A print coming from molten plastic one might assume that it is water-tight, but that is not always the case. How to make an object look good and what makes it watertight does not always overlap. That said, the tips presented here might help you make your printed parts more robust, even if they should not be a container for liquid.

Geometry

The shape of the model obviously matters. Thick walls which require infill is often waste in this case. It can cause irregularities and may leak into the void between the inner and outer walls, creating a place where all kinds of nasty stuff can grow.

A wall should be even. Artifacts like protrusions for showing the water-level etc. can cause issues. In the picture below is a PLA print where everything is water-tight, except by a little nubbin for this purpose.

Perimeters

More of them! You want to go with at least 3-4 perimeters for a single wall. Depending on the geometry you can also increase this to 5-6, but is rarely necessary.

Temperature

More of if it! To ensure a proper bond between the layers we would recommend raising the Nozzle-temperature with 5-10C over the presets available or use the highest recommended temperature on the box of the filament (You can also go about 5c above this). Some experimentation needed.

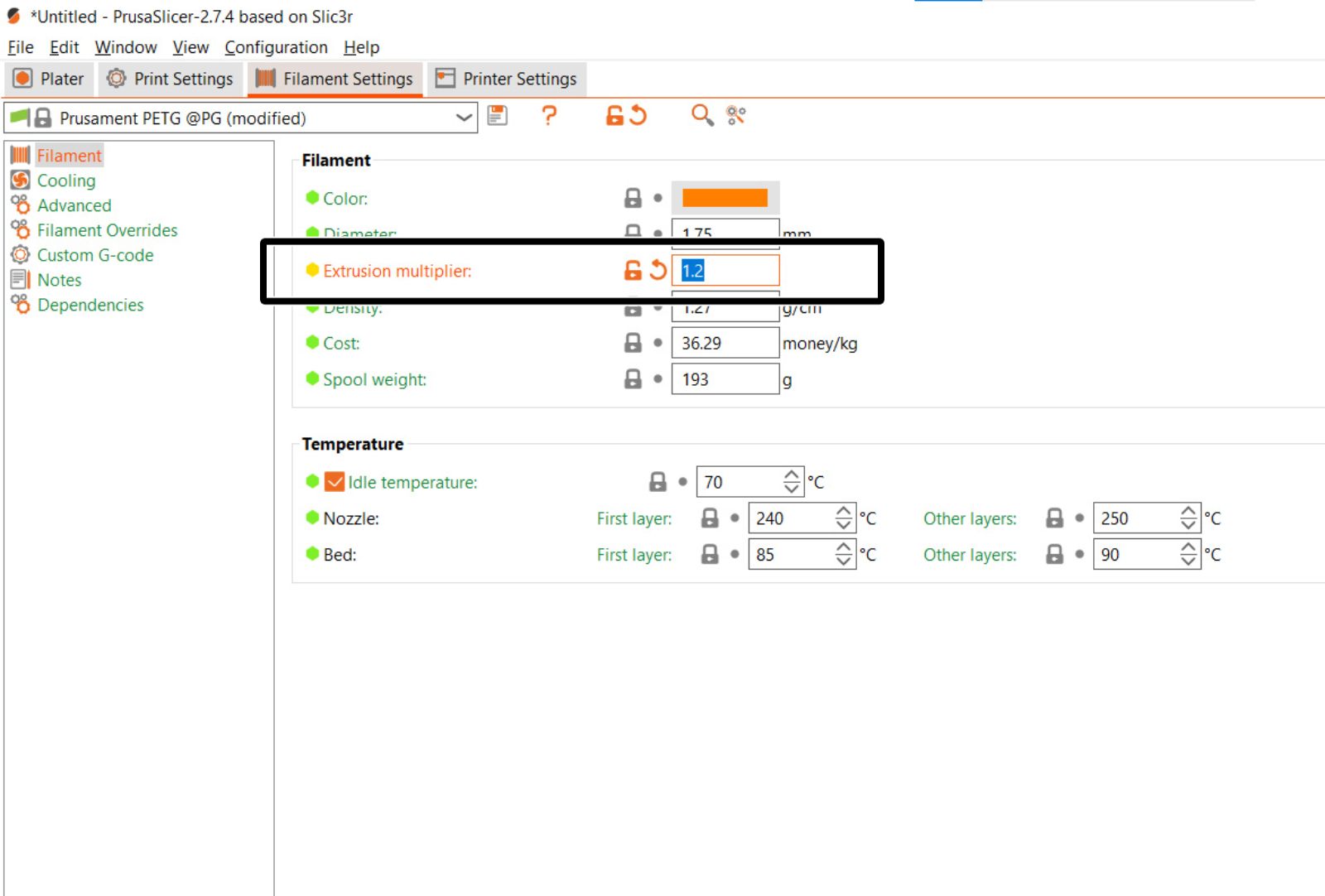

Extrusion-multiplier

This refers to the flow rate of the filament and is set in PrusaSlicer under Filament Settings. Increase this by 5-10 percent from the default value. Another way of manipulating this is to set the line width 5-10% wider (i.e. from 0.4mm to 0.44mm), but this can affect other aspects of your print. If in doubt experiment, or do the simple option.

Layer-height

Very high layer-heights just won't do, but having very tight layers will also increase the number of places where something can go wrong. CNC-kitchen found that the most durable prints were at 0.15mm height, but 0.2 will do fine. If you want to print fast and have very high layers (like 0.4mm+) get a larger nozzle. Generally, for best results, you should not use a height of more than 60-65% of your nozzle width.

XY-Overlap and other settings

This applies more to if your print leaks from the bottom, and you have tested with the previous suggestions. XY-Overlap is a variable in PrusaSlicer that says how much a line of solid infill crosses the perimeter. This is by default set to 10% (of nozzle diameter, so 0.04mm). Increasing the temperature and extrusion multiplier will affect this, but if you still see leakage you can try to increase this to 25-35%.

Materials

These tricks should work with most materials. These tricks might not be necessary on materials like ASA or ABS if you smooth them with acetone.

2 comments

The standard has been changed after the monotonic lines started being used. The article has been updated to reflect it.