- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- Home

- MMU3

- Assembly manuals

- Original Prusa MMU3 Assembly

- 4. Idler Body Assembly

4. Idler Body Assembly

- Original Prusa MMU3 Assembly

- 1. Introduction

- 2. MMU2S Disassembly (UPG)

- 3. MMU2S Buffer Disassembly (UPG)

- 4. Idler Body Assembly

- 1. Tools necessary for this chapter

- 2. Idler versions

- 3. Idler parts preparation

- 4. Idler bearings assembly (part 1)

- 5. Idler bearings assembly (part 2)

- 6. Idler center bearing assembly

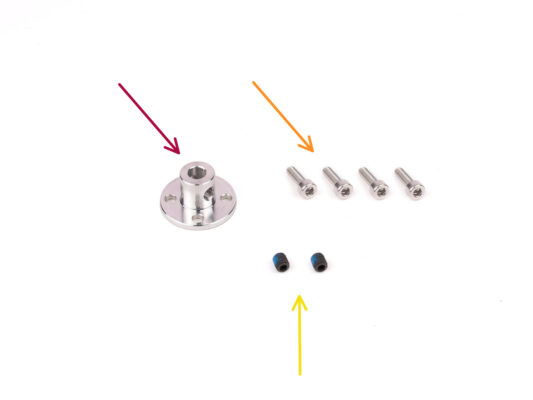

- 7. Coupler parts preparation

- 8. Coupler preparation

- 9. Coupler assembly

- 10. Final check

- 11. Idler Body parts preparation

- 12. Silicone stopper instalation

- 13. Idler installation

- 14. Idler center shaft assembly

- 15. Idler body M3nS nut

- 16. Idler motor assembly (part 1)

- 17. Idler motor assembly (part 2)

- 18. Idler motor assembly (part 3)

- 5. Selector Assembly

- 6. Pulley Body Assembly

- 7. Cassette Buffer Assembly

- 8. Spool holder Assembly

- 9A. MK4 Nextruder mod

- 9B. MK3S+ / MK3.5 Extruder mod (KIT)

- 9C. MK3S+ Extruder (UPG)

- 10A. MK4 Setup and Calibration

- 10B. MK3S+ Setup and Calibration

- 10C. MK3.5 Setup and Calibration

- 11. First Flight

4. Idler Body Assembly

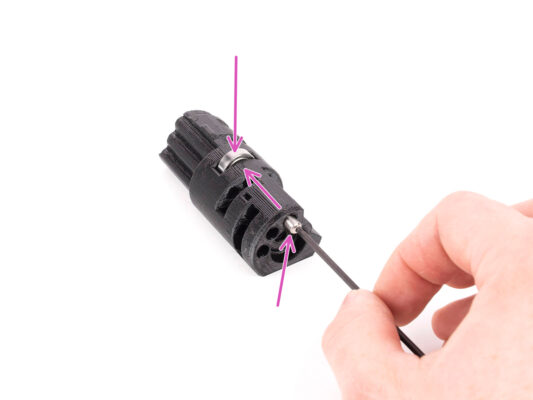

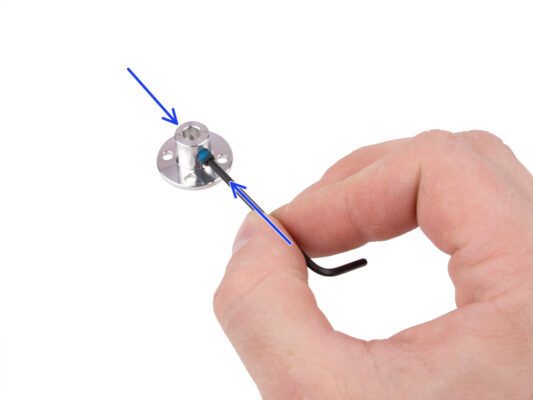

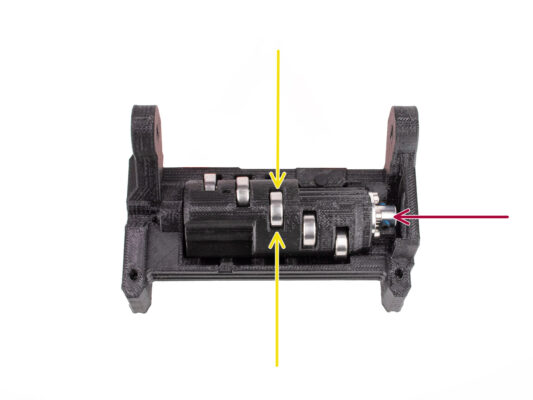

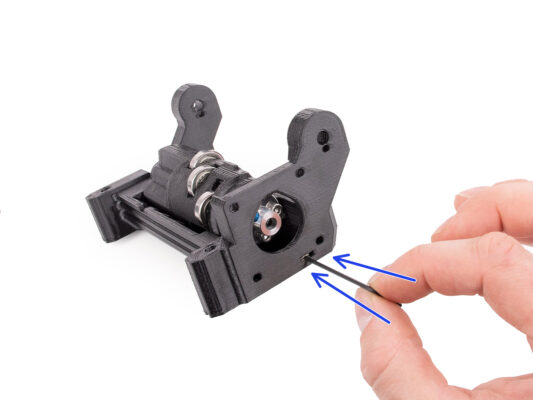

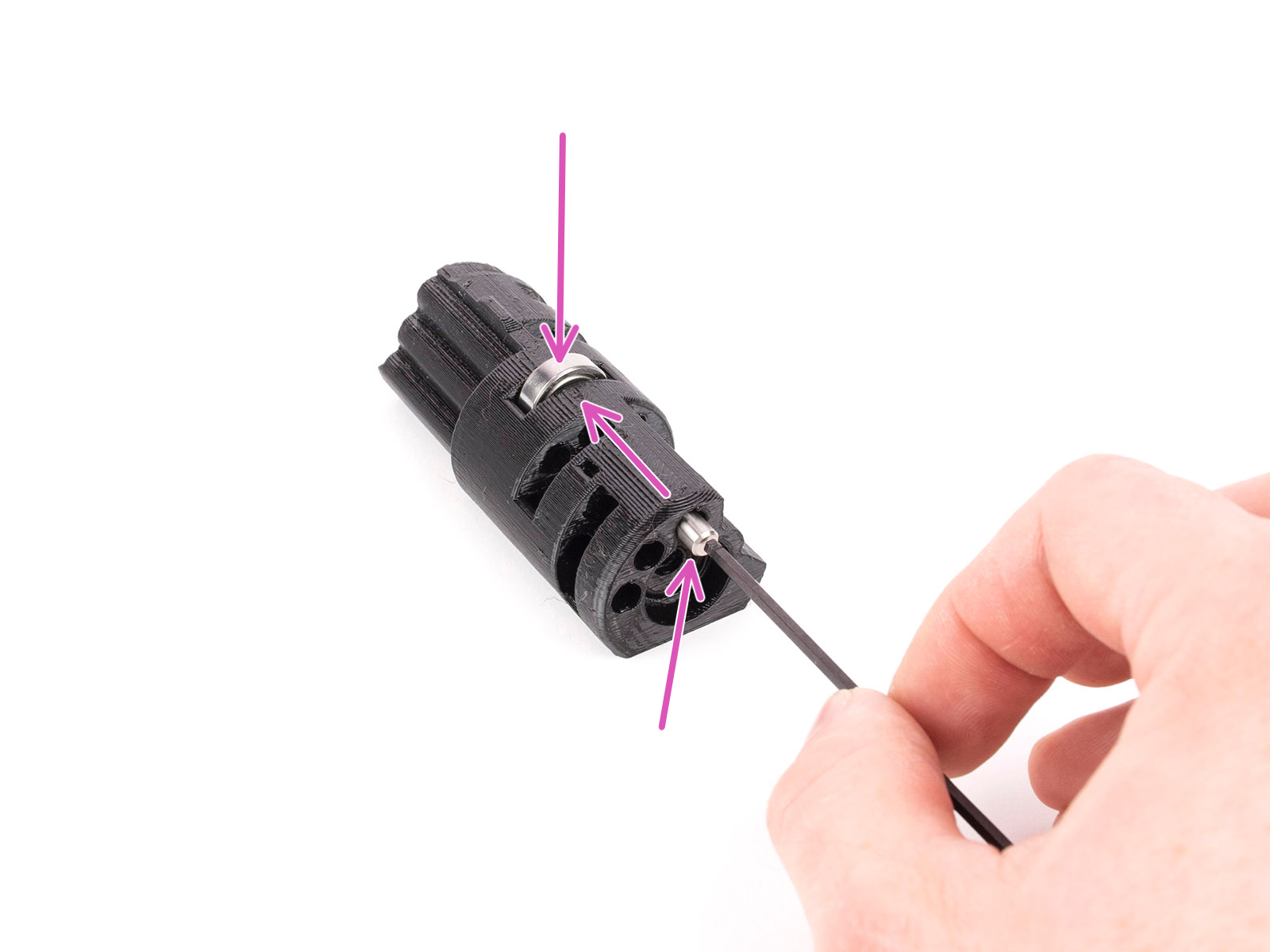

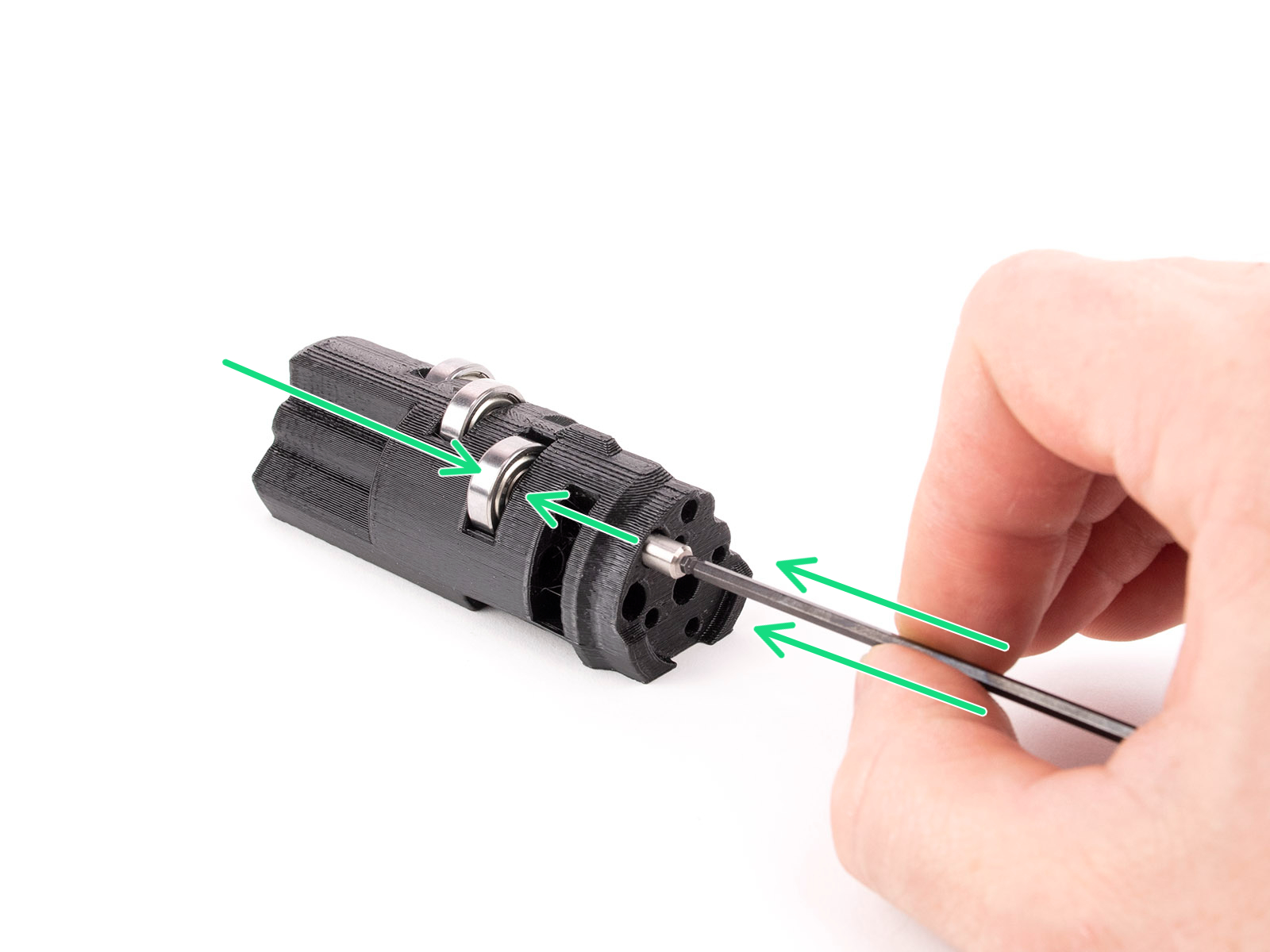

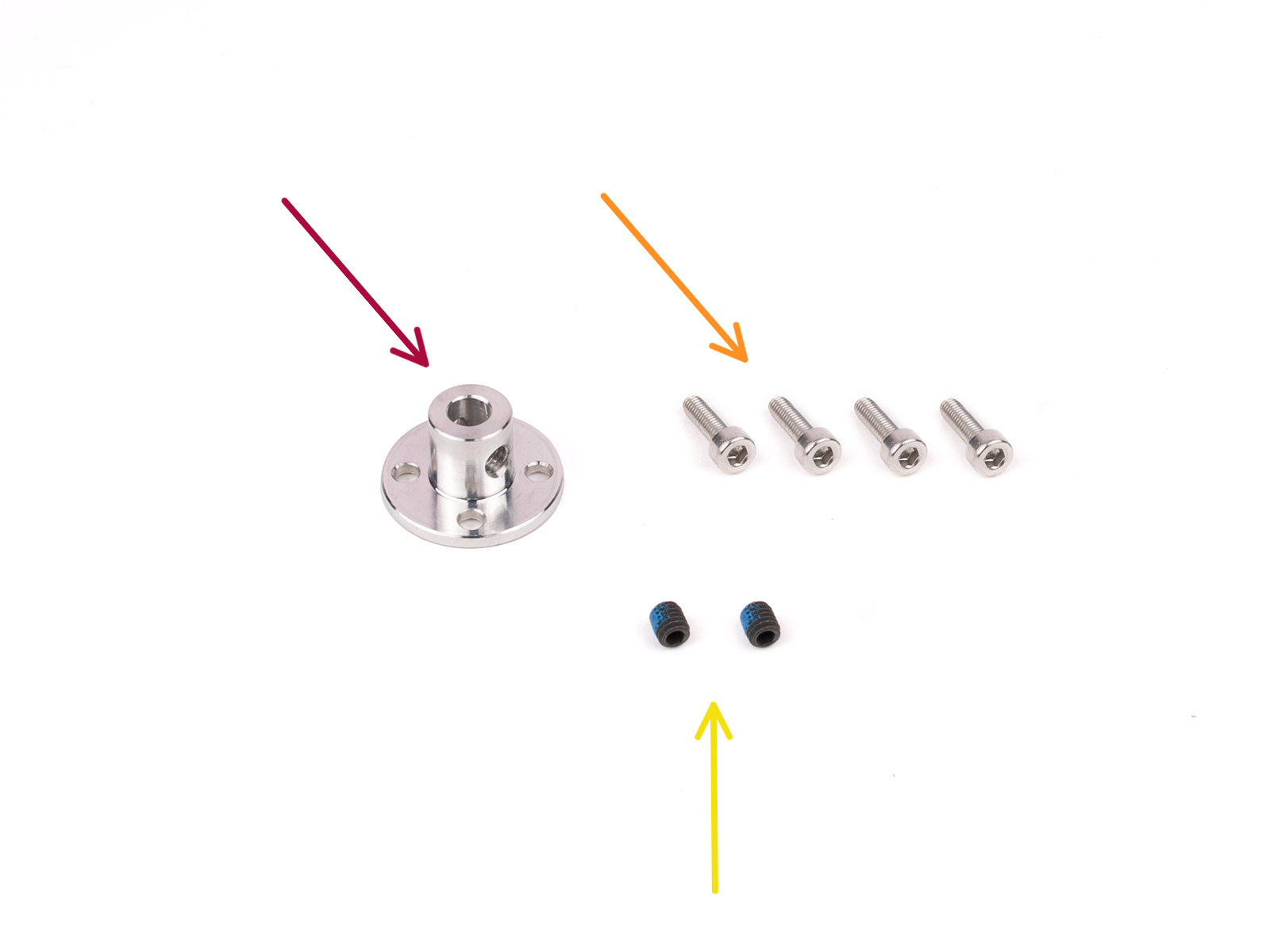

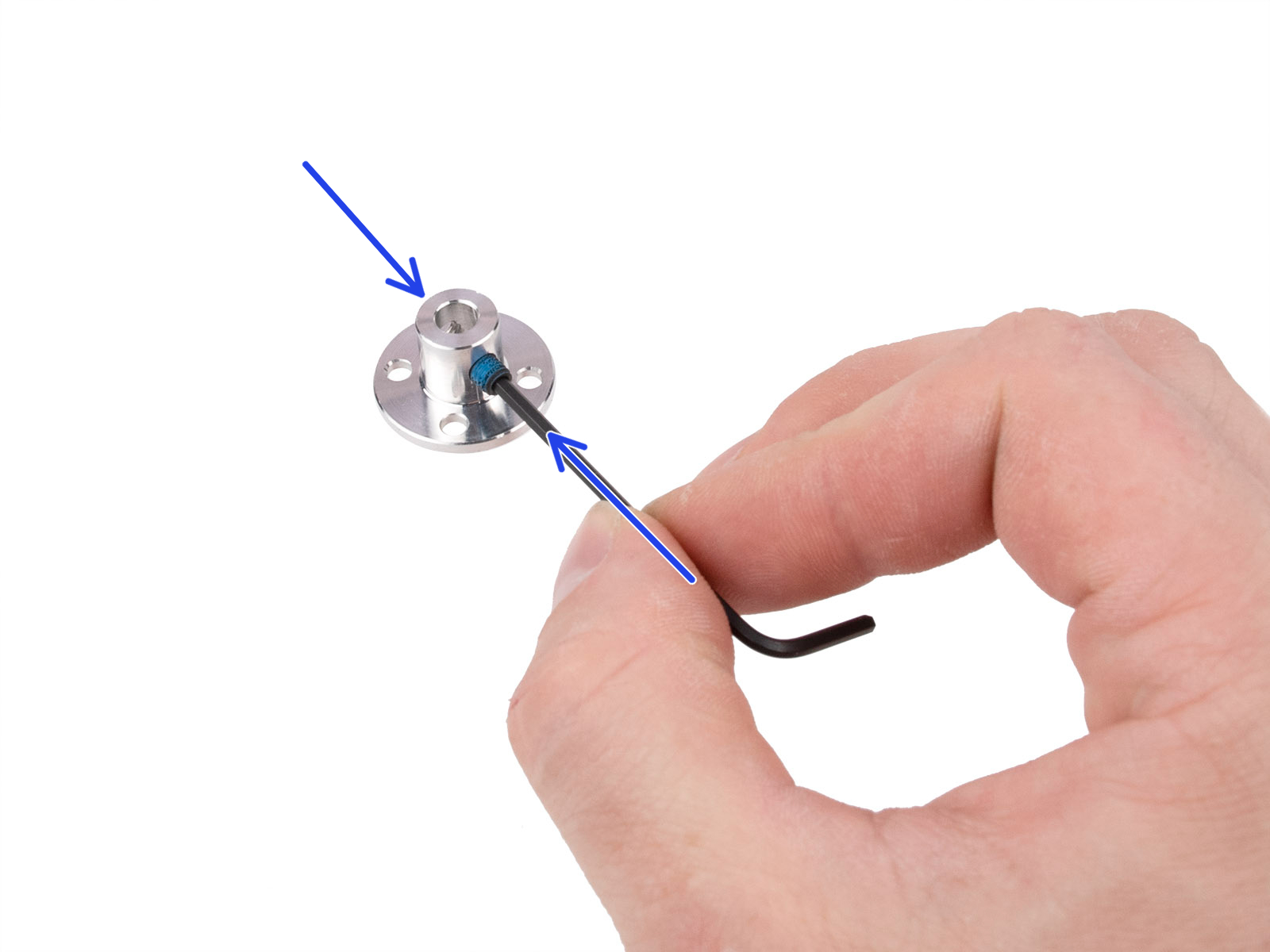

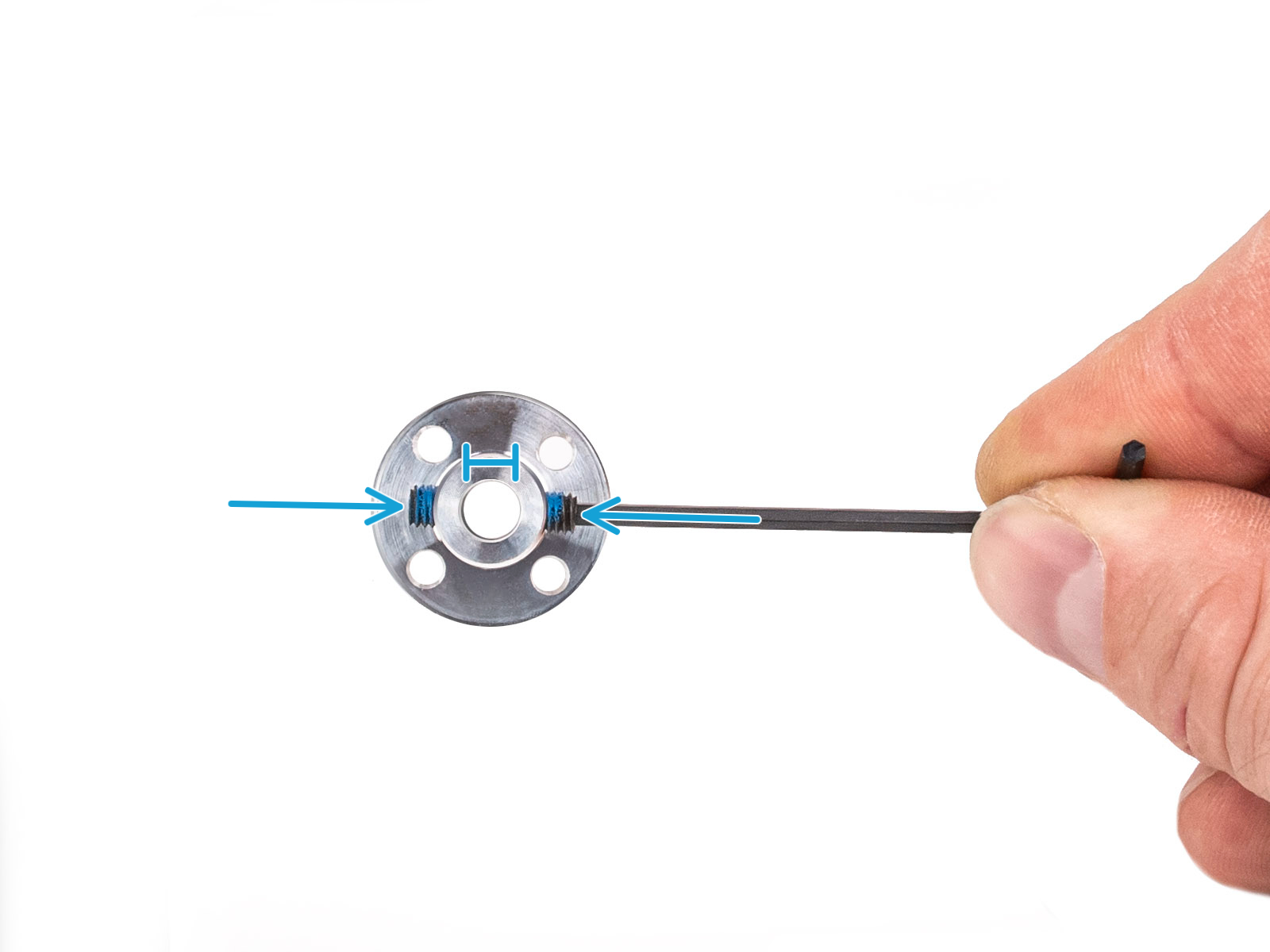

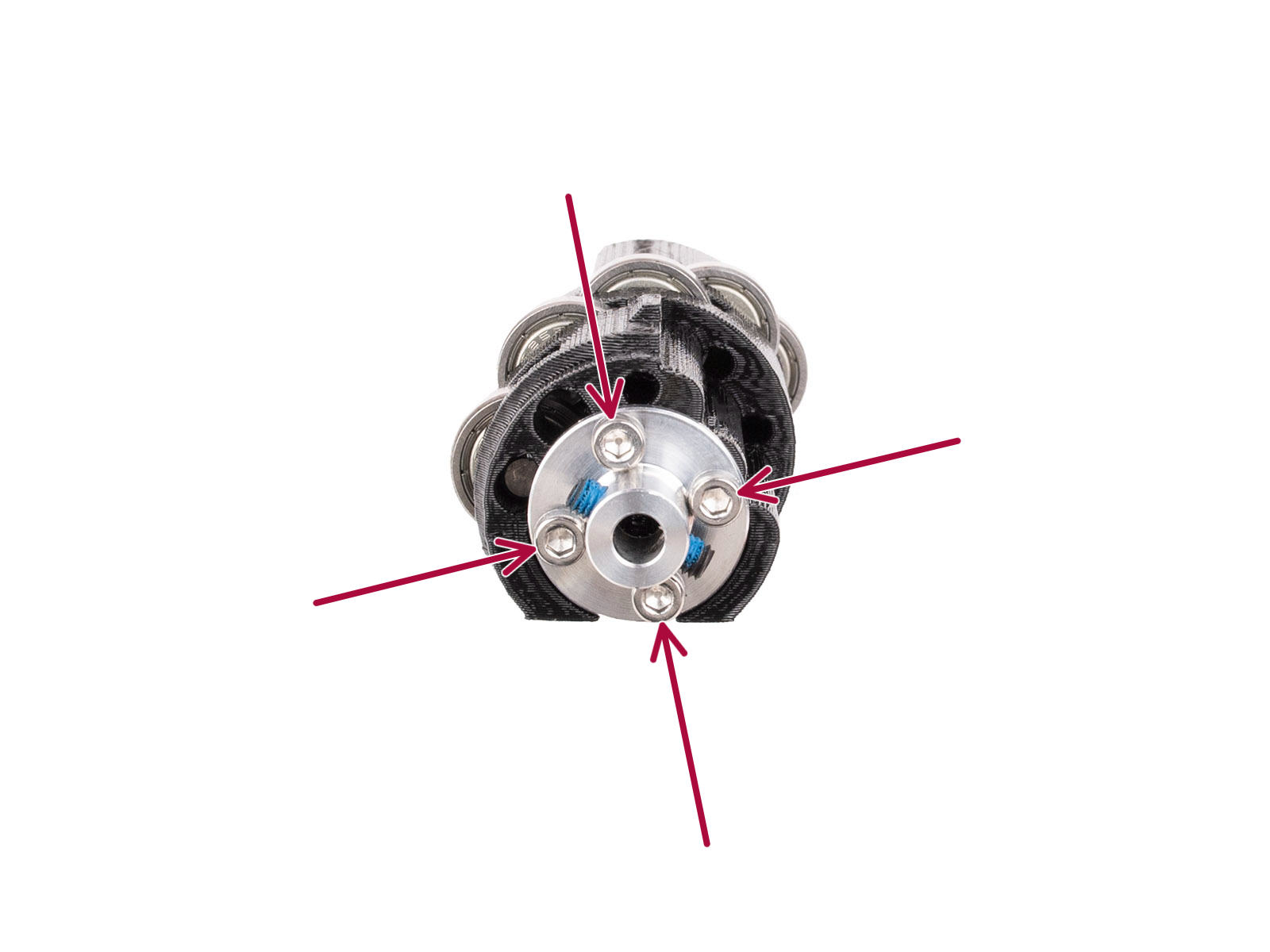

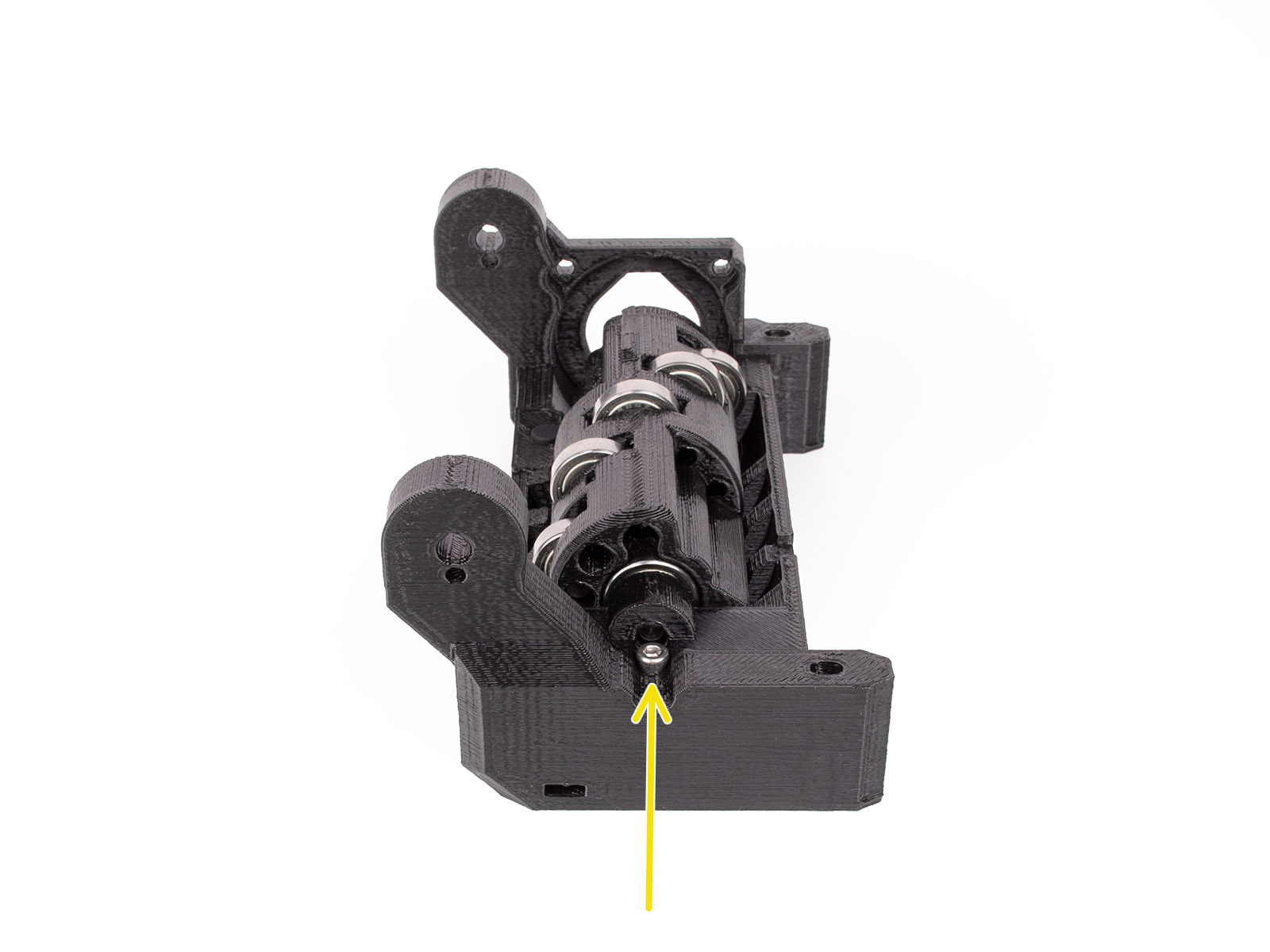

Using the 2mm Allen key, install the M4 grub screws into the threaded openings on the sides of the coupler.

Just start the thread so that the grub screw holds in.

Verify it is seated properly and won't fall out.

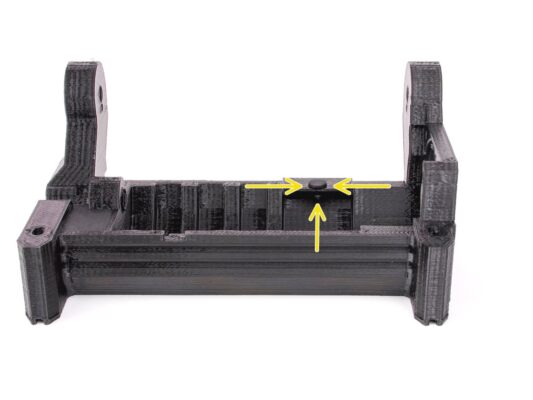

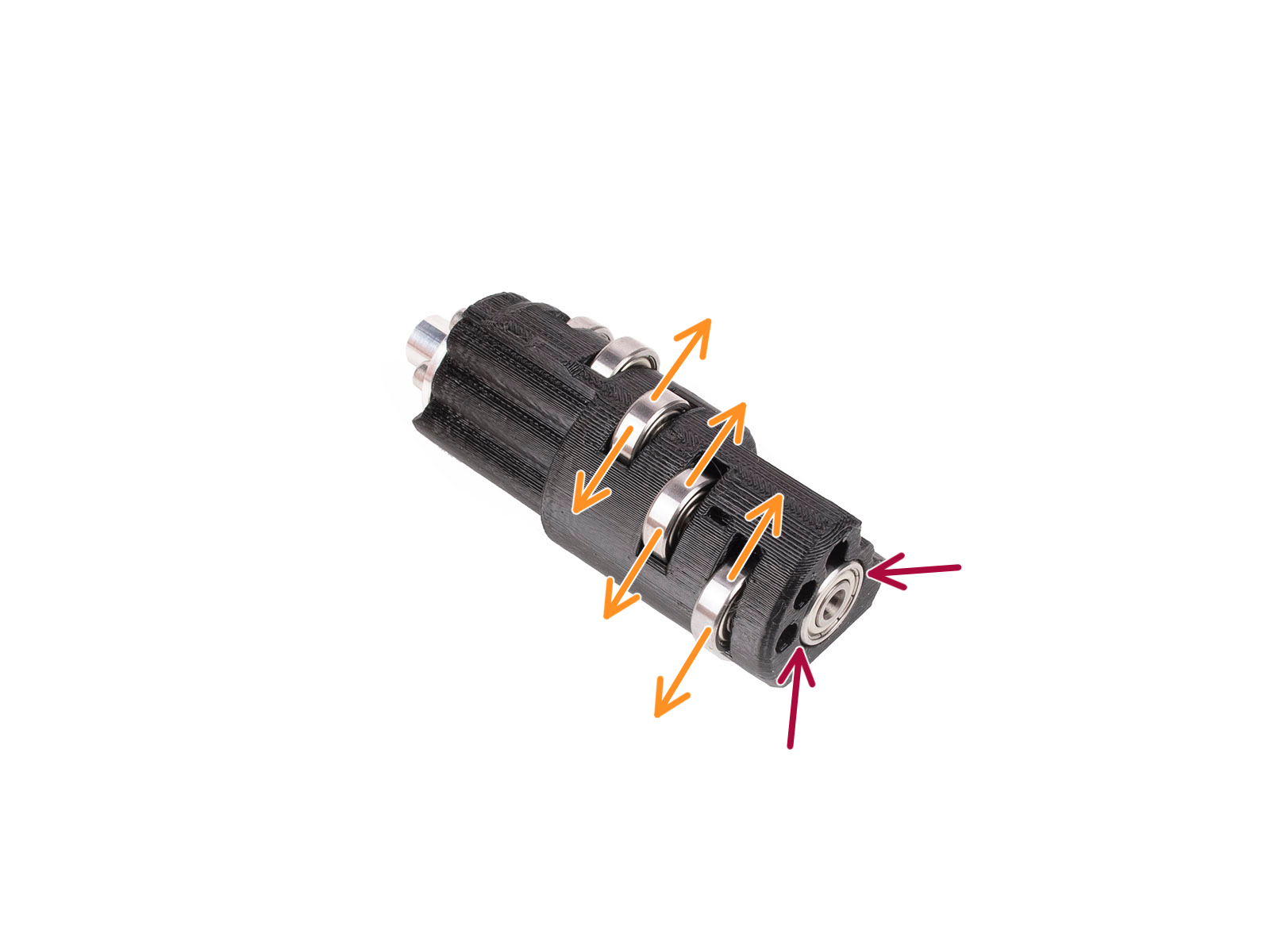

The top part should be flush and there should be bottom part of the stopper visible from the side.

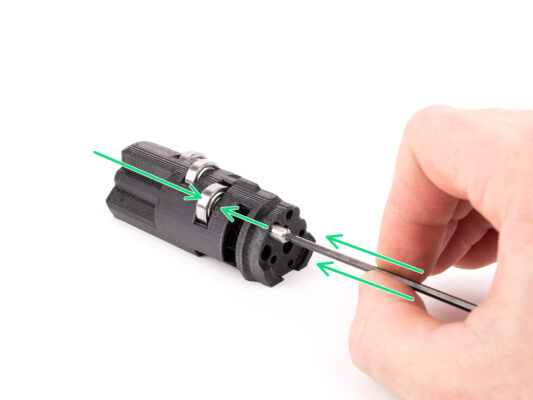

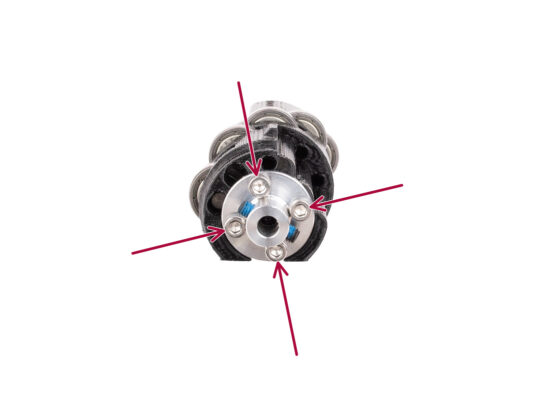

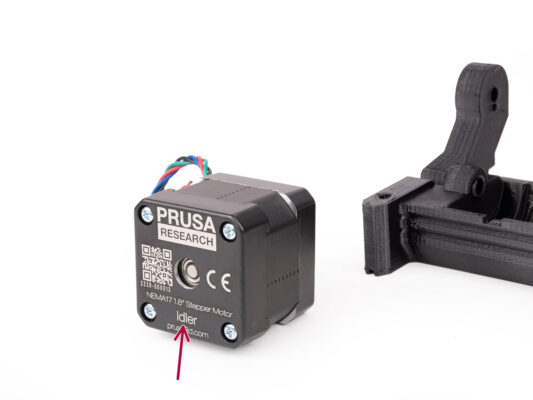

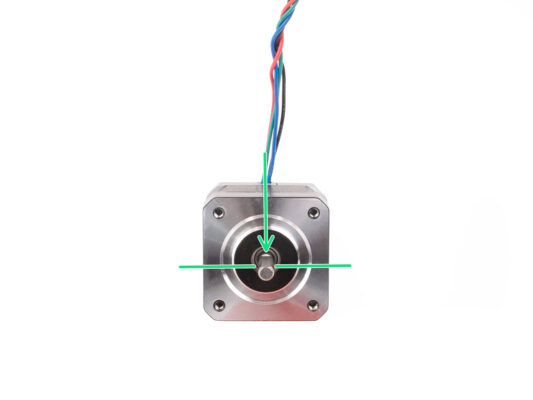

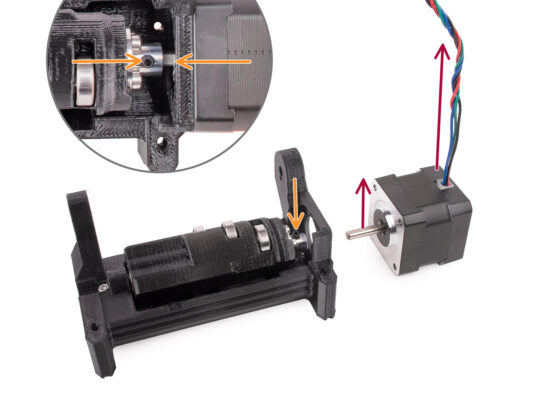

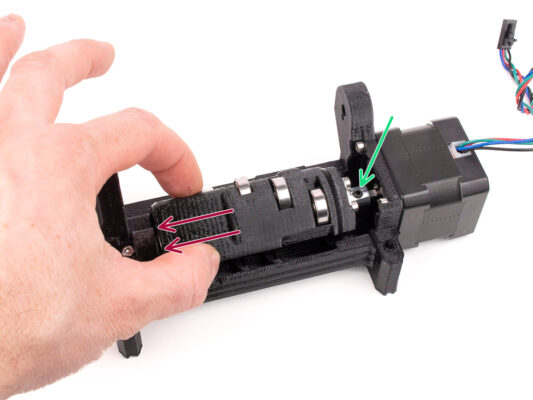

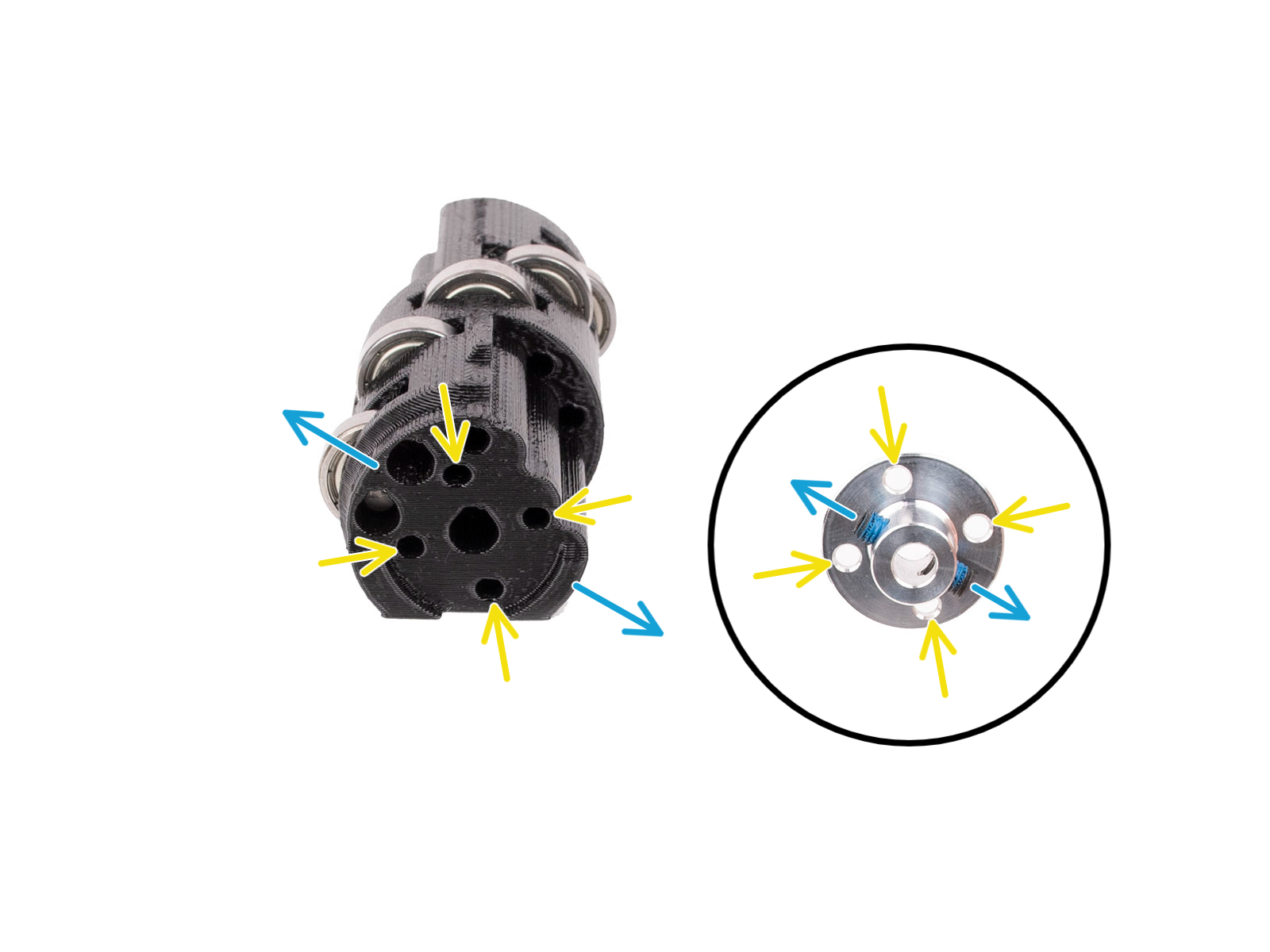

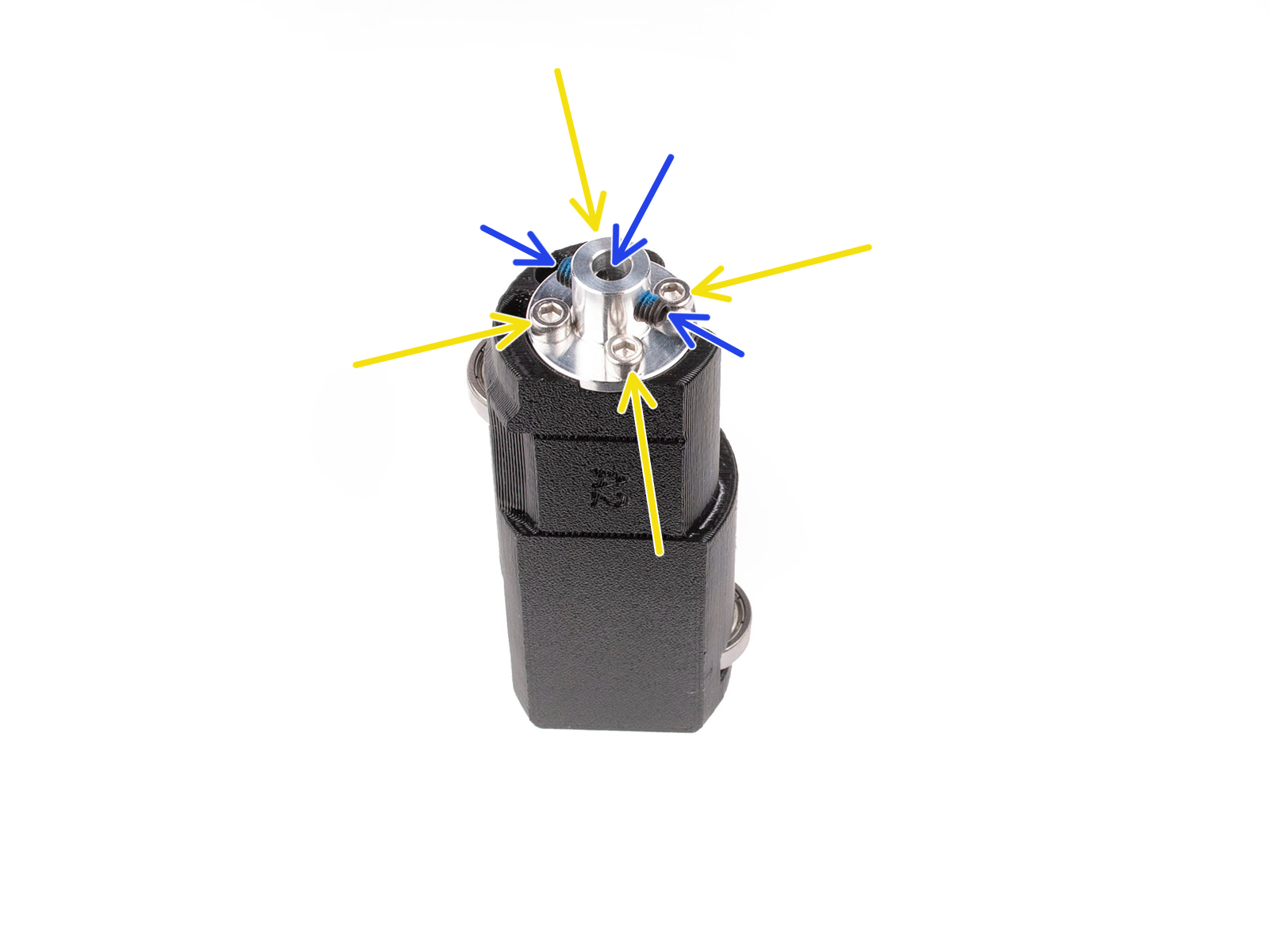

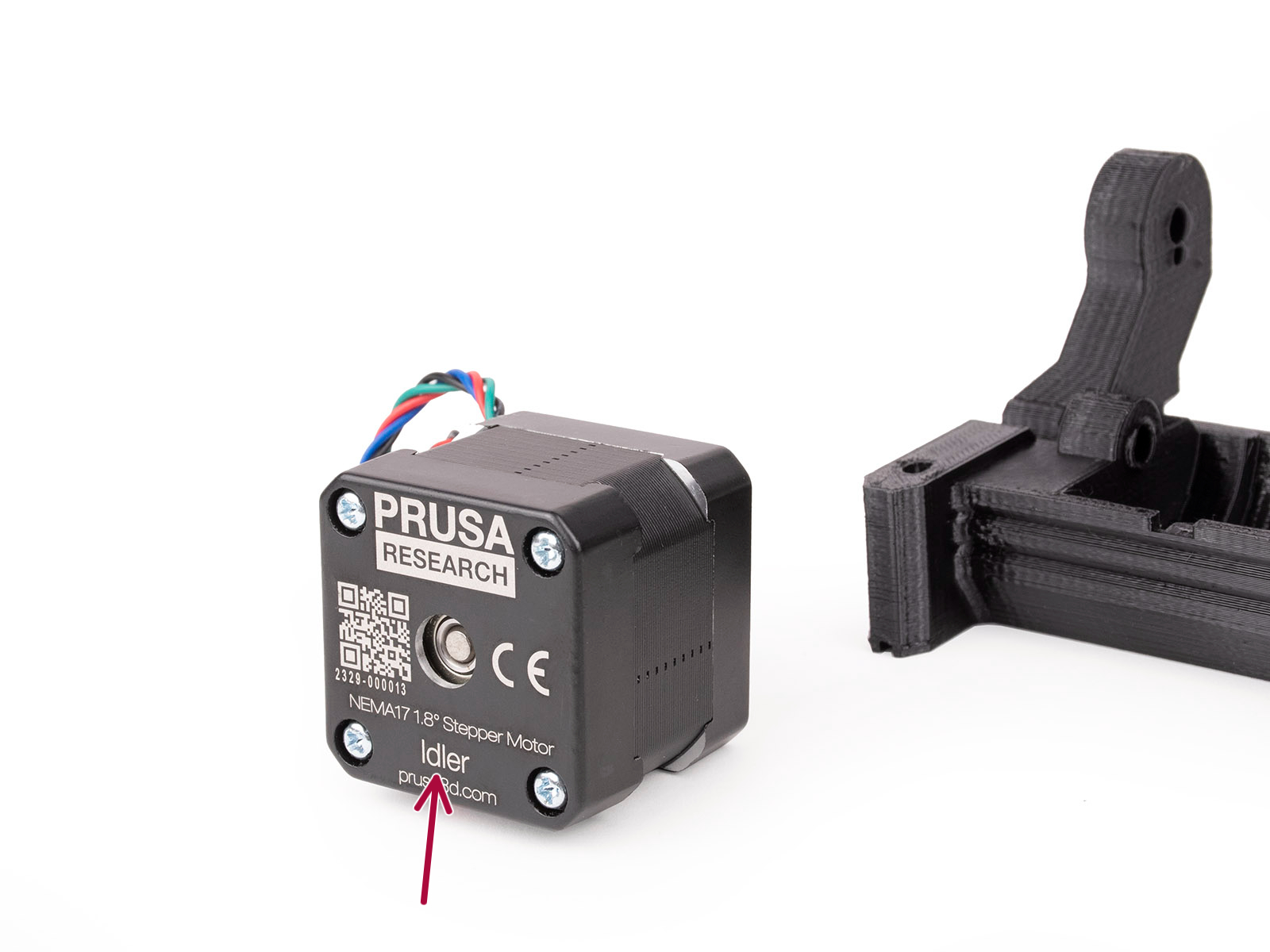

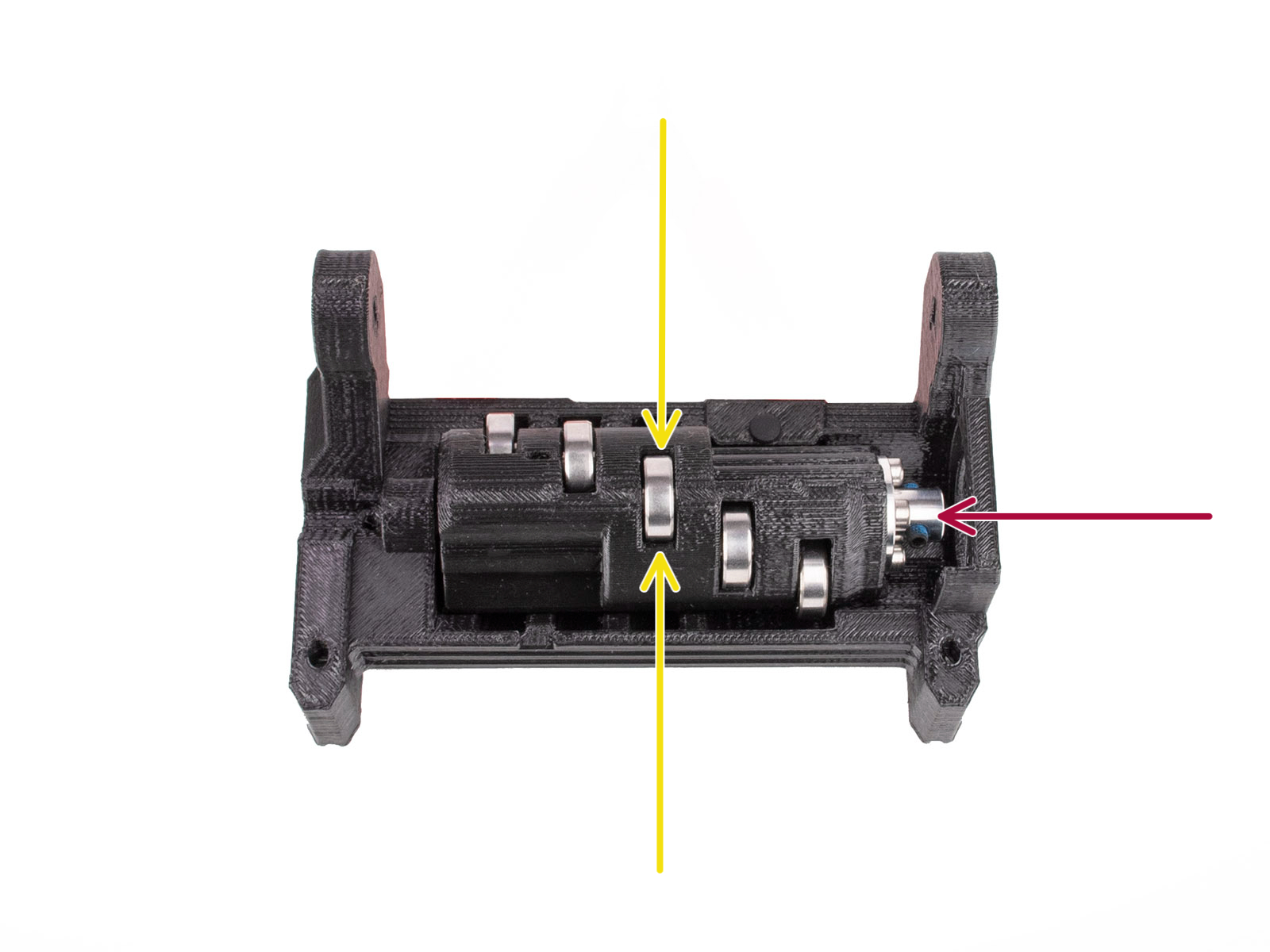

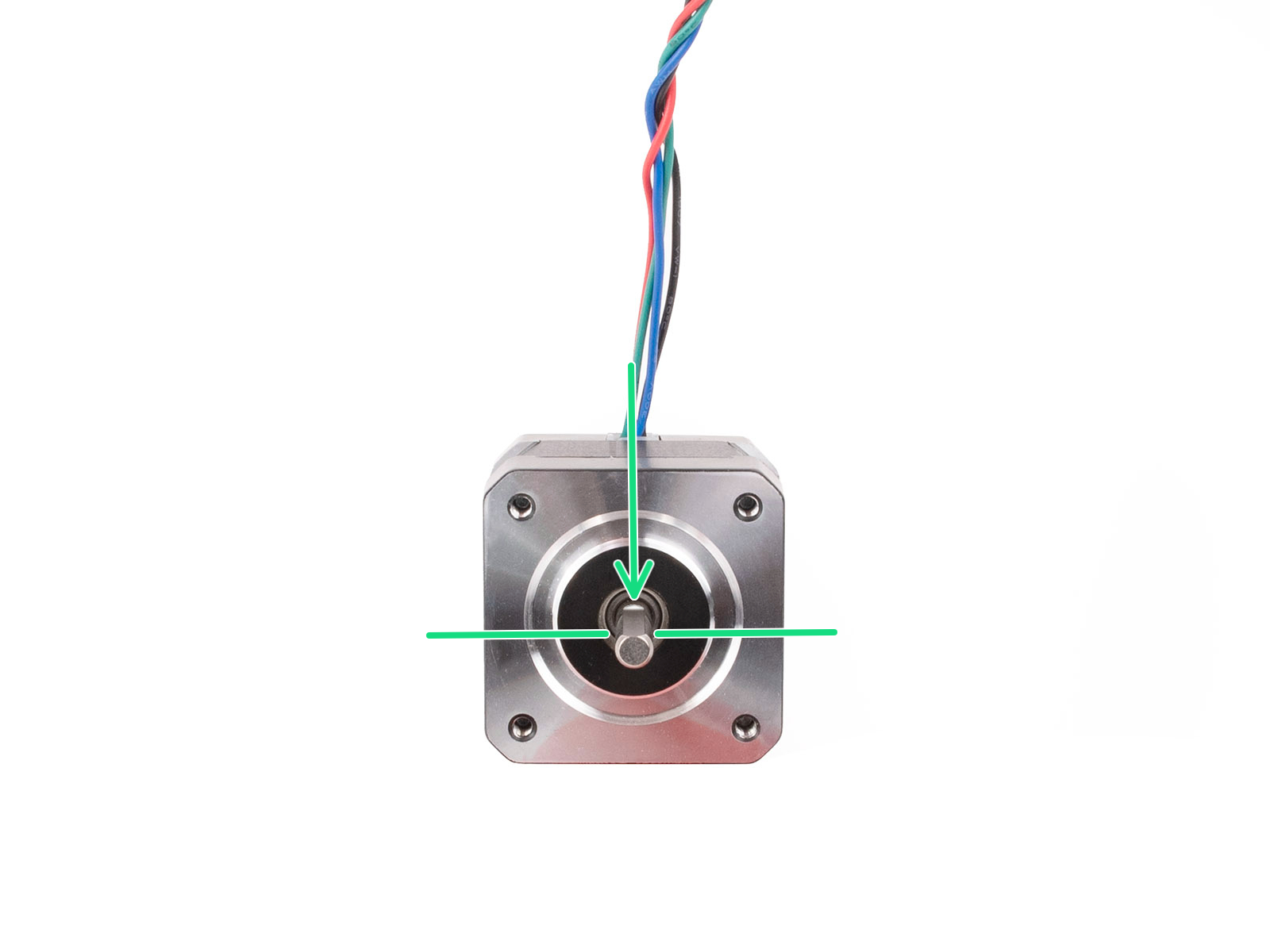

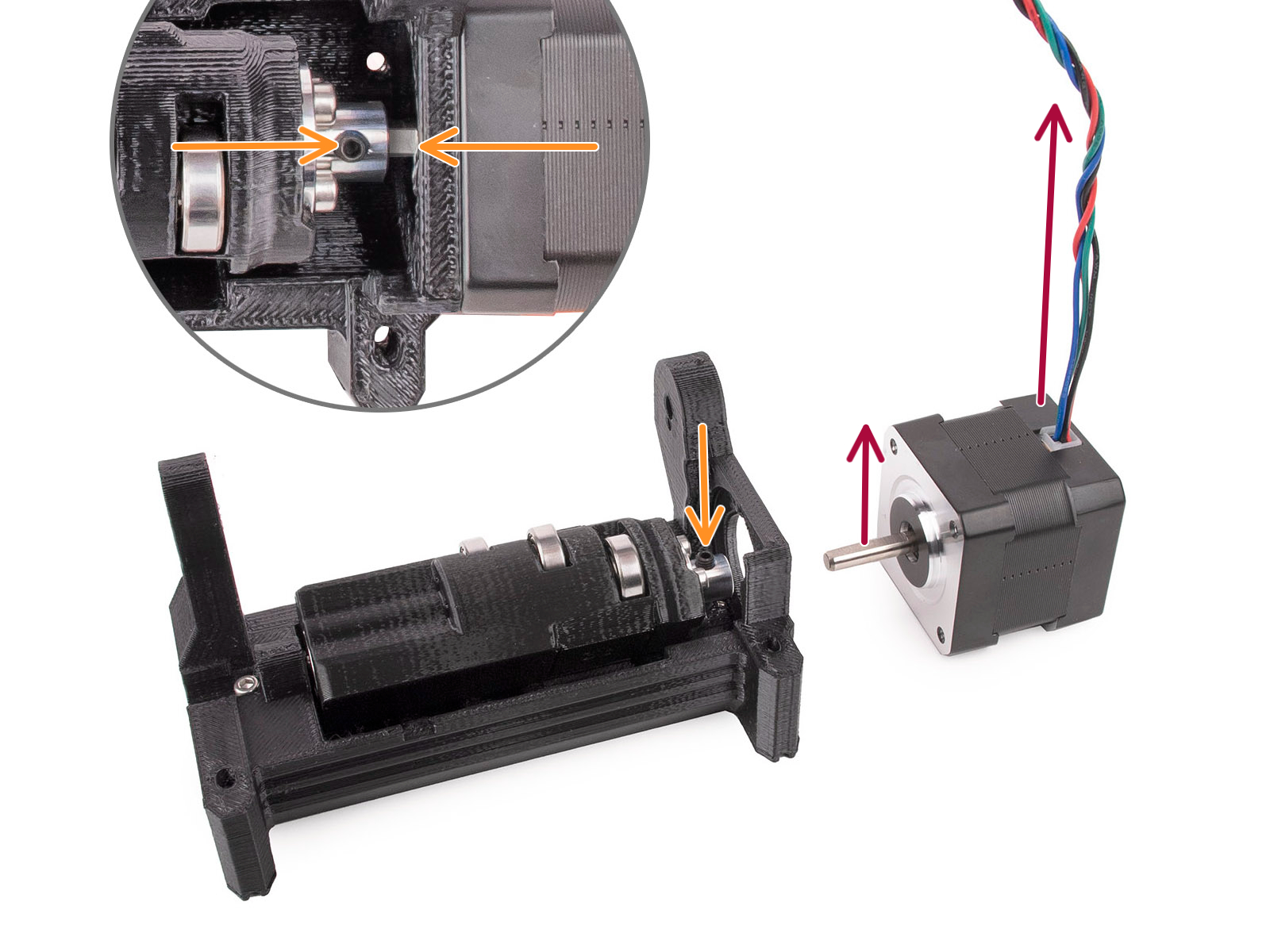

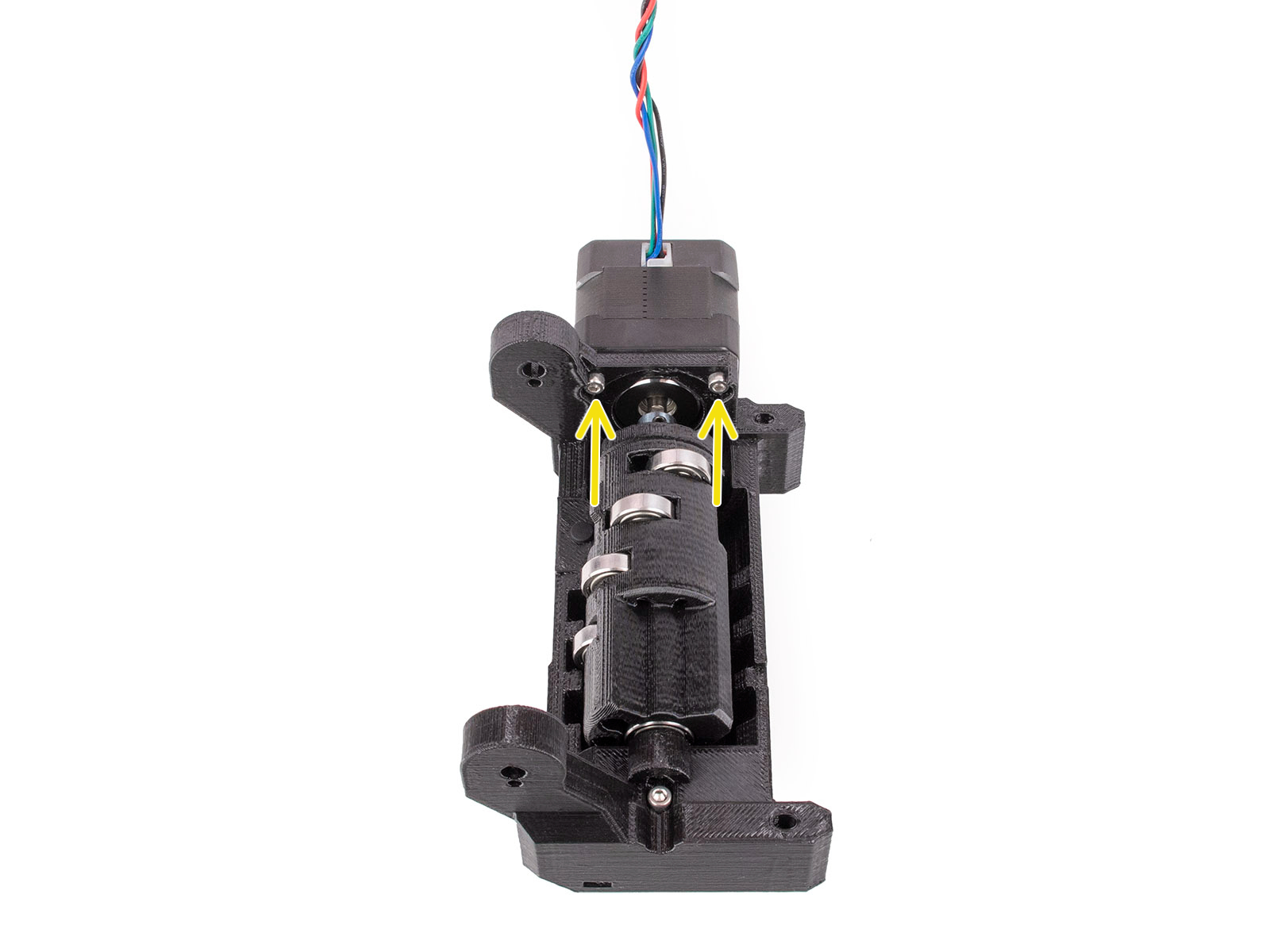

Before you start installing the motor, the flat part of the motor shaft must be aligned with one of the two grub screws in the metal coupler.

Orient the coupler so that one of the grub screws is pointing up.

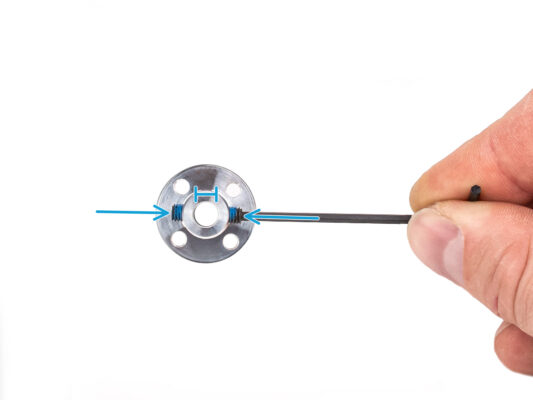

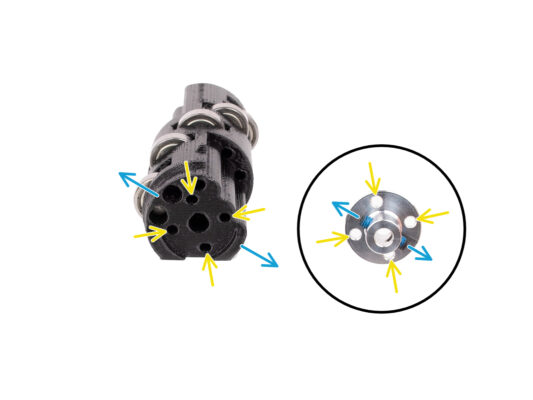

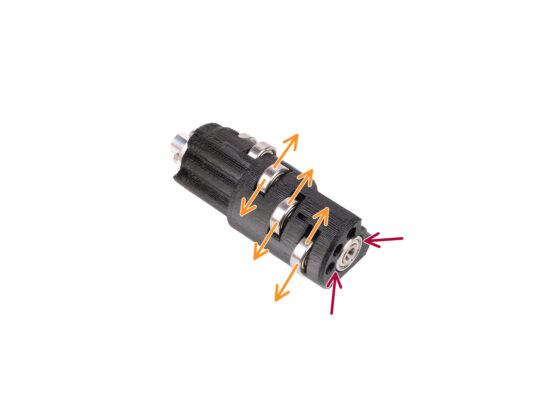

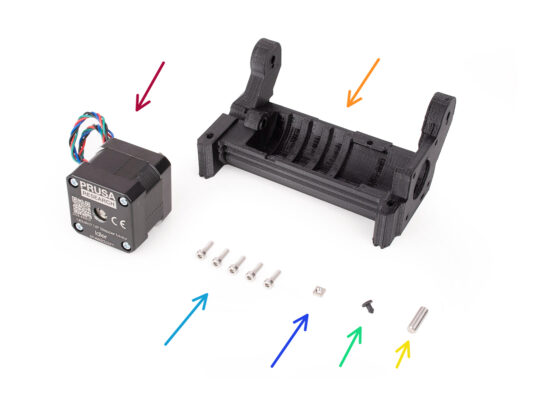

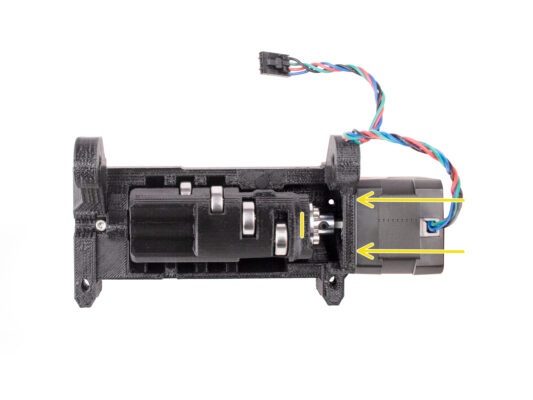

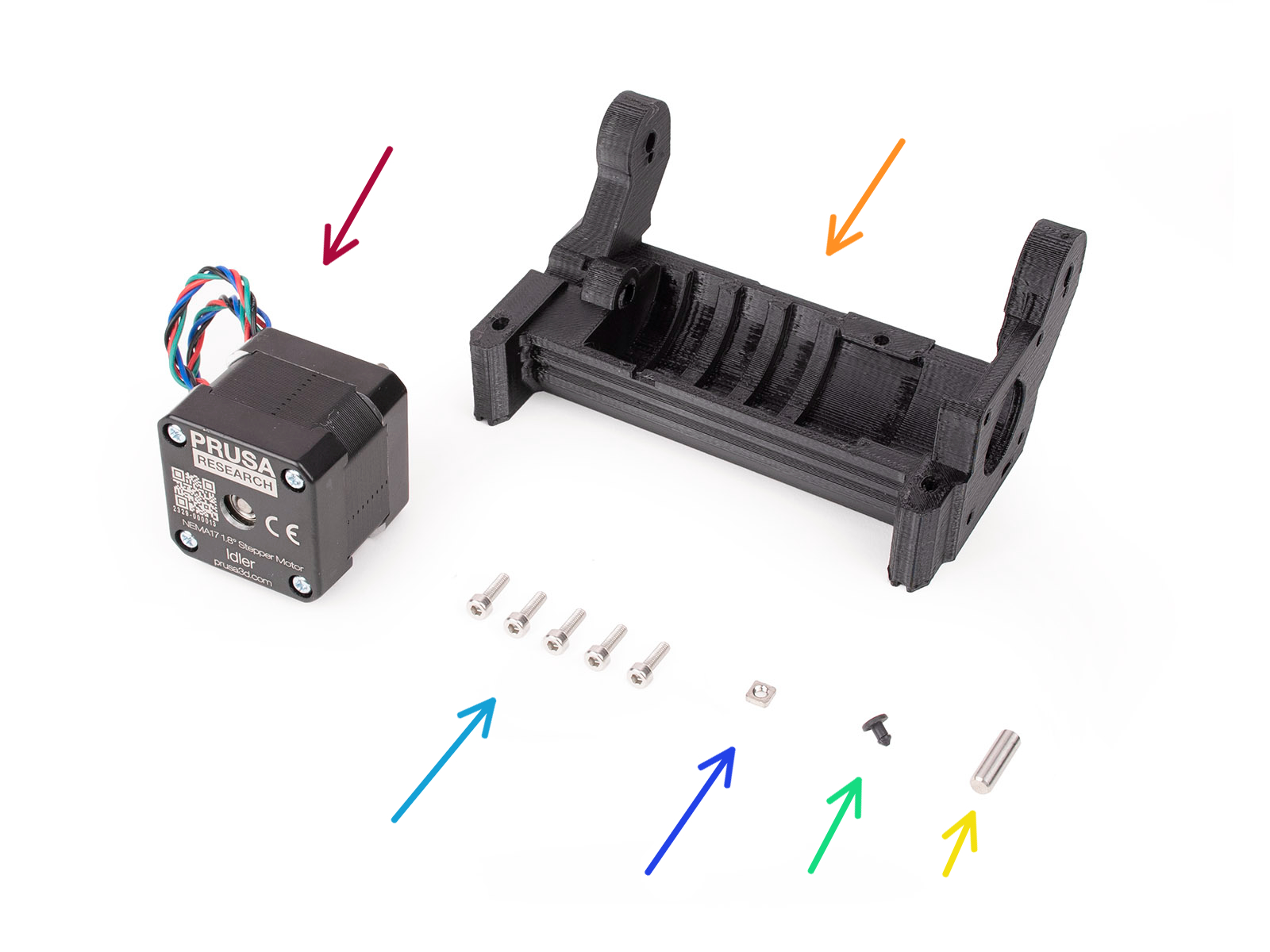

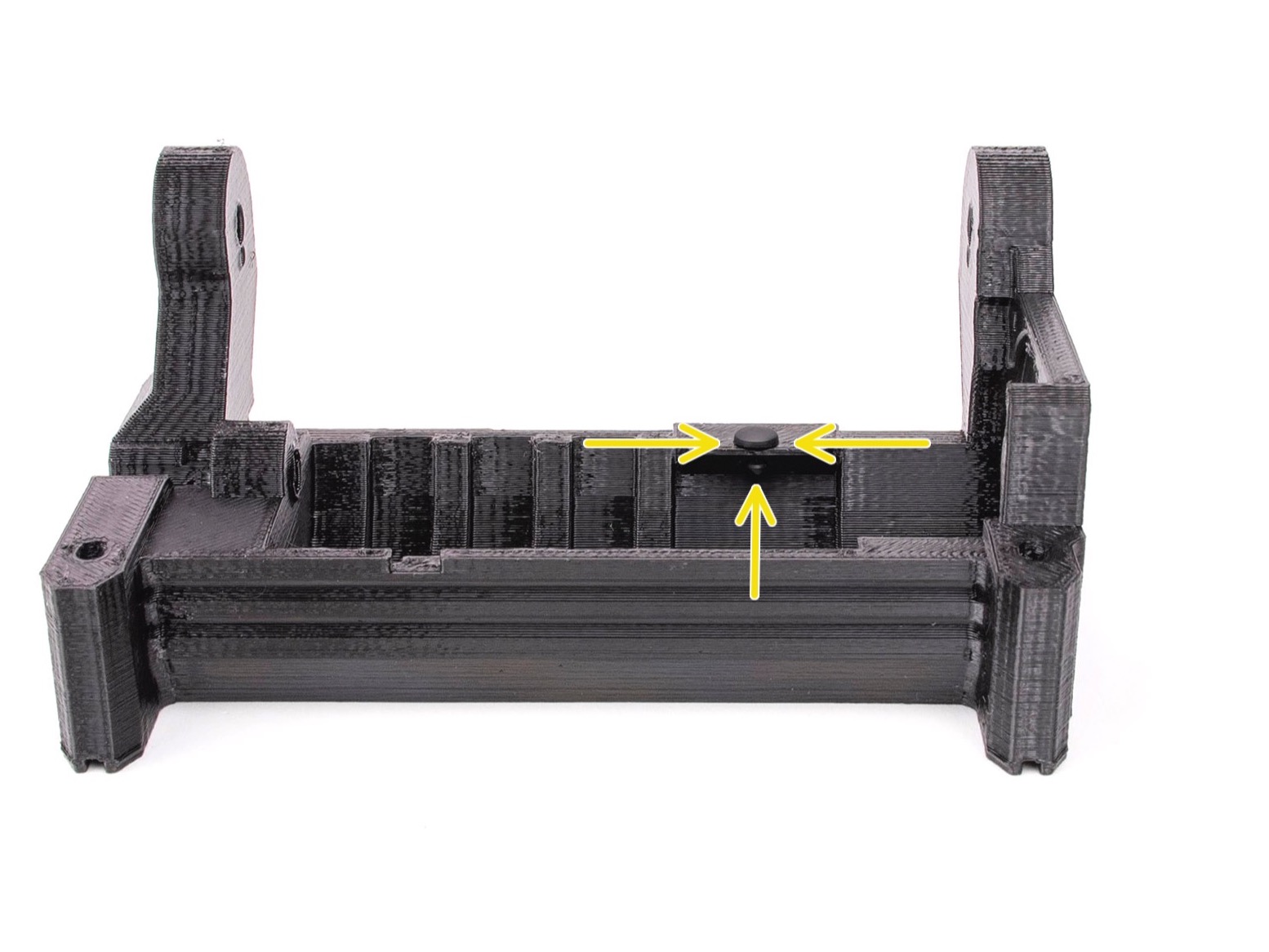

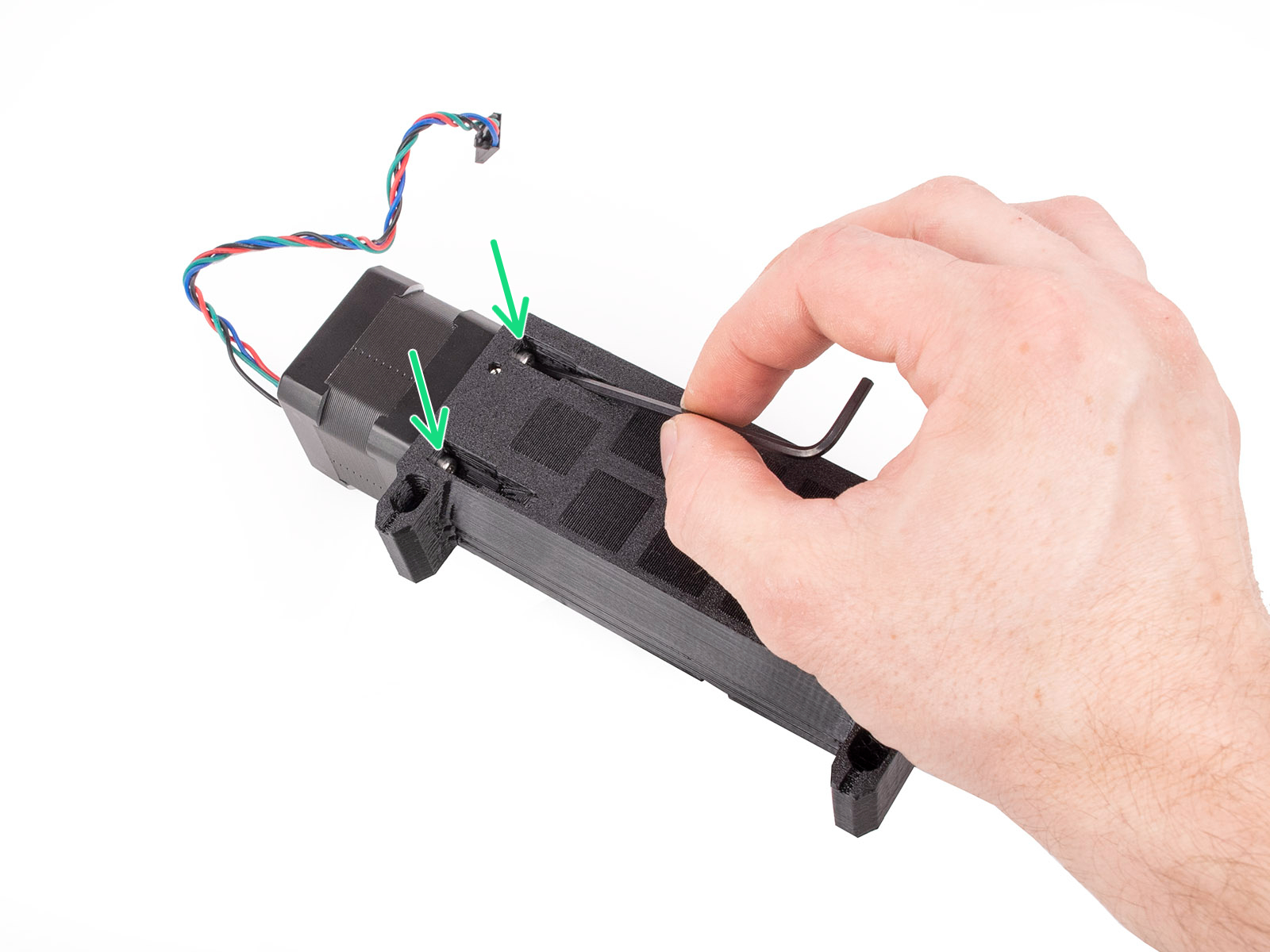

Insert two M3x10 screws into the marked openings.

Start the thread so that the screws engage into the motor. Don't tighten them up all the way yet!

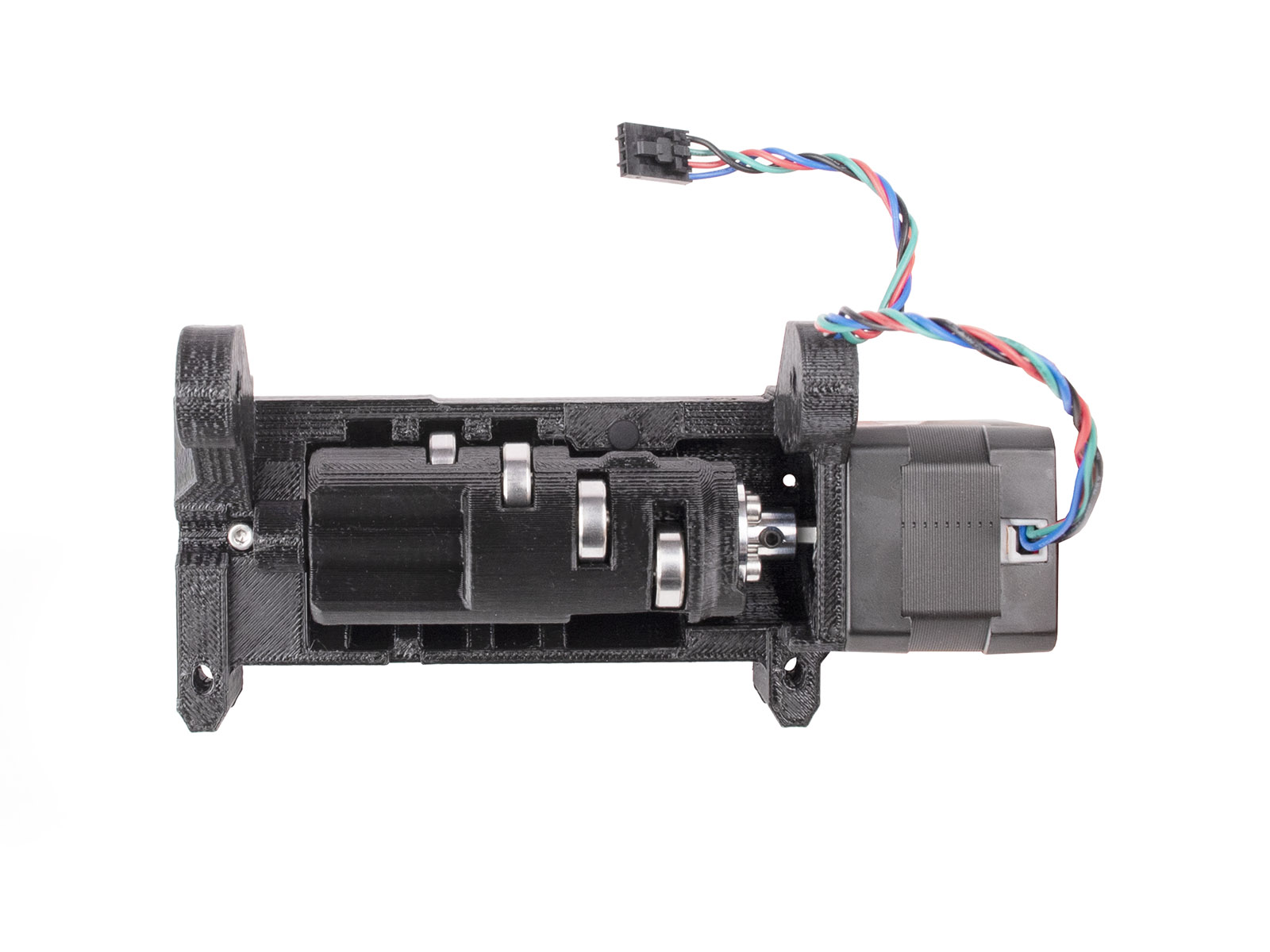

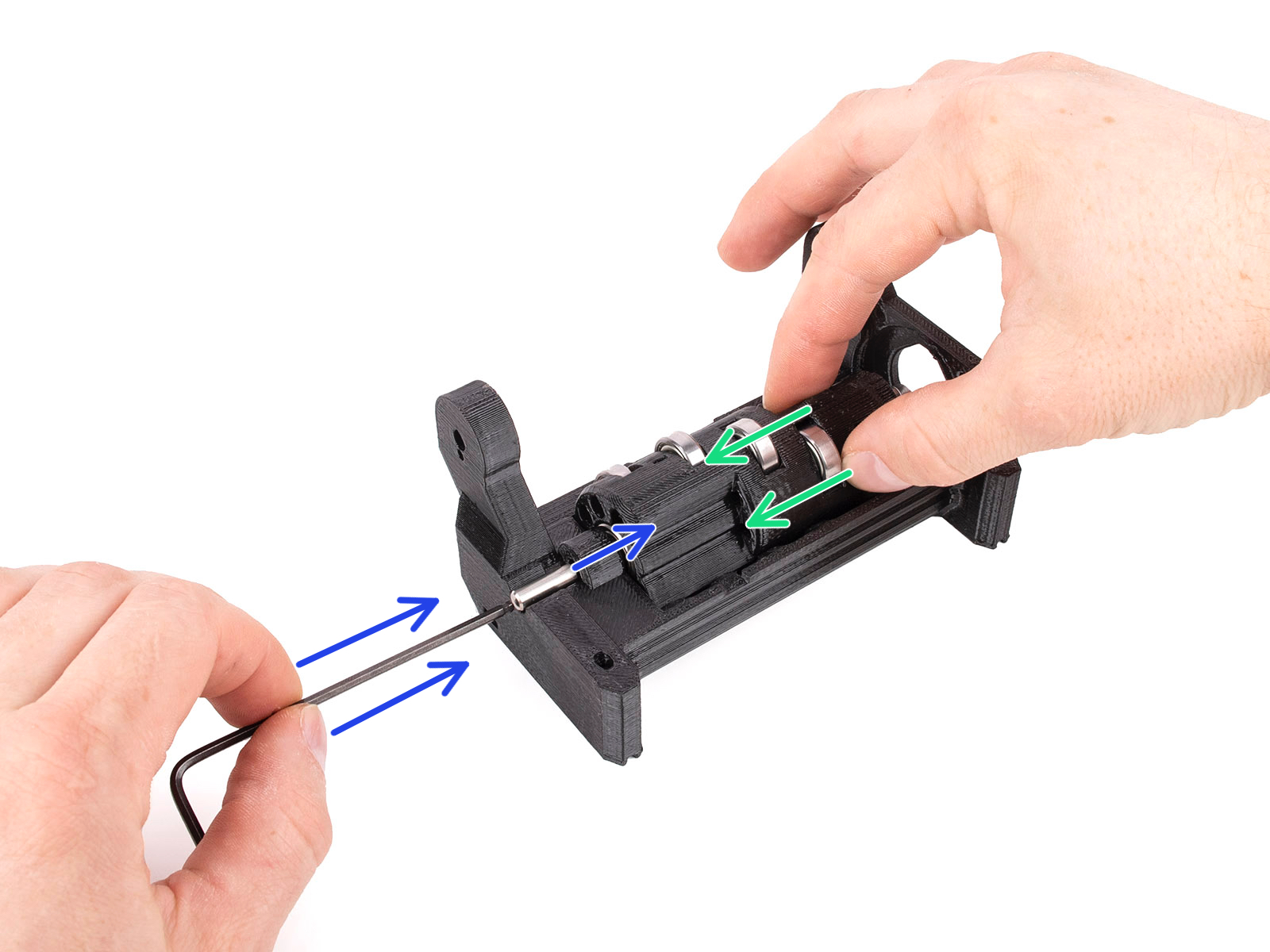

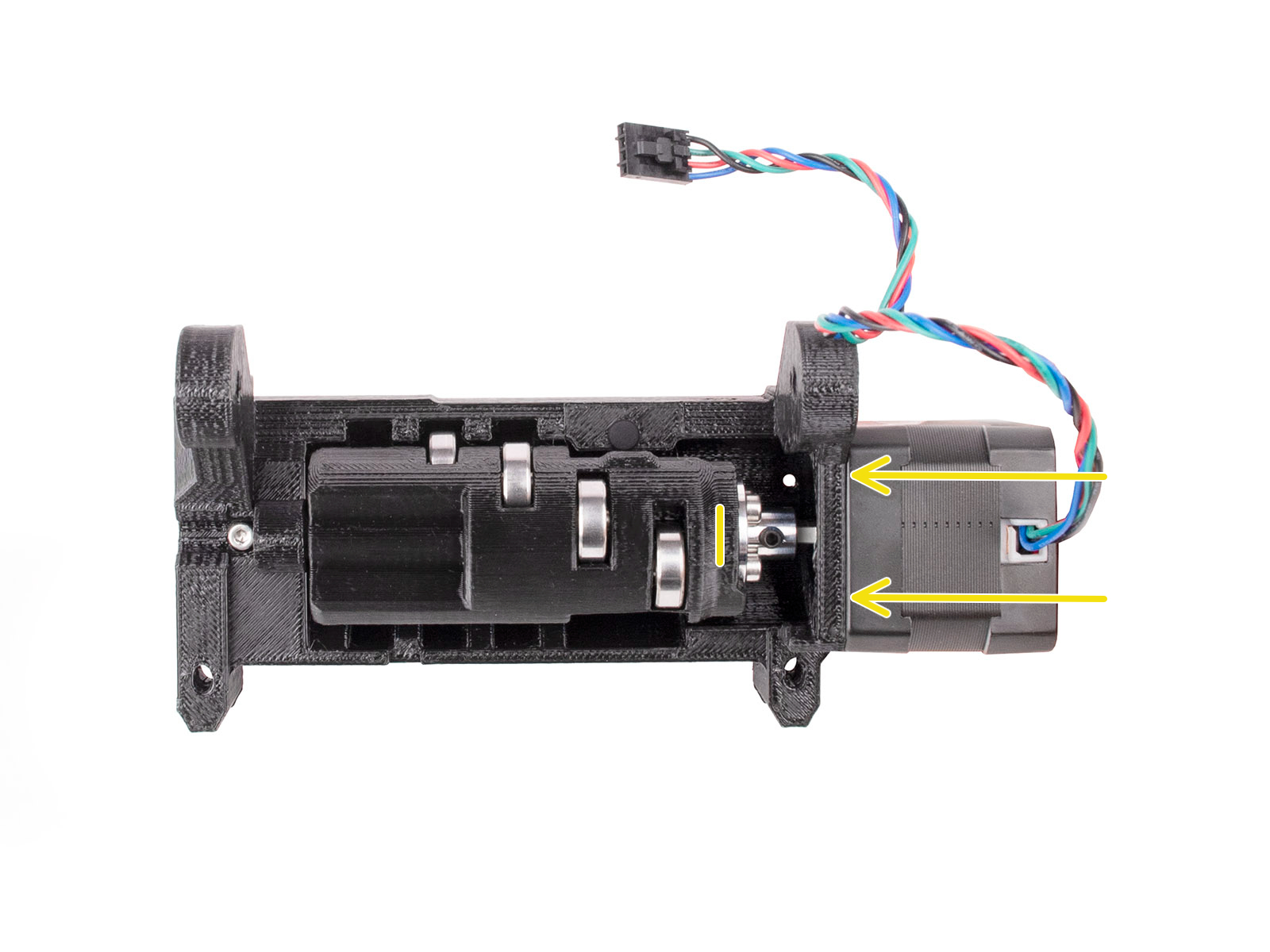

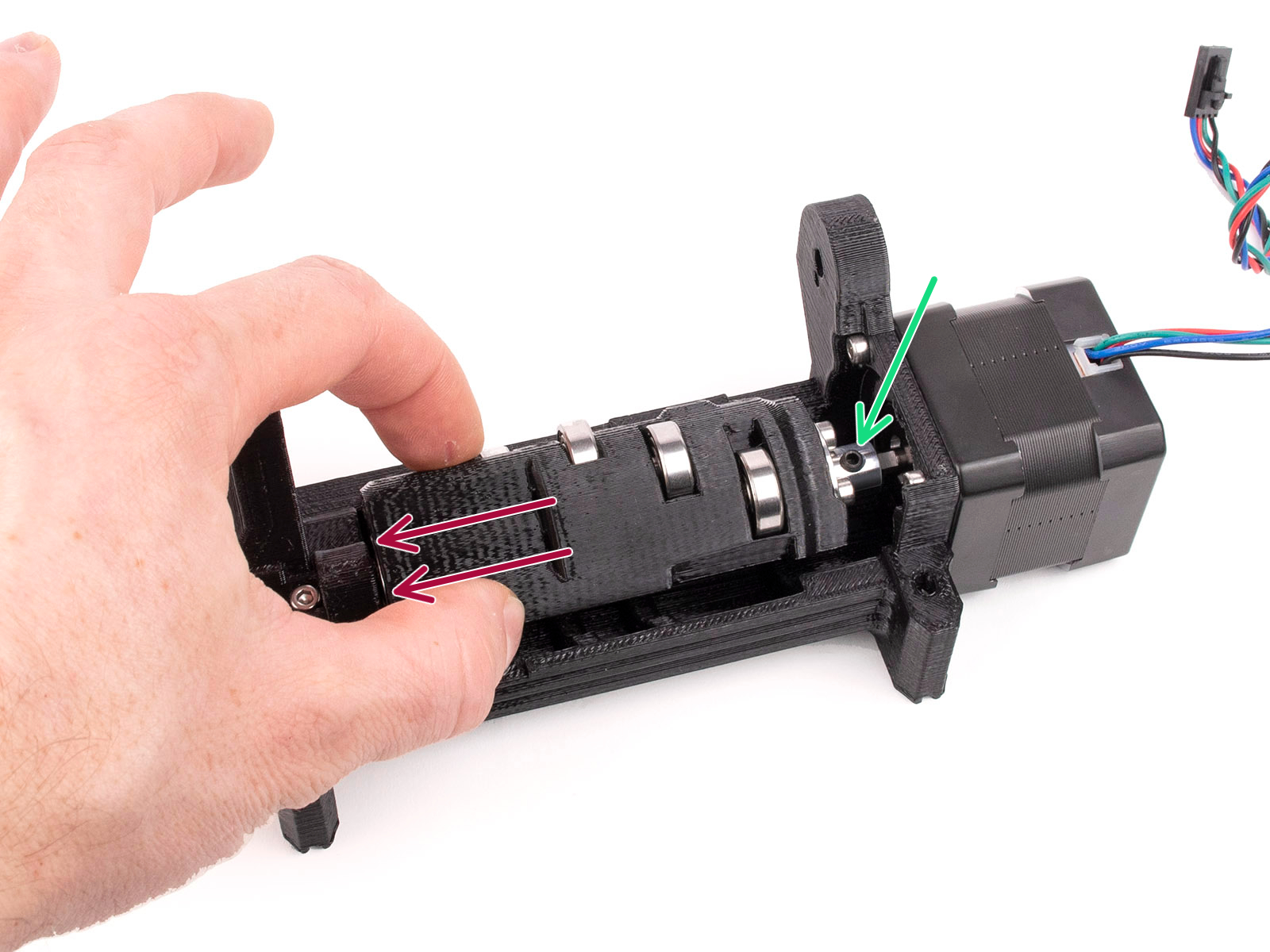

From the opposite side, add another two M3x10 screws into the openings. Push them towards the motor. Using the ball-end 2.5mm Allen key at an angle, tighten them up fully.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.