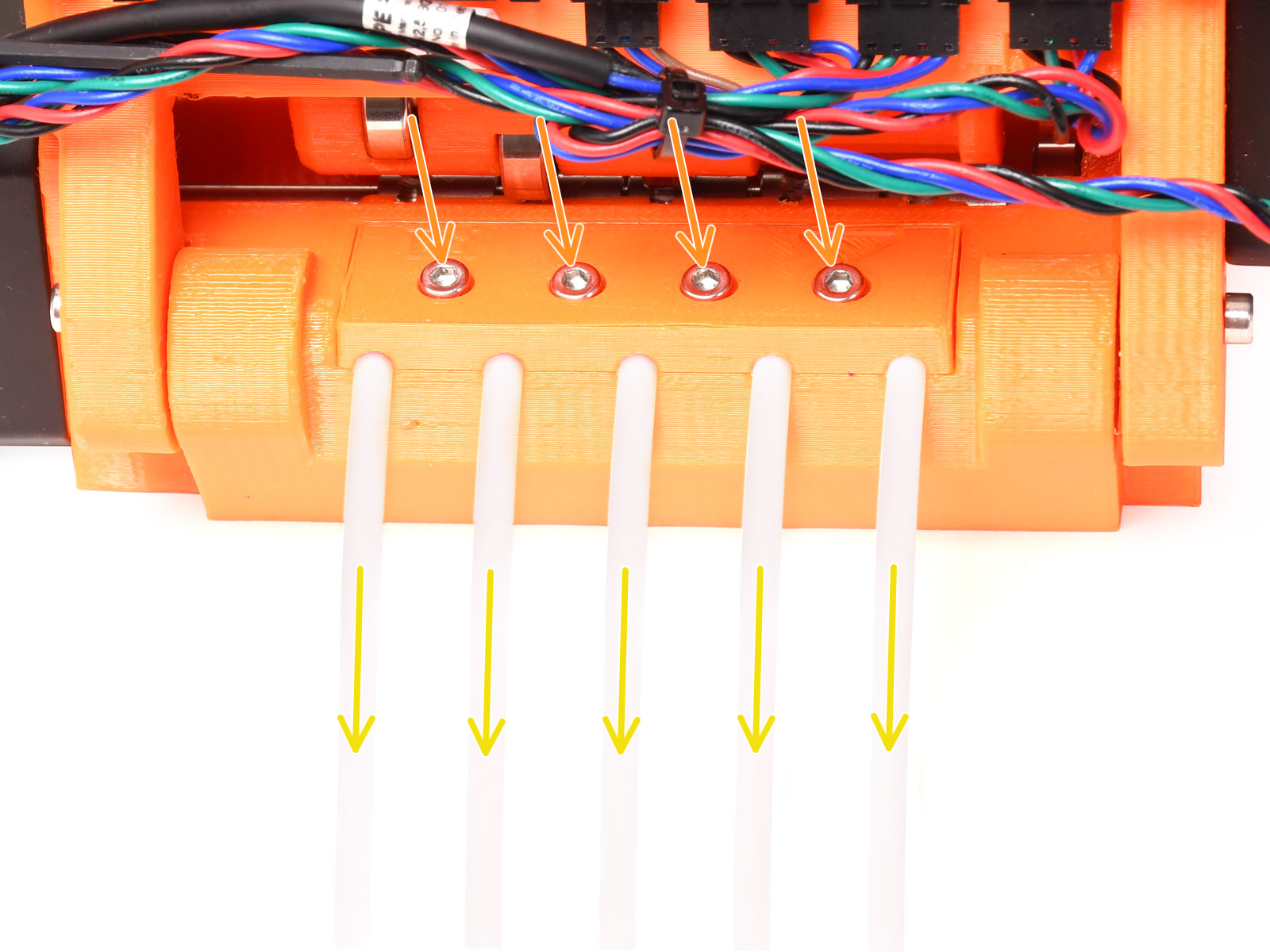

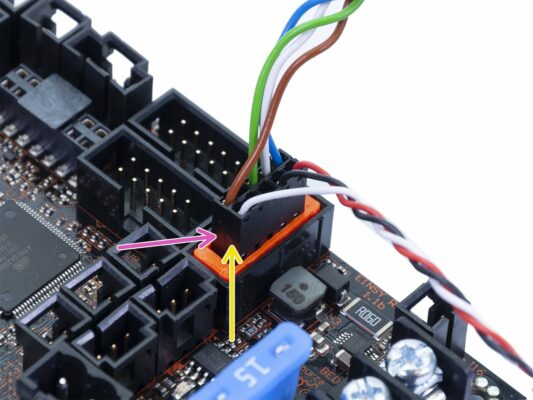

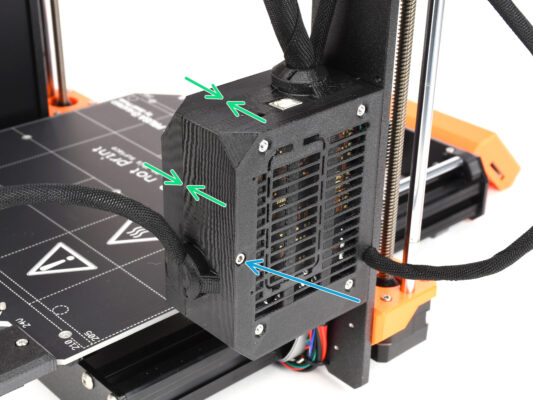

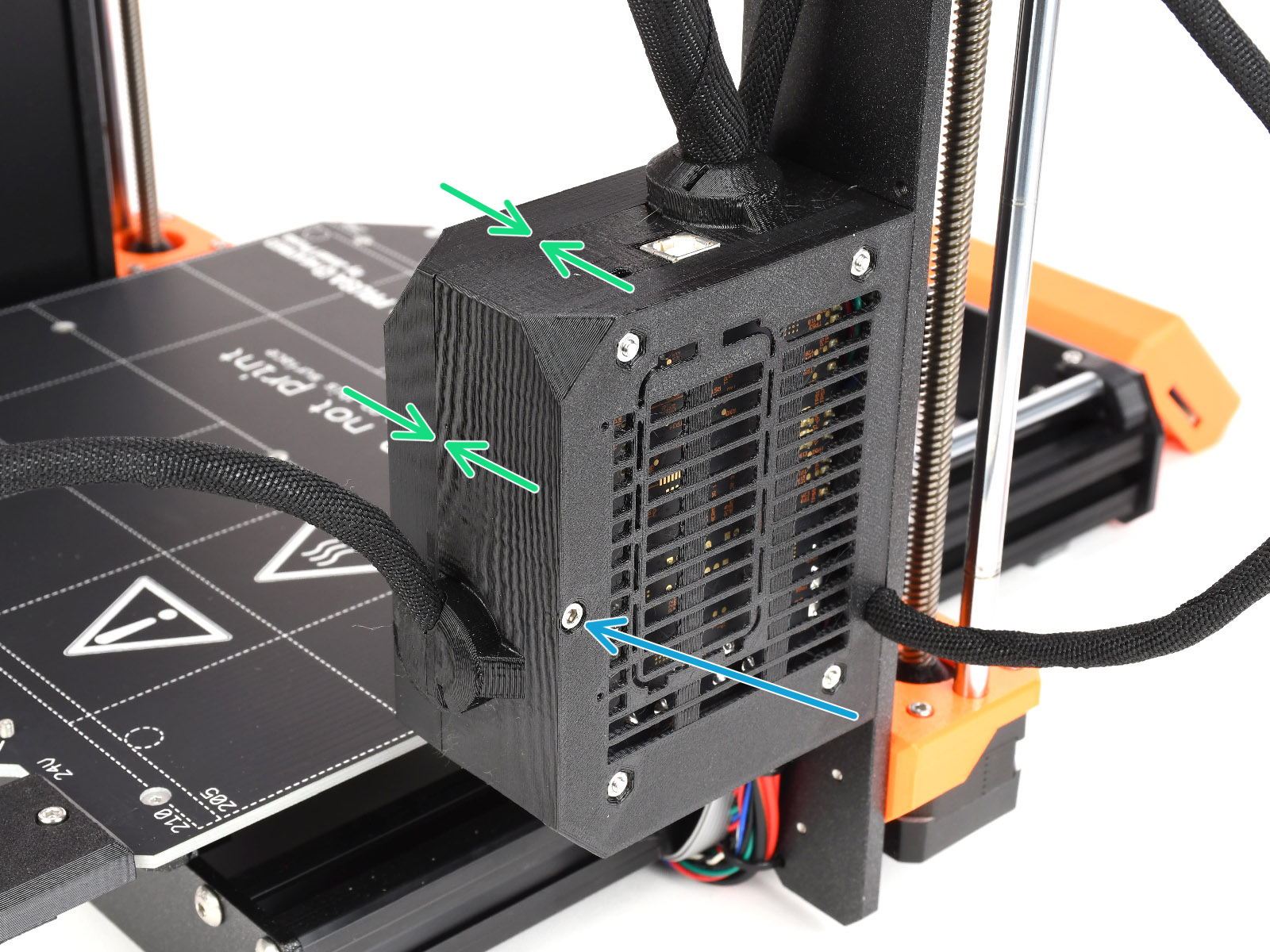

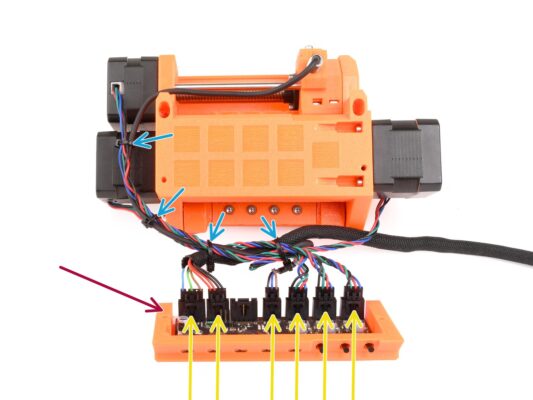

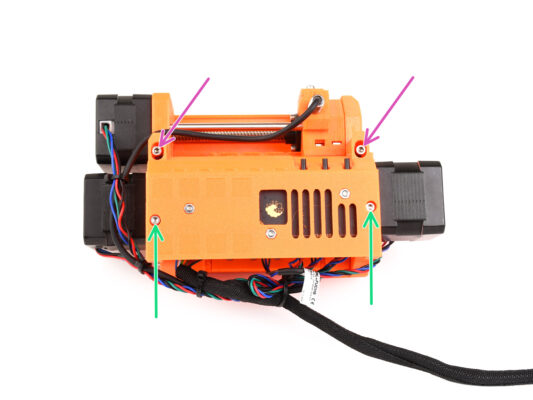

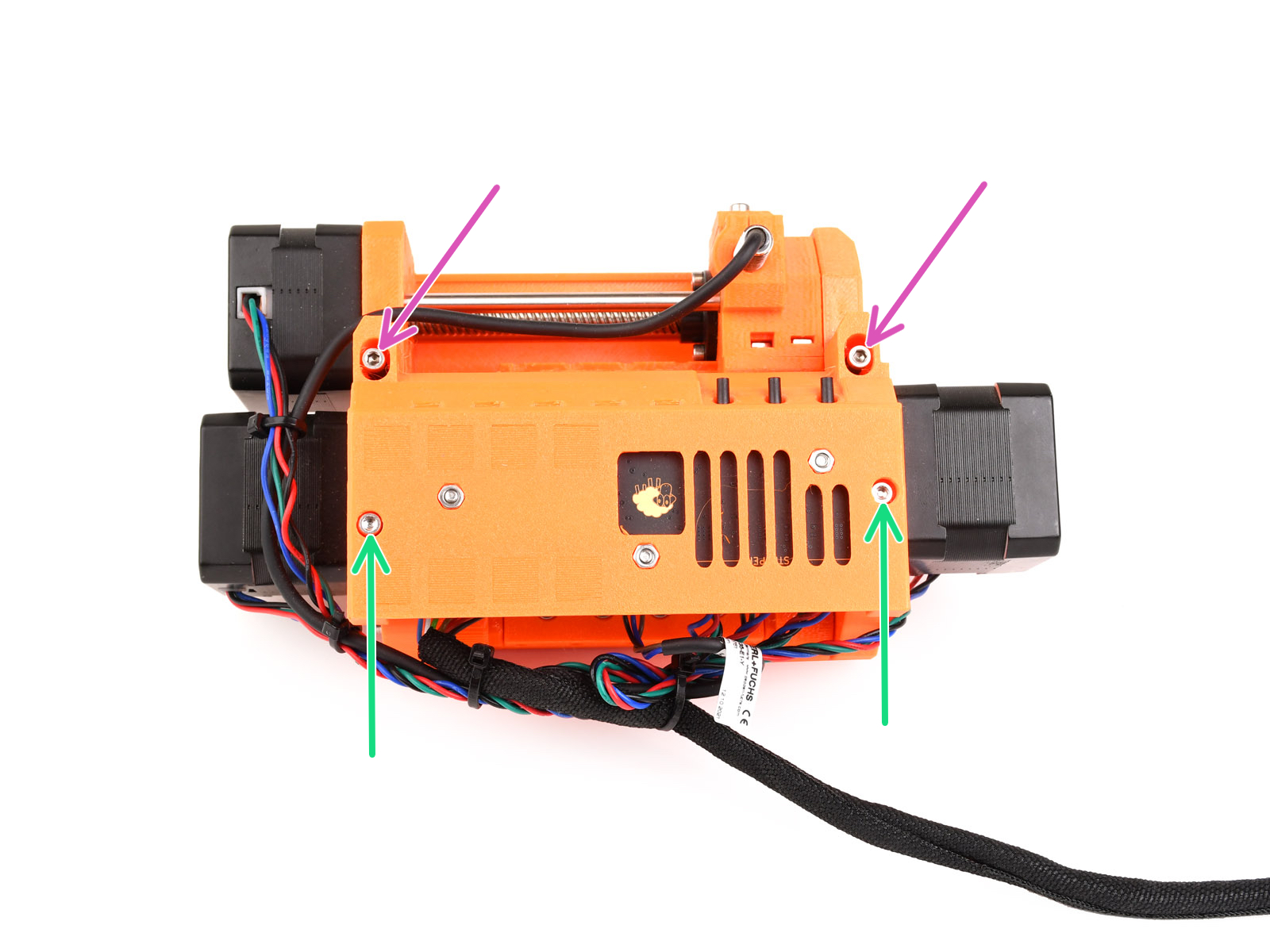

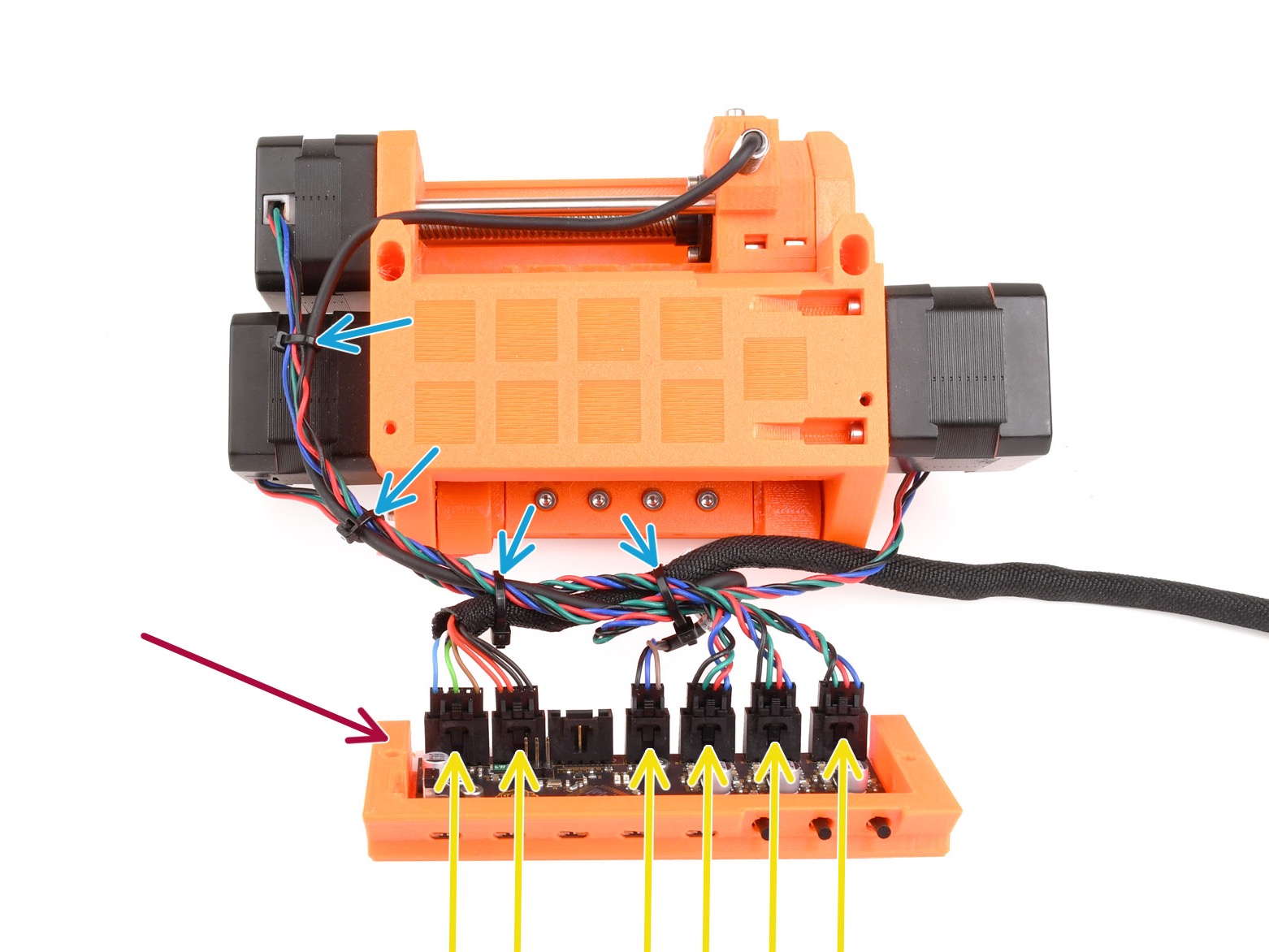

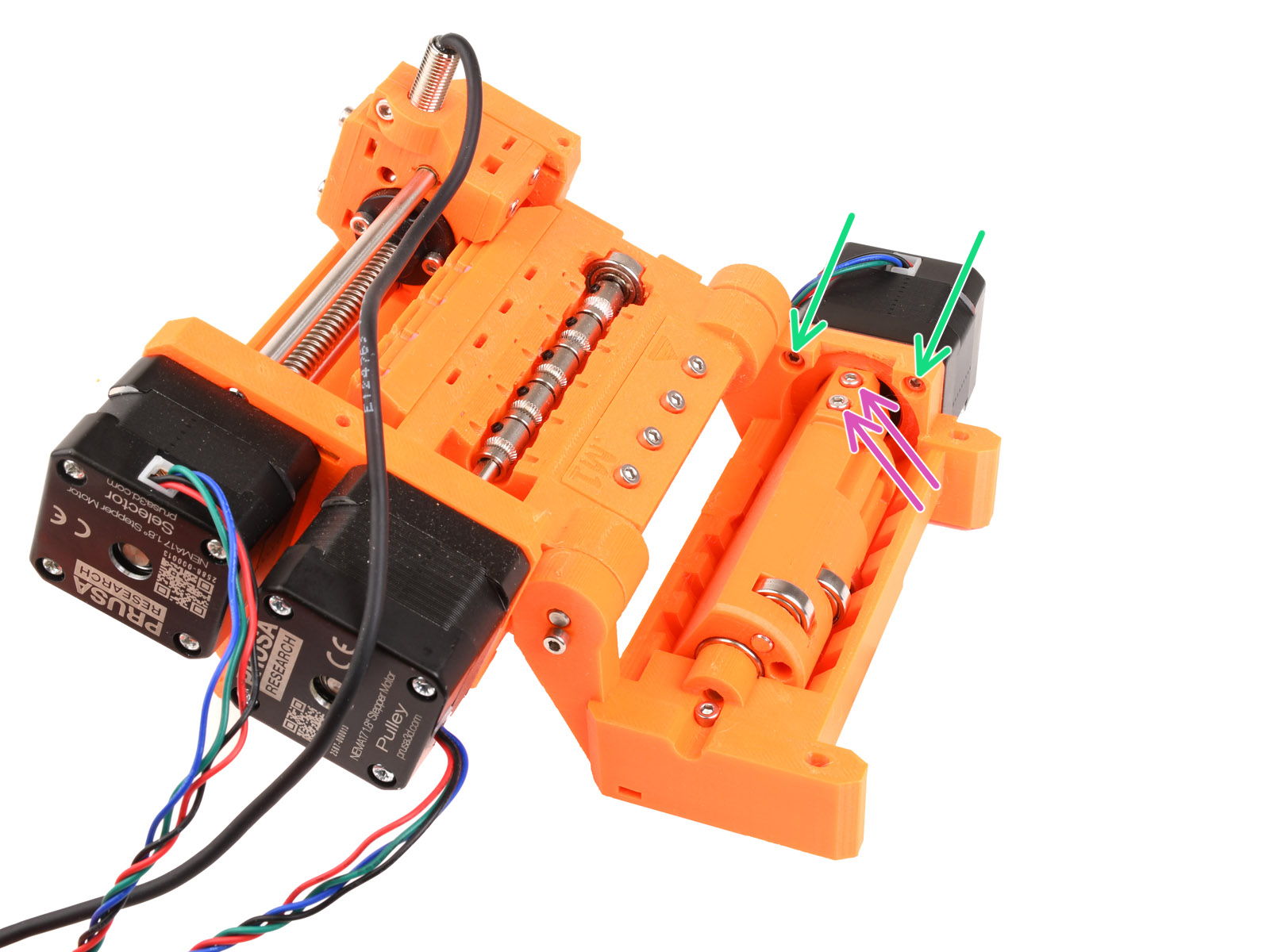

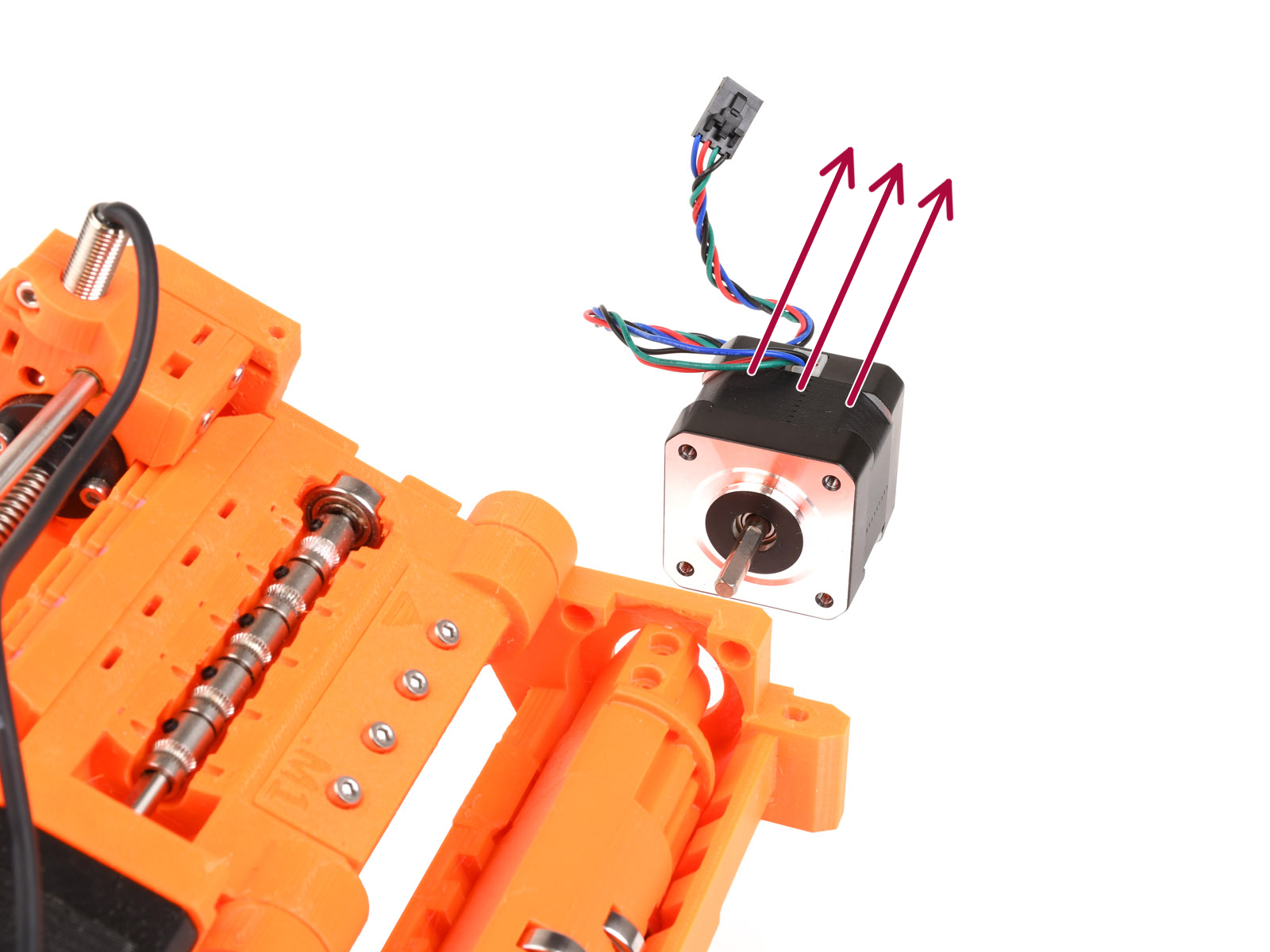

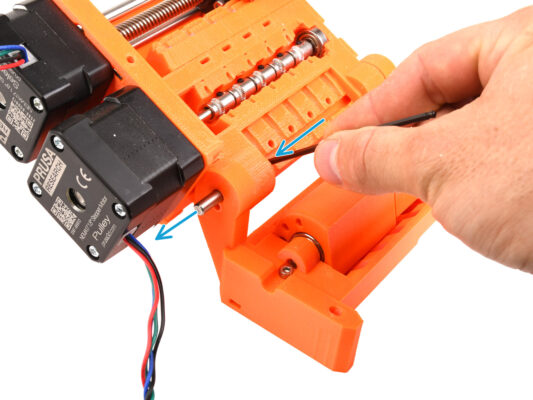

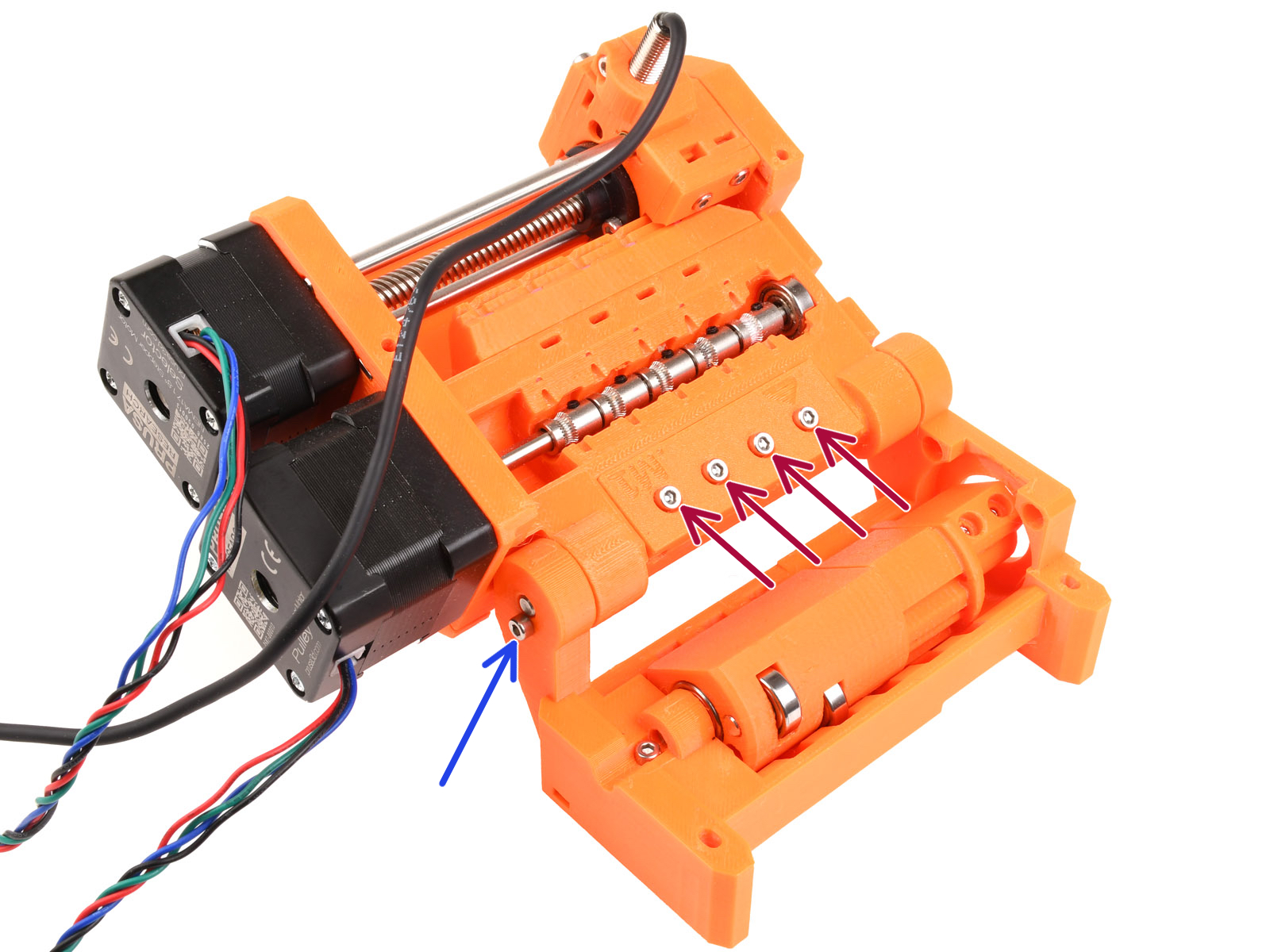

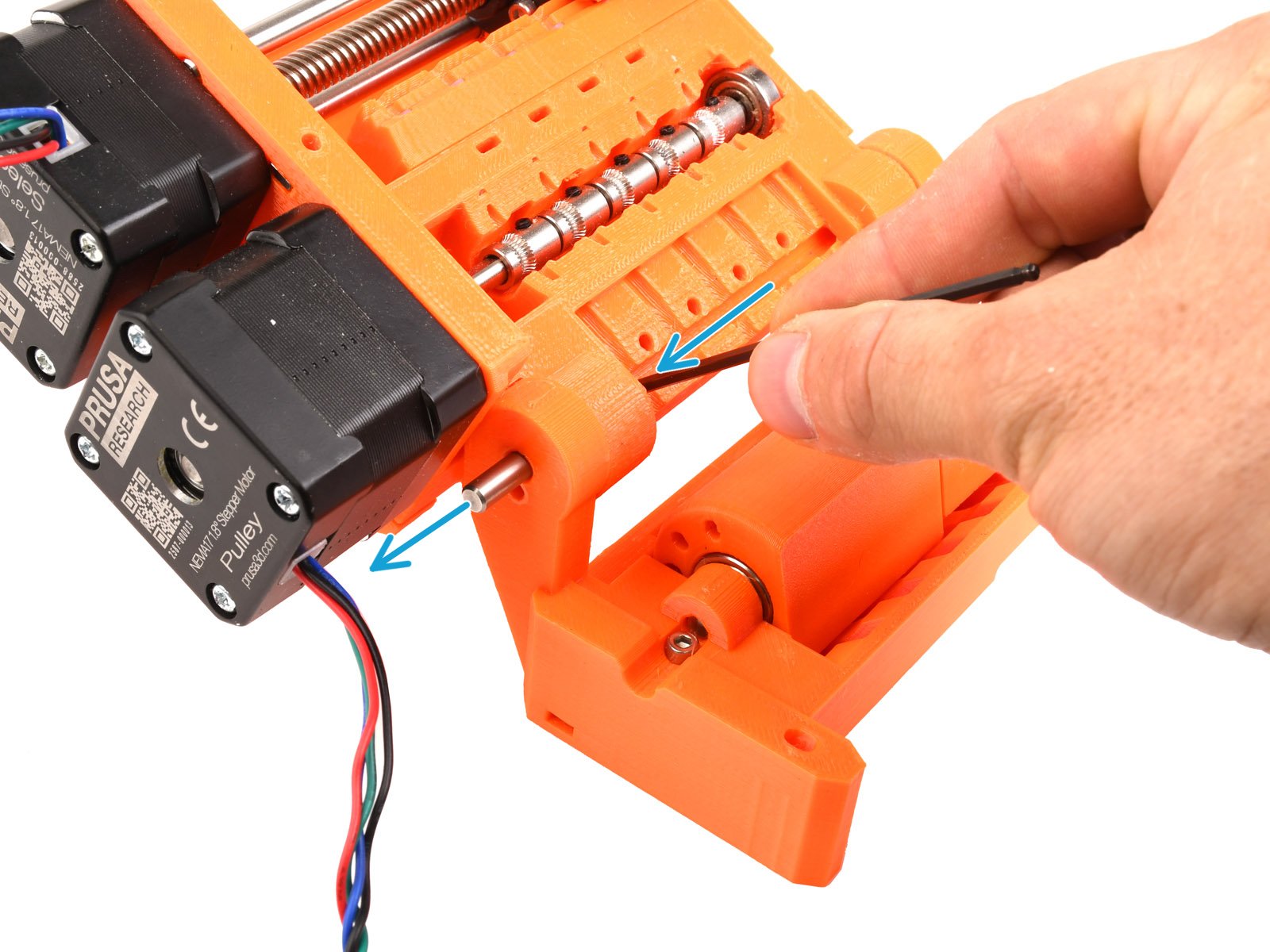

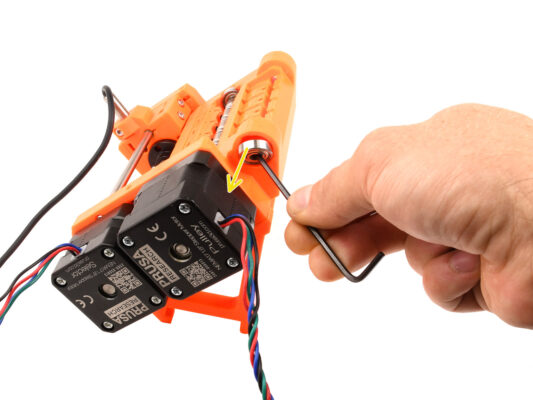

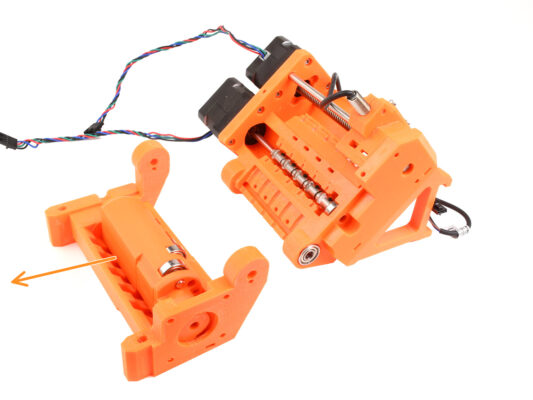

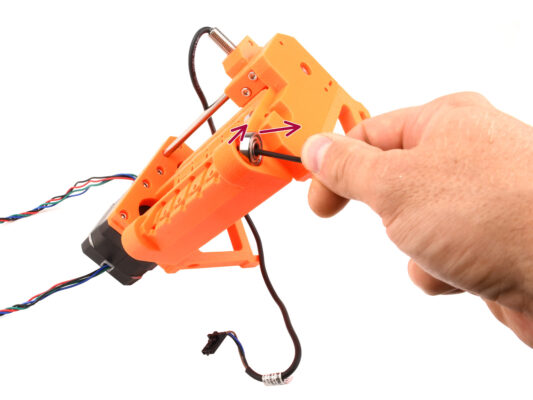

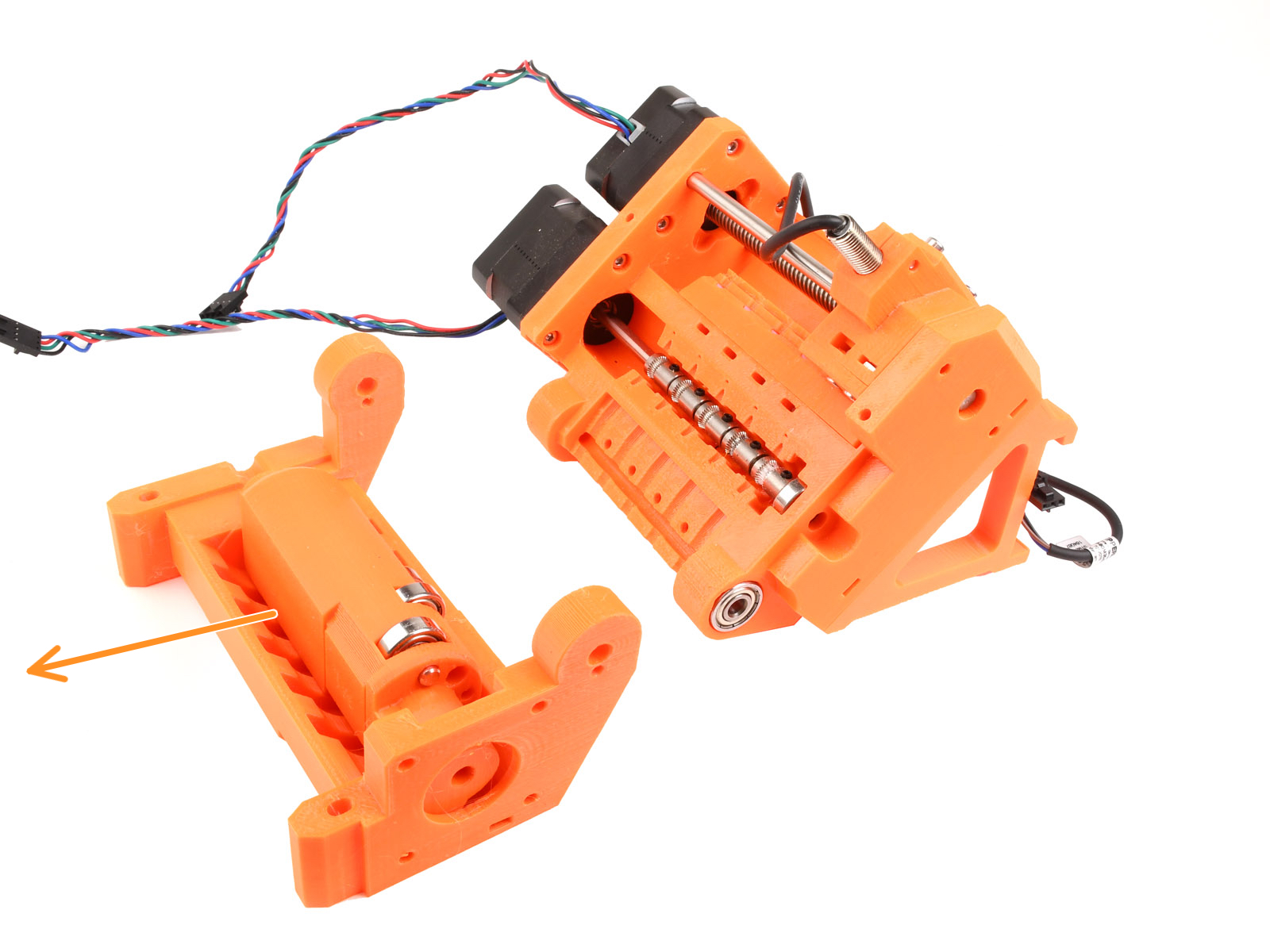

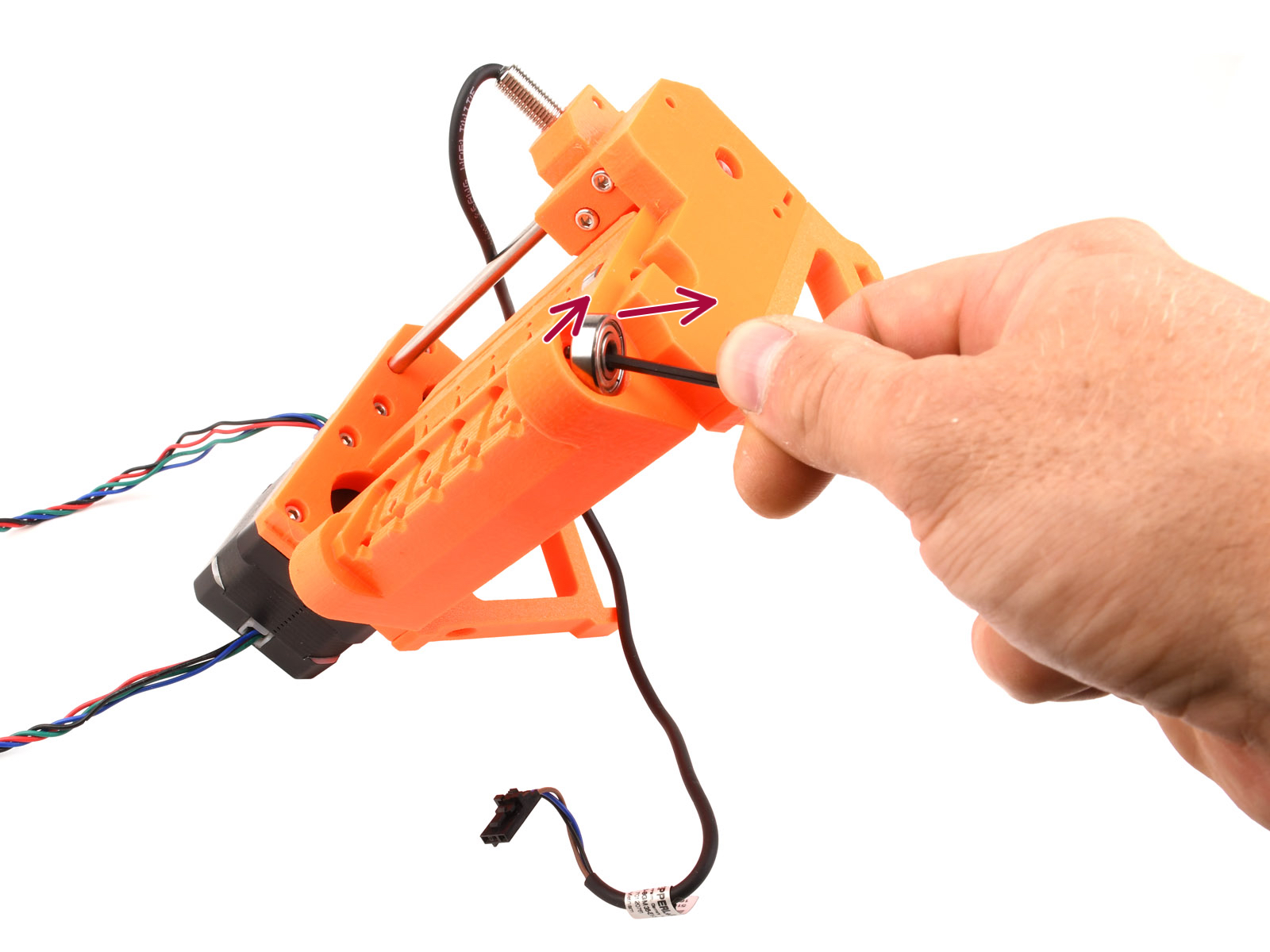

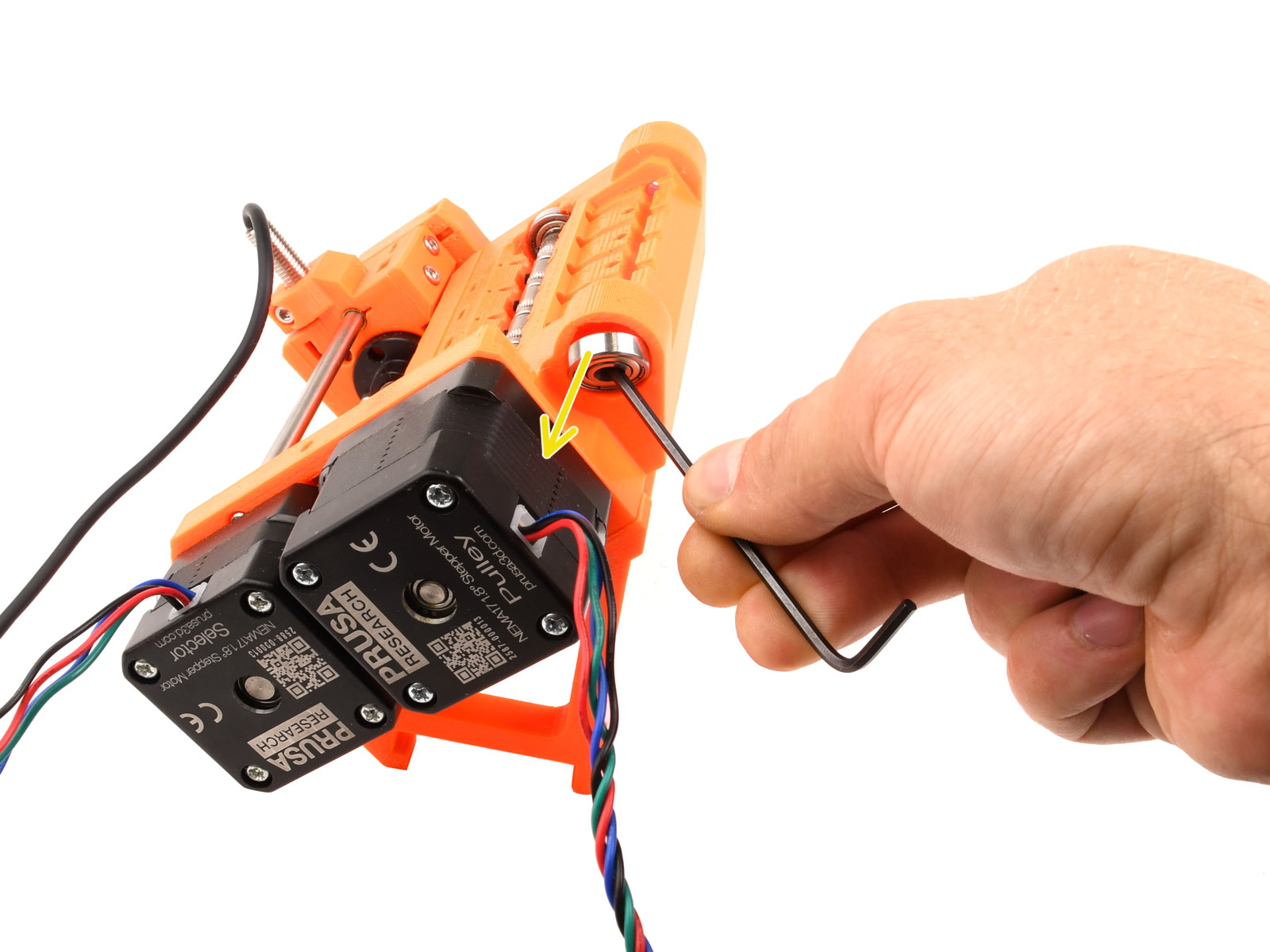

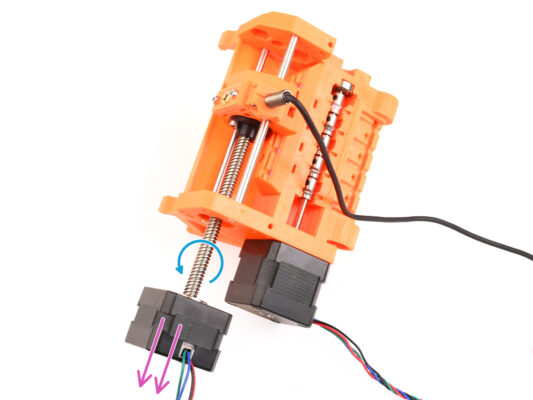

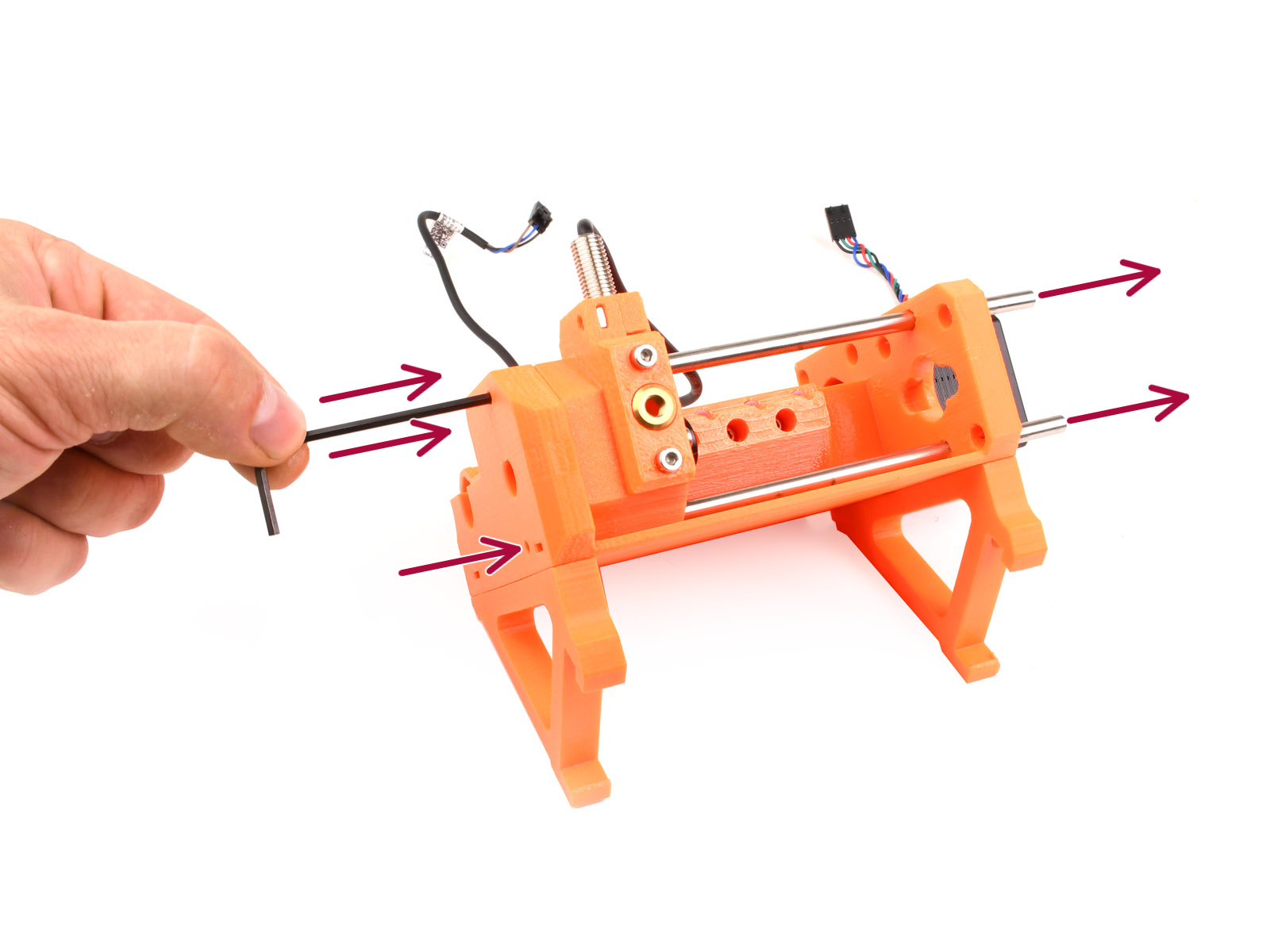

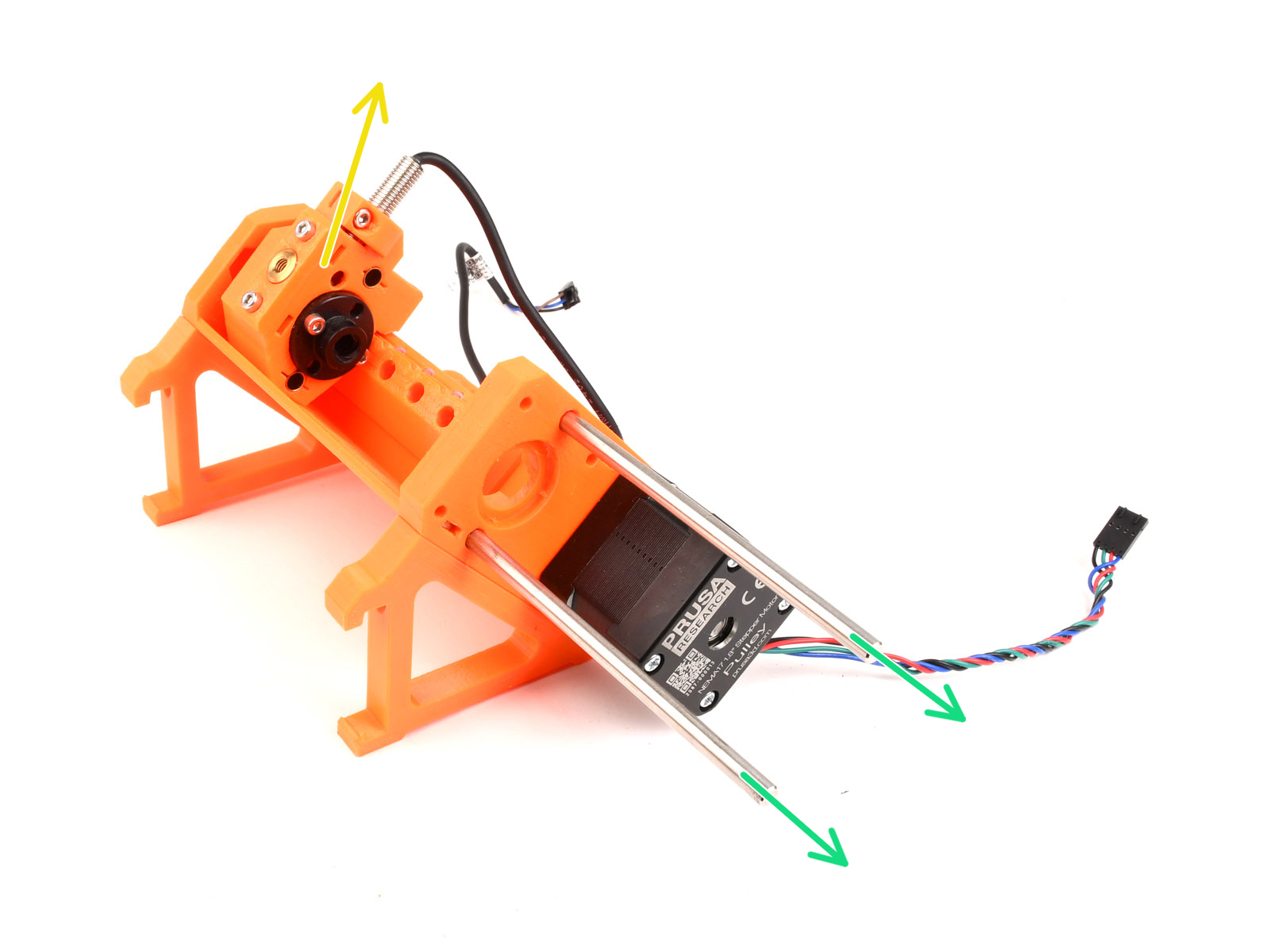

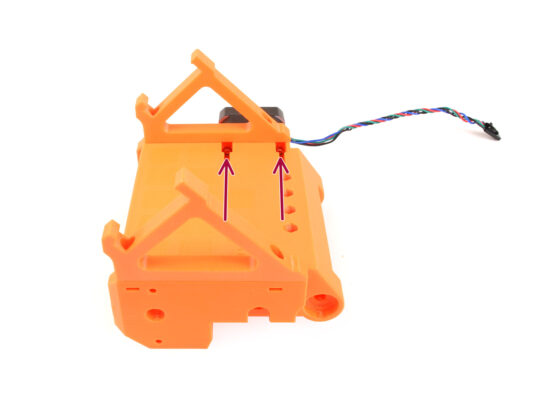

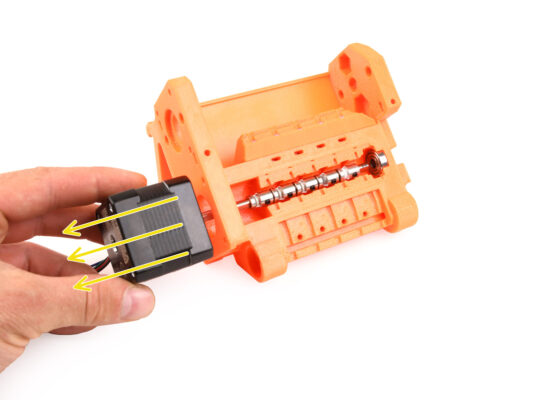

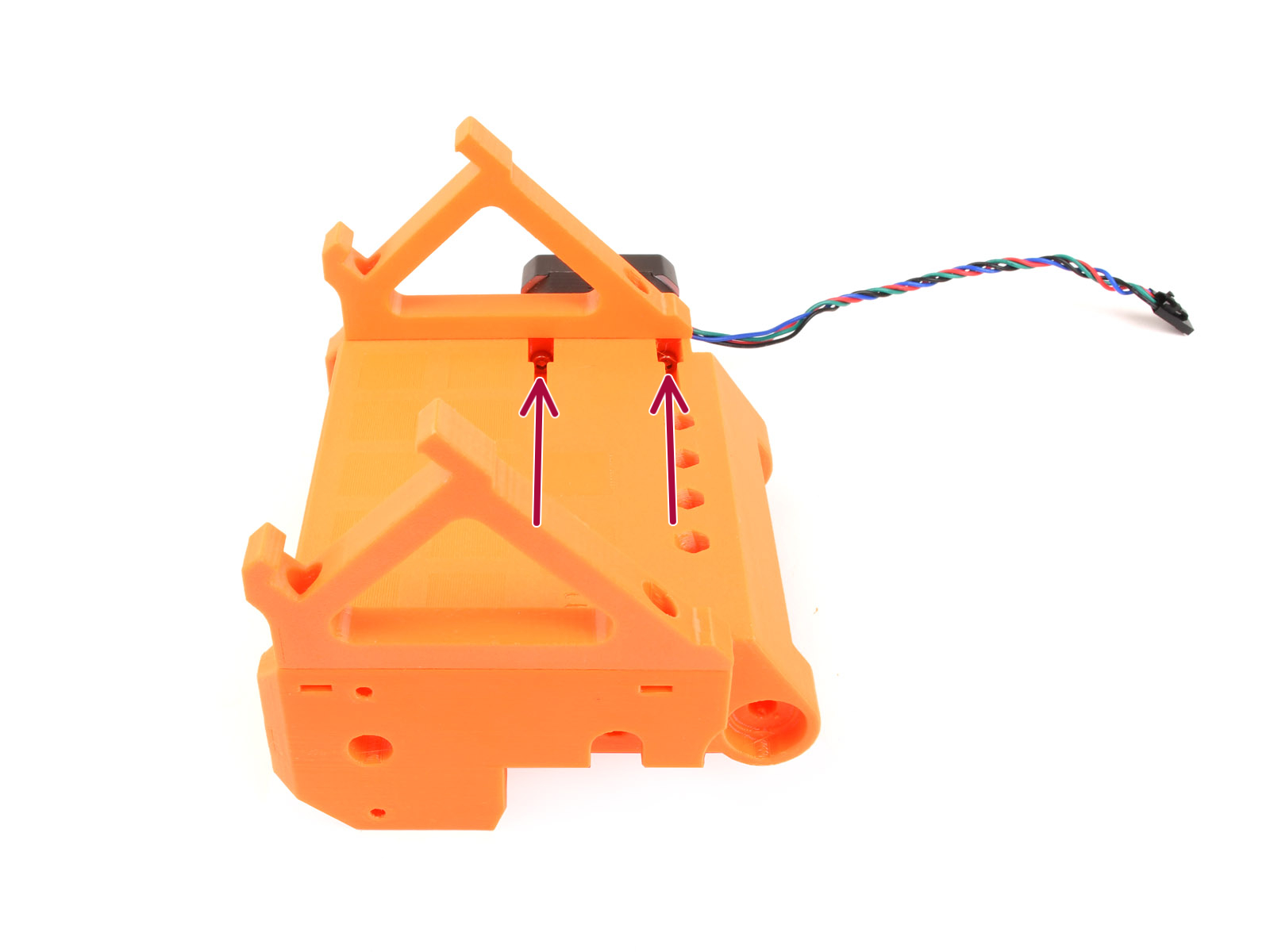

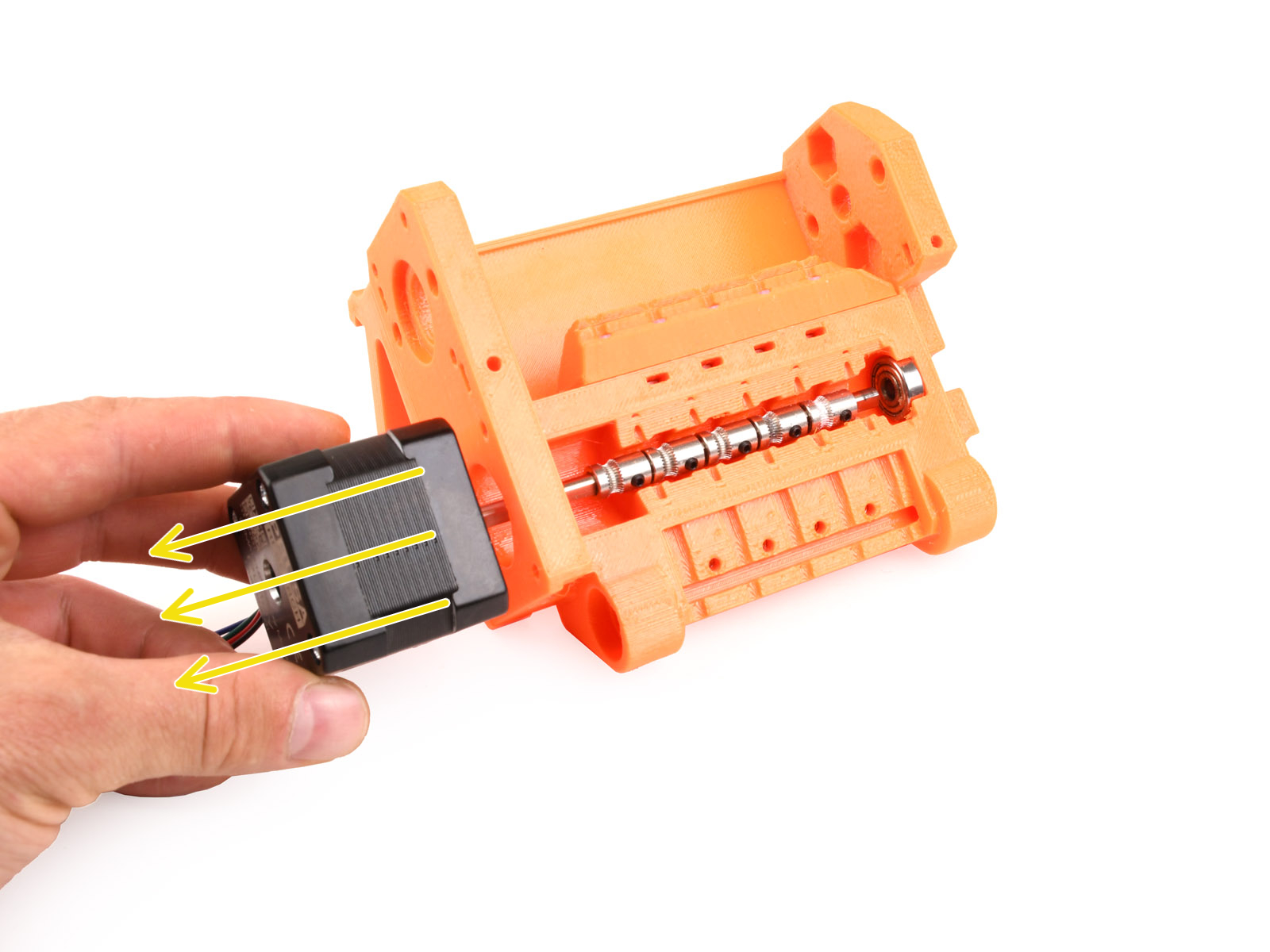

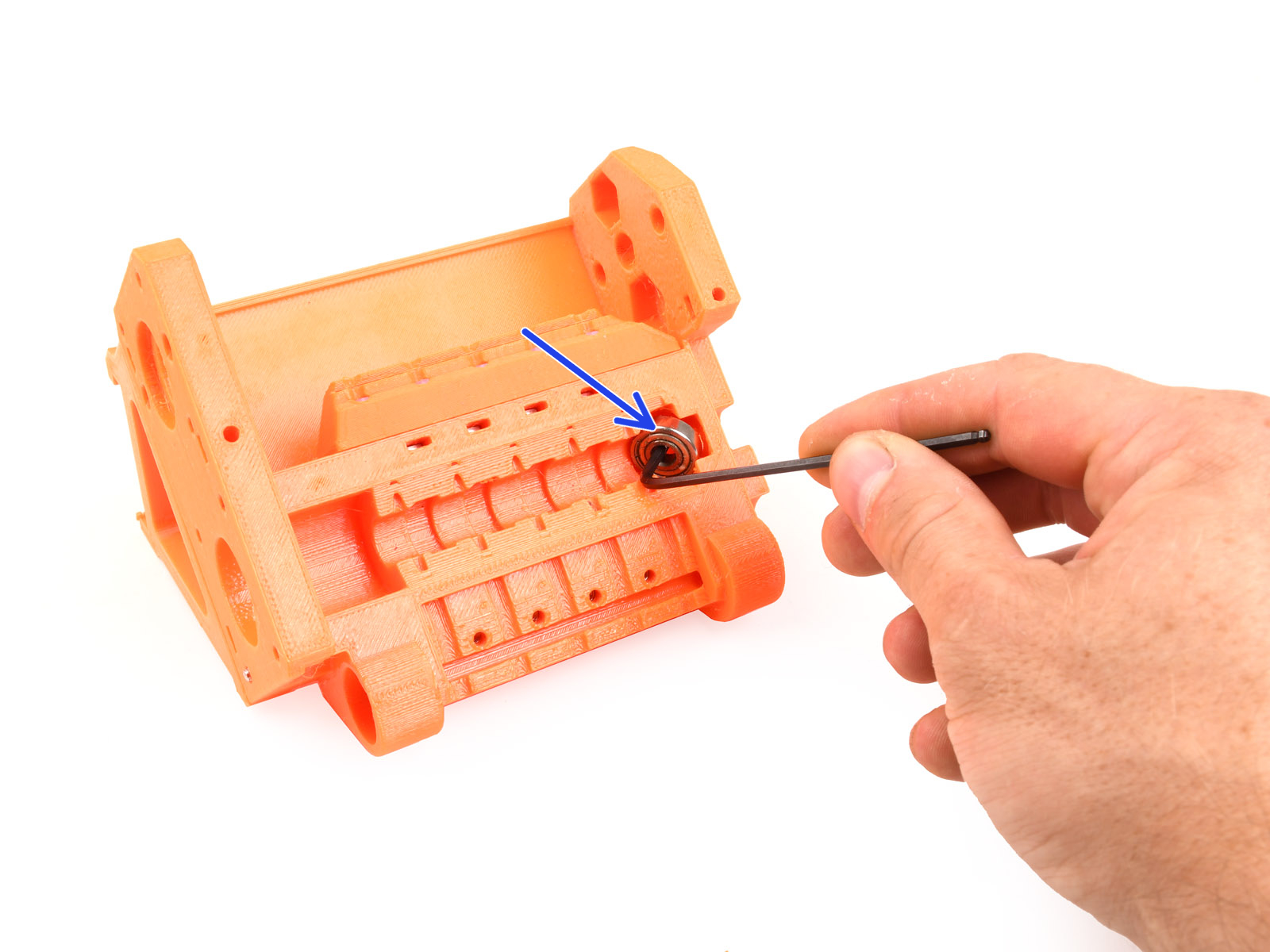

In the upcoming steps, we'll start by detaching the MMU unit from the printer and disconnecting the buffer from it.

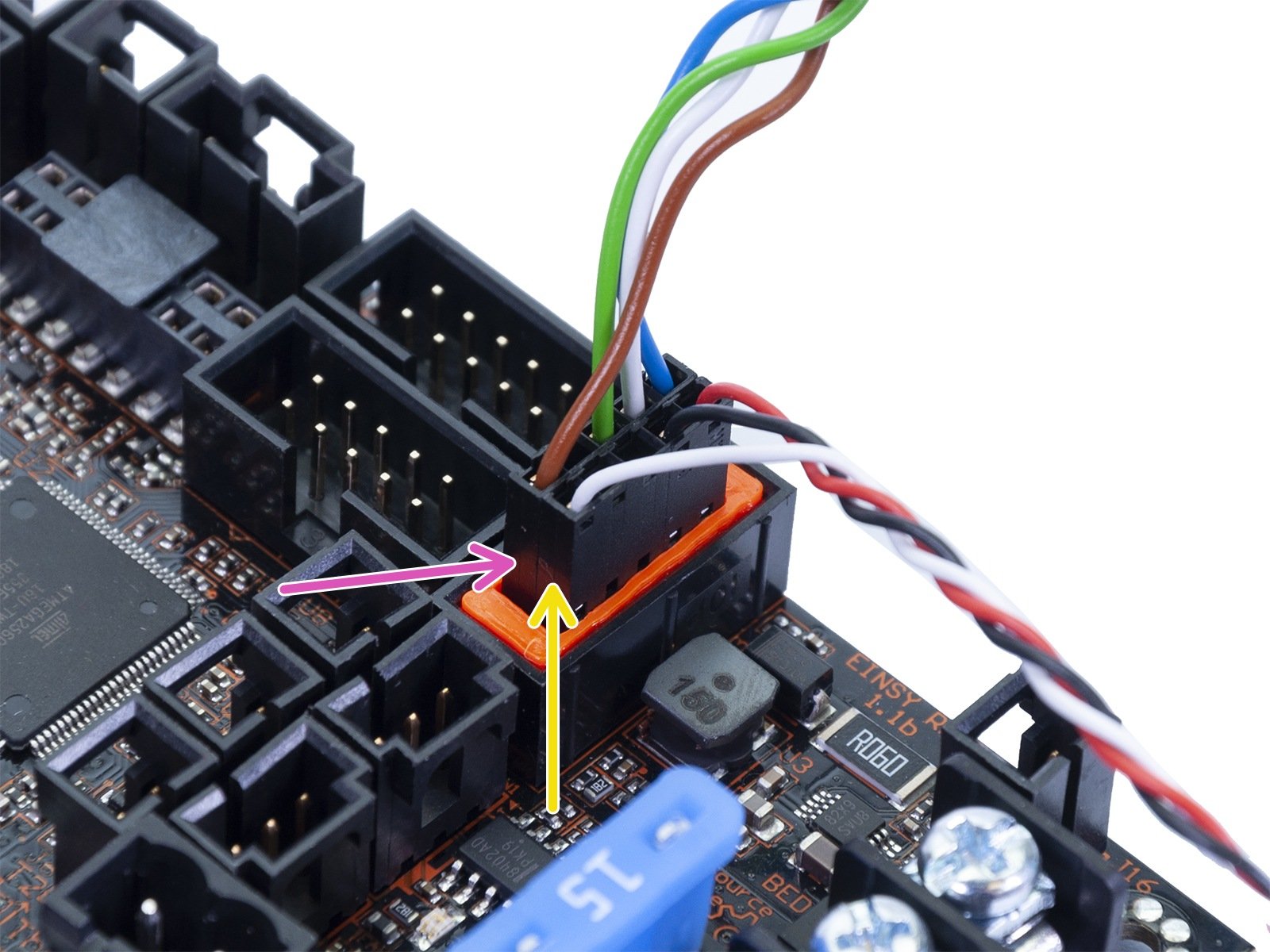

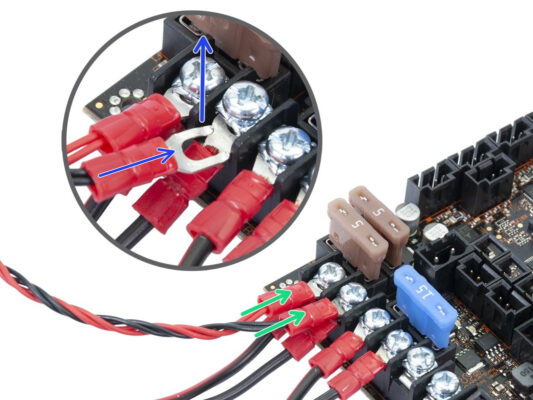

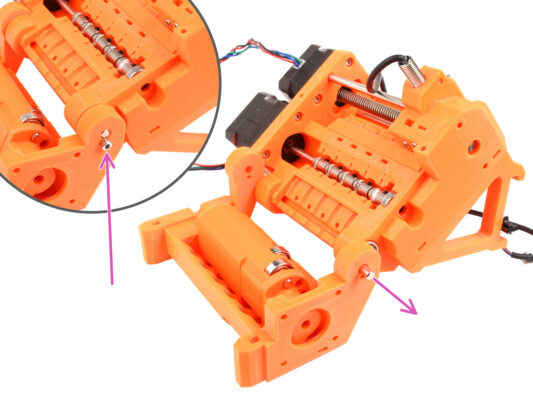

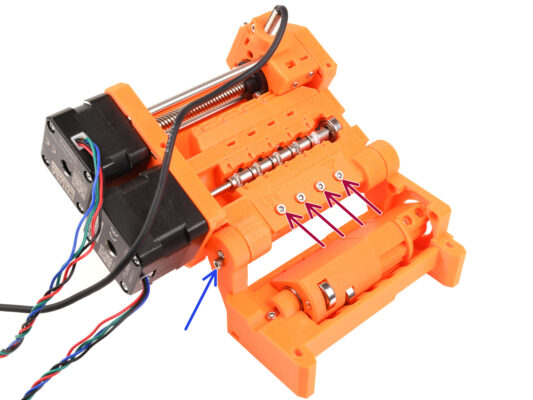

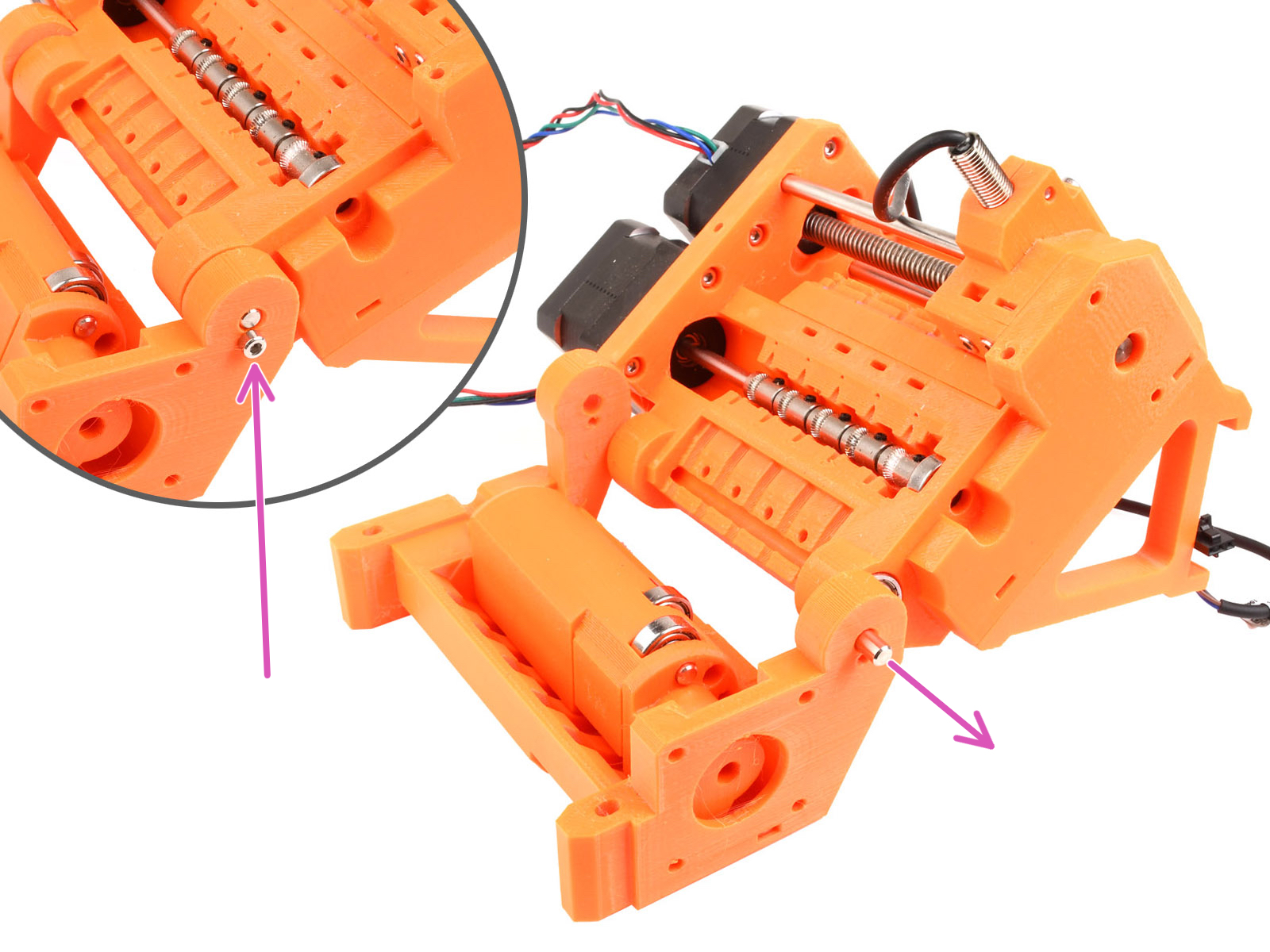

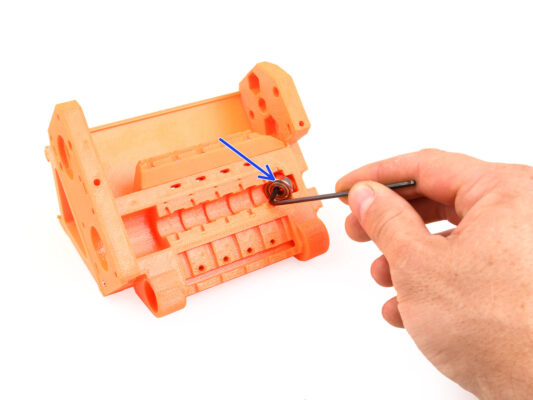

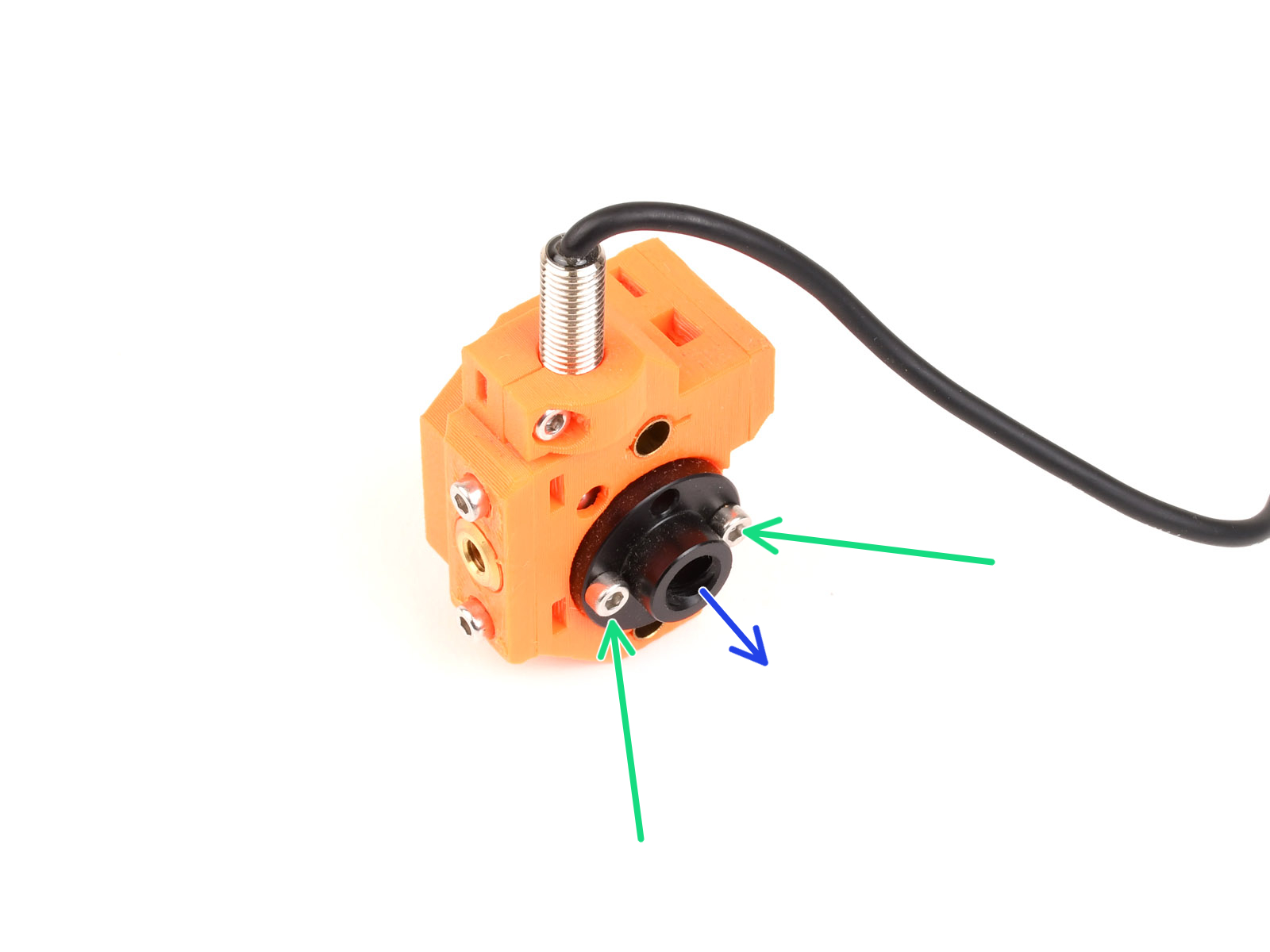

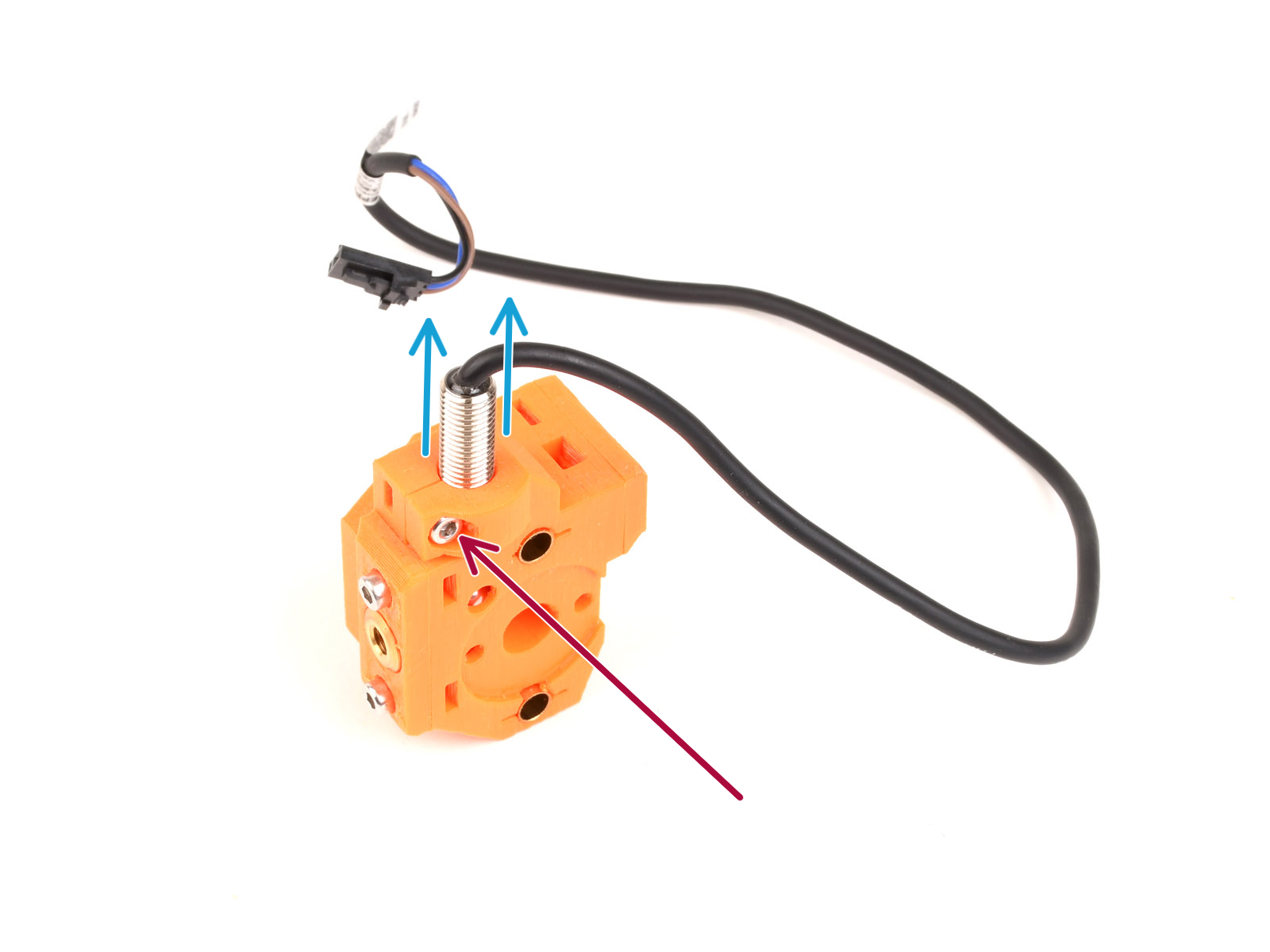

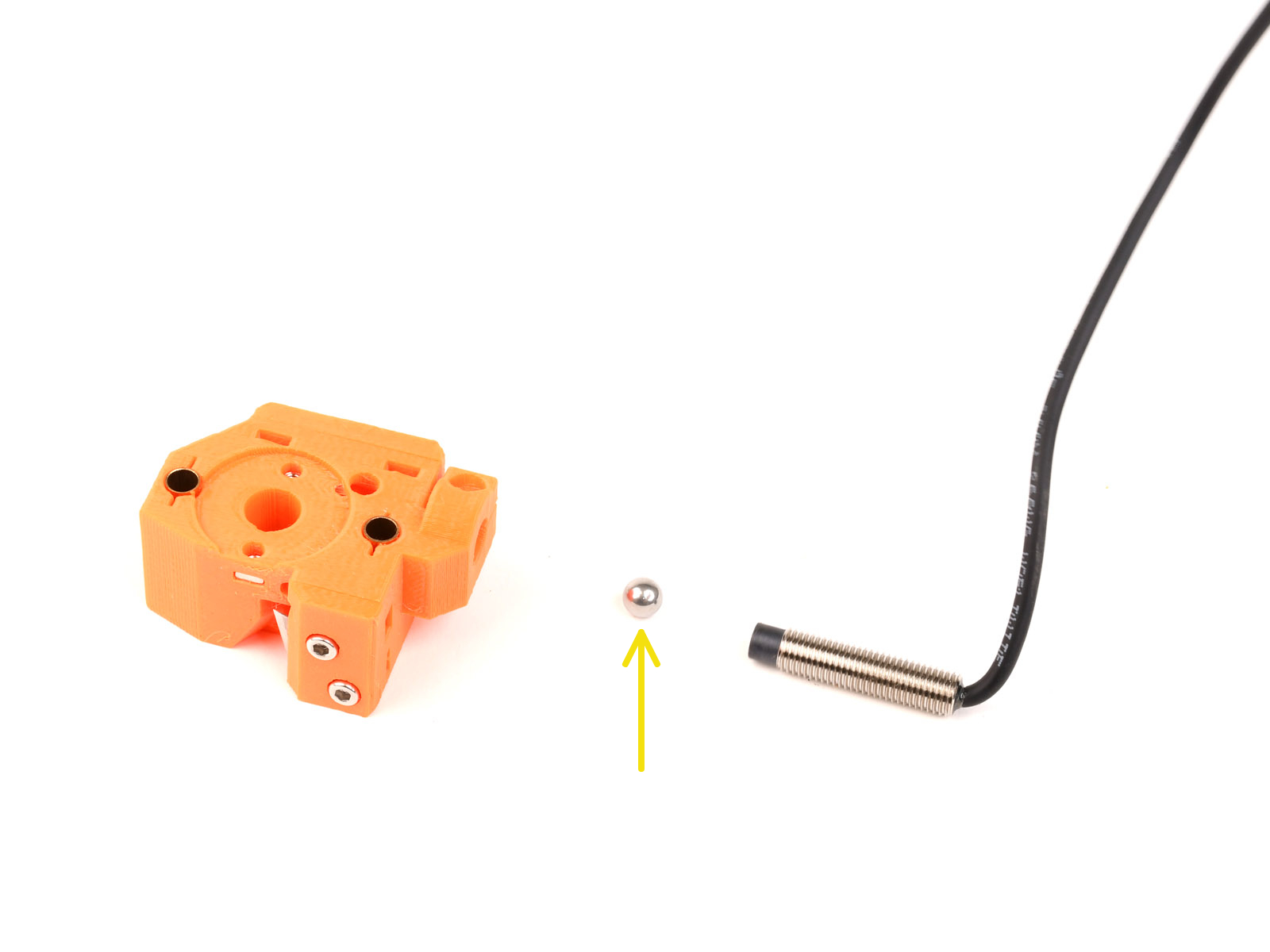

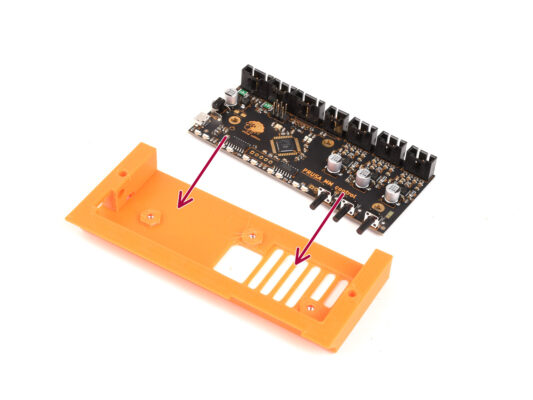

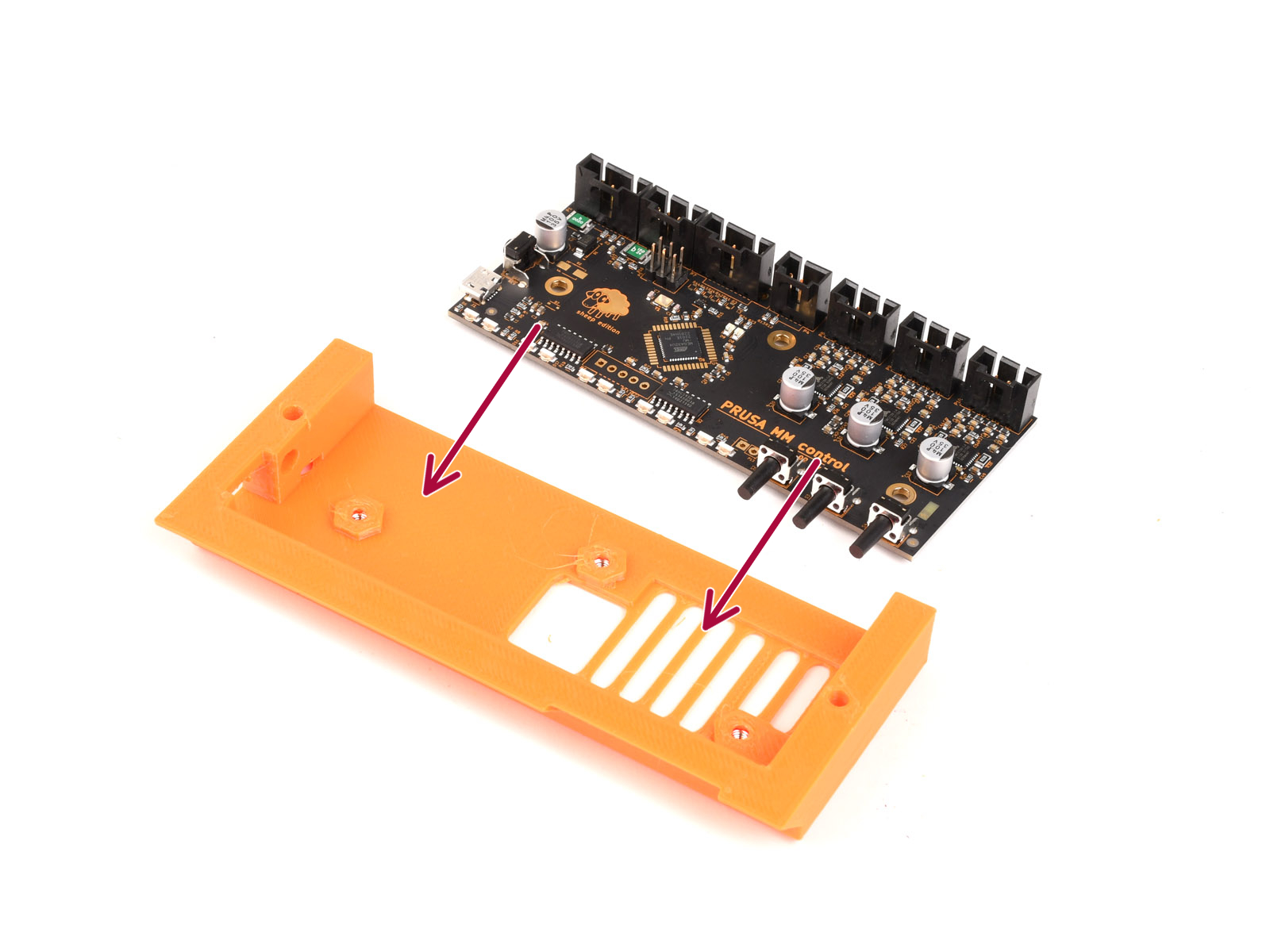

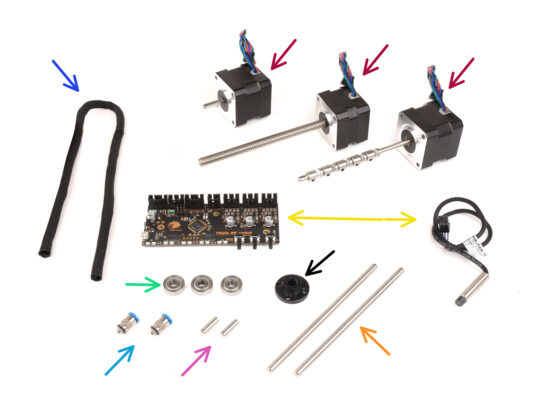

Pay close attention to the description. When instructed, put aside the components from the MMU2S. Specific parts will be used again in a later step.

Maintain a well-organized workspace to avoid mixing older parts with the new ones. Although some new components might resemble the old ones, they are actually distinct. Note that certain components shouldn't be reused for MMU3, while others are necessary for the upgrade.