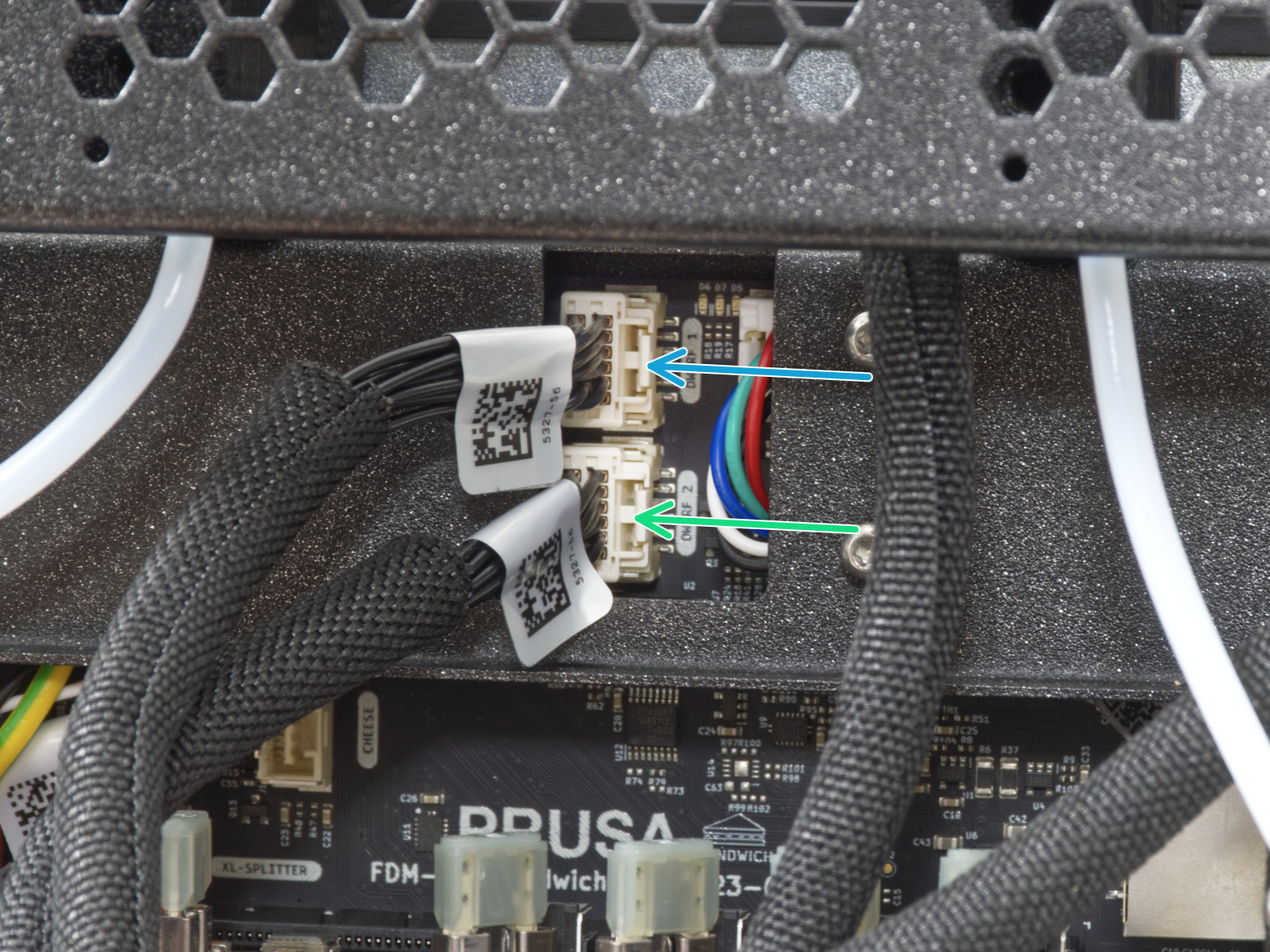

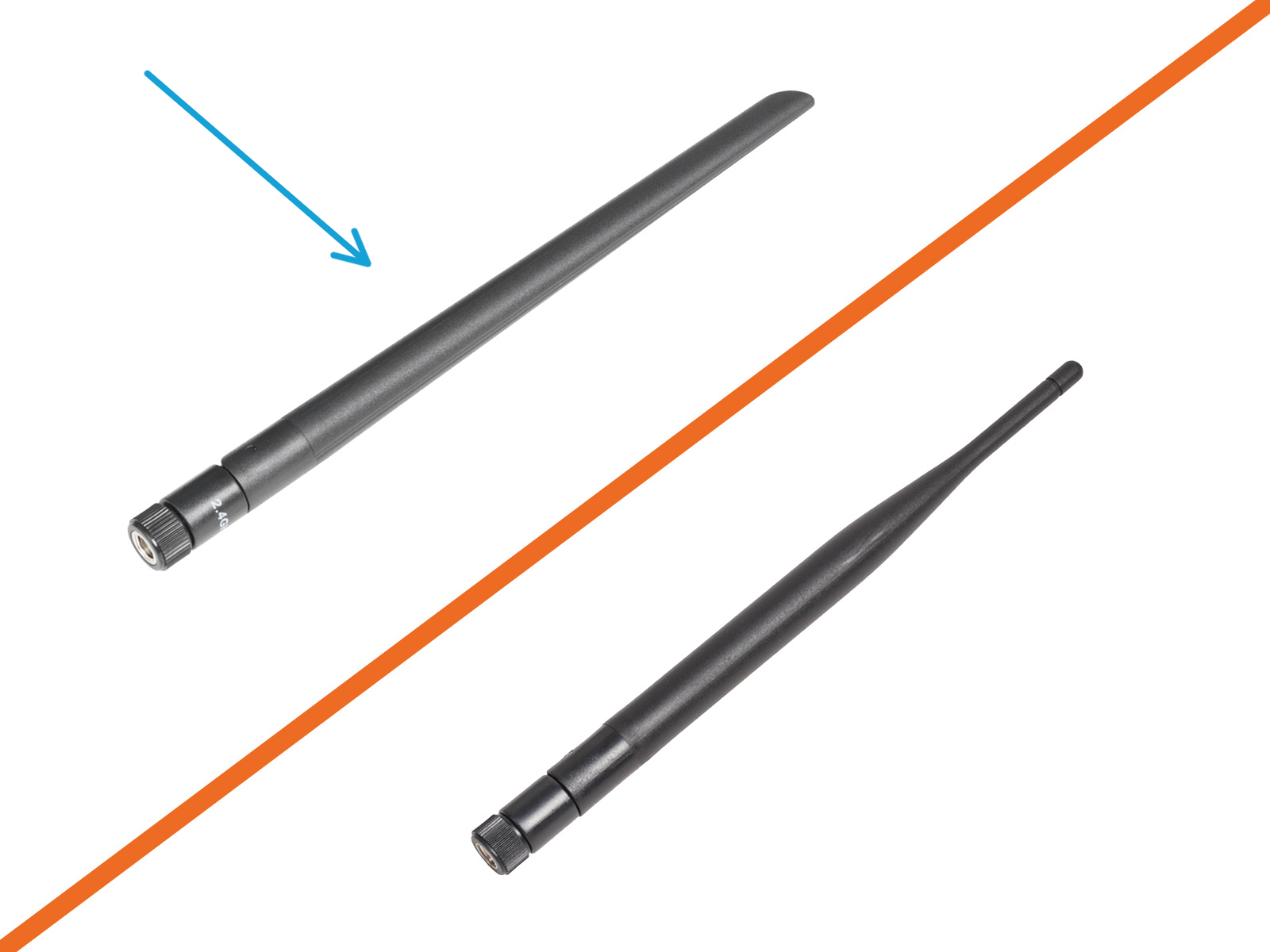

⬢For the next steps, please prepare:

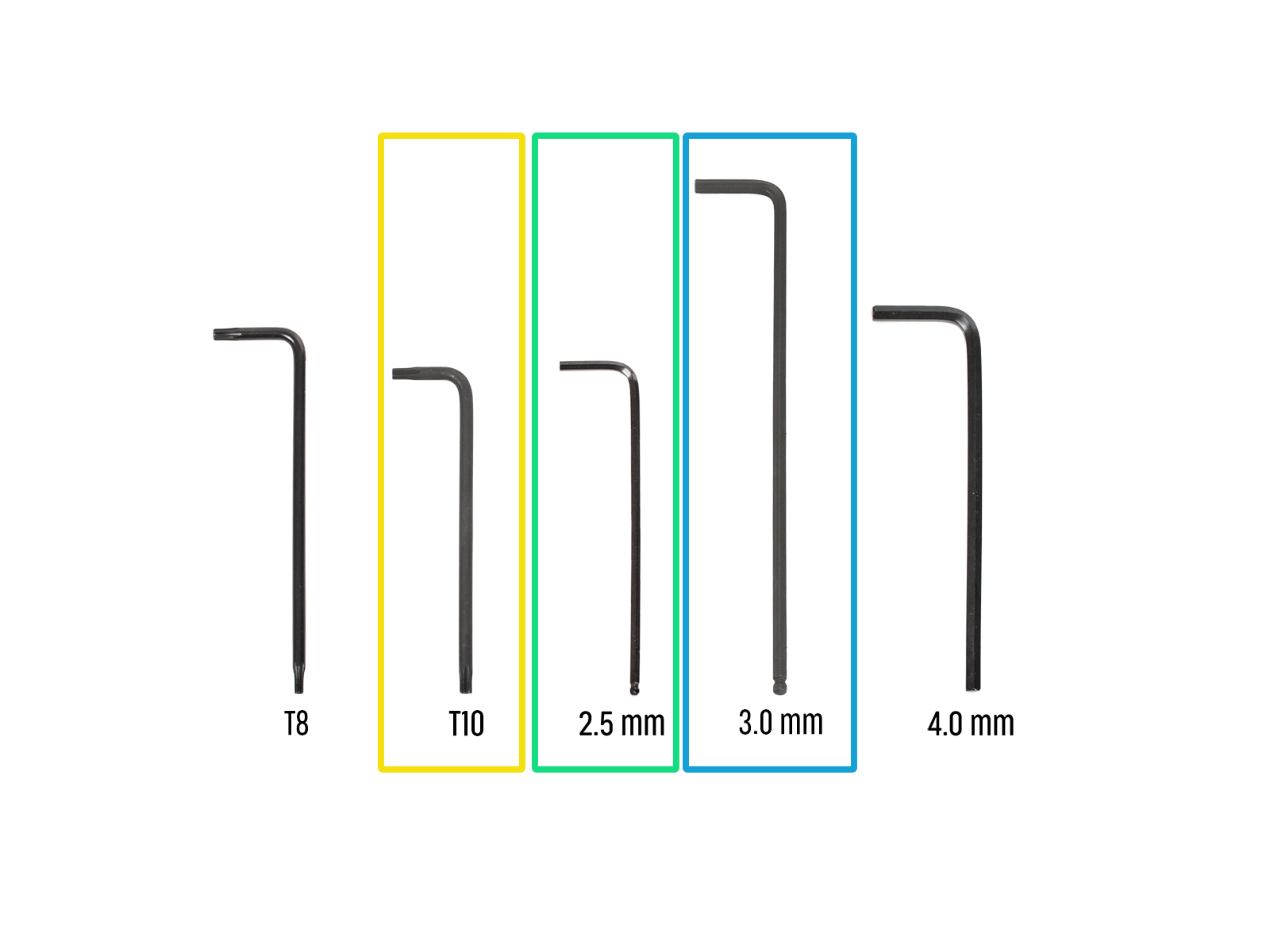

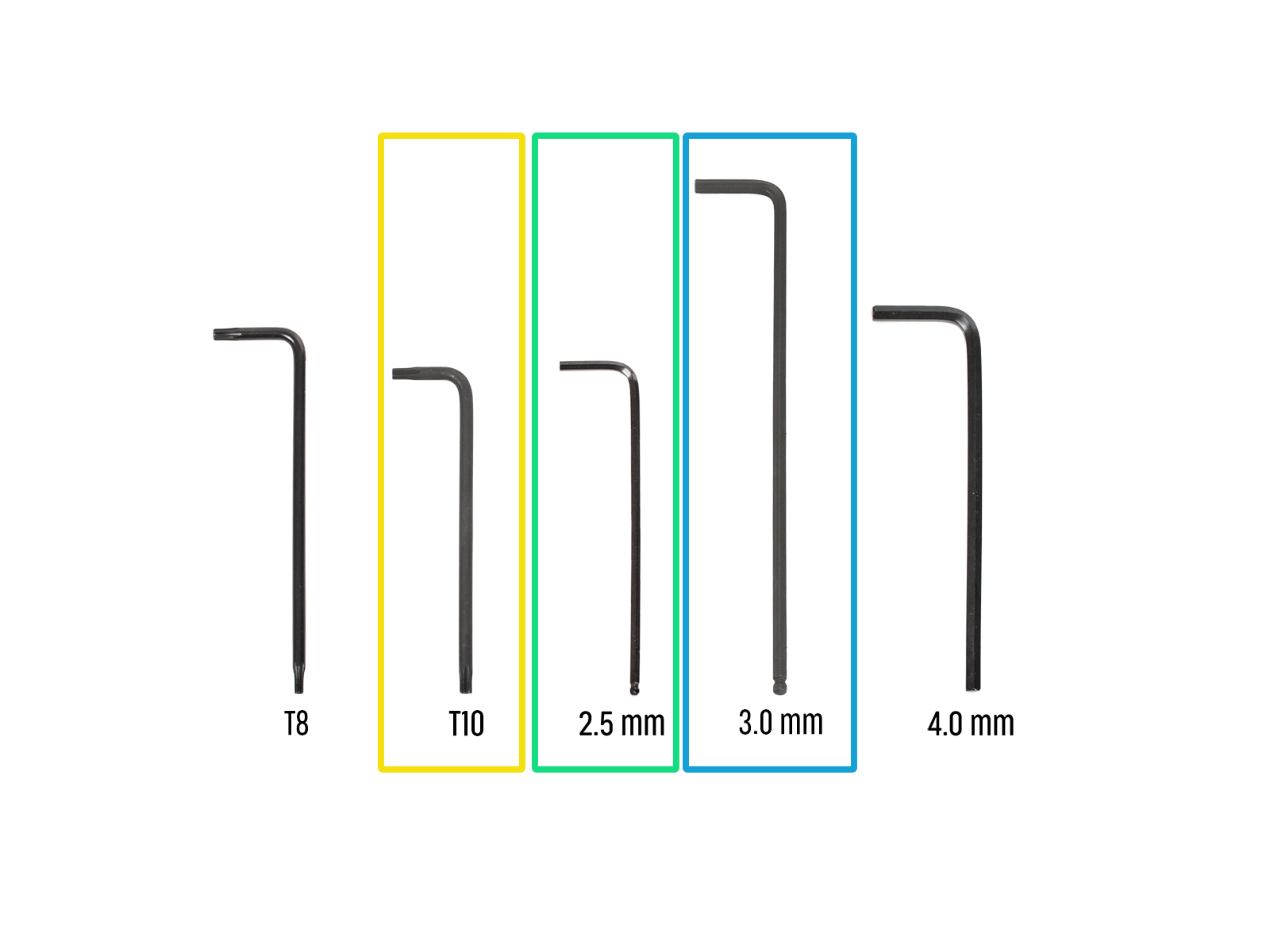

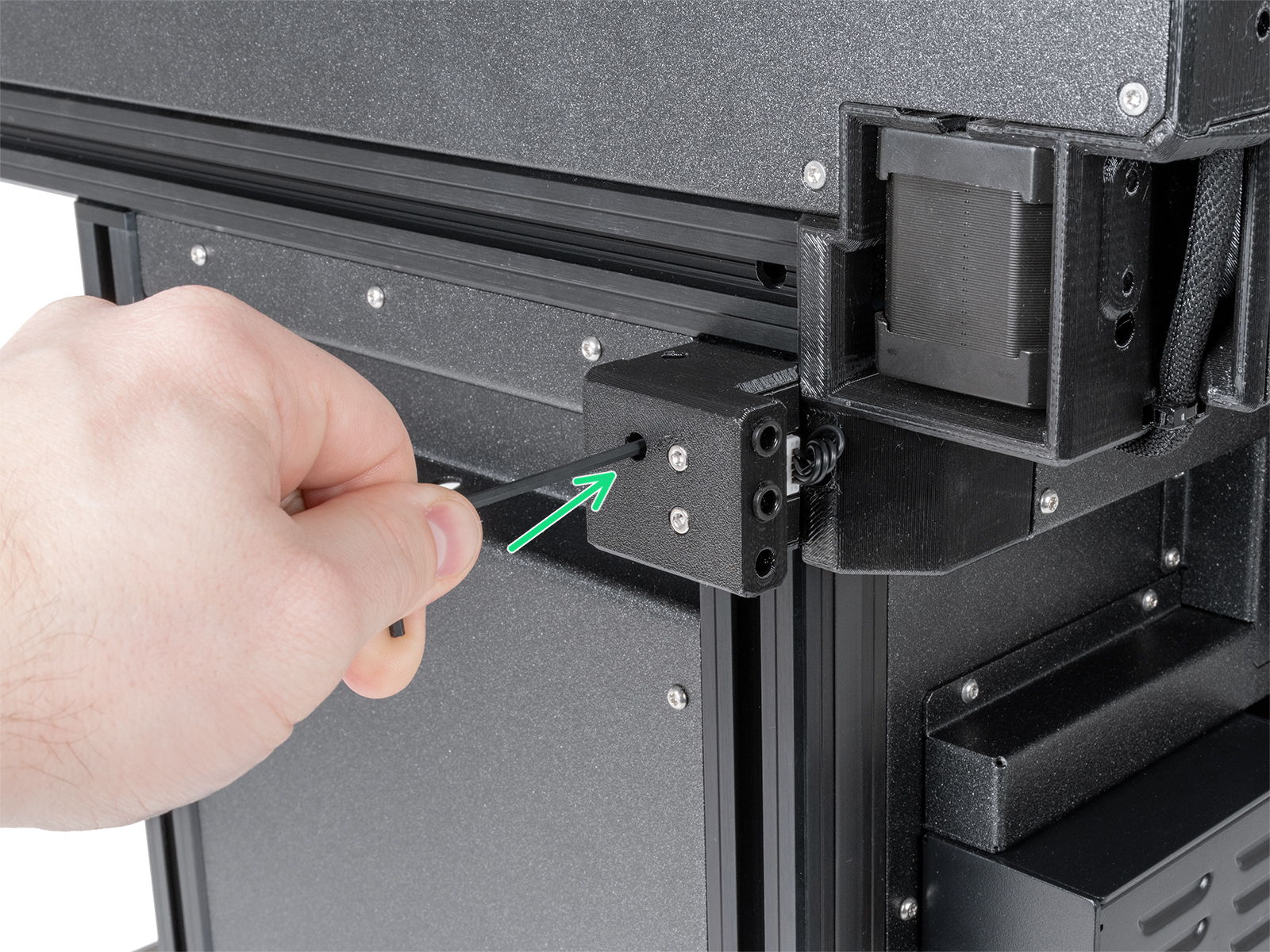

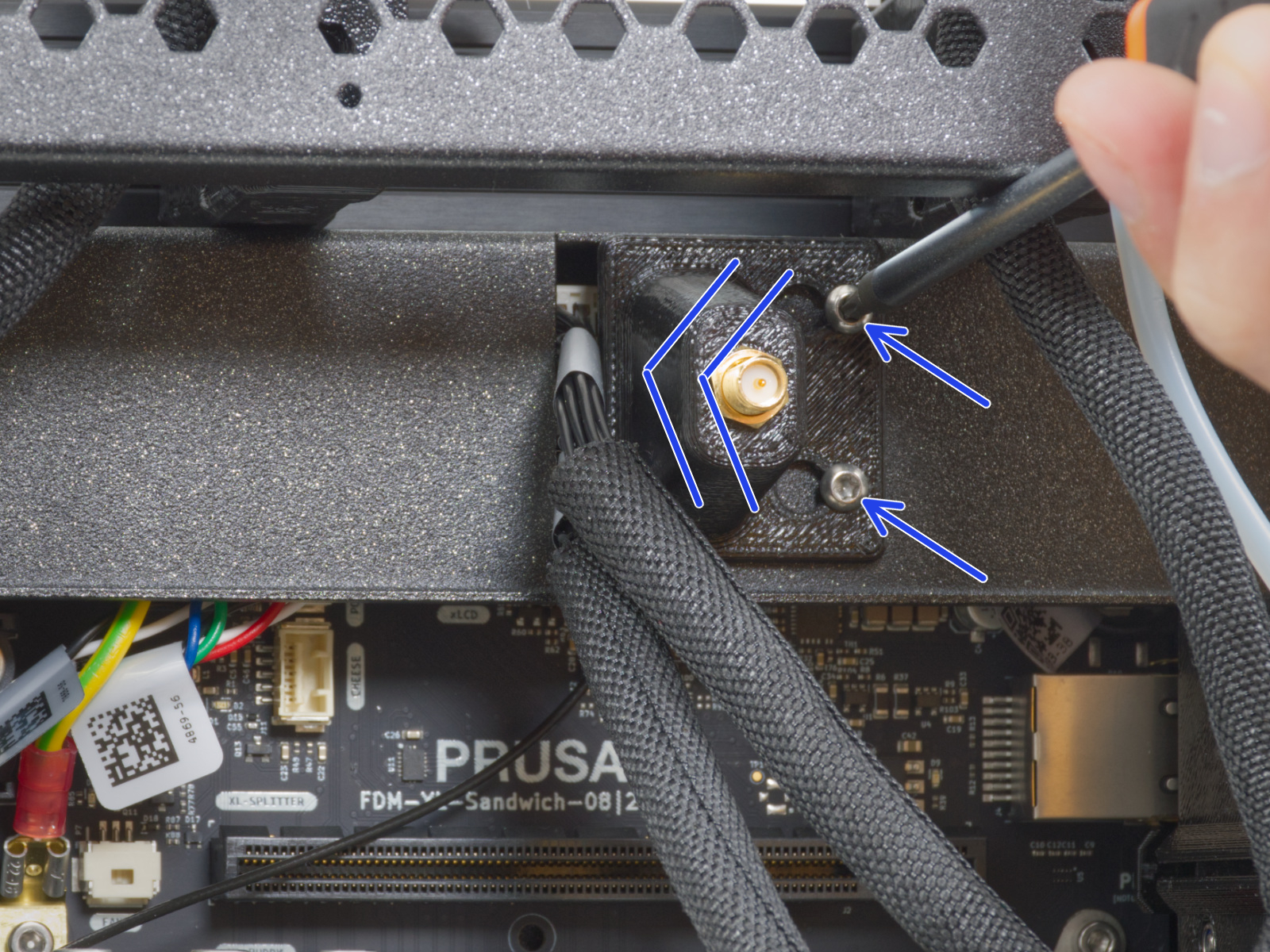

⬢T10 Torx key

⬢2.5 mm Allen key

⬢3.0 mm Allen key

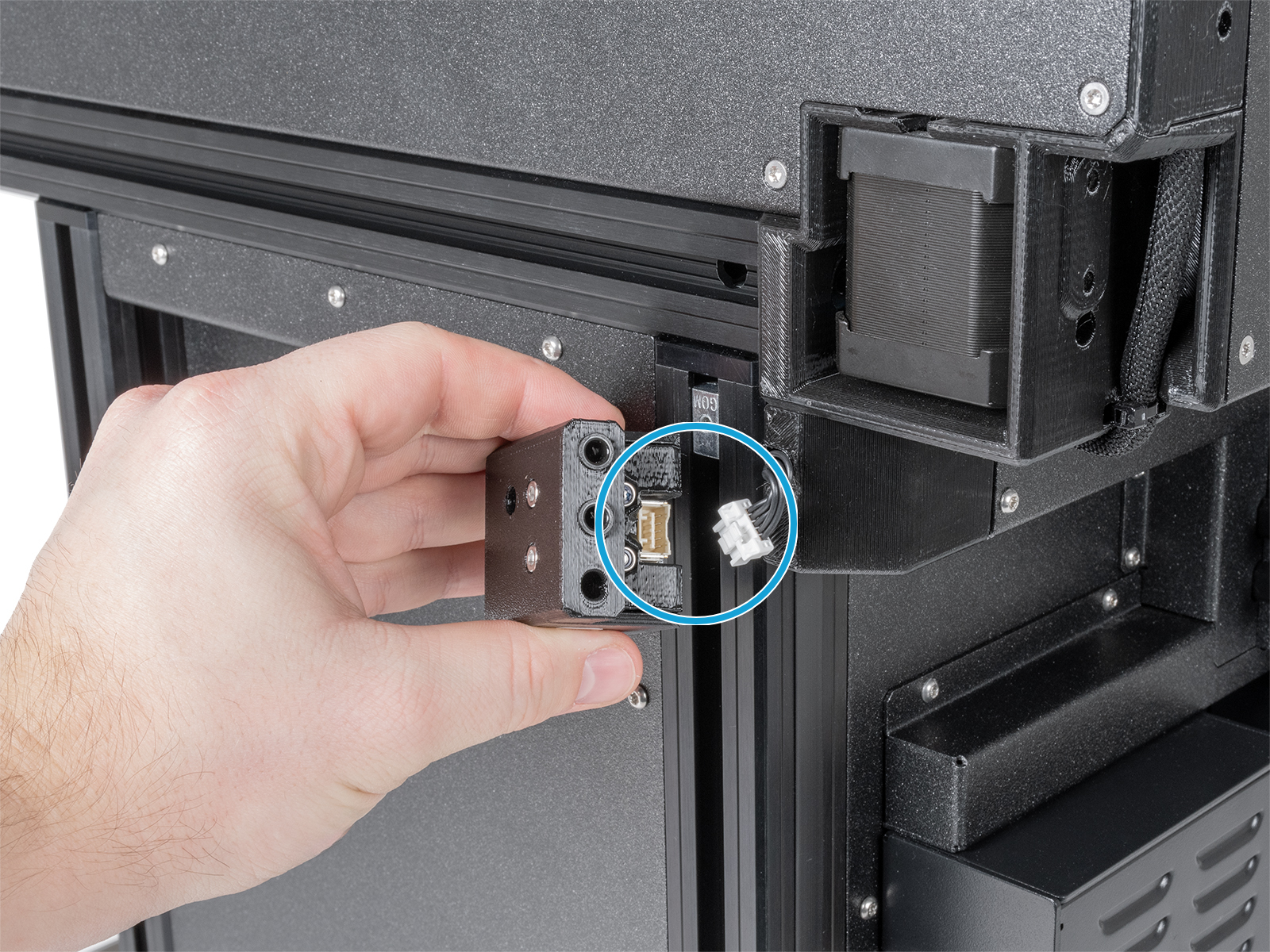

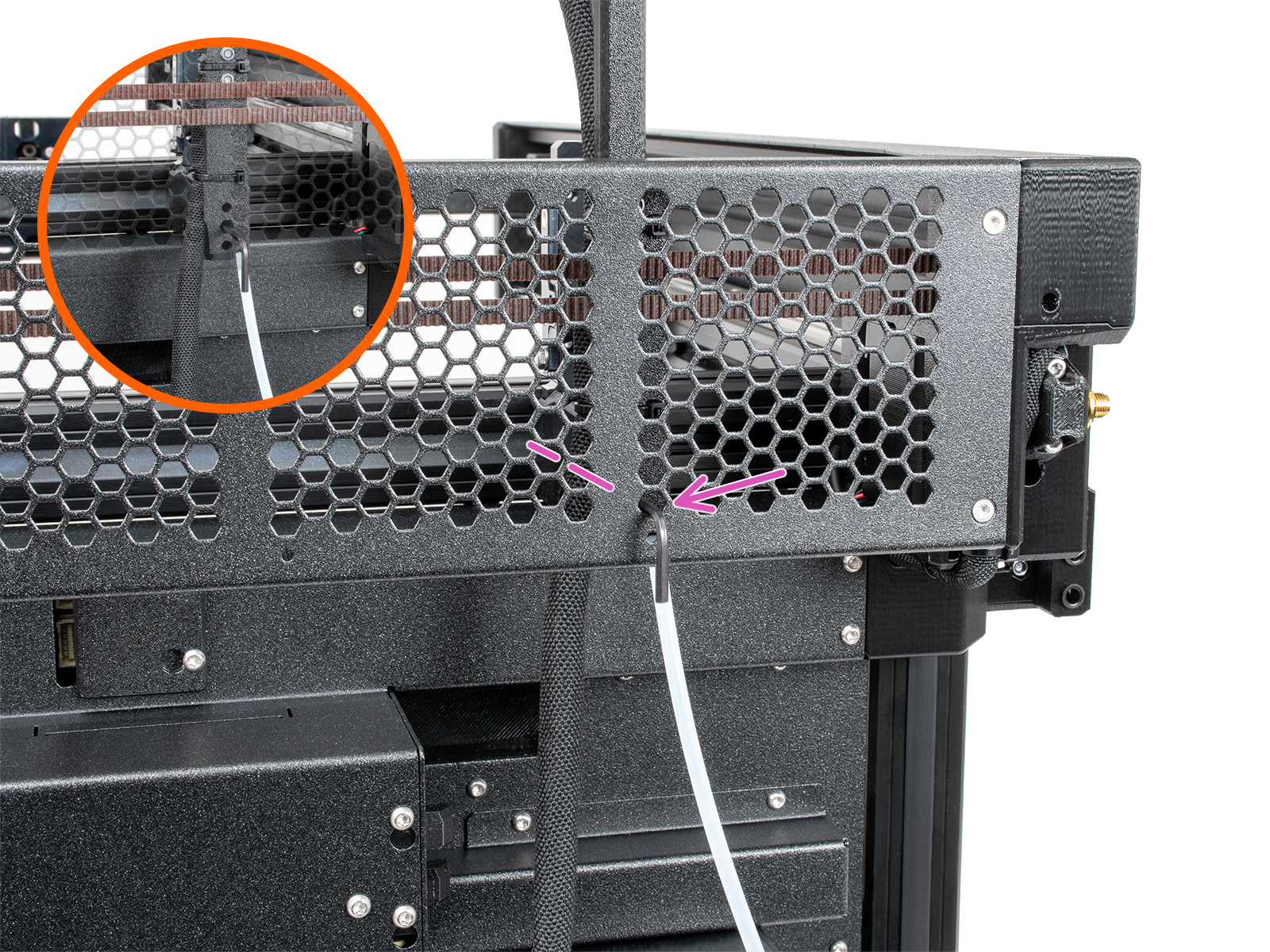

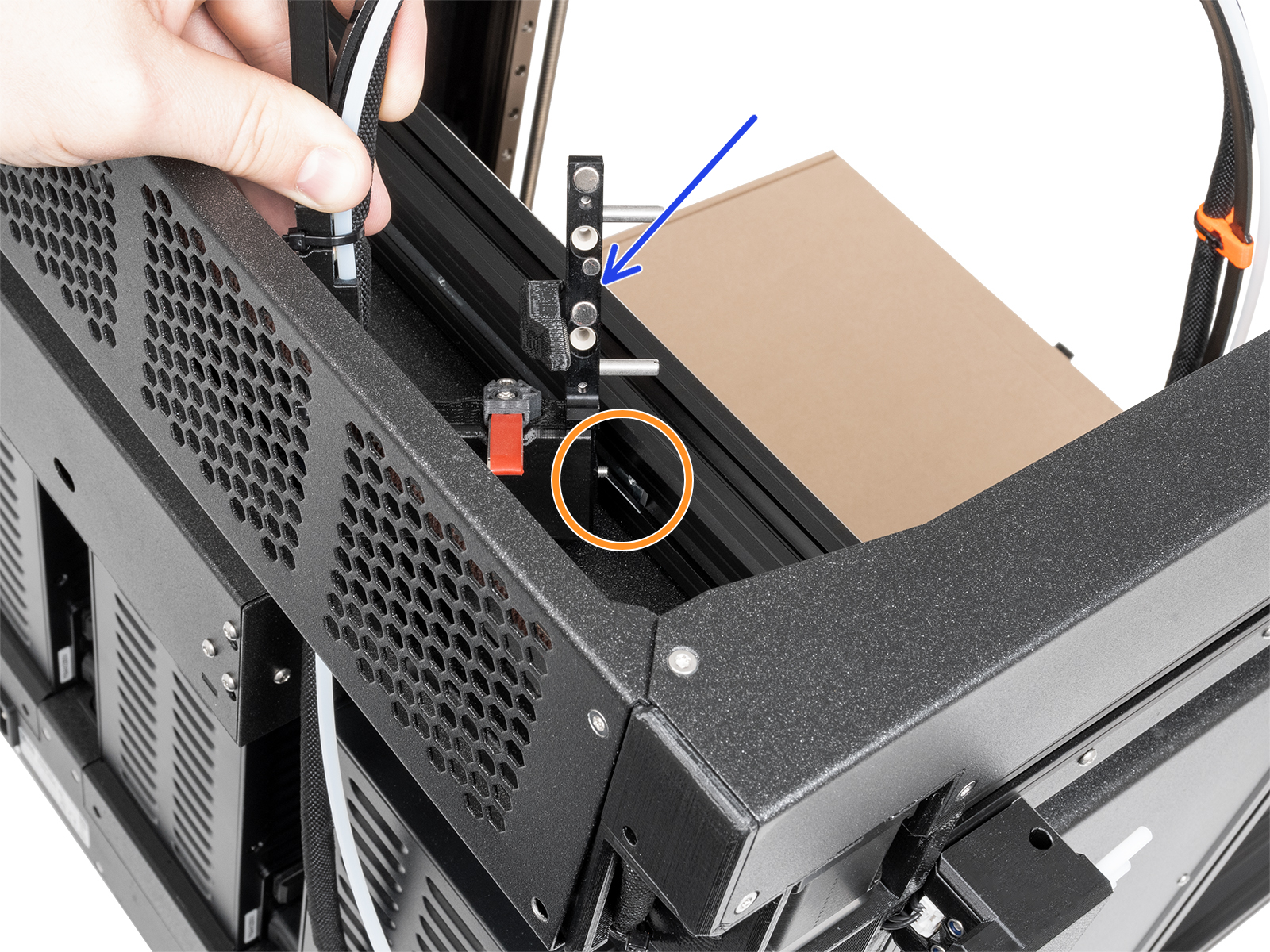

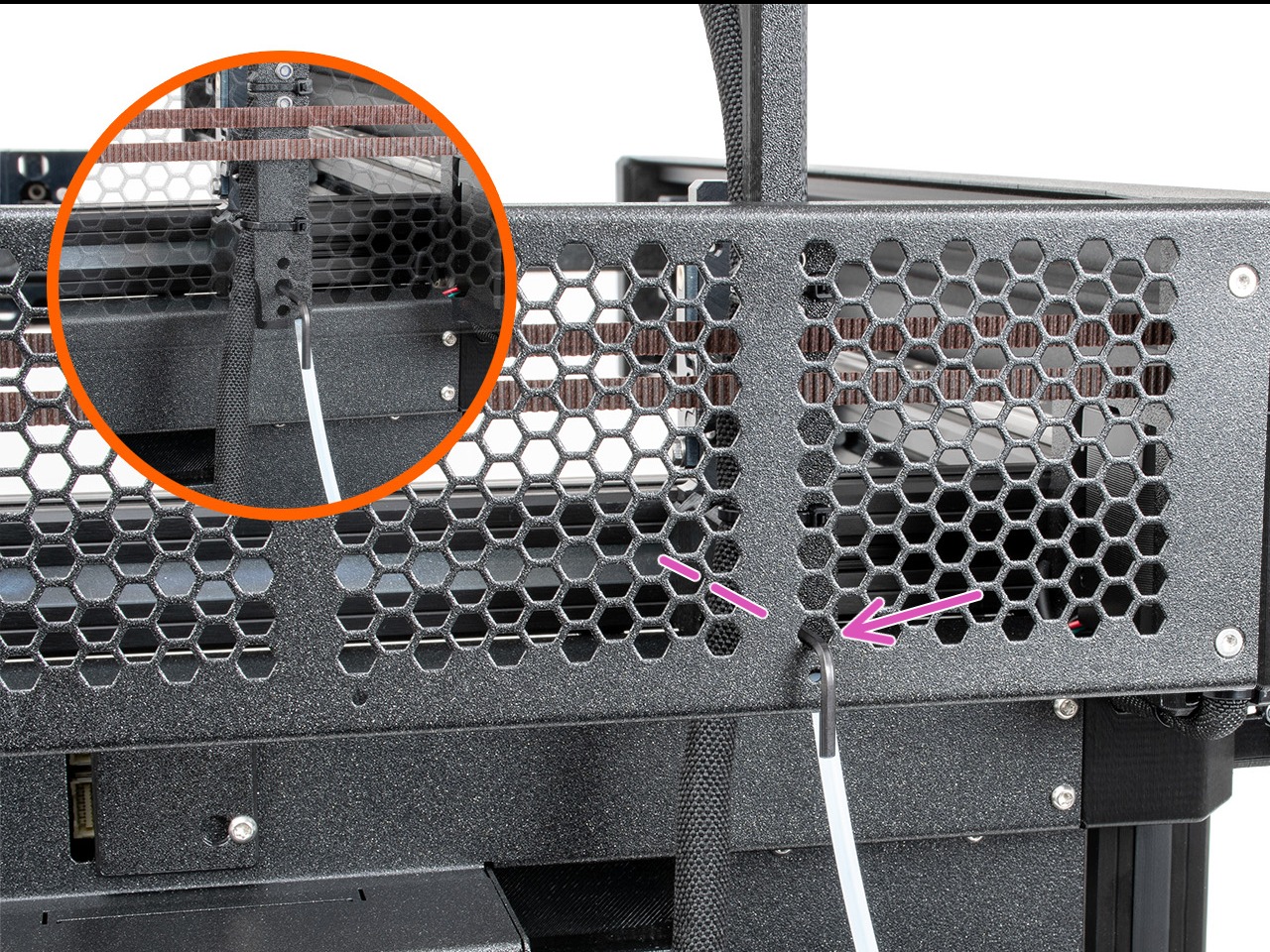

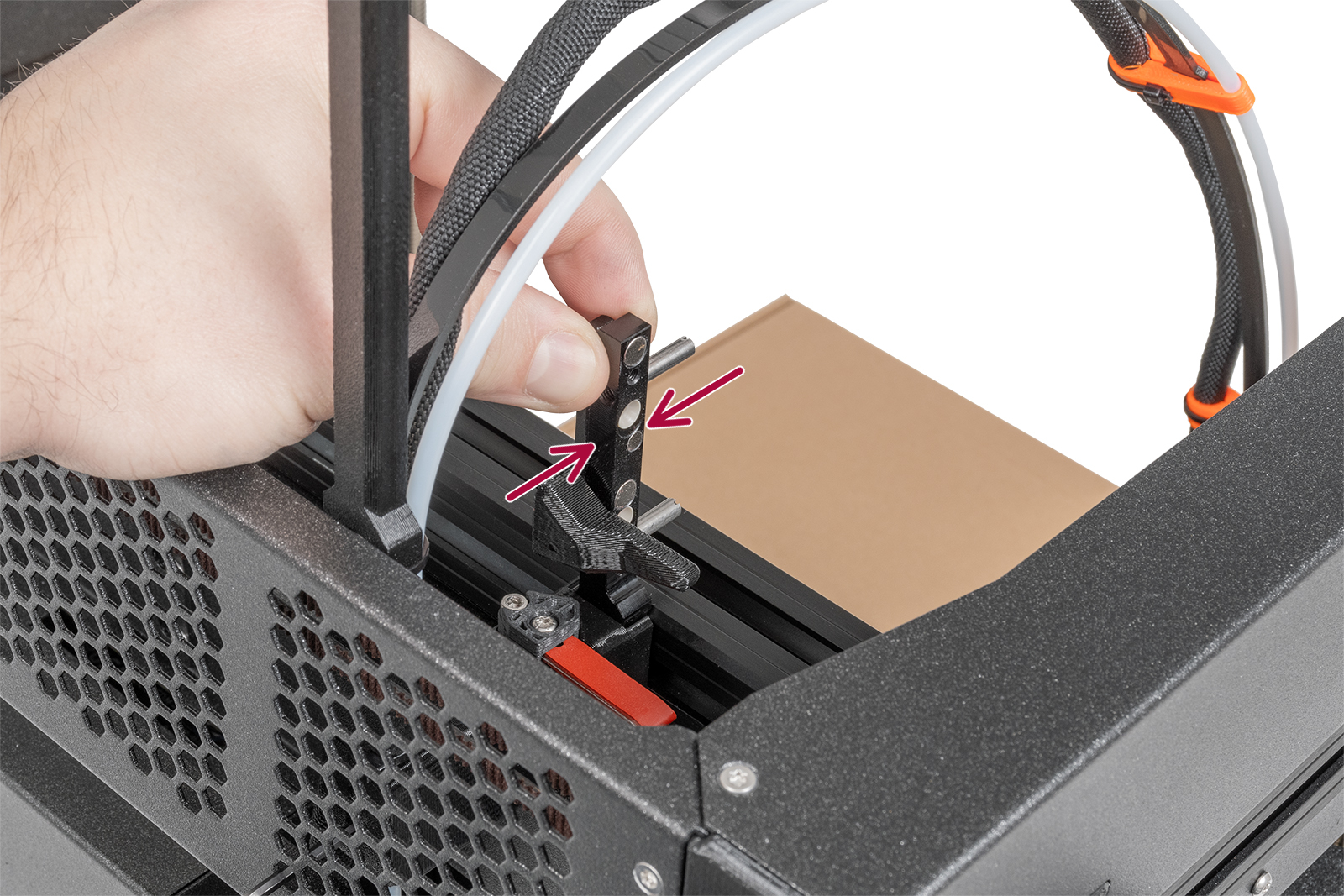

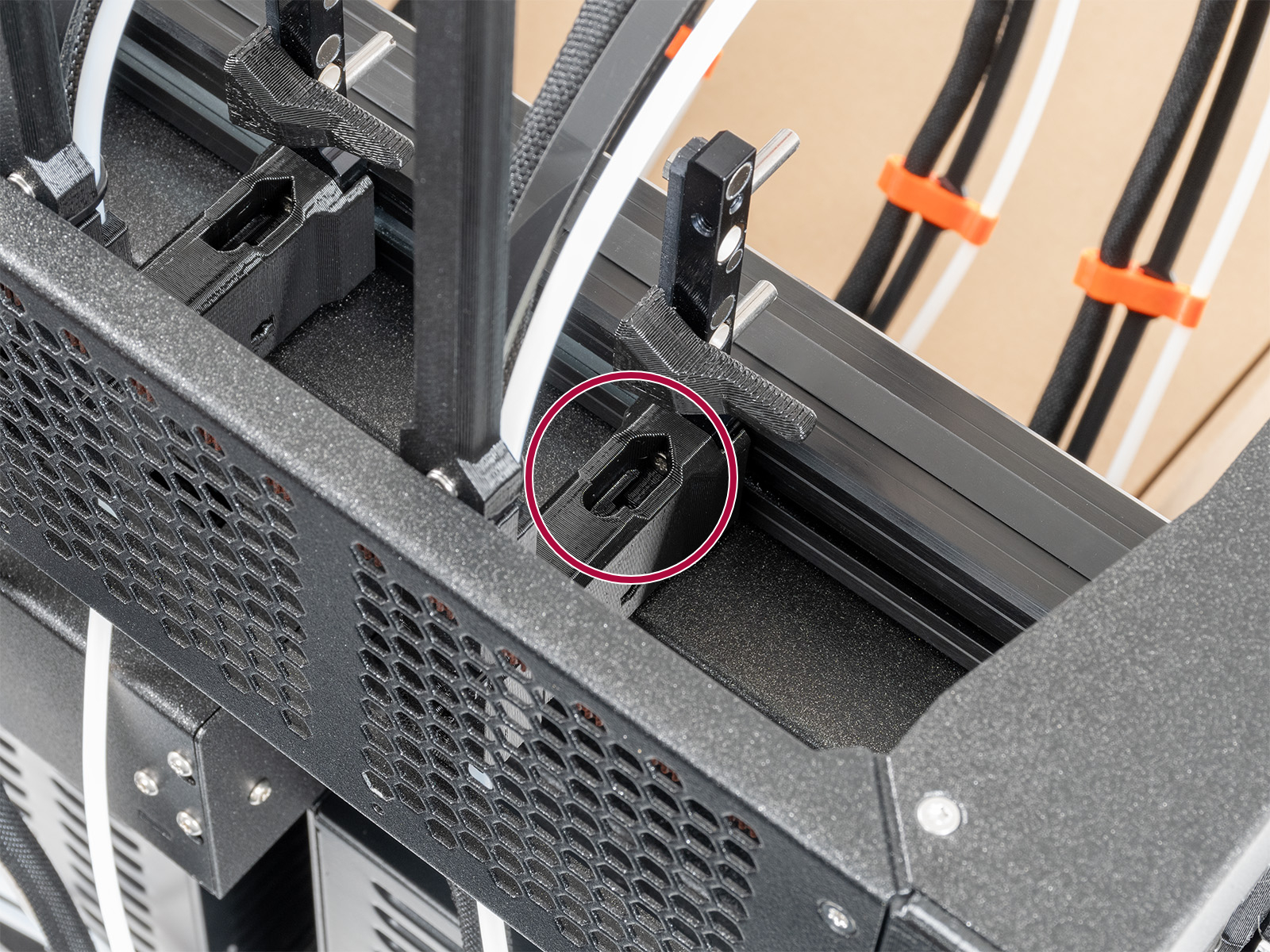

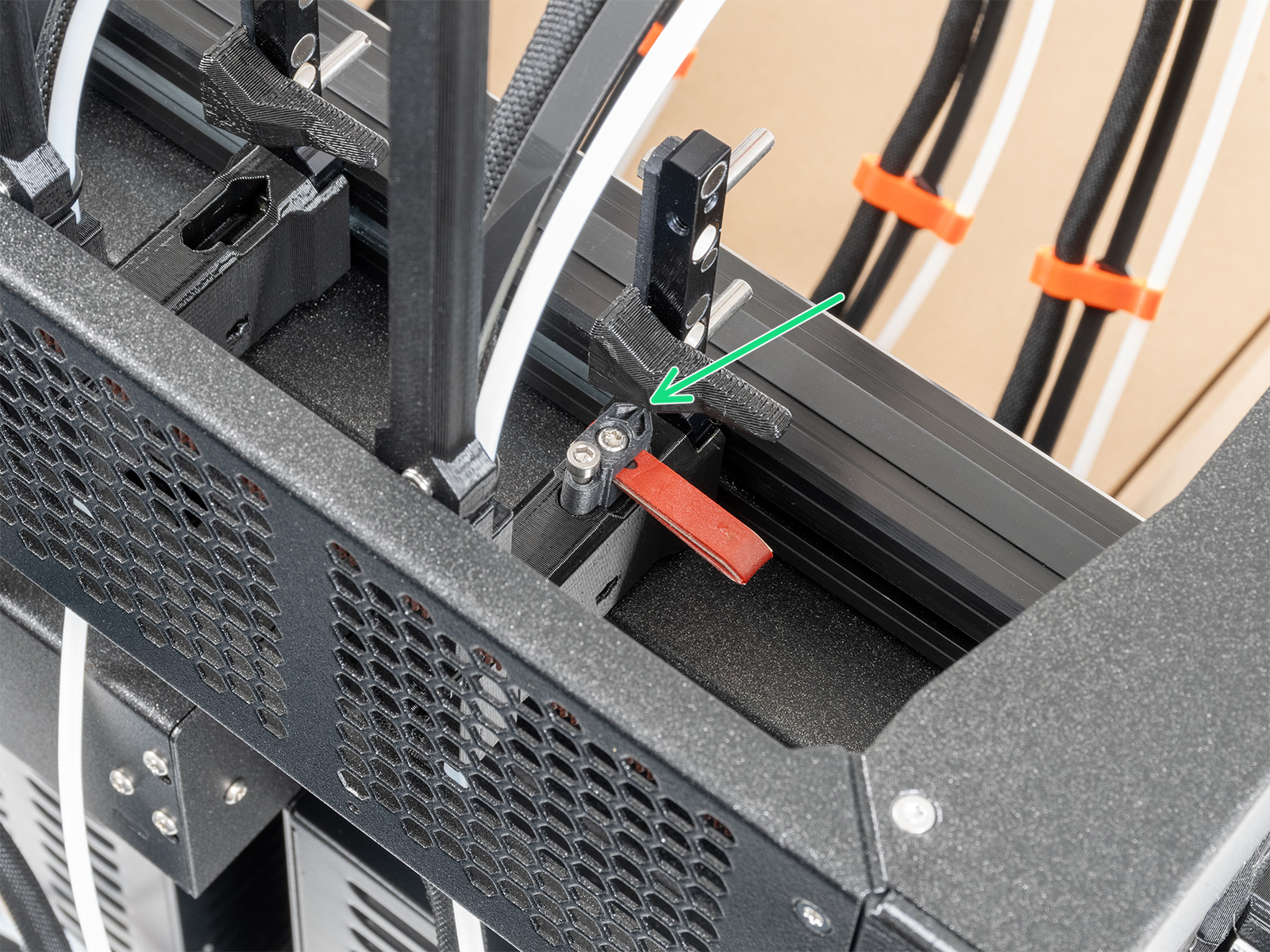

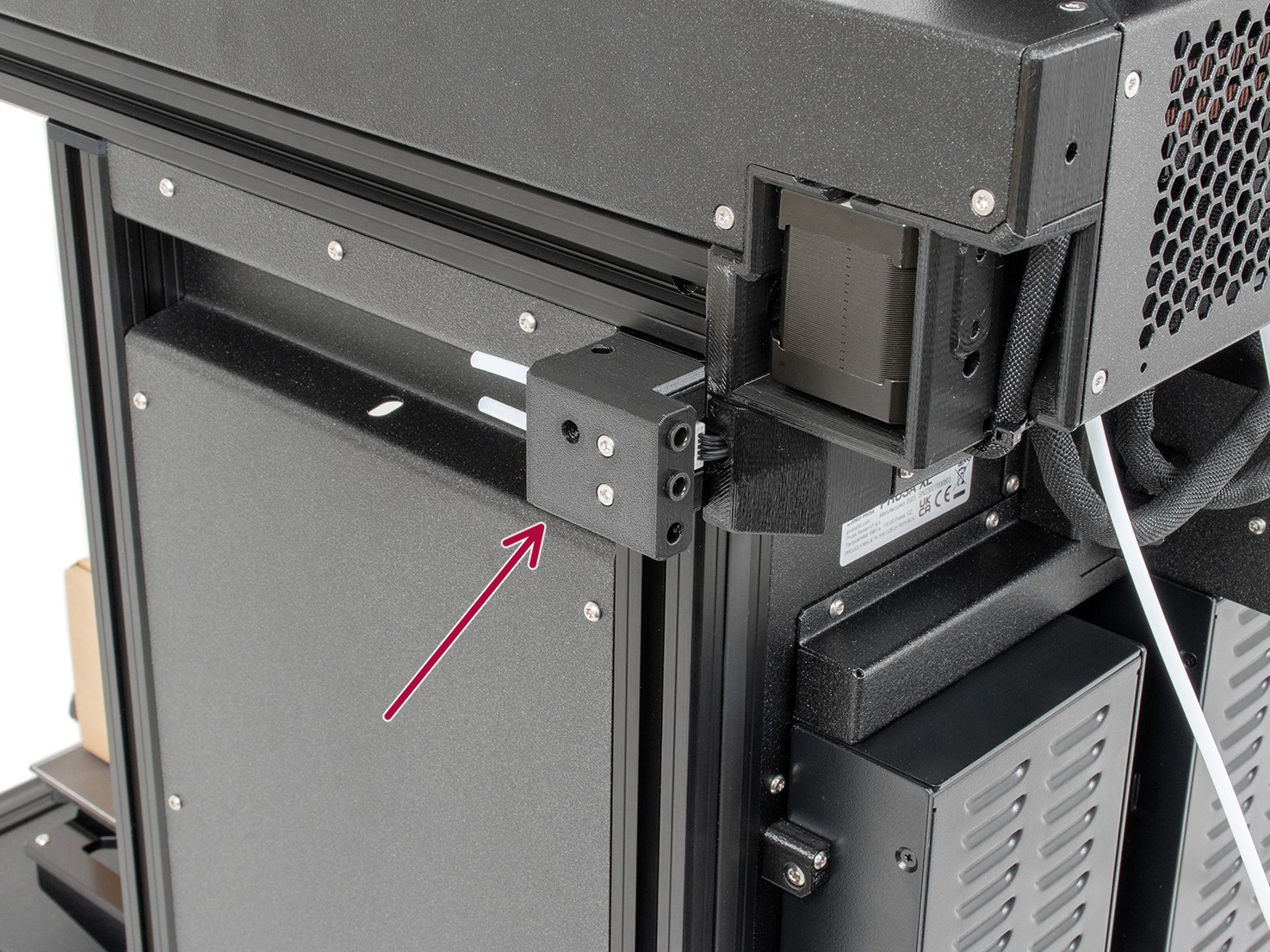

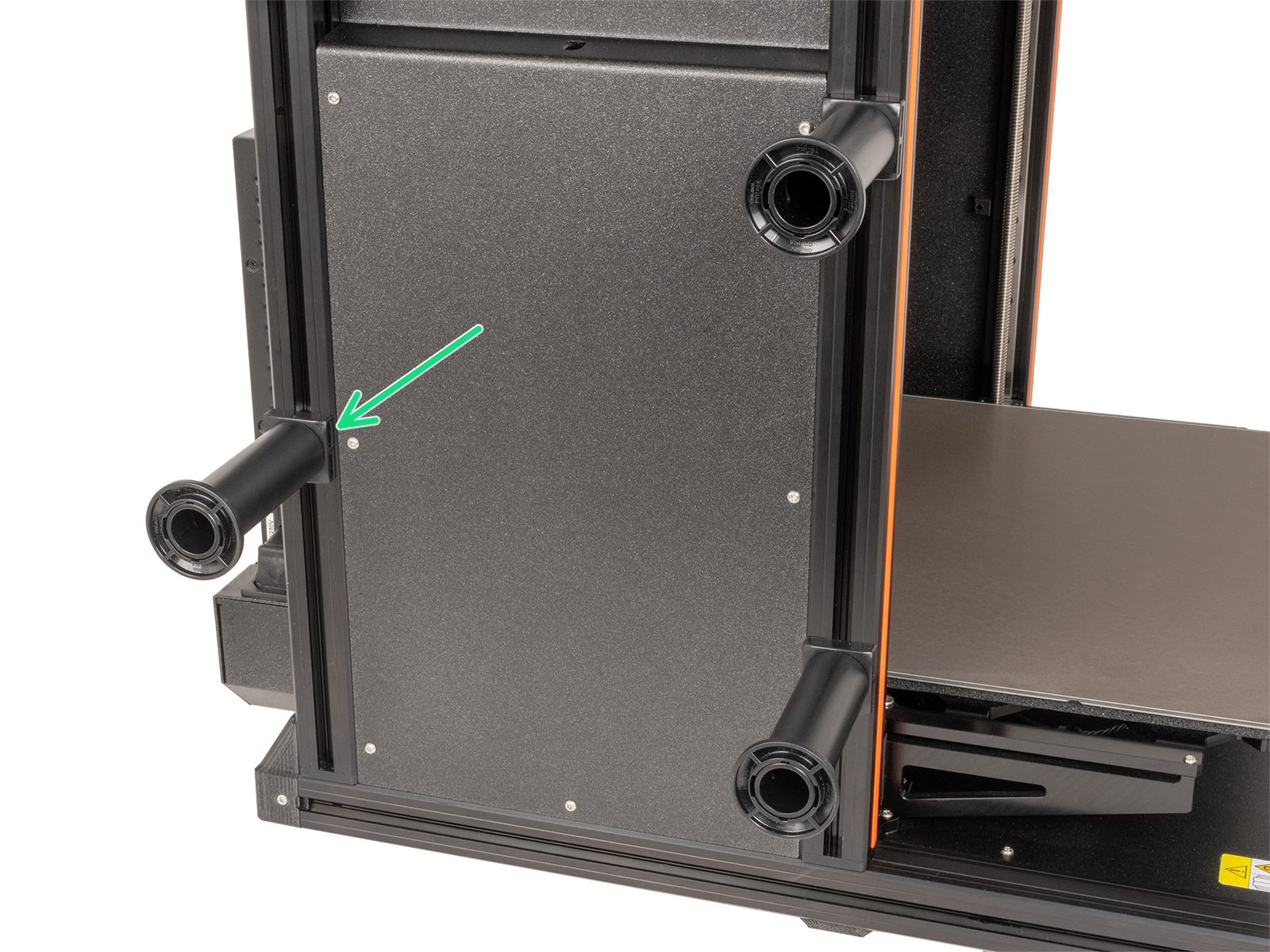

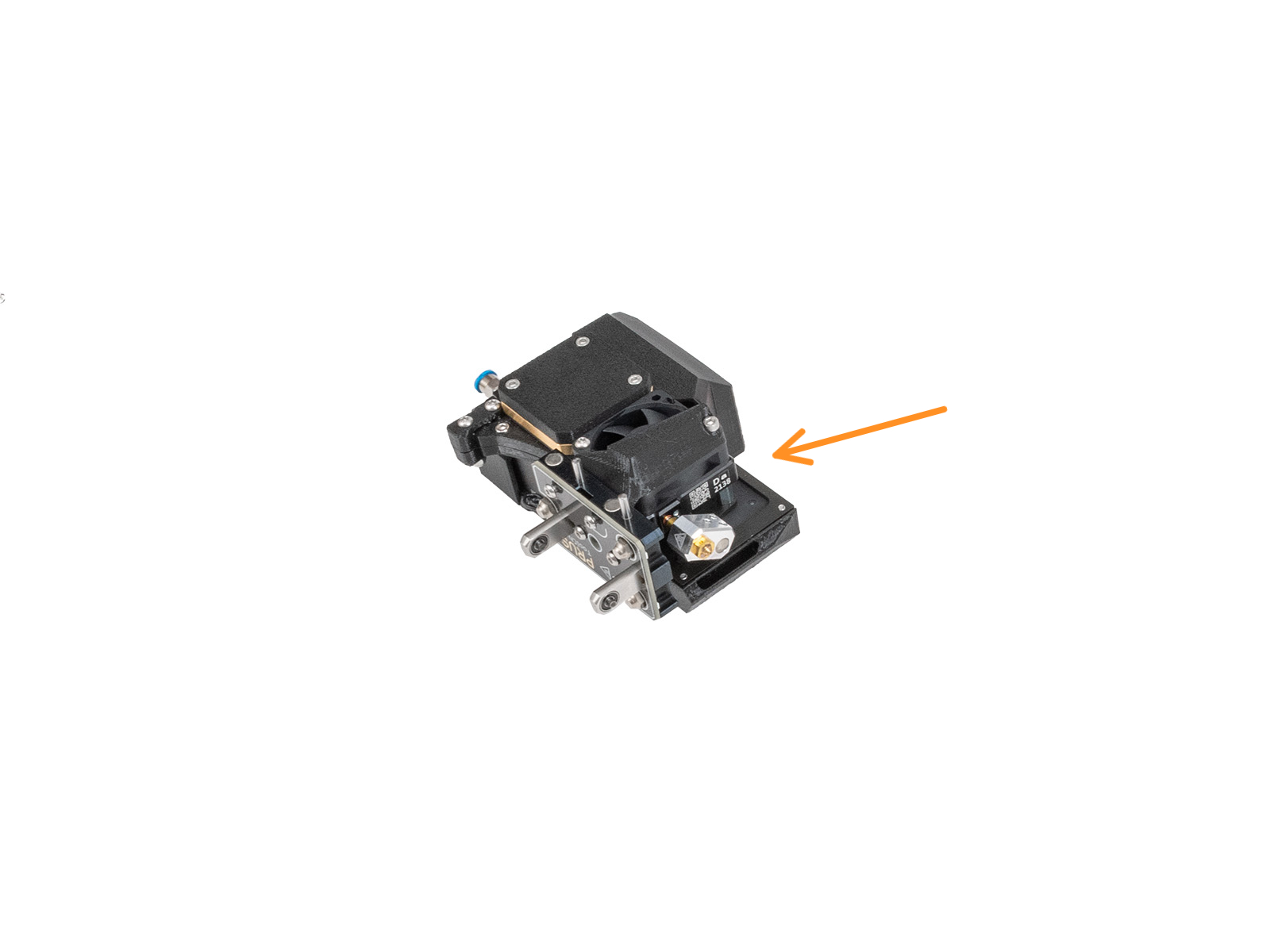

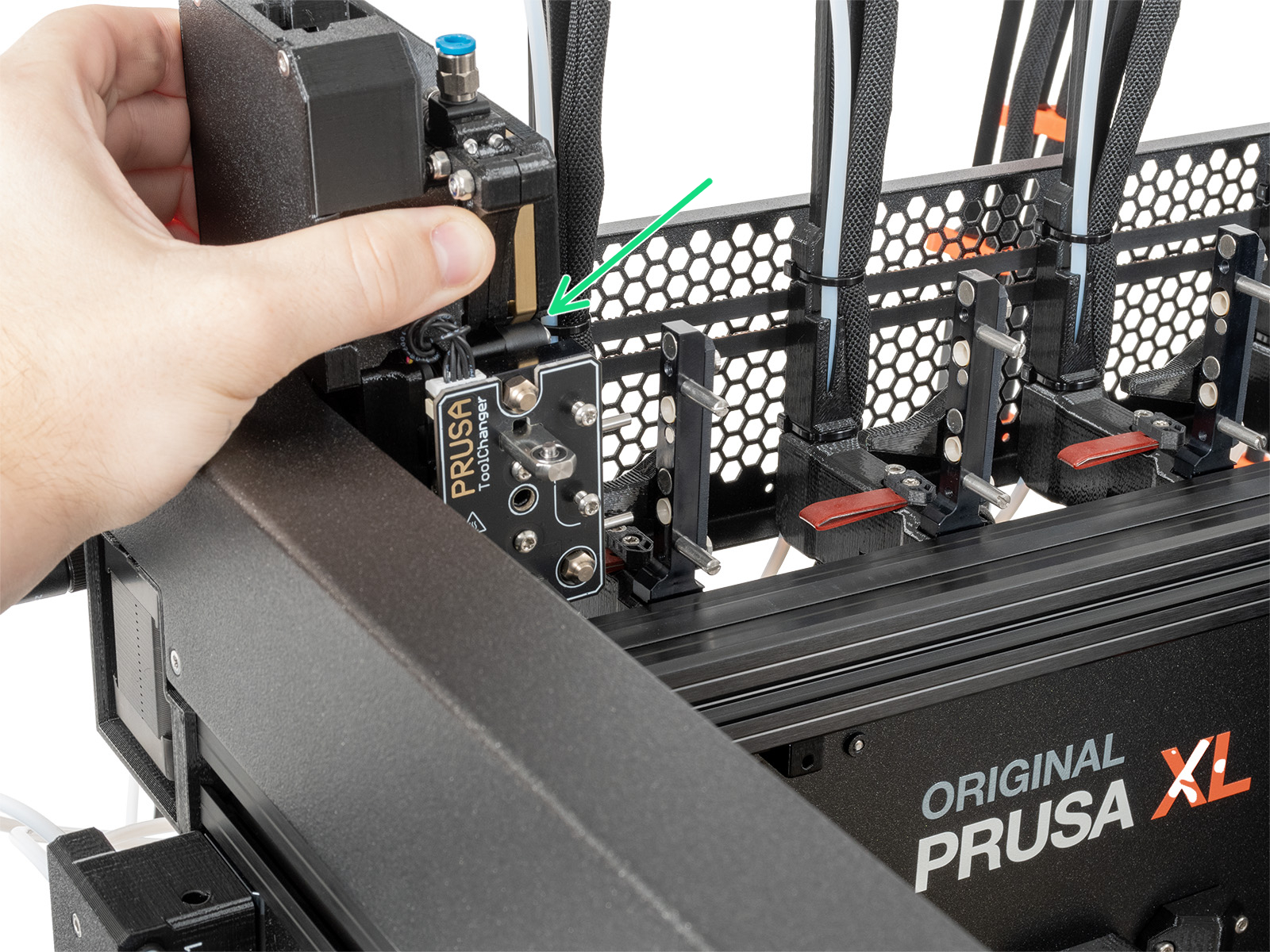

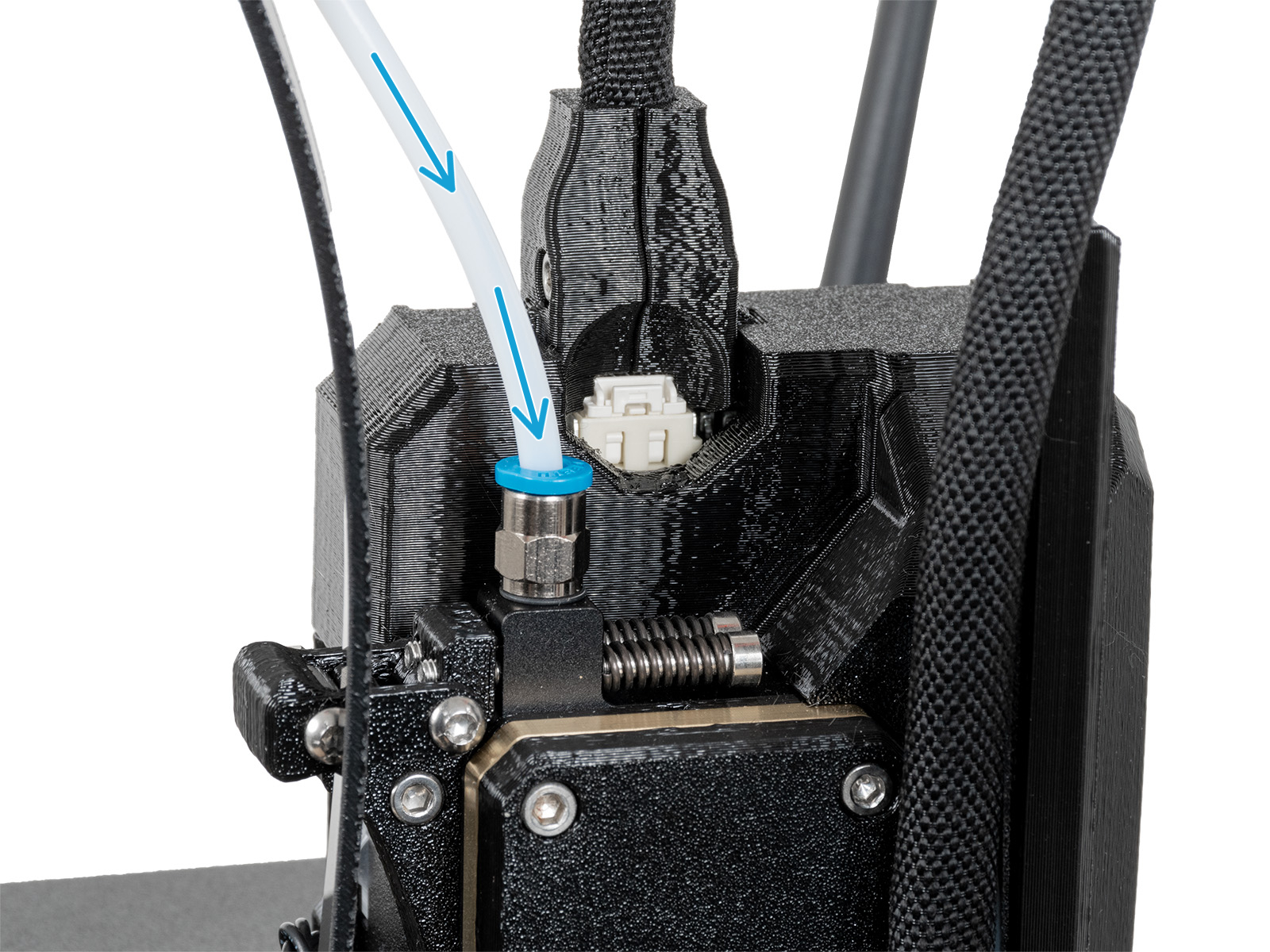

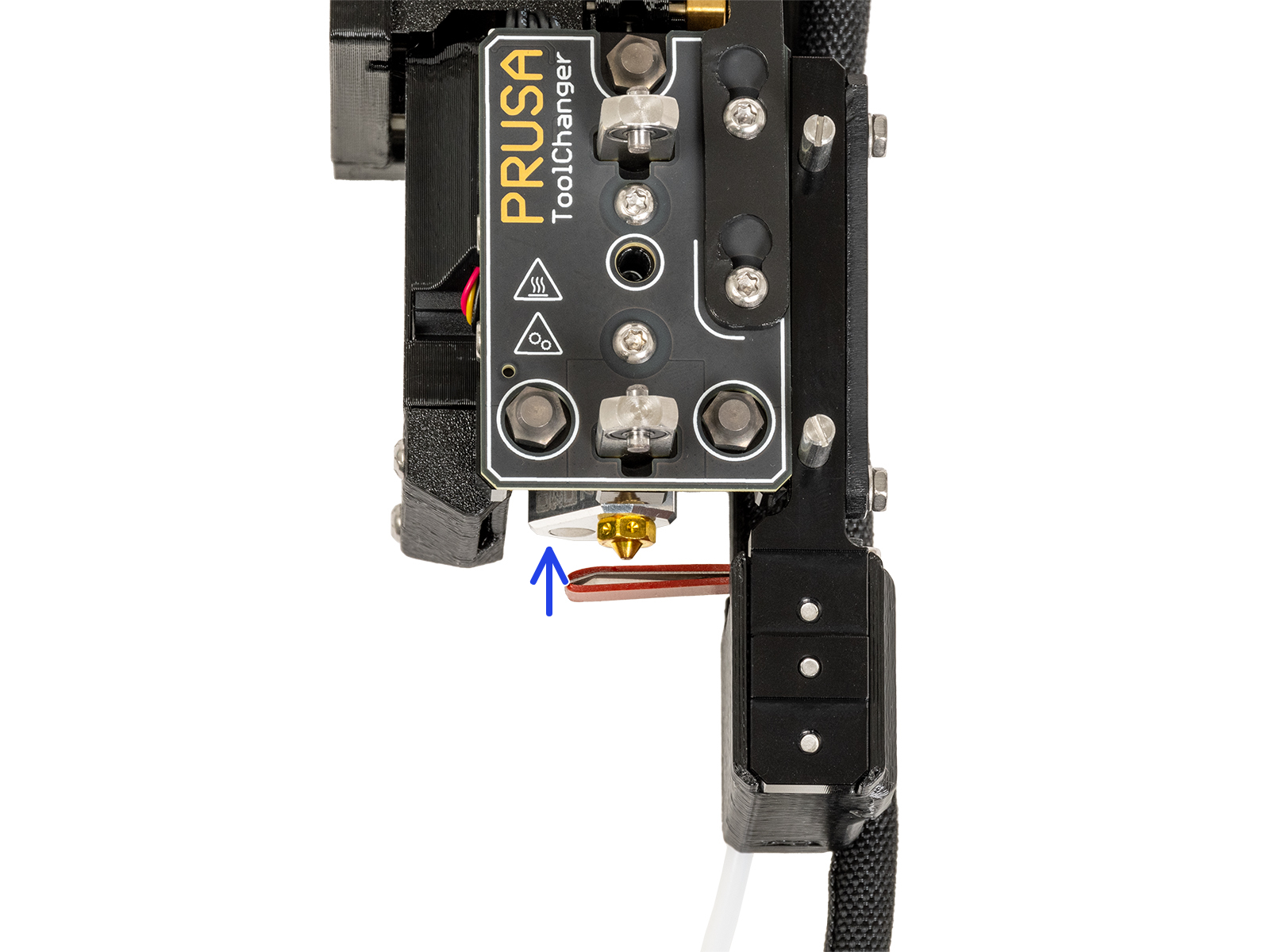

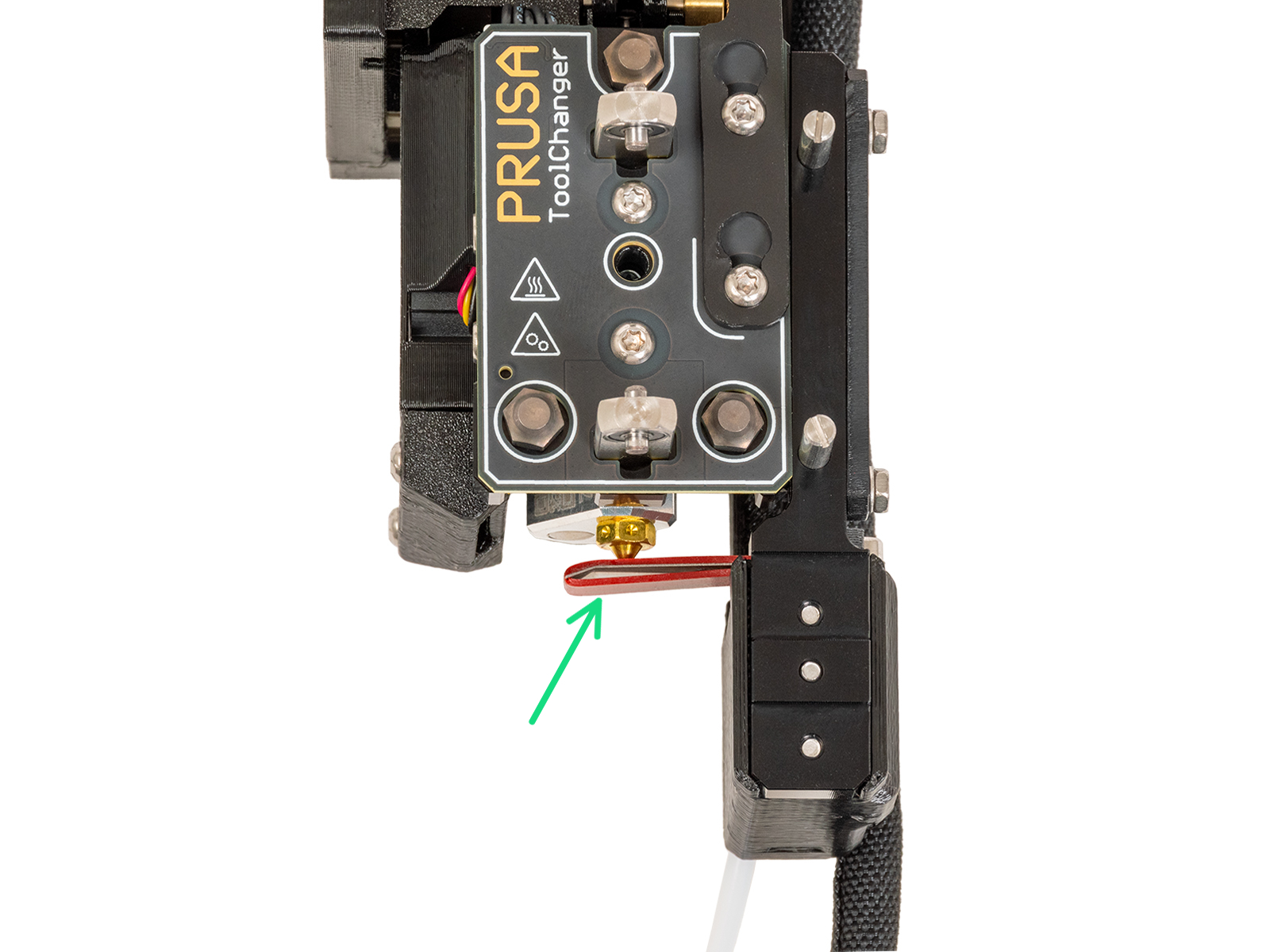

Insert the semi-transparent PTFE tube into the FESTO fitting on the Nextruder. Push it all the way in.

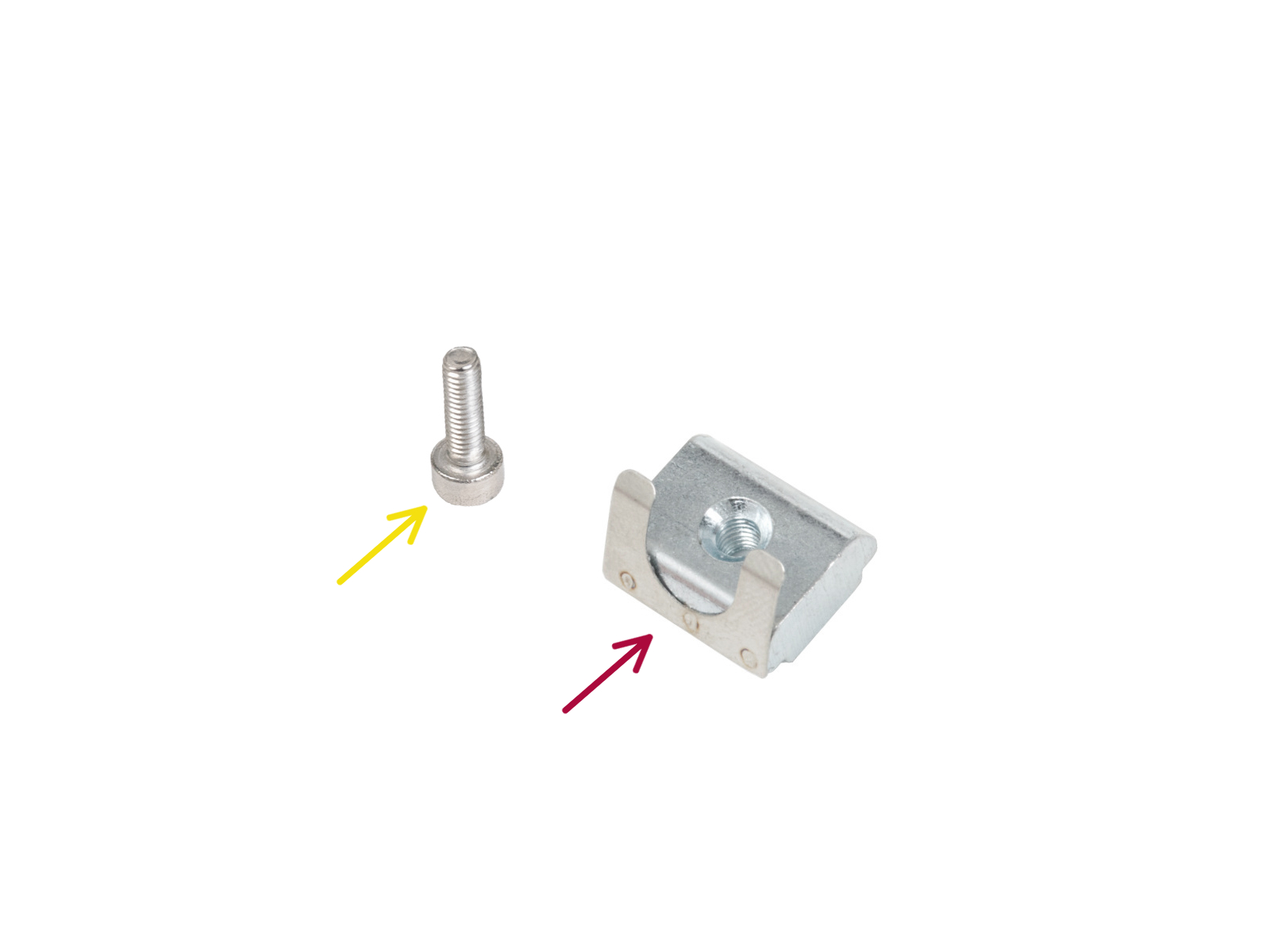

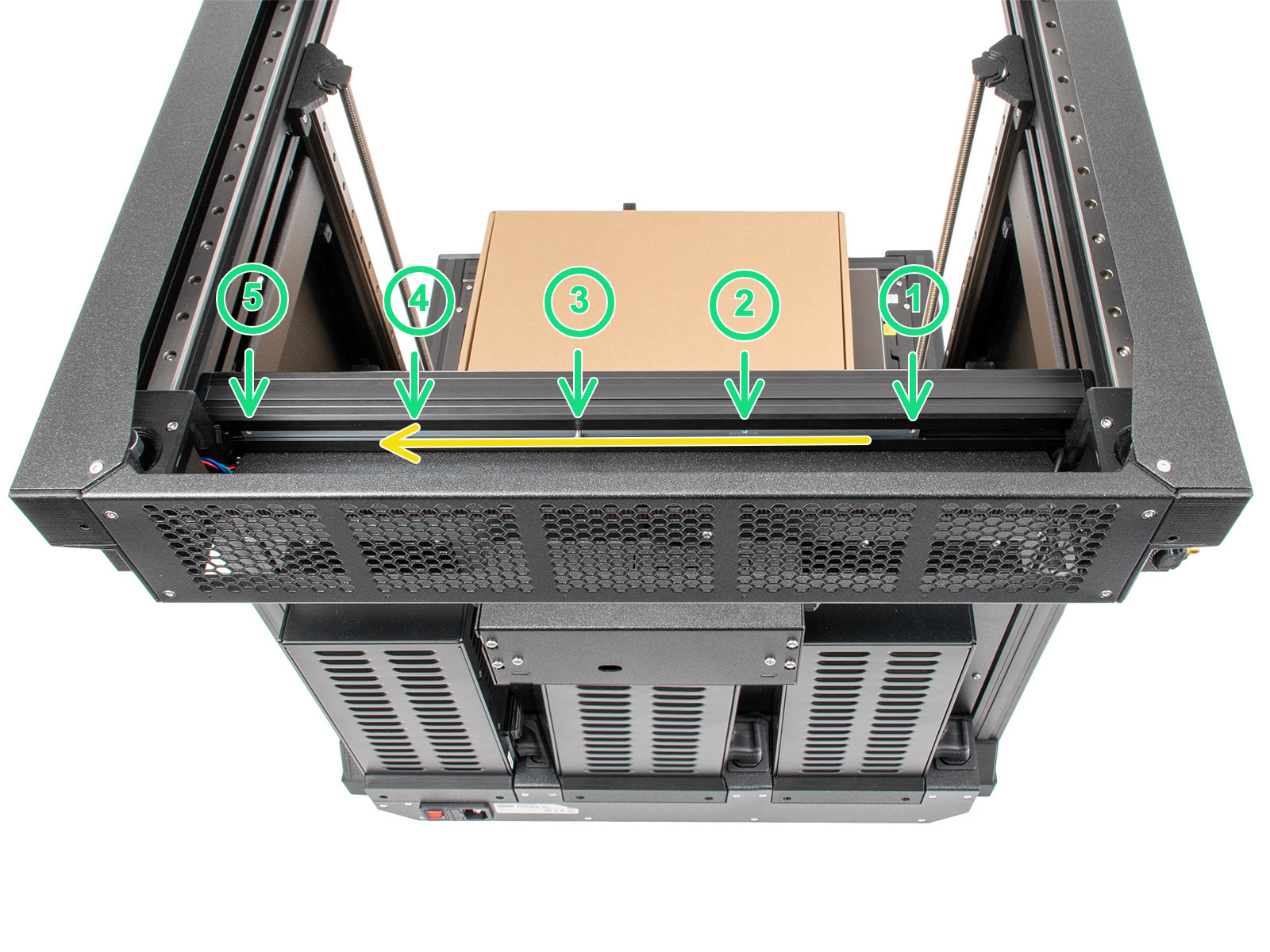

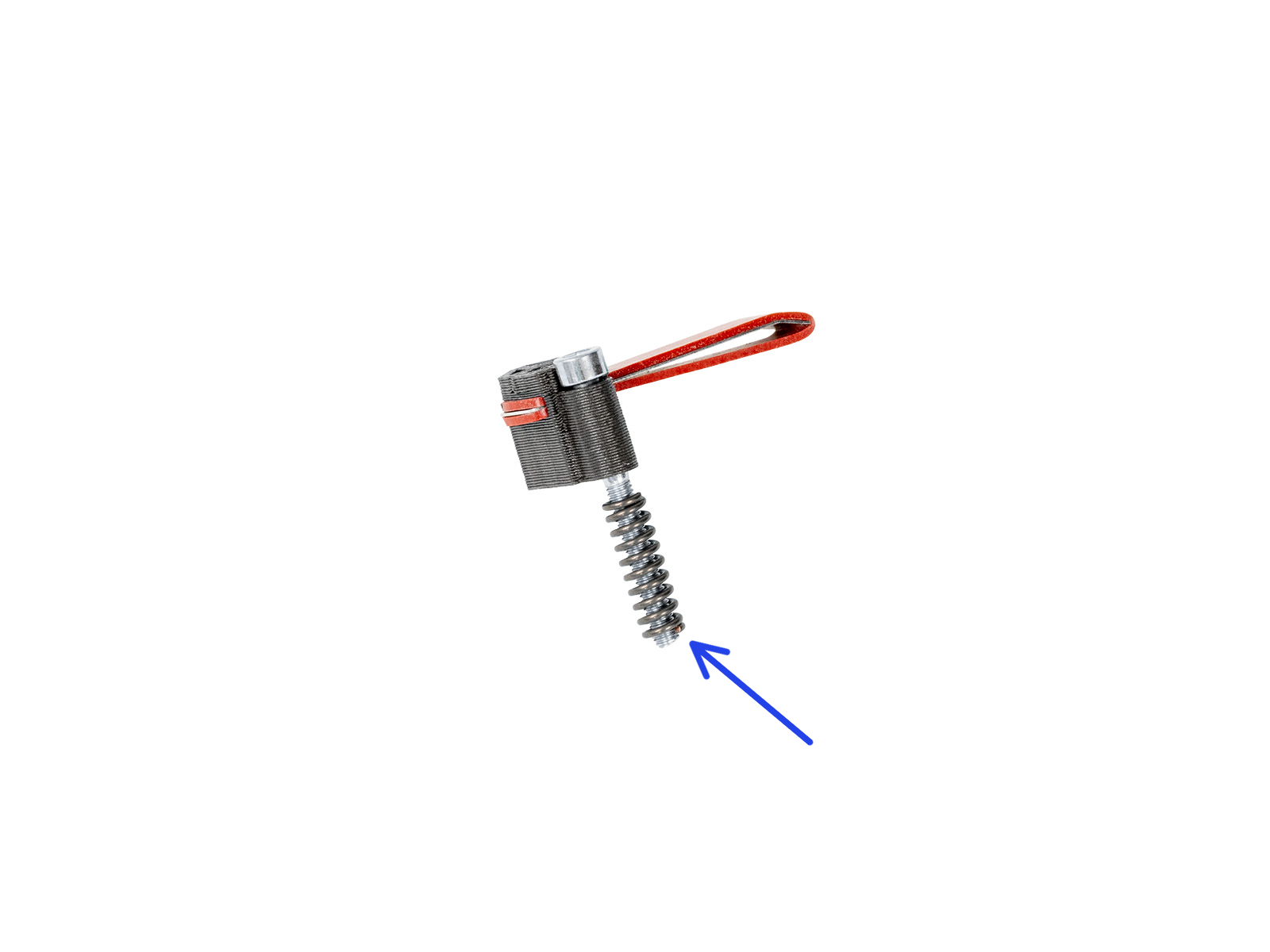

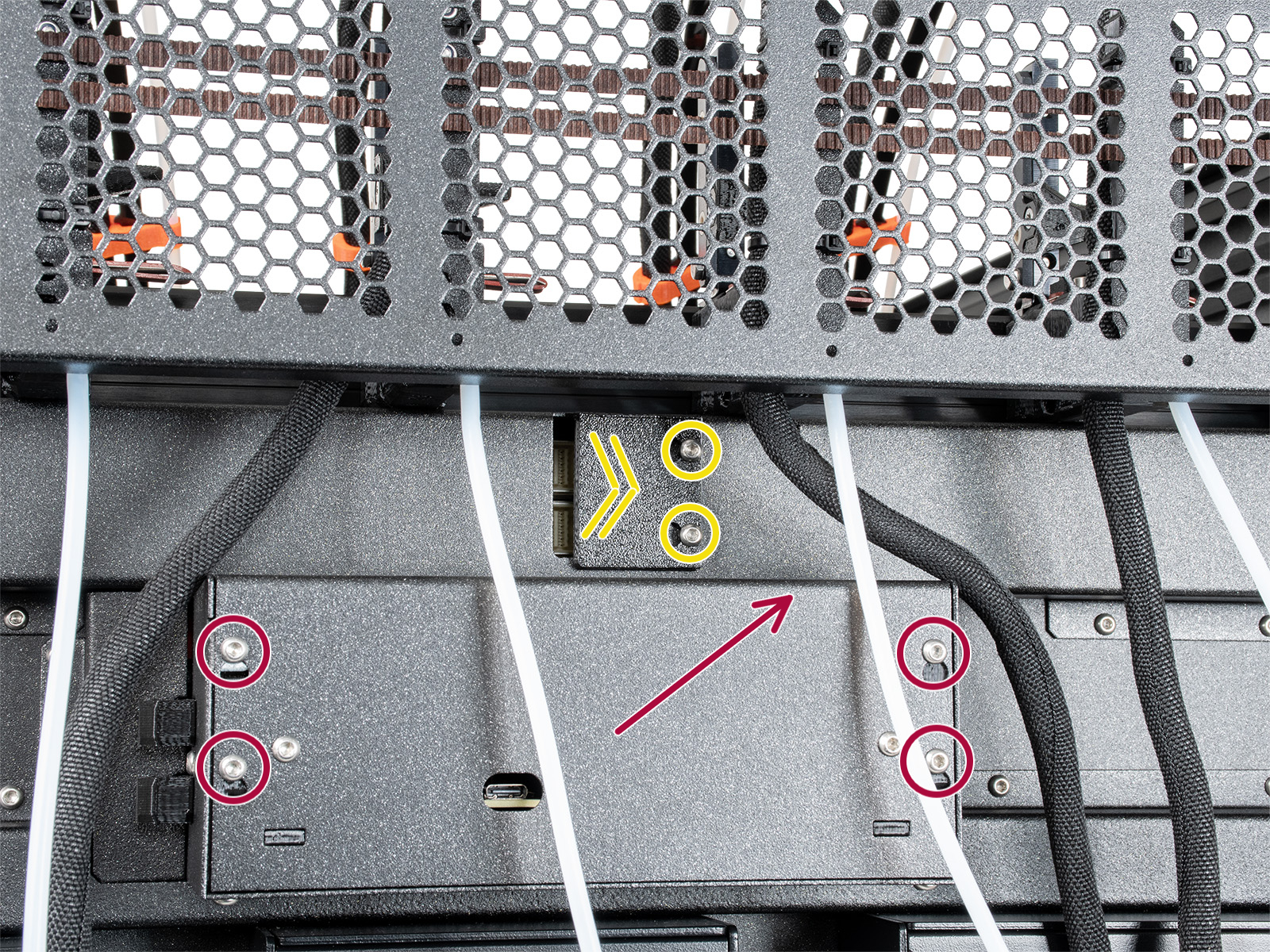

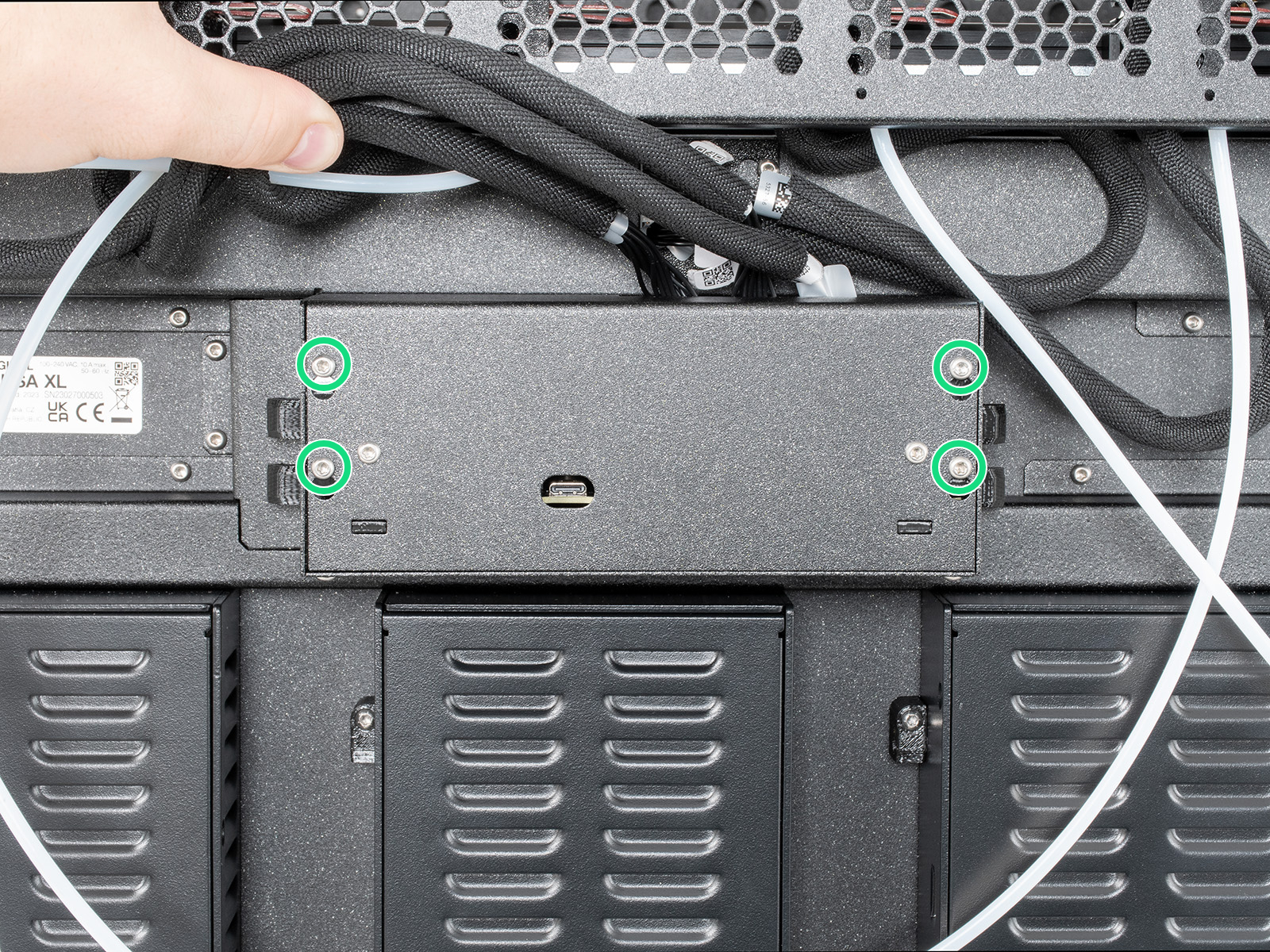

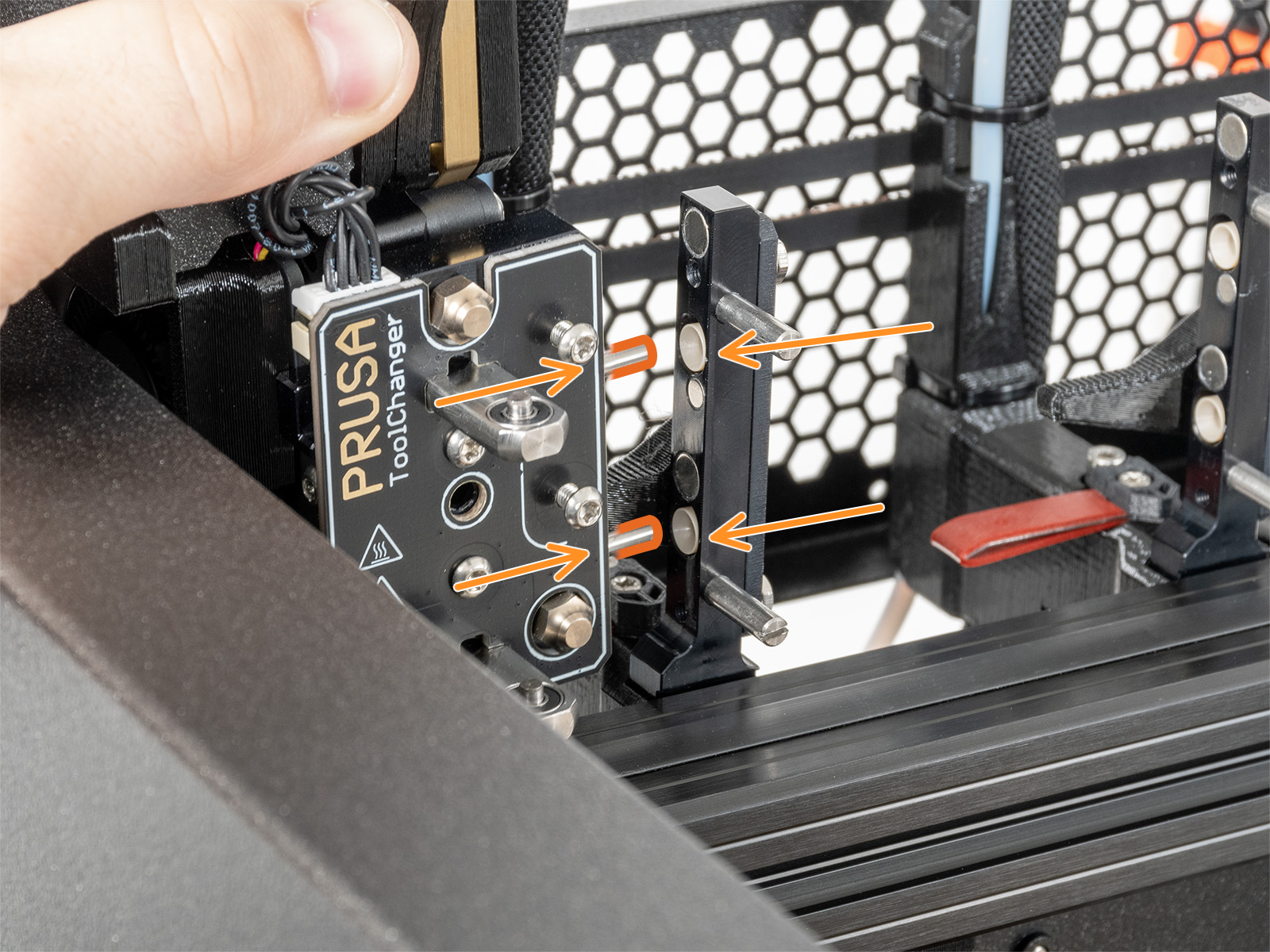

Remaining fastener items:

- Terminal screw (1x)

- M3x6 (1x)

- M3x8 (1x)

- M3x10 (2x)

- M3x12 (1x)

- M3x20rT (2x)

- M4x12 (1x)

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.