The Selftest checks for issues in the assembly of the printer, its wiring and the electronic components. It is the first part of the Calibration Wizard, which is prompted automatically when you turn on the printer for the first time or after a Factory reset (MK2S/MK2.5S/MK3S). After the initial calibration, the Selftest can be found at LCD Menu -> Calibration -> Selftest.

- Extruder and print fan functionality

- Heatbed and hotend wiring

- XYZ motors wiring and functionality

- XY axis length

- XY belts tension

- Loose belt pulley

- Filament sensor / IR sensor

Progress and results of each step are displayed on the LCD screen. In case the process runs into an issue, the LCD screen will display an error message. All errors are described below.

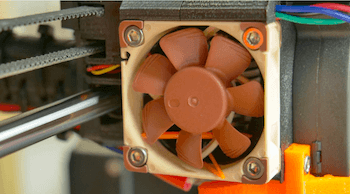

Extruder & Print fan test

Front print fan/Left hotend fan - Not spinning:

The MK3 Selftest procedure is capable of telling you which of the fans doesn't work. Simply check the one that is diagnosed as not OK.

- Make sure that both of your fans are connected according to the Einsy RAMBo electronics wiring (MK3/MK3S/MK3S+).

- Check for any blockage that could prevent either of the fans from spinning.

- Go over the wiring and make sure that none of the zip-ties is overtightened, which prevents the fans from spinning.

Your fan may be black

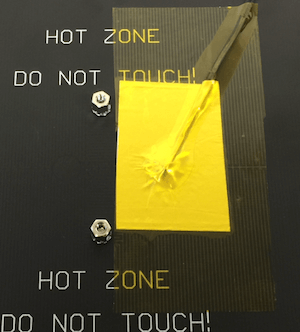

Heatbed & Hotend test

Please check/ Not connected - Heater/ Thermistor:

Bed/ Heater - Wiring error:

- Make sure that both thermistors and heater are connected properly according to the Einsy RAMBo electronics wiring (MK3/MK3S/MK3S+).

- Check your heated bed cables and confirm they are not damaged by an overtightened zip-tie.

- Make sure that your heated bed thermistor is firmly attached underneath the Golden Kapton tape.

XY axis length test

Please check: Axis length - Axis {XYZ}:

- Start the Selftest routine again in LCD Menu - Calibration - Selftest. Carefully observe, whether no obstacles are blocking the path on any of the axis.

- Pay attention to extruder cable management and the assembly of the printer's axes. The most common cause of an improper X-axis movement is the cable harness hitting the EINSY/Mini RAMBo cover.

- Check that you can move the axis by hand, smoothly, in both directions. If movement is not smooth, try to lubricate the rods as shown in Maintenance tips.

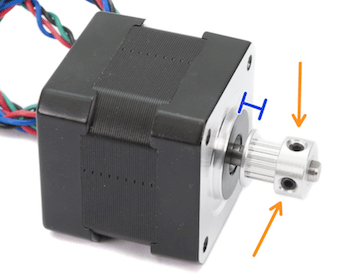

Loose belt pulley test

Loose pulley - {XY}:

- Make sure that both pulleys are properly tightened, on the flat side of the motor-rod. Give the pulley a light tug. If any of them are loose, then the motor's shaft won't be able to move the axis.

- Make sure that the belts aren't extremely loose, as they might be going around the pulleys without actually moving either of the axes.

- Check that you can move the axis by hand, smoothly, in both directions. If movement is not smooth, try to lubricate the rods as shown in Maintenance tips.

Filament sensor test

Filament sensor wiring error

Make sure the Filament sensor functioning and is connected, according to our illustrated article.