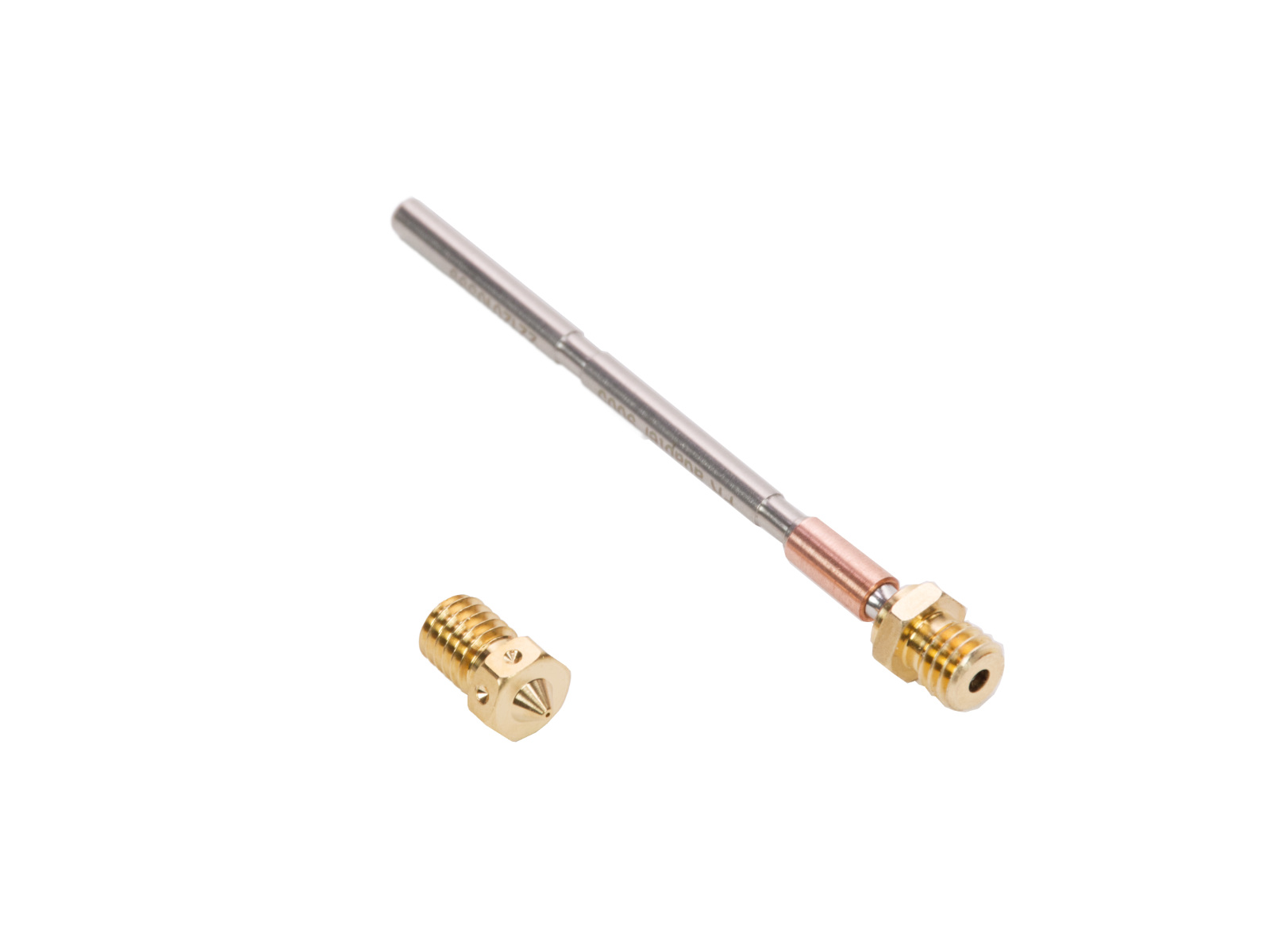

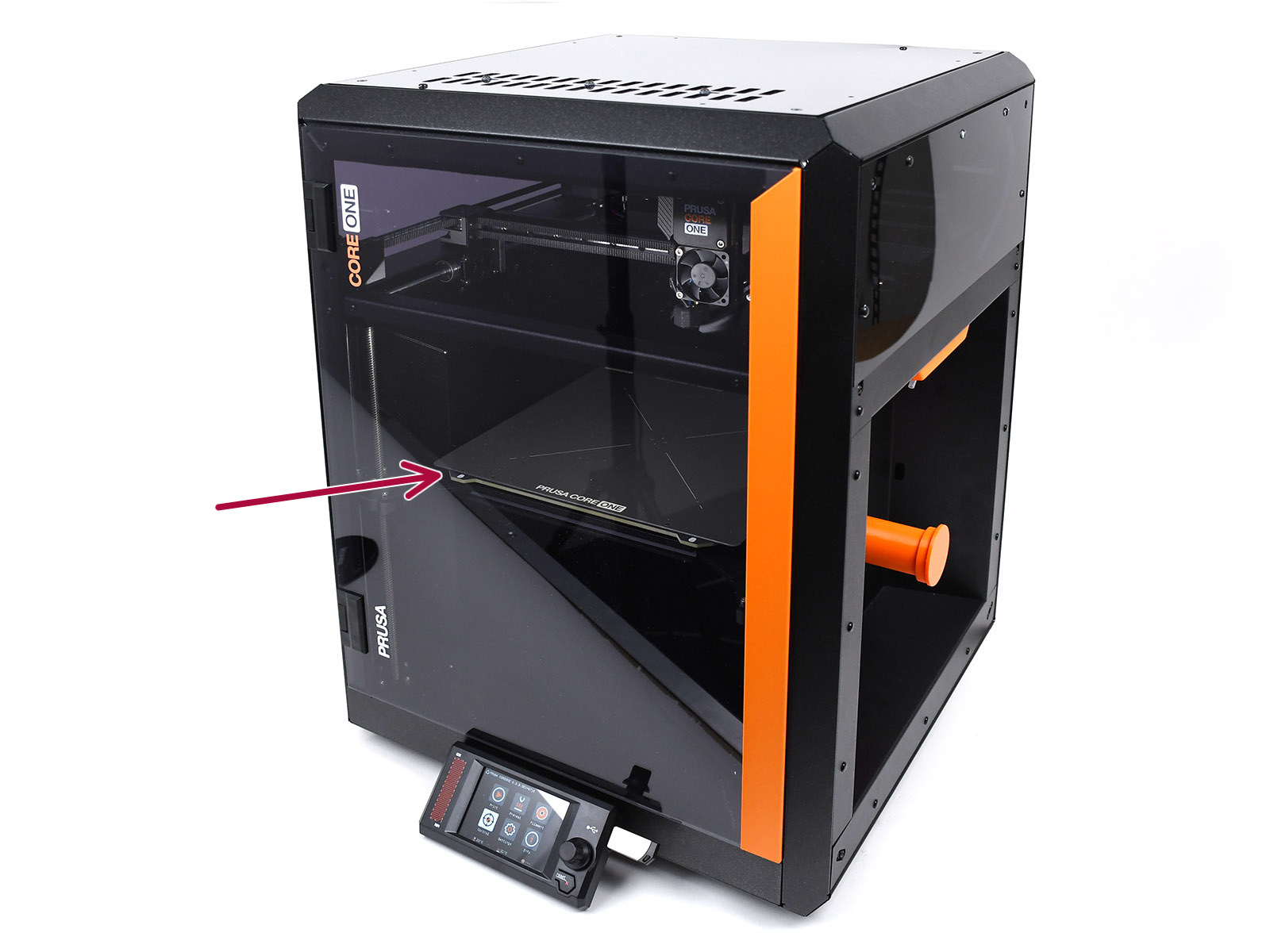

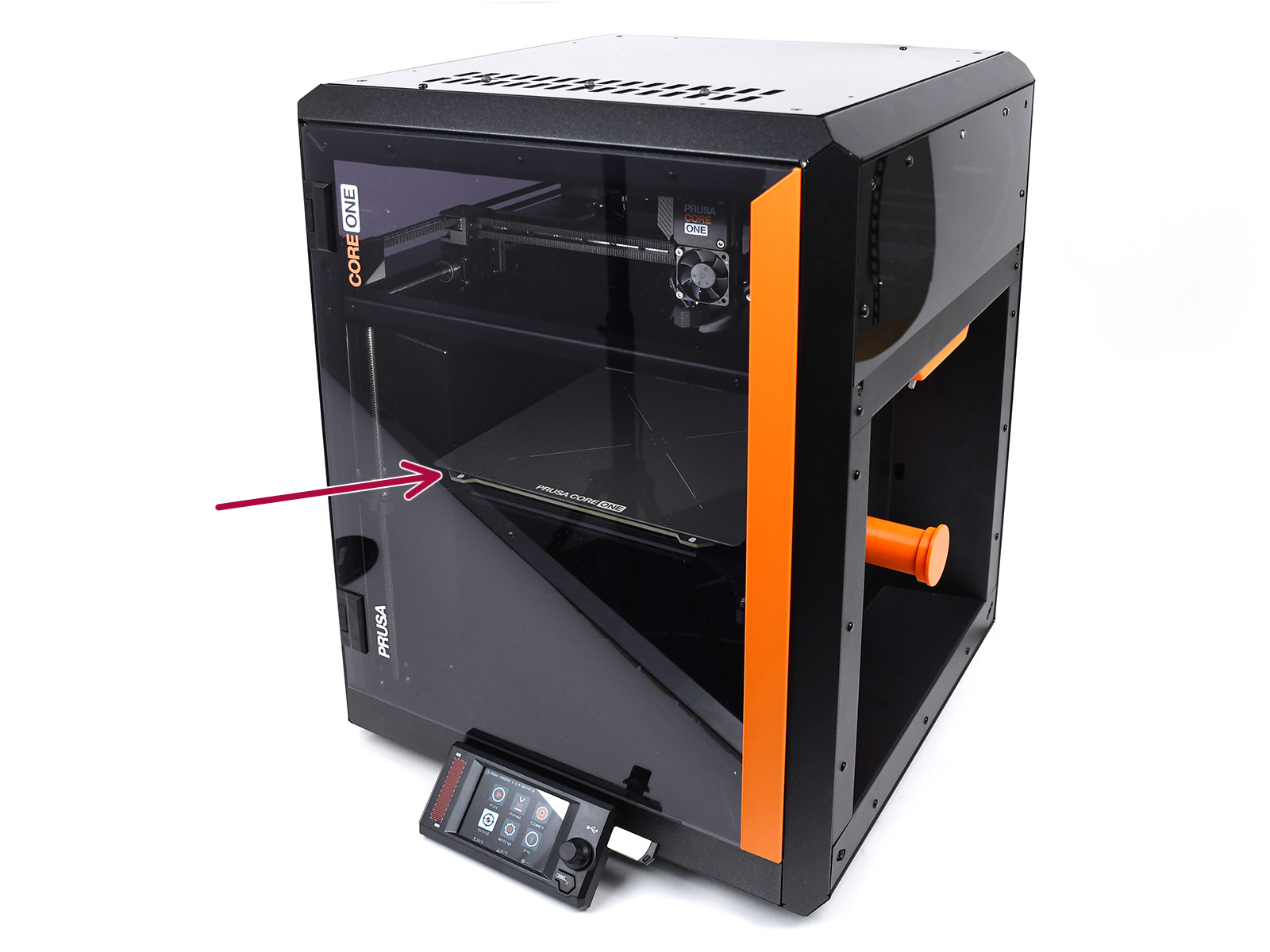

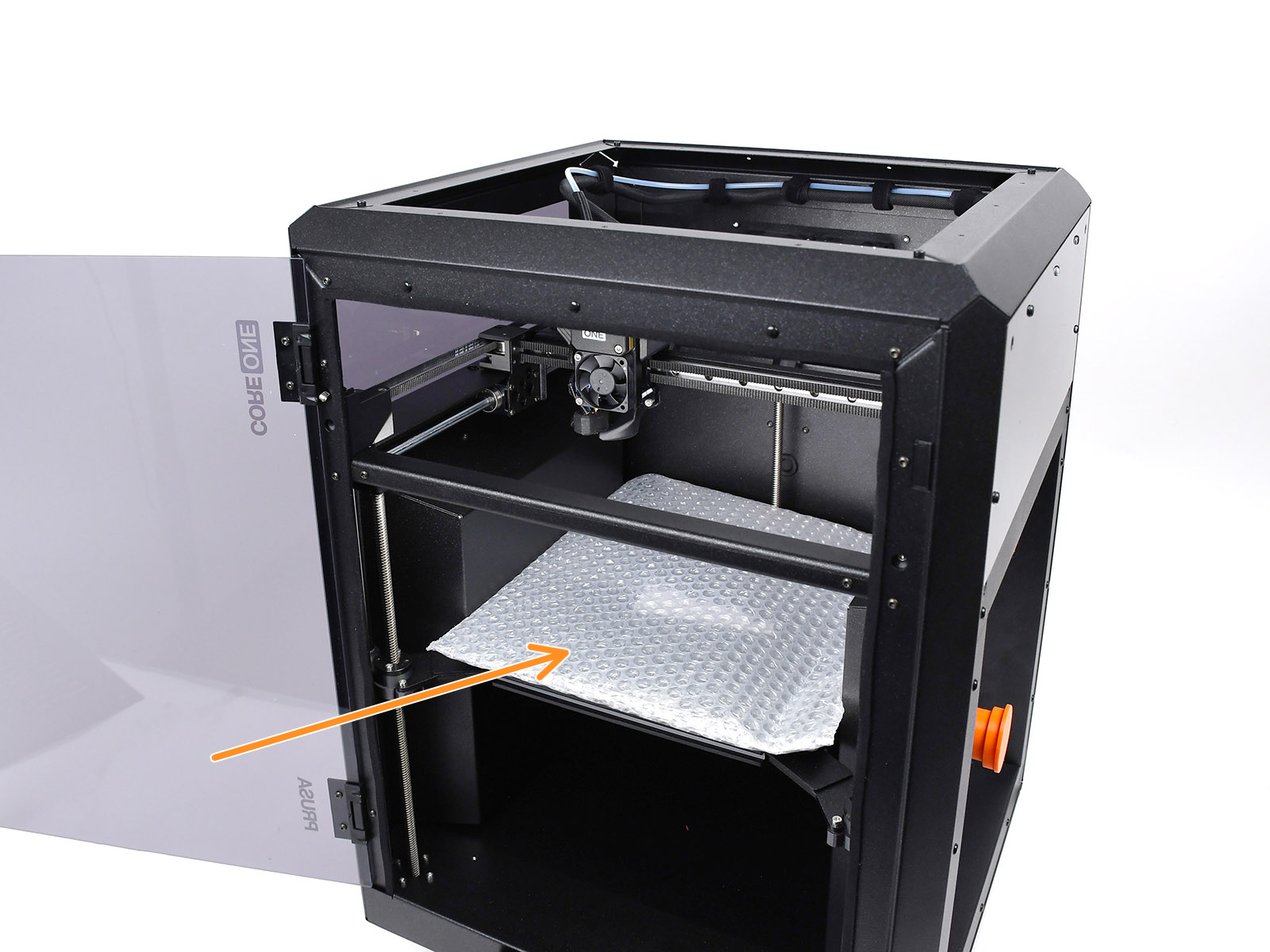

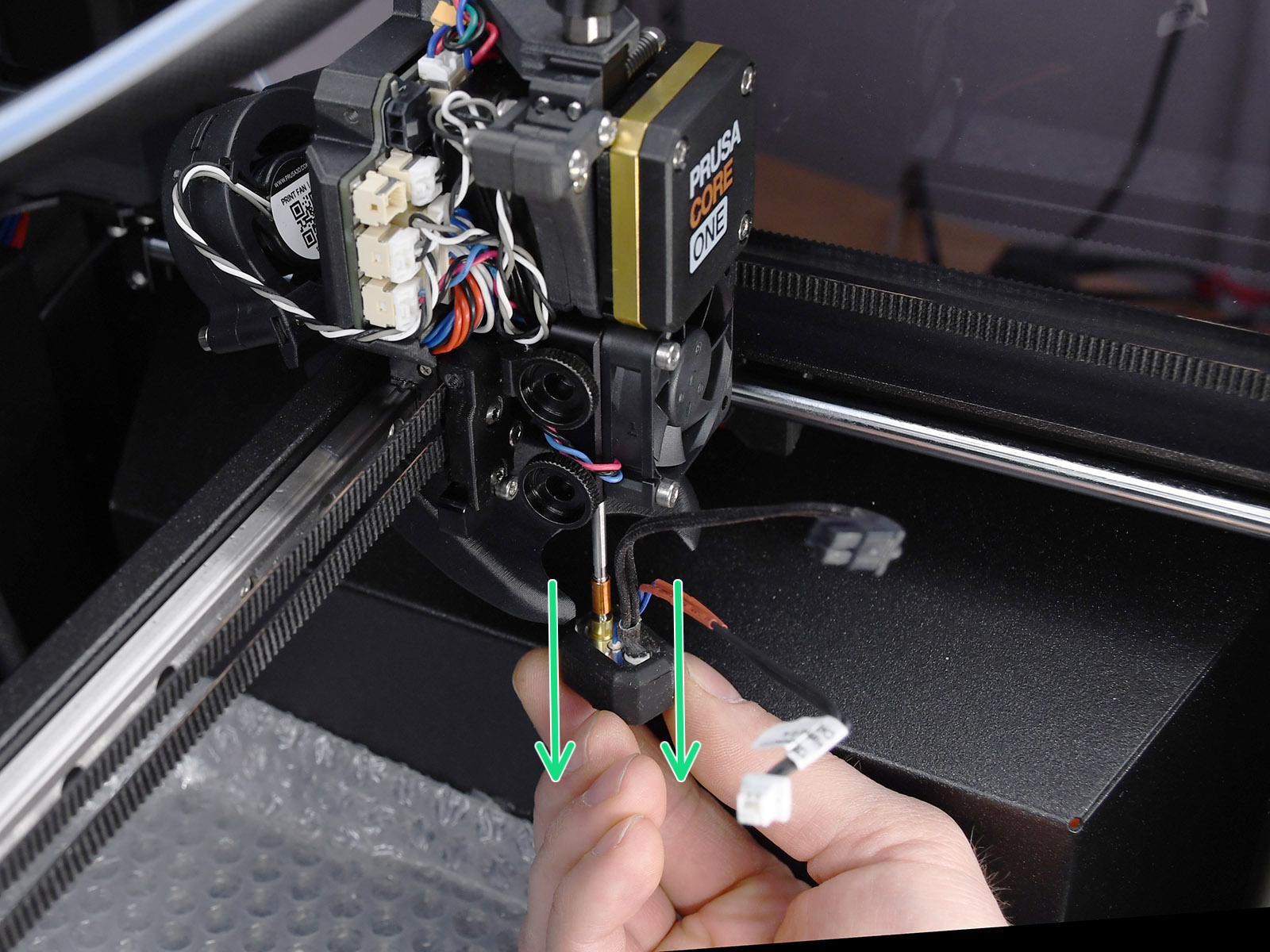

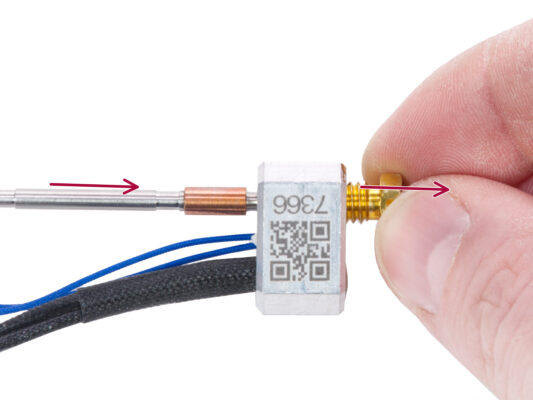

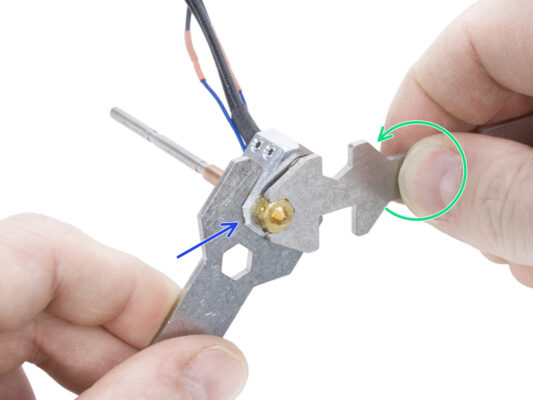

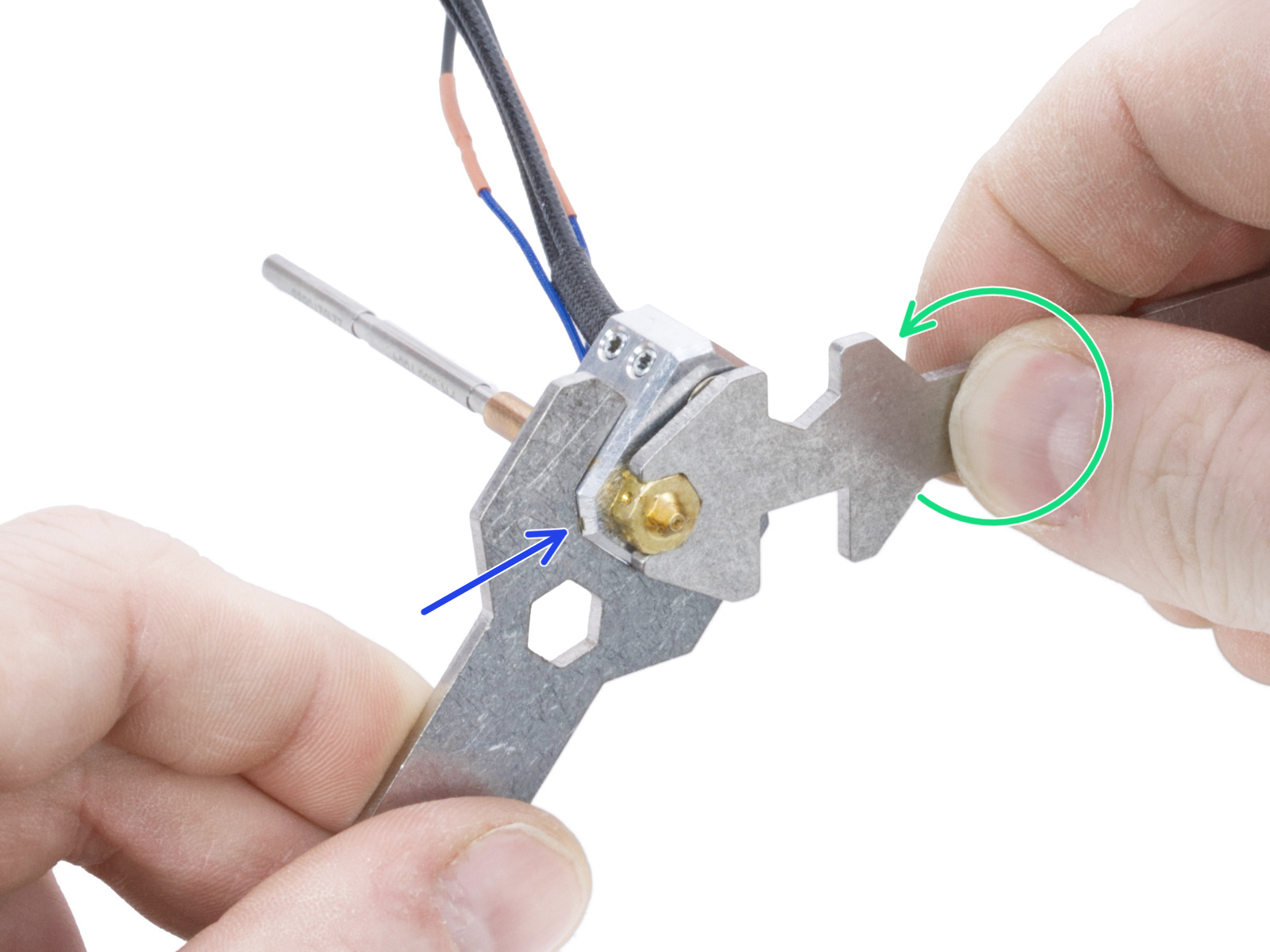

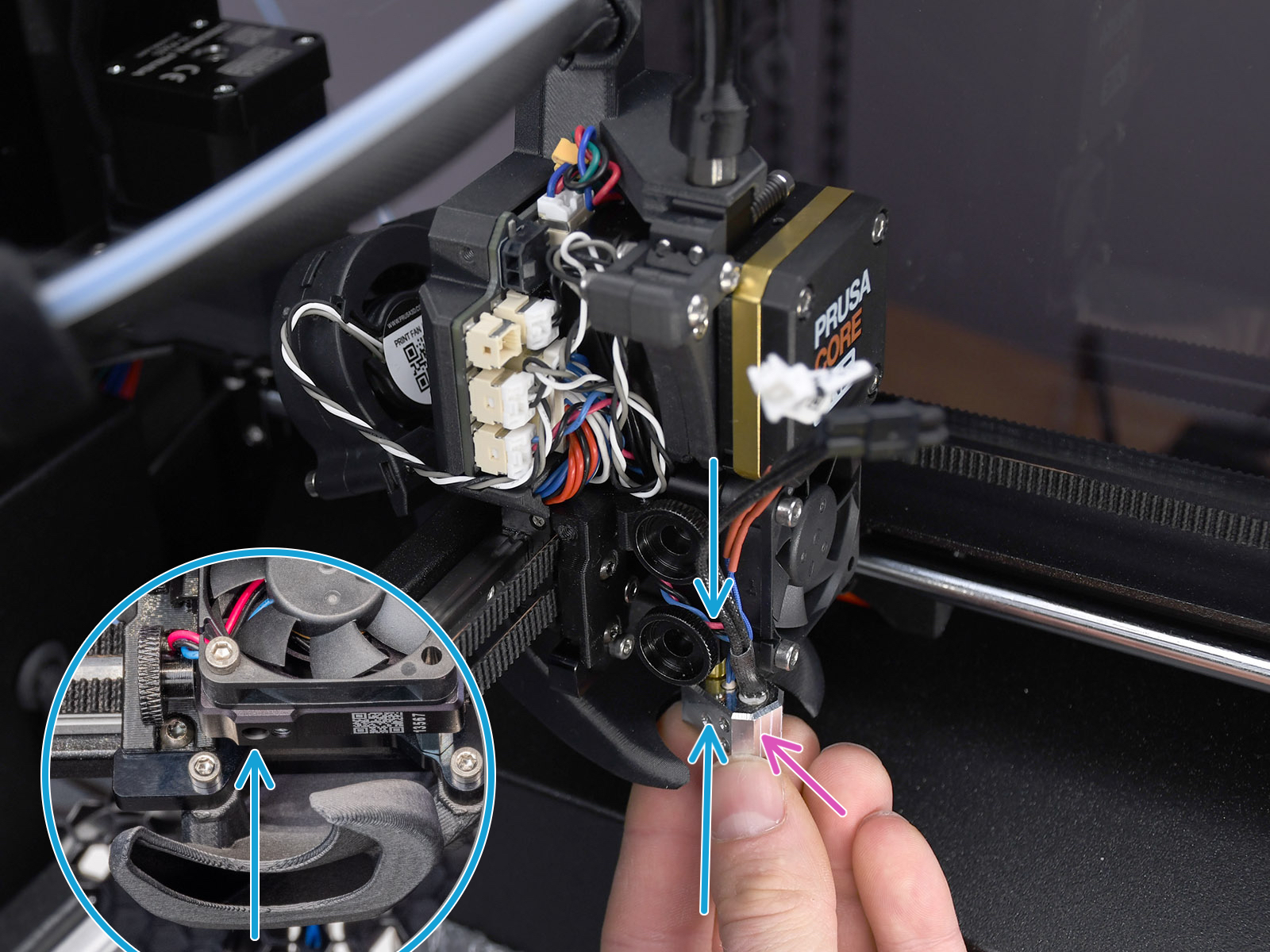

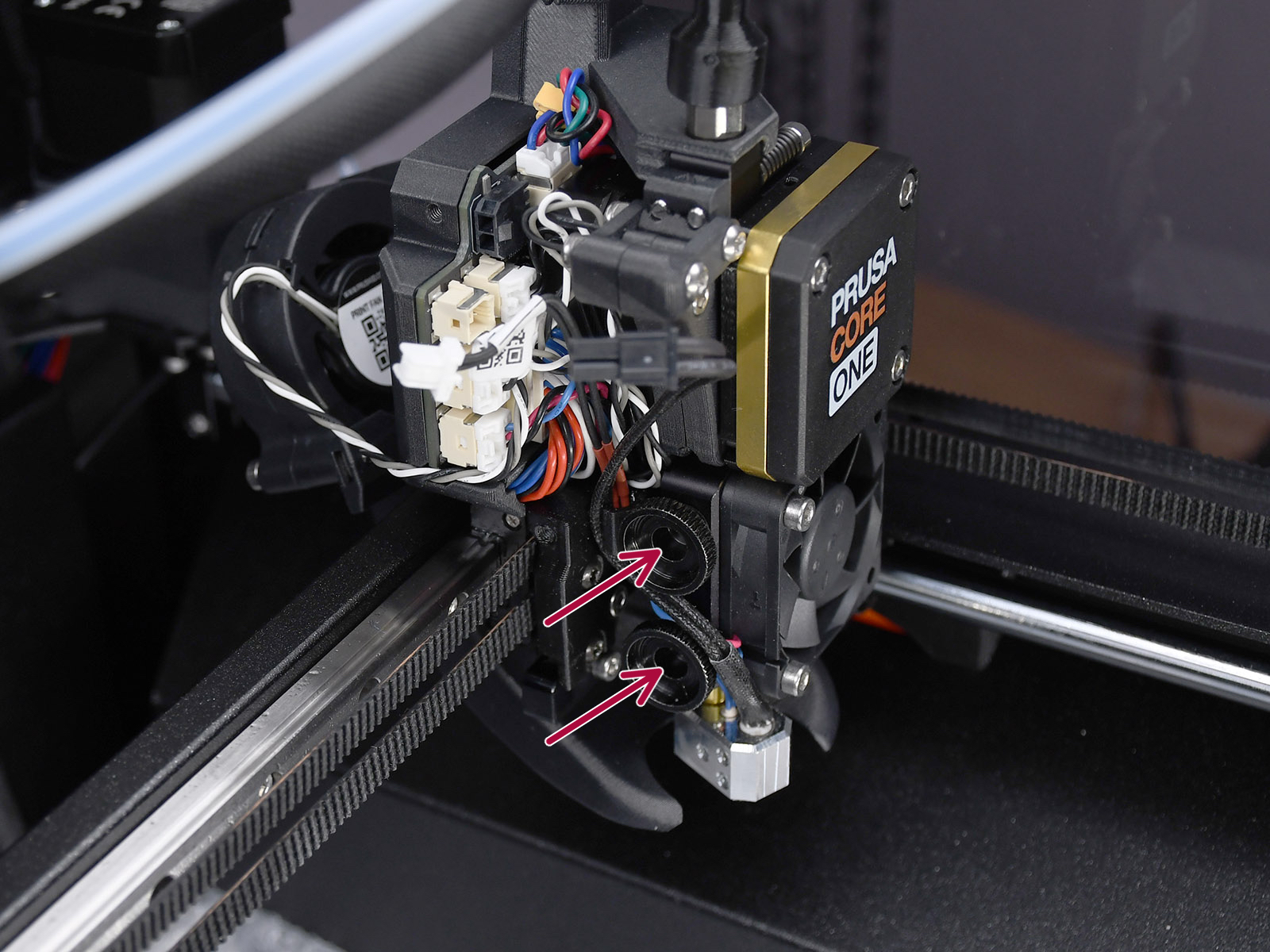

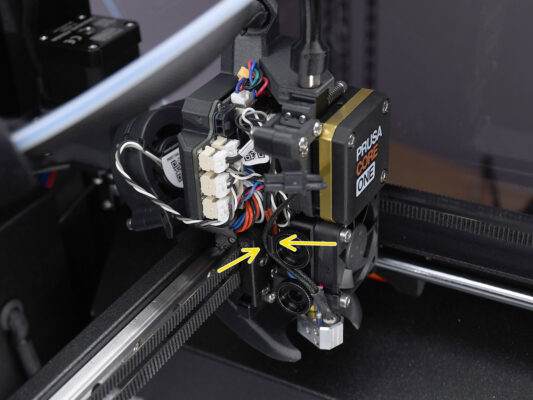

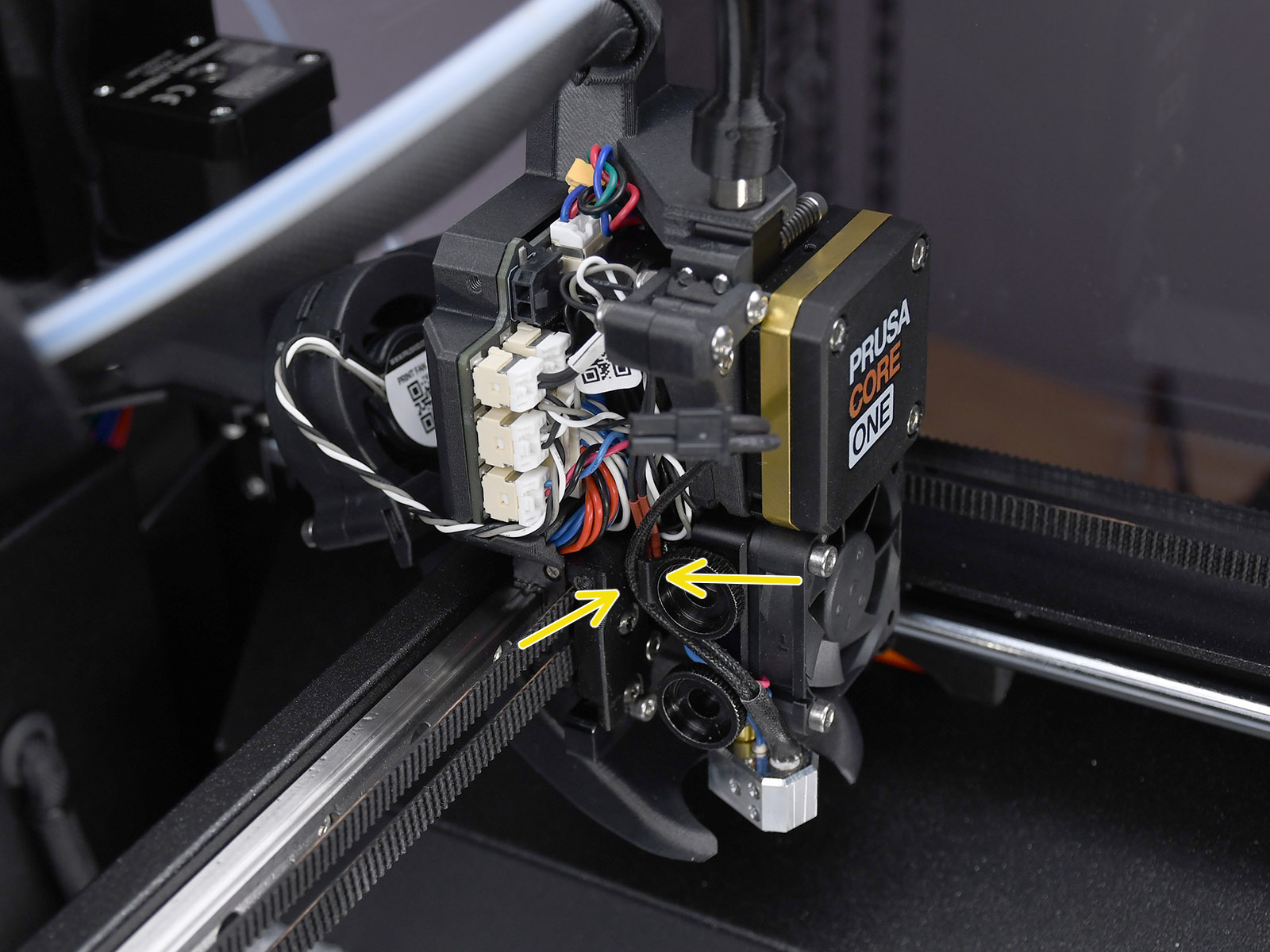

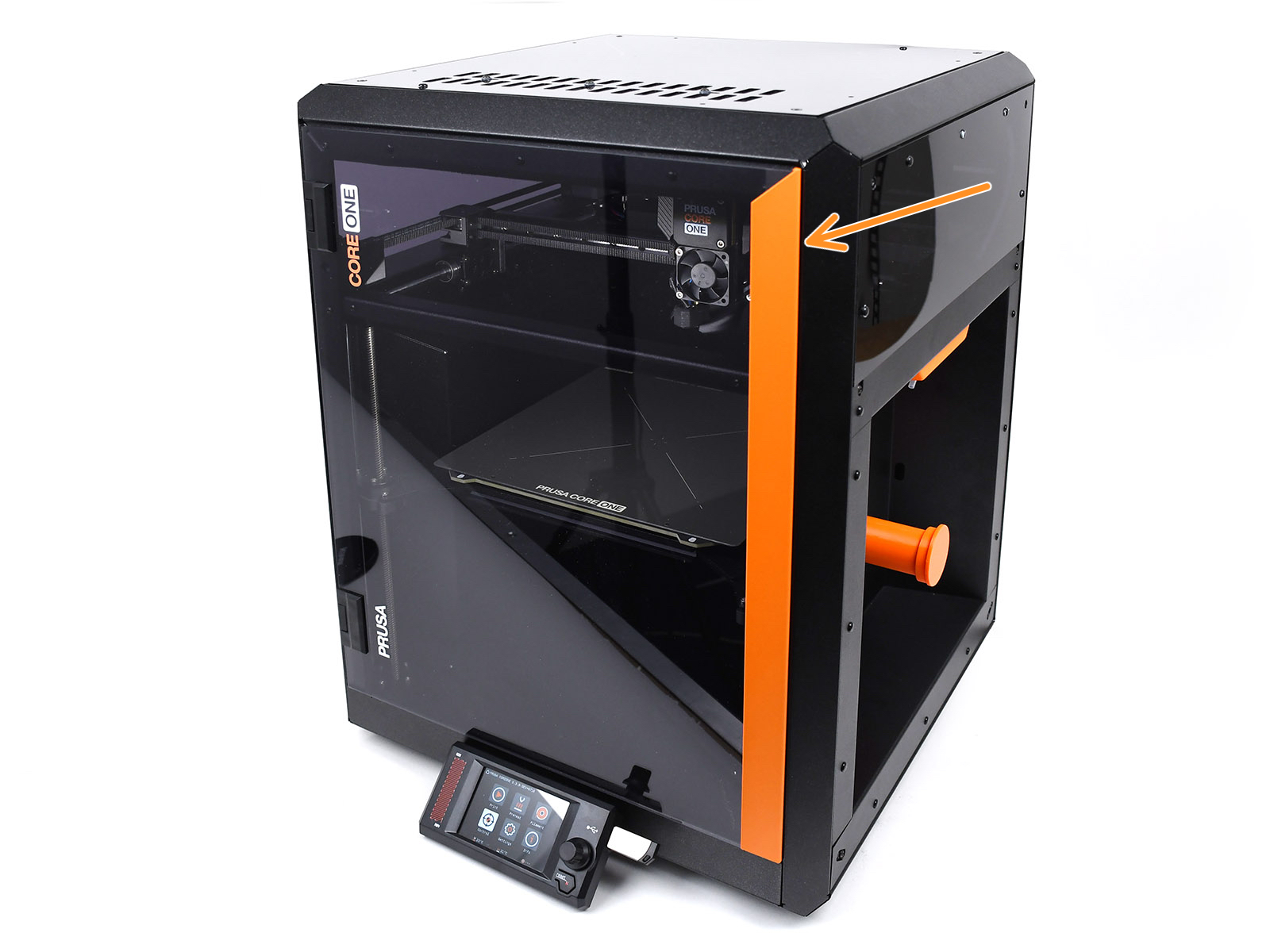

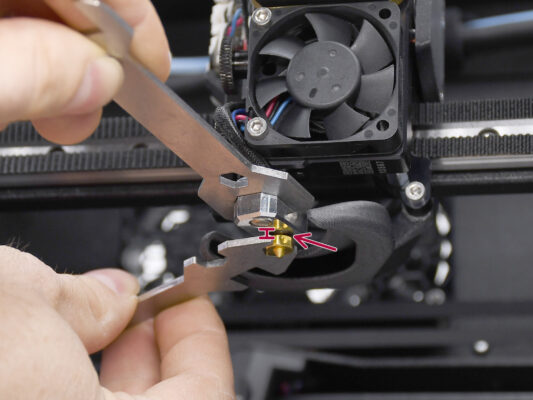

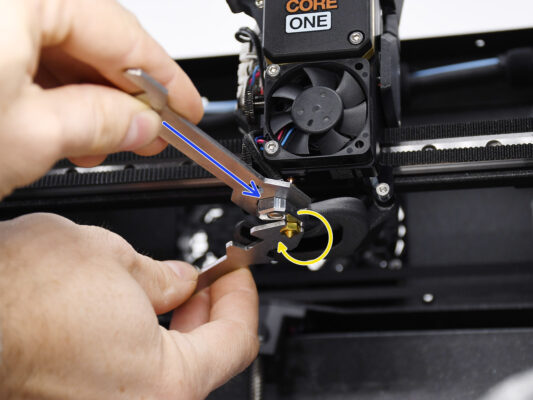

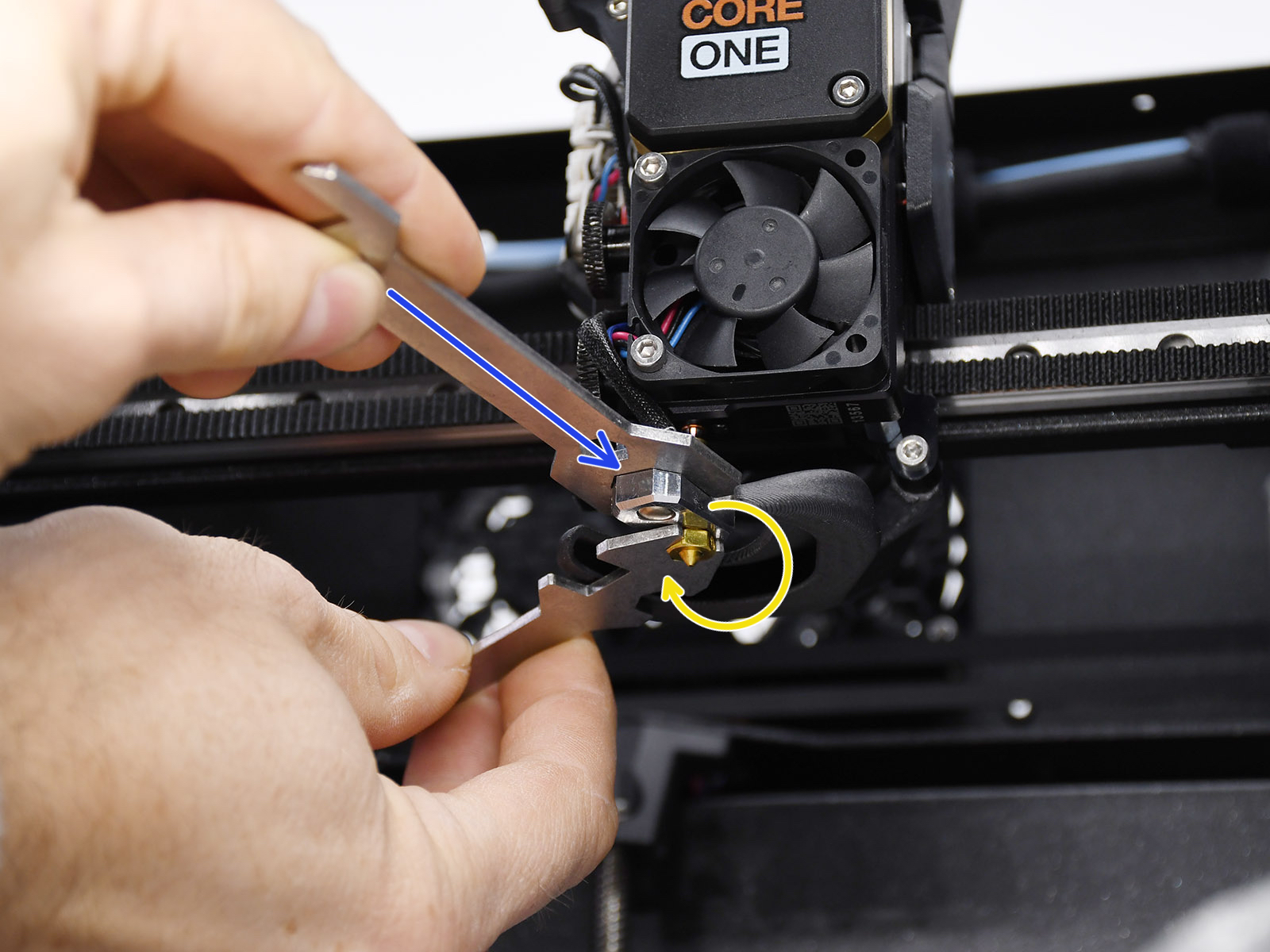

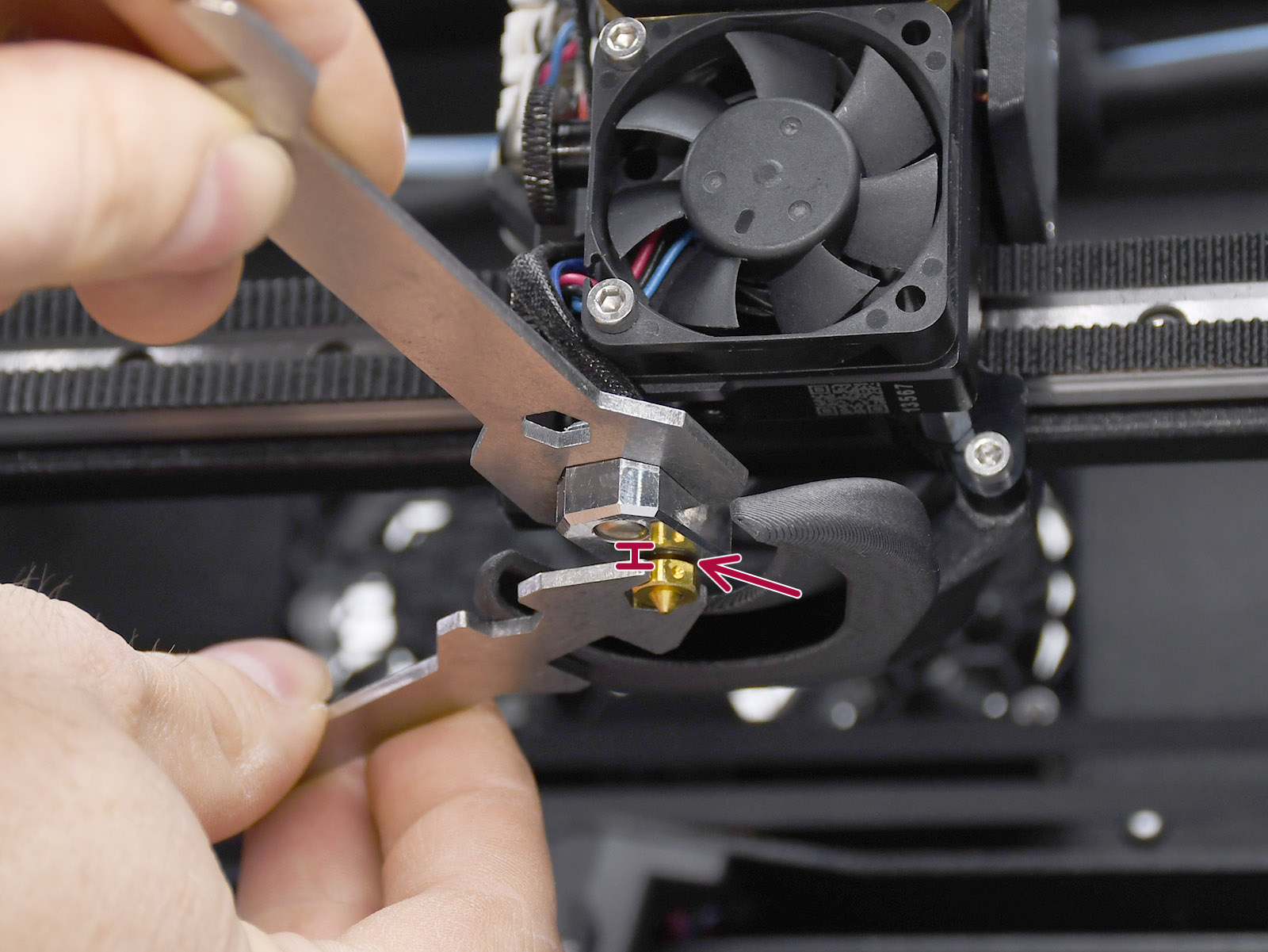

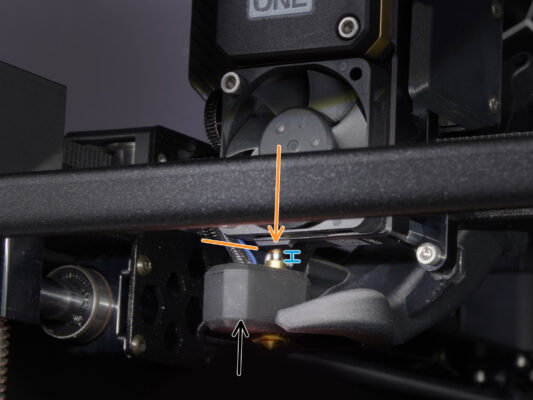

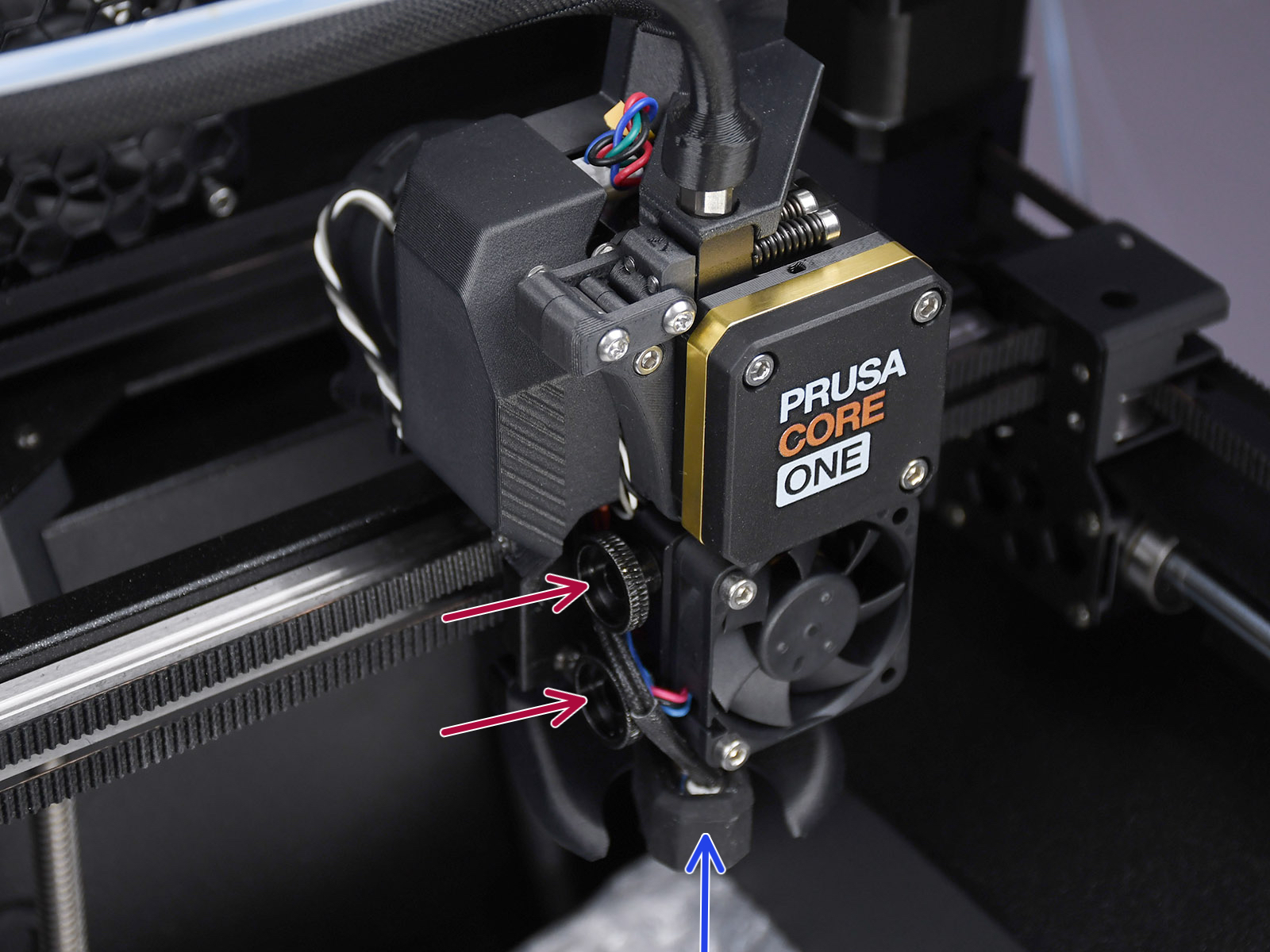

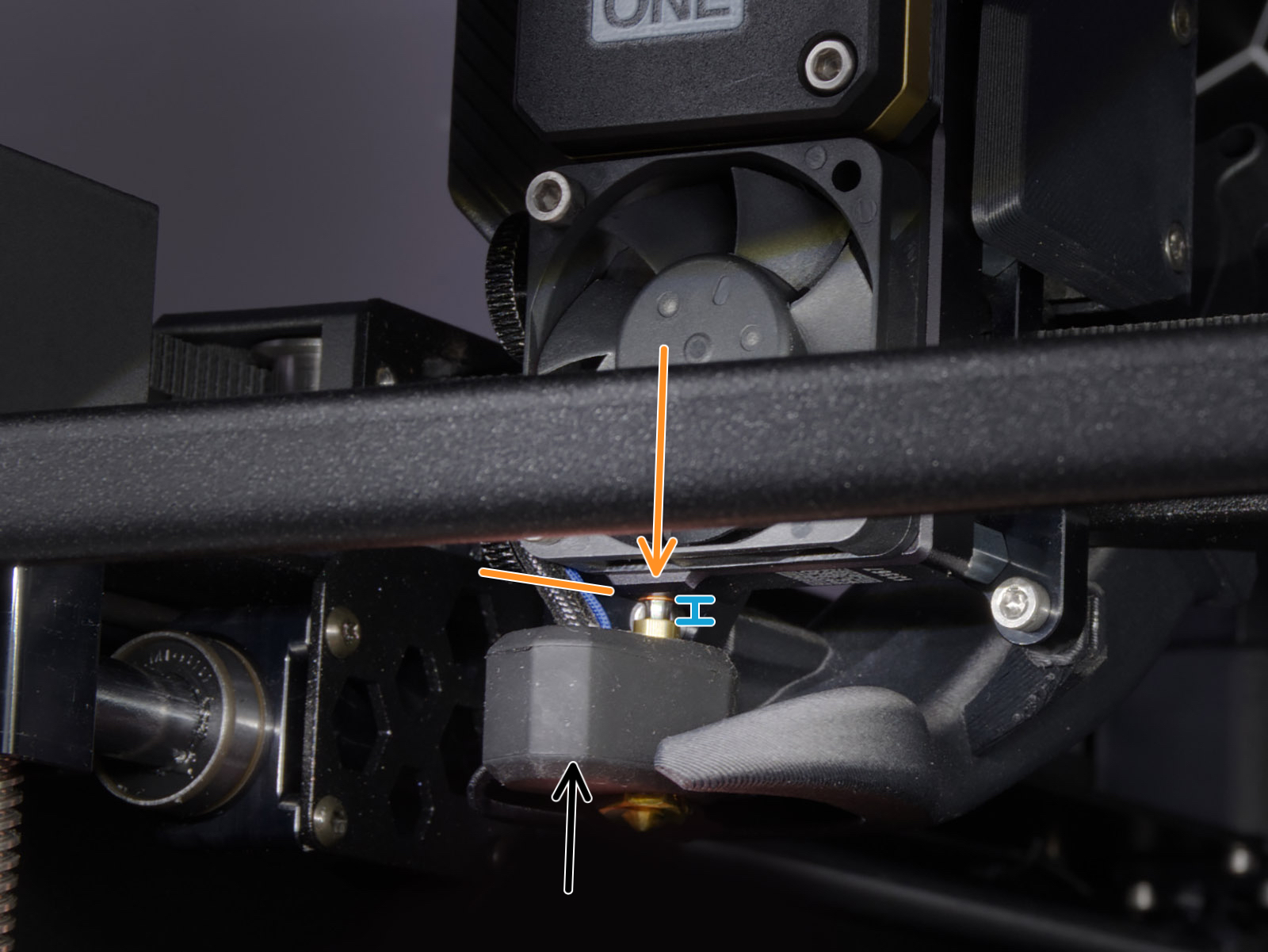

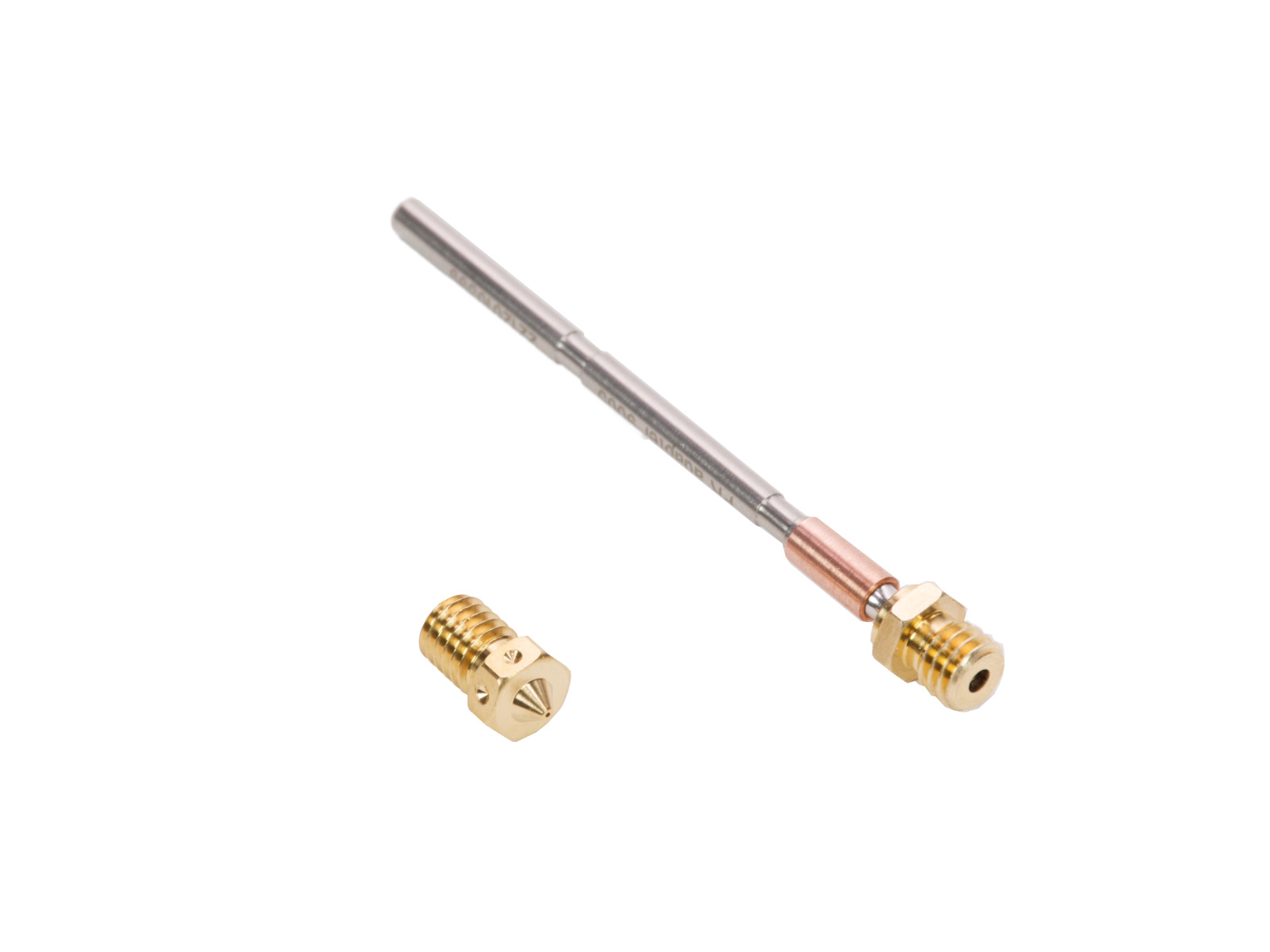

⬢This guide will take you through the installation of the Nextruder V6 Nozzle Adapter on the Original Prusa CORE One.

Las siguientes instrucciones son compatibles con todos los diámetros de las boquillas Prusa.

⬢Todas las piezas necesarias están disponibles en nuestra tienda prusa3d.com.

Ten en cuenta que debes iniciar sesión para tener acceso a la sección de repuestos.