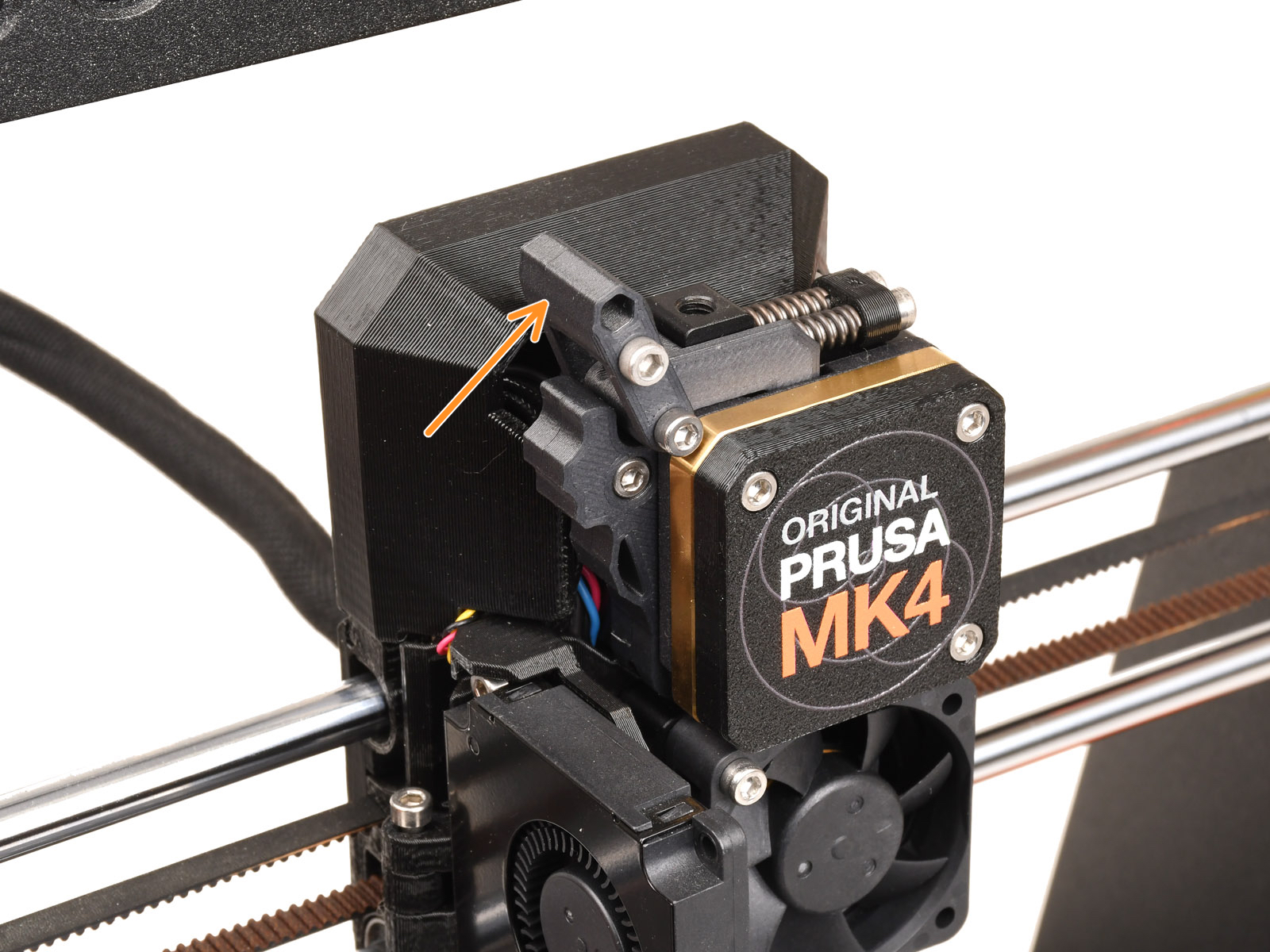

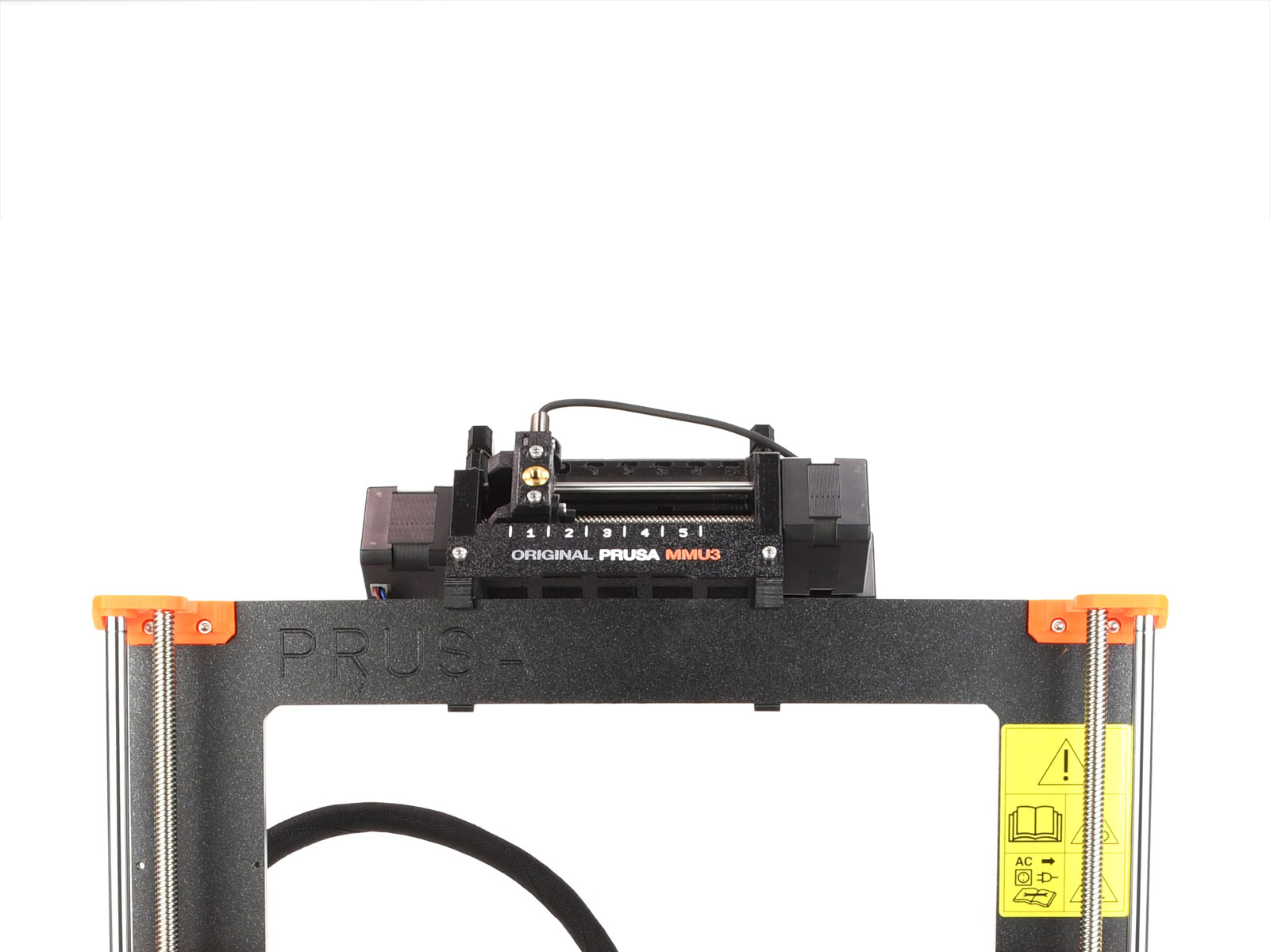

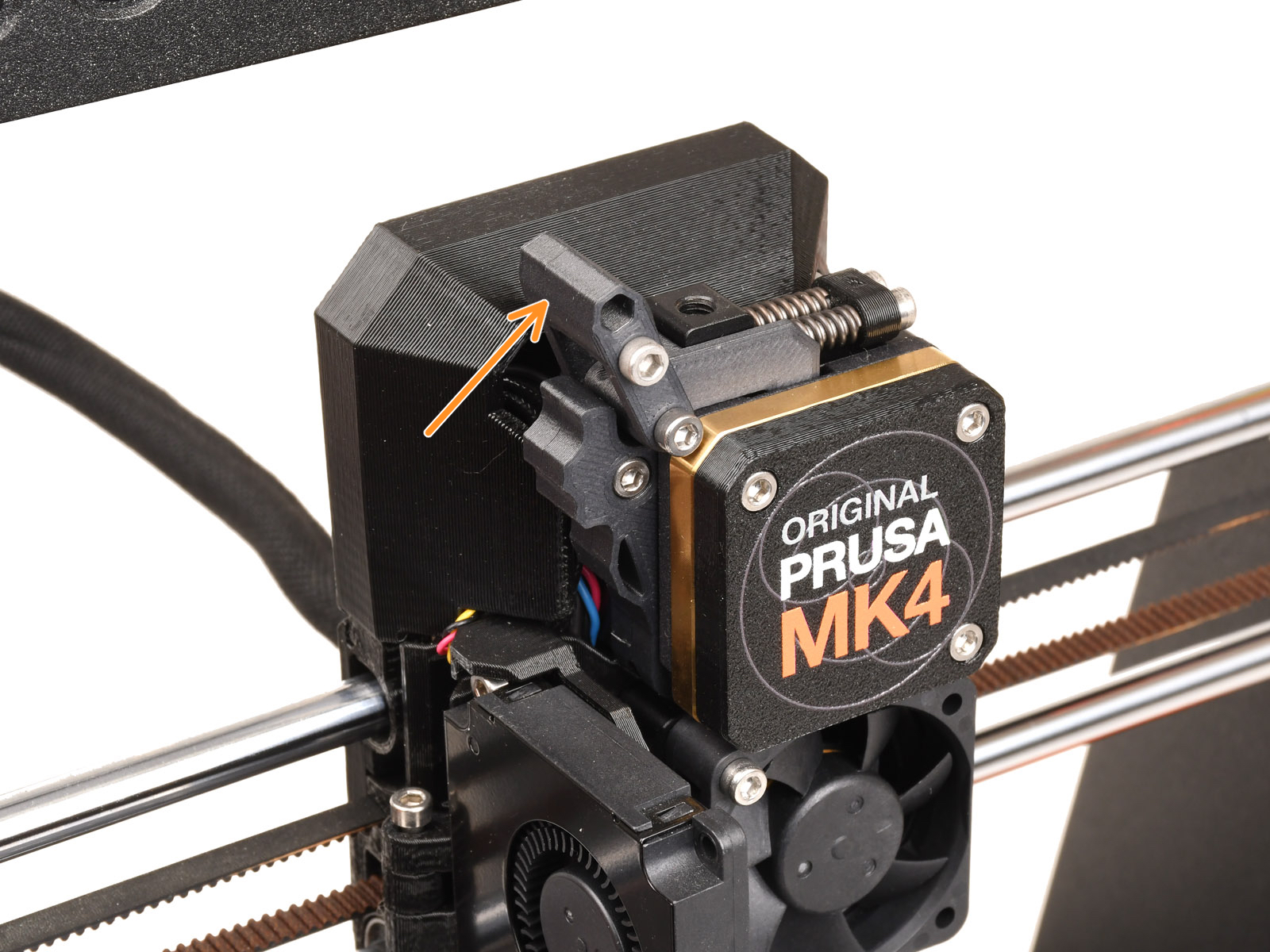

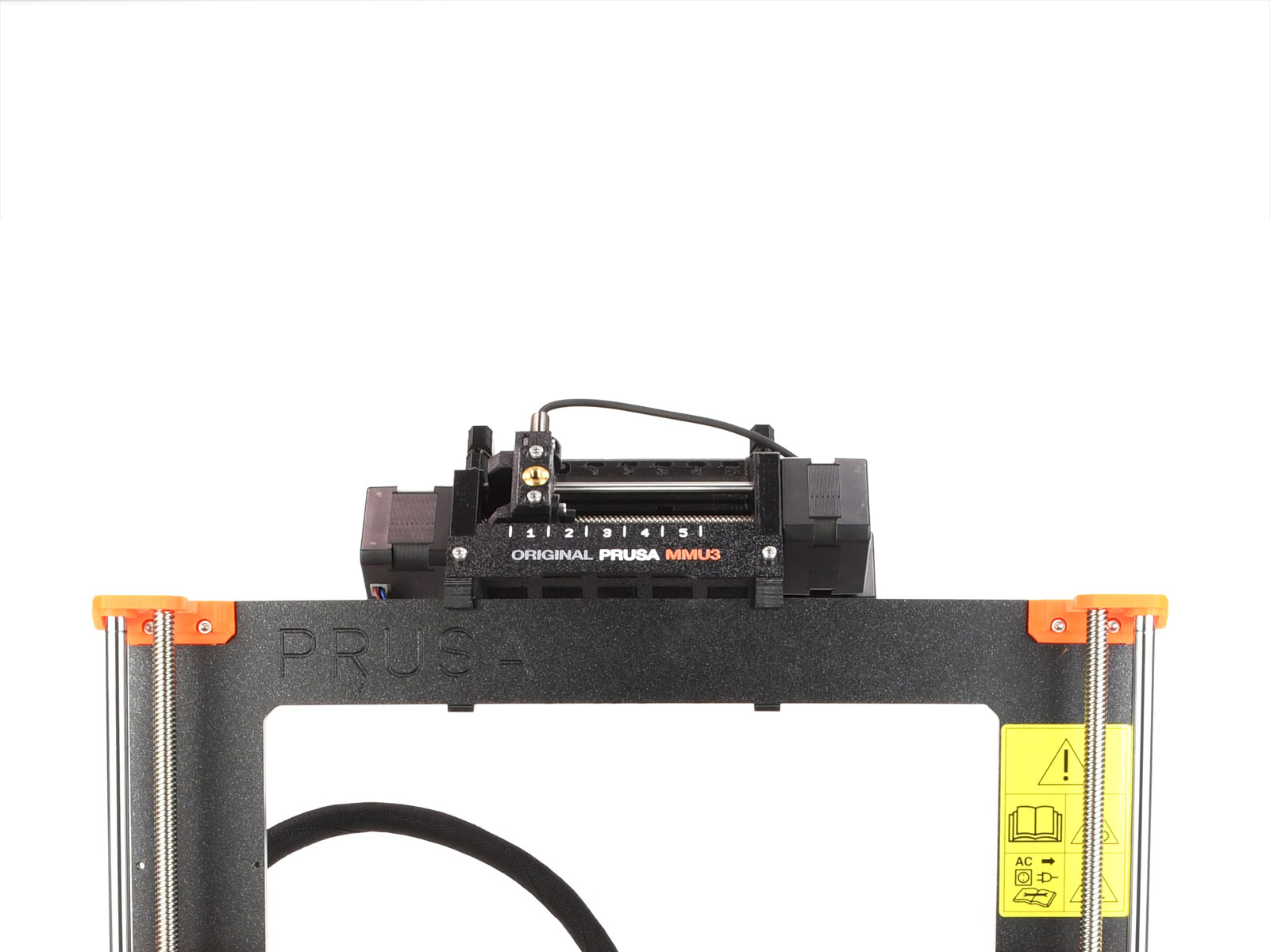

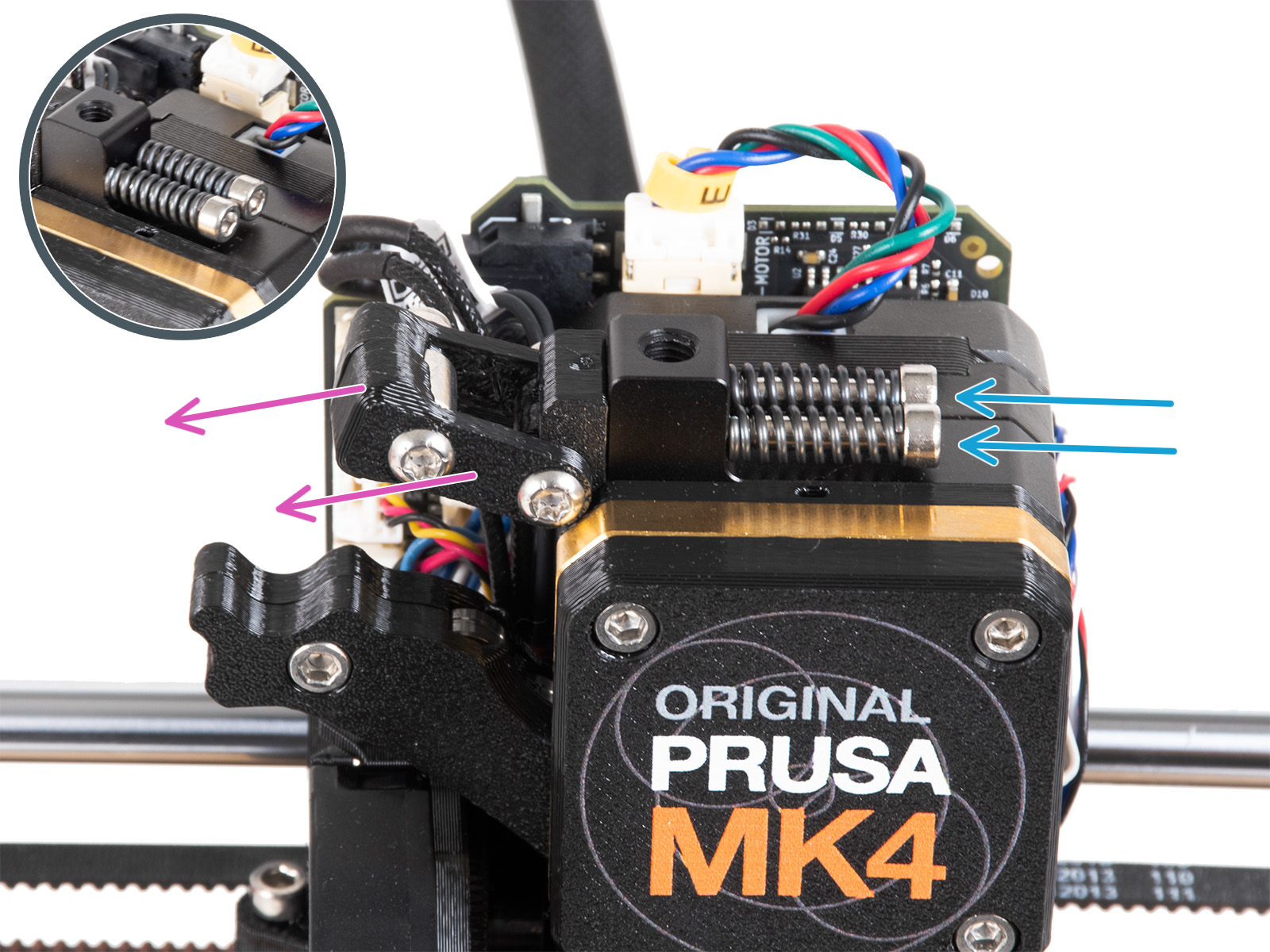

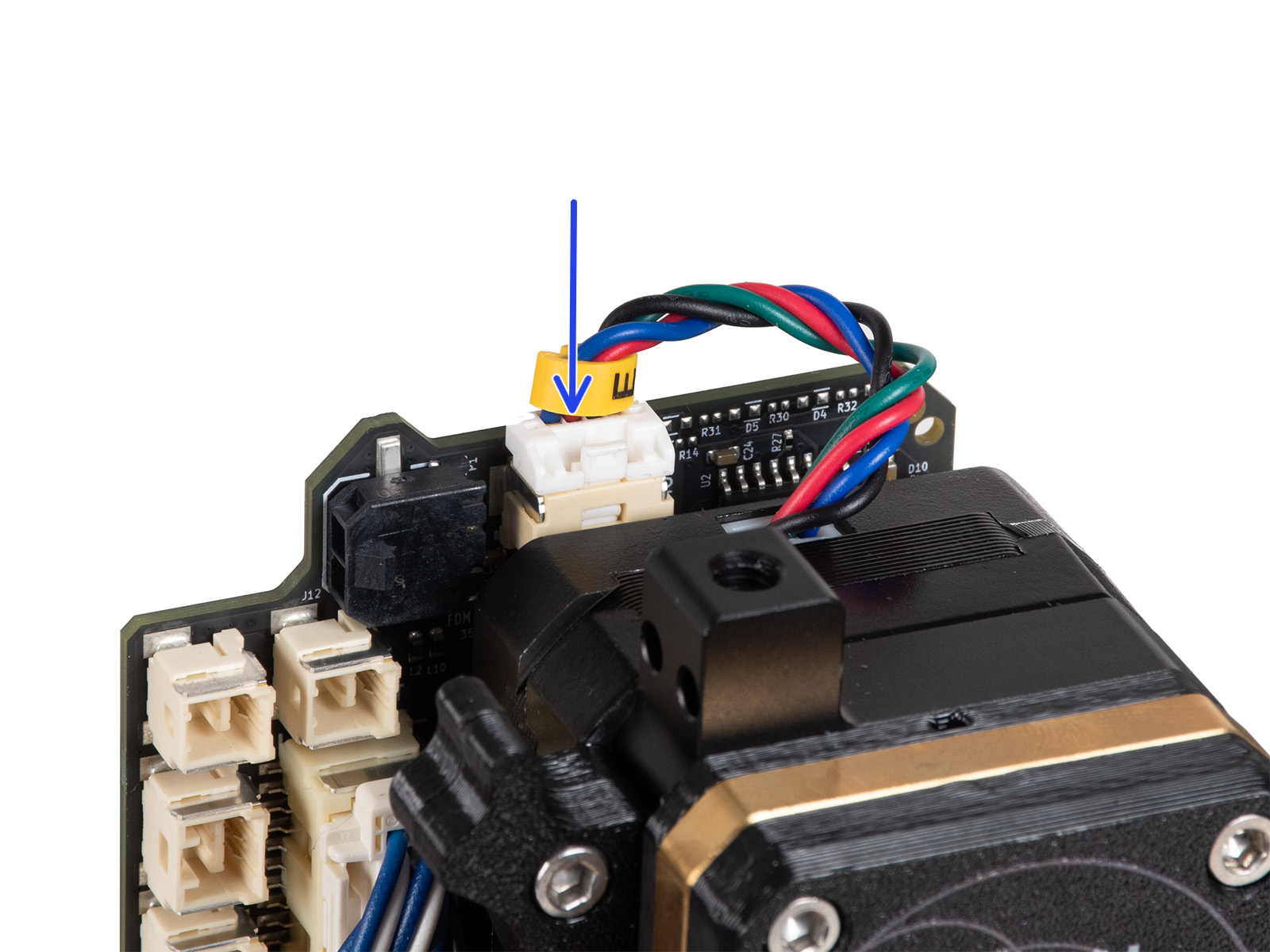

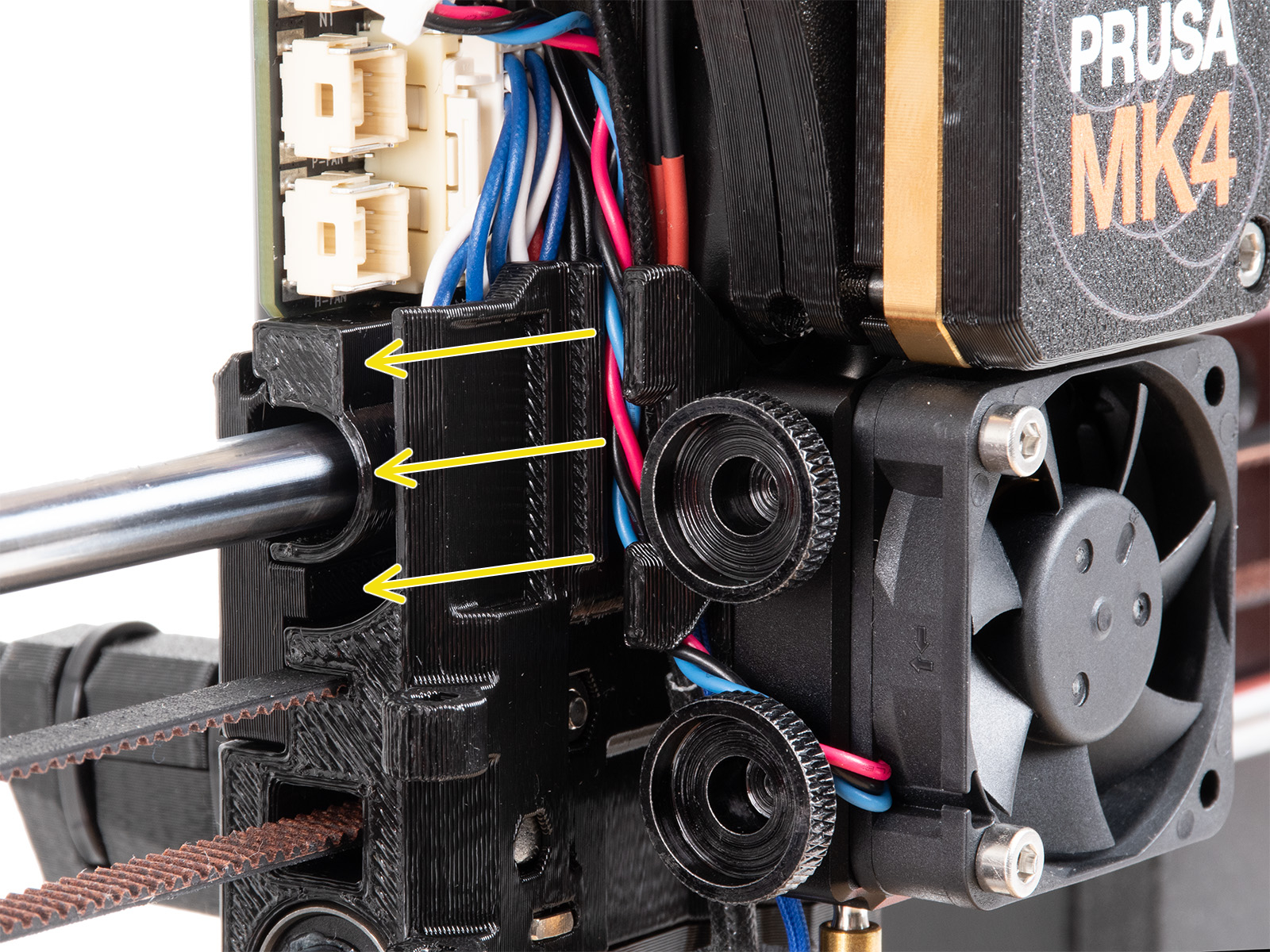

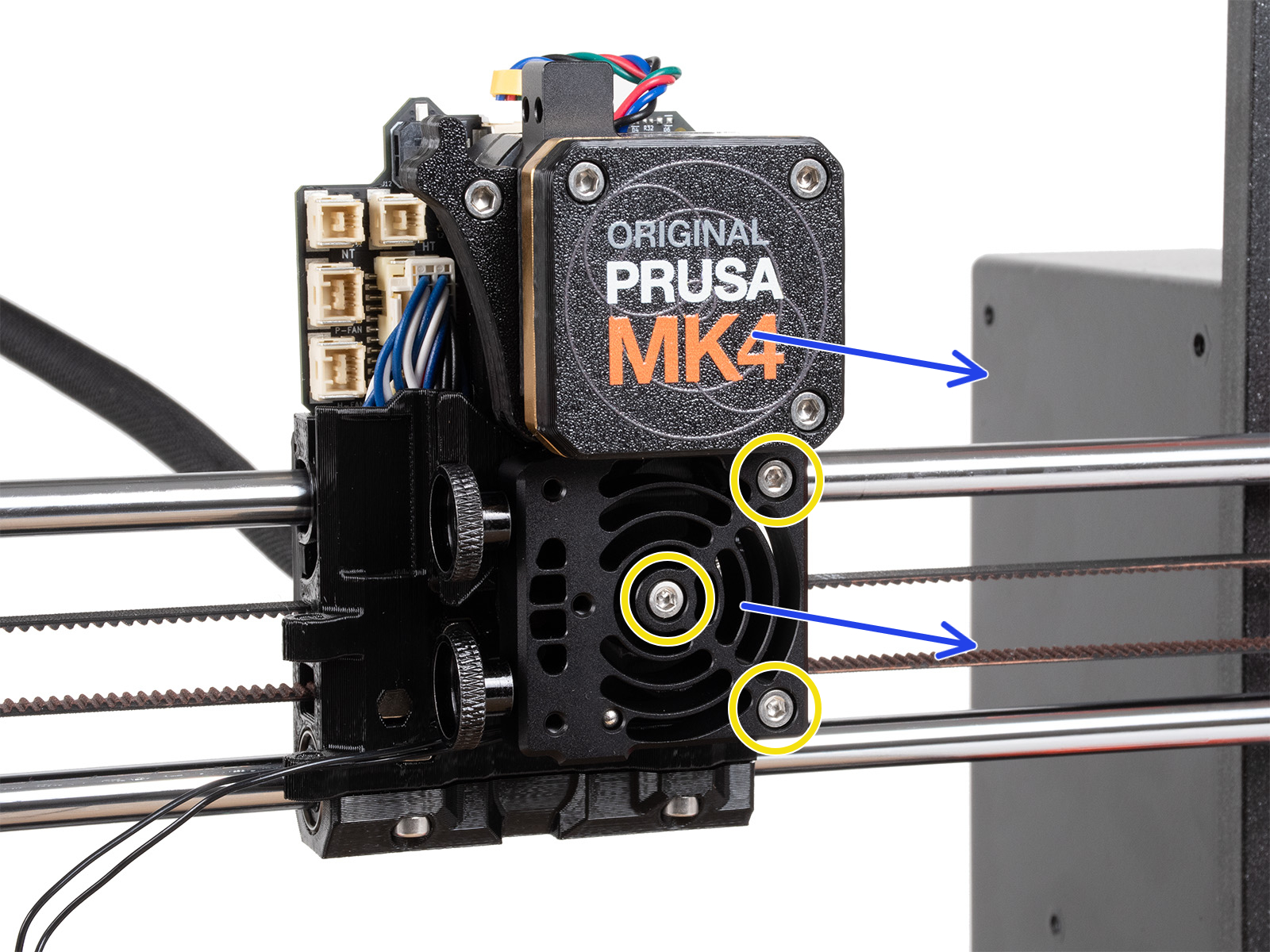

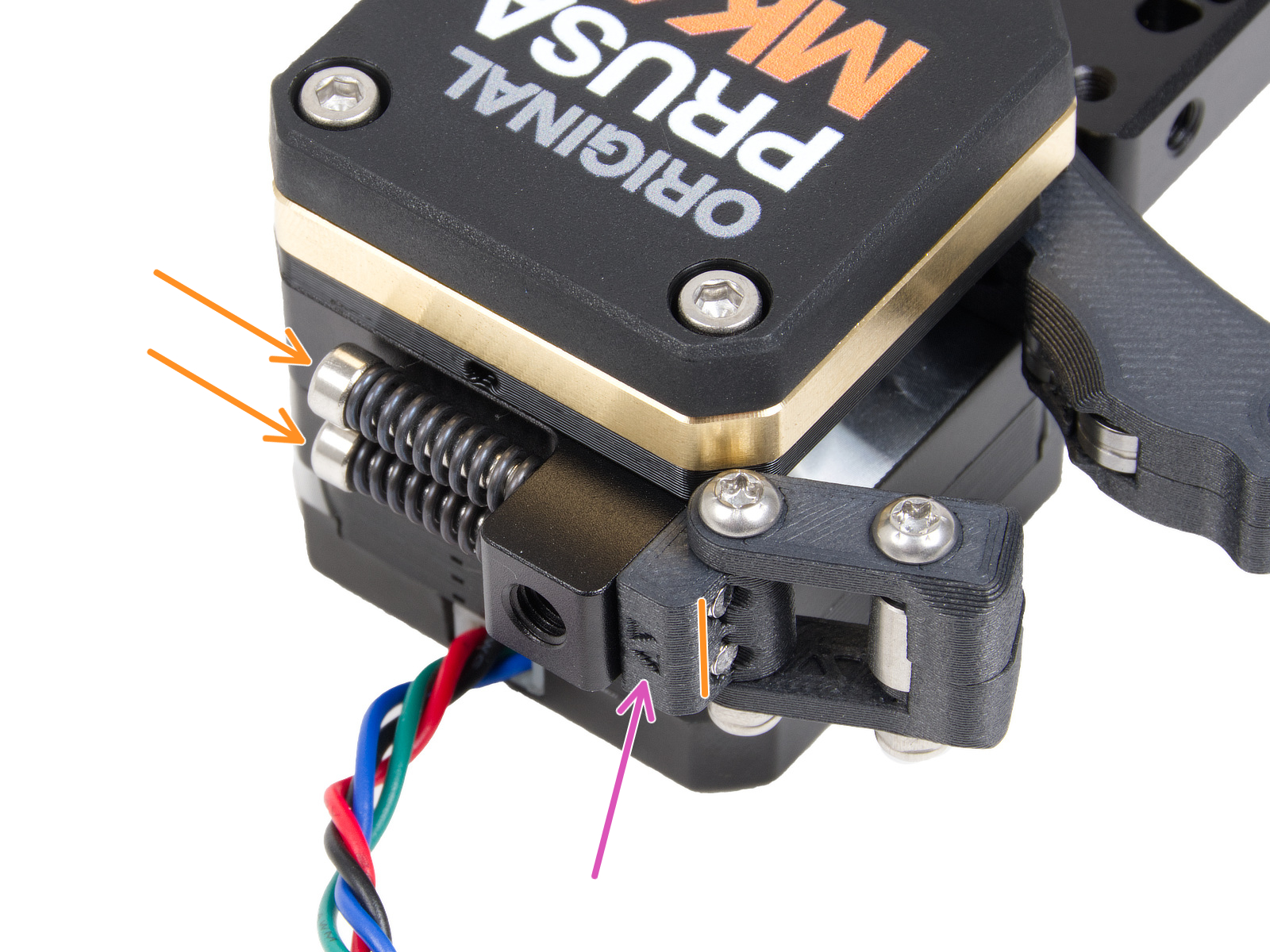

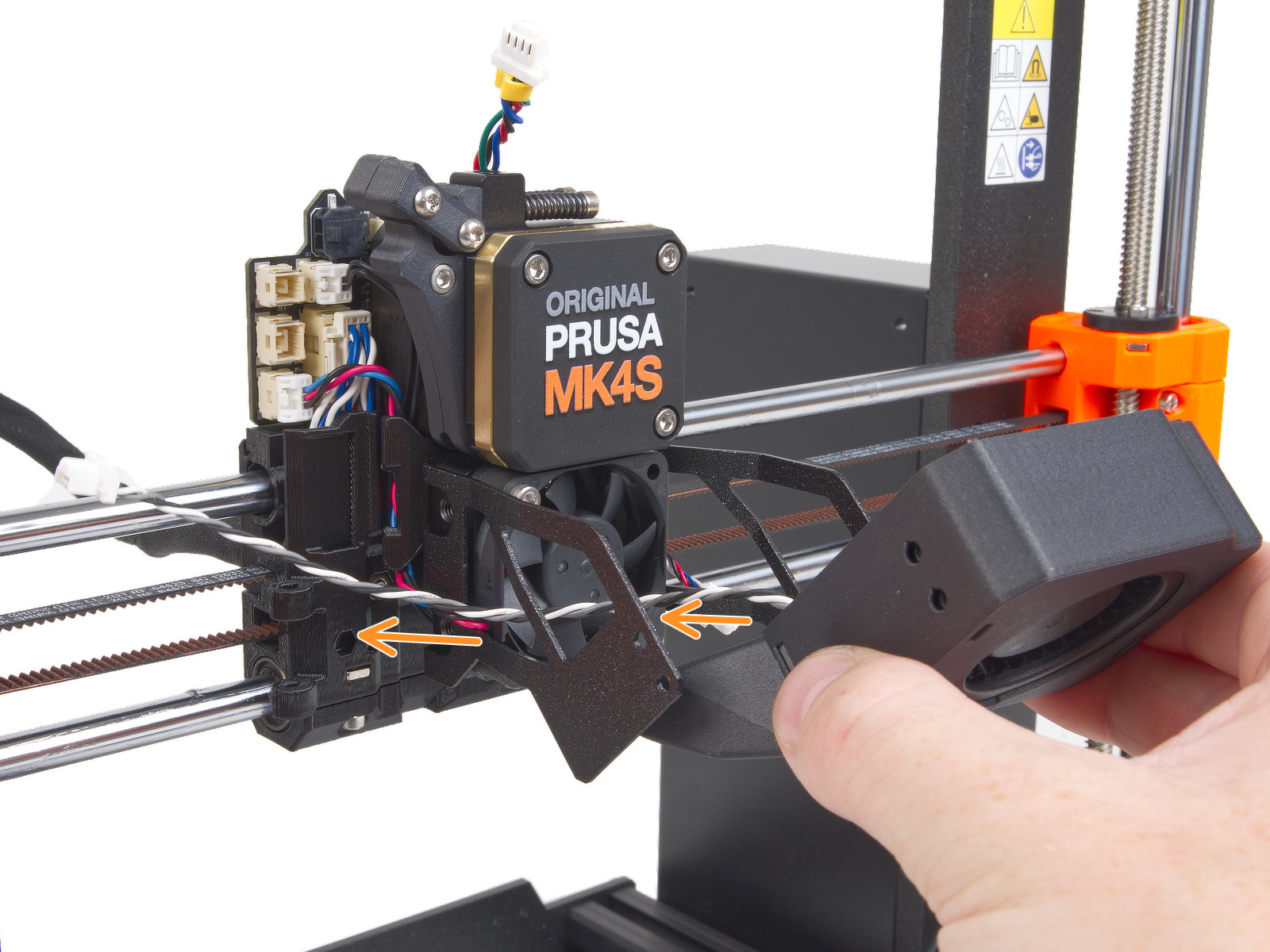

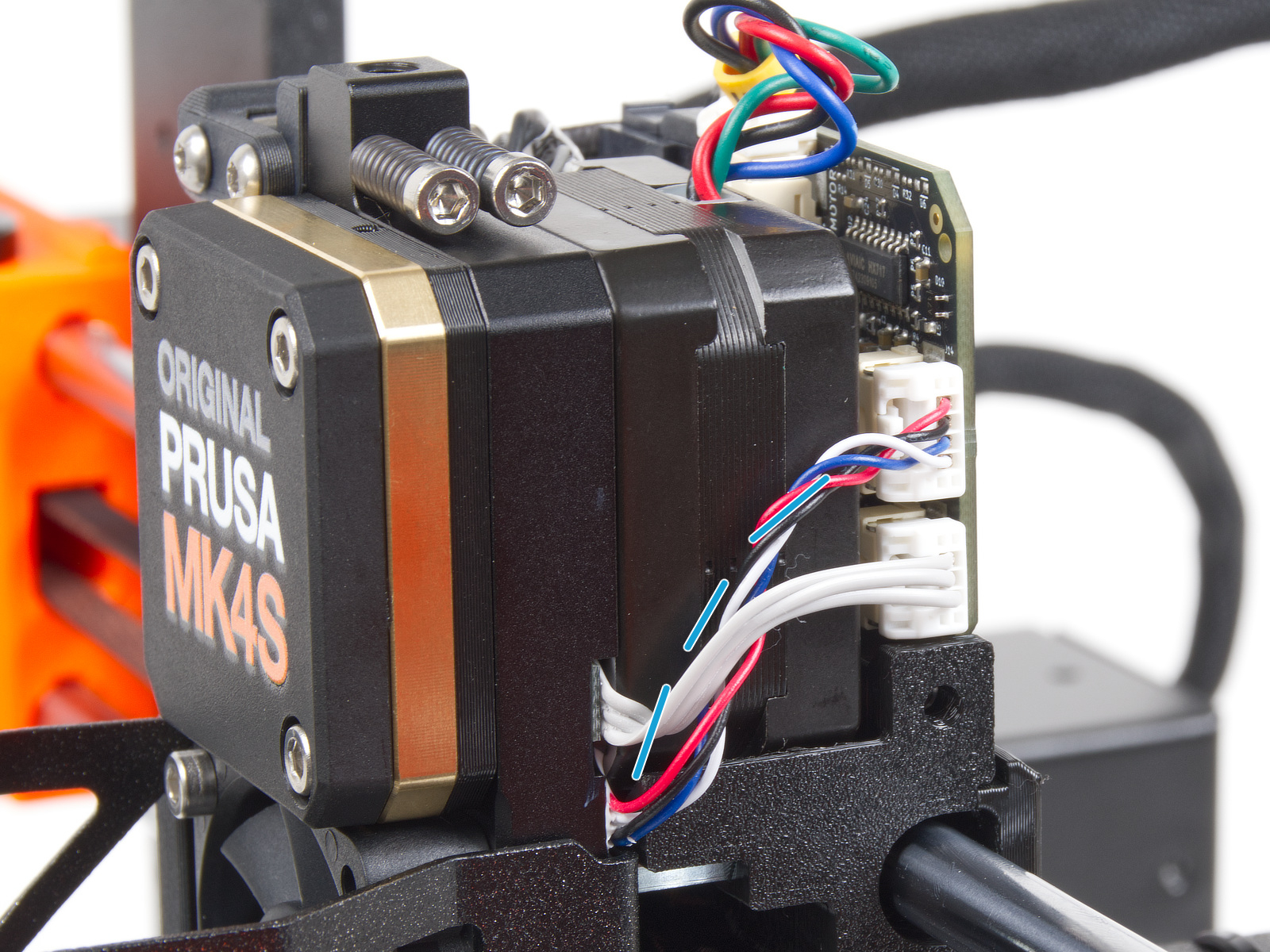

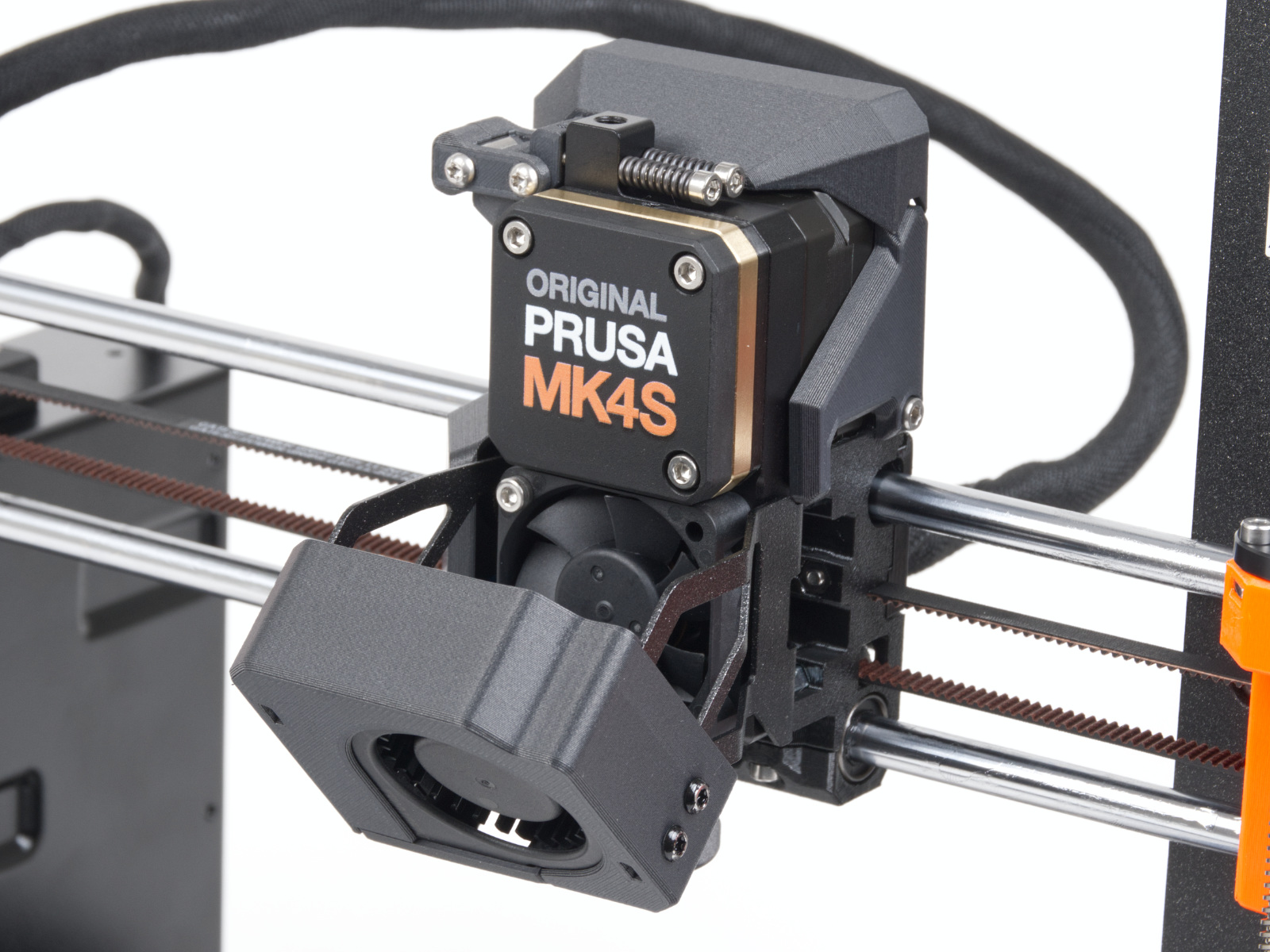

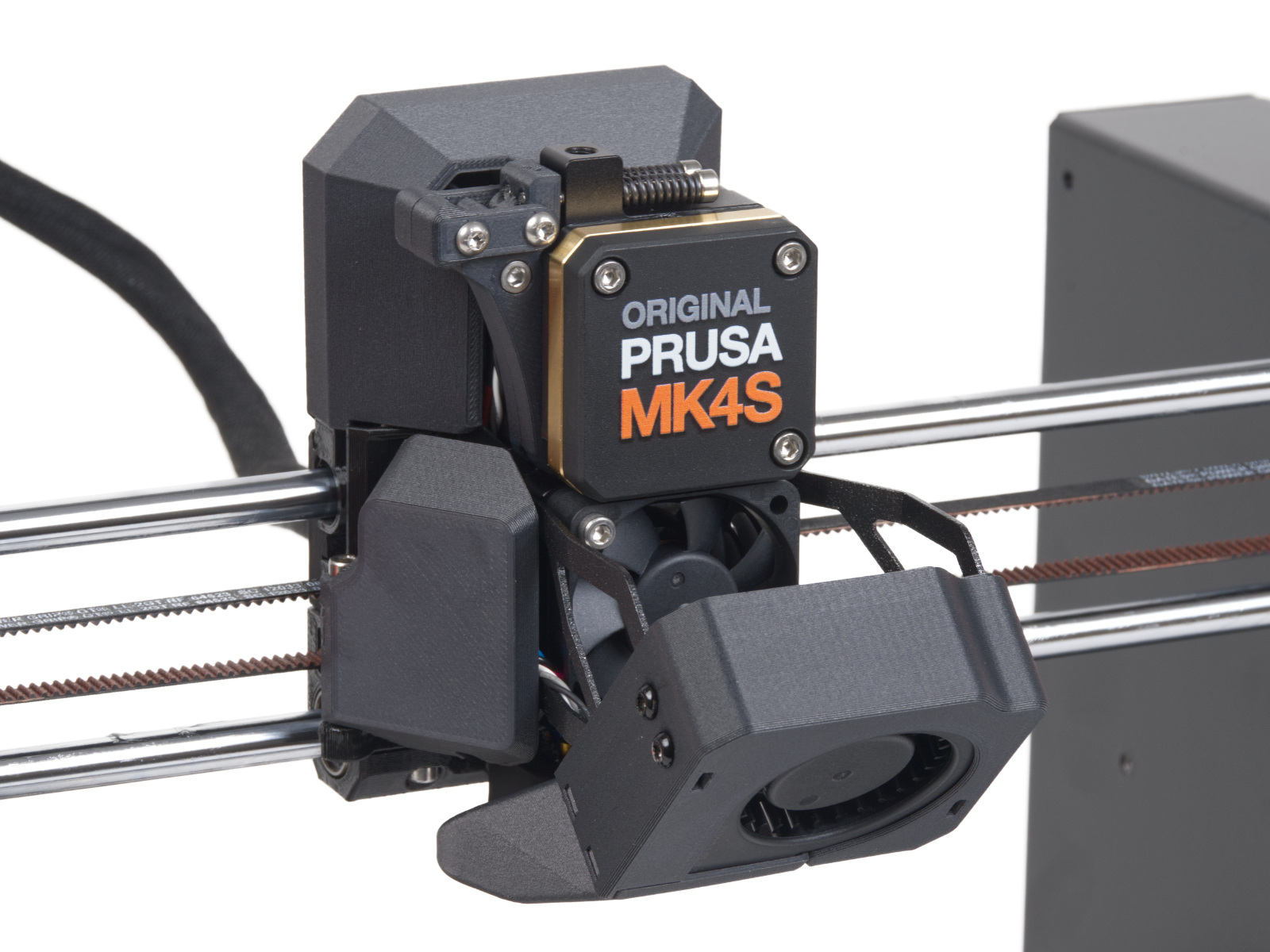

If you have used MMU3 unit on your MK4/MK3.9 printer, your extruder is slightly different. In that case, please proceed to the dedicated chapter:

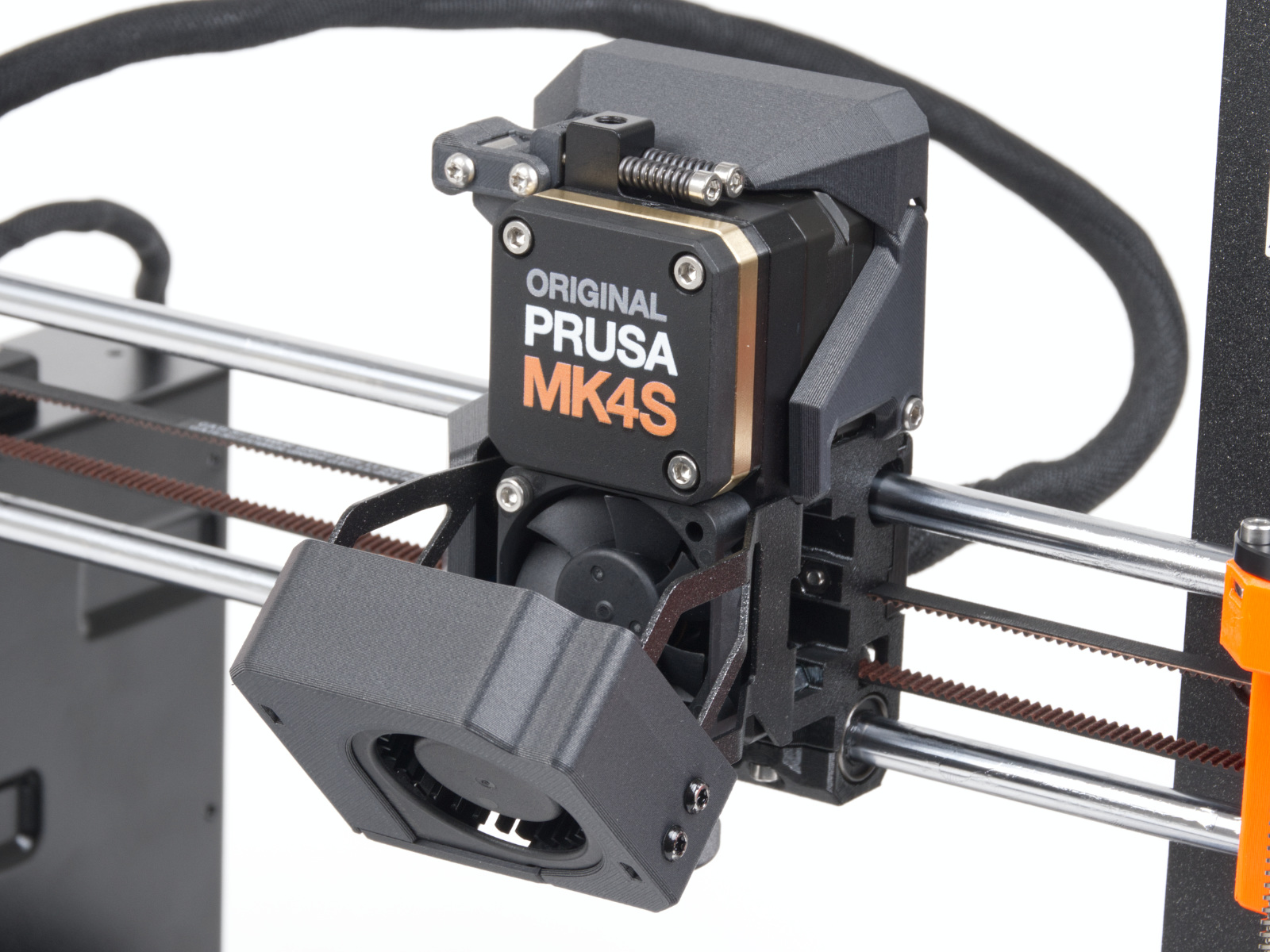

⬢If you have a single-material printer, continue to the next step.

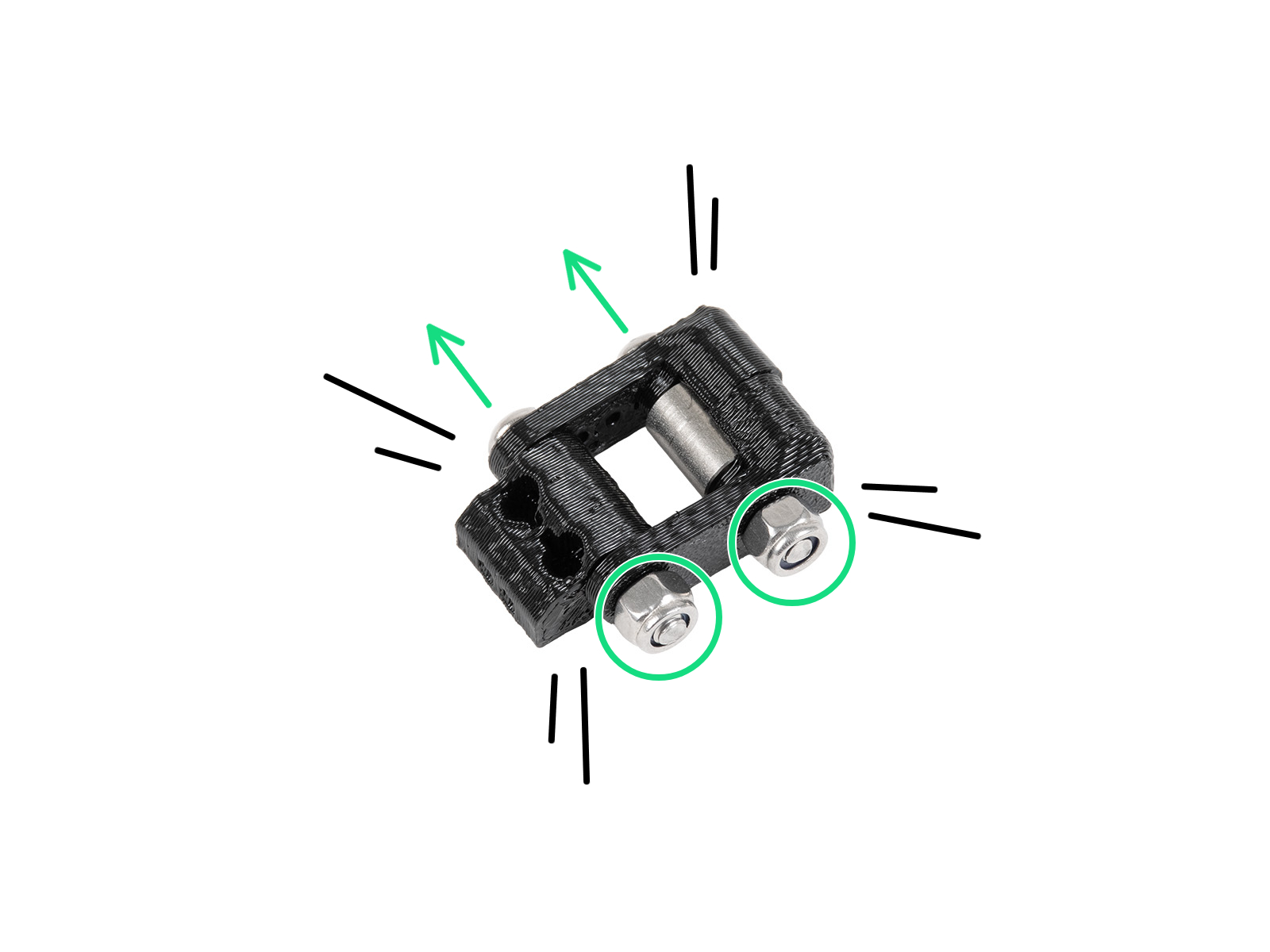

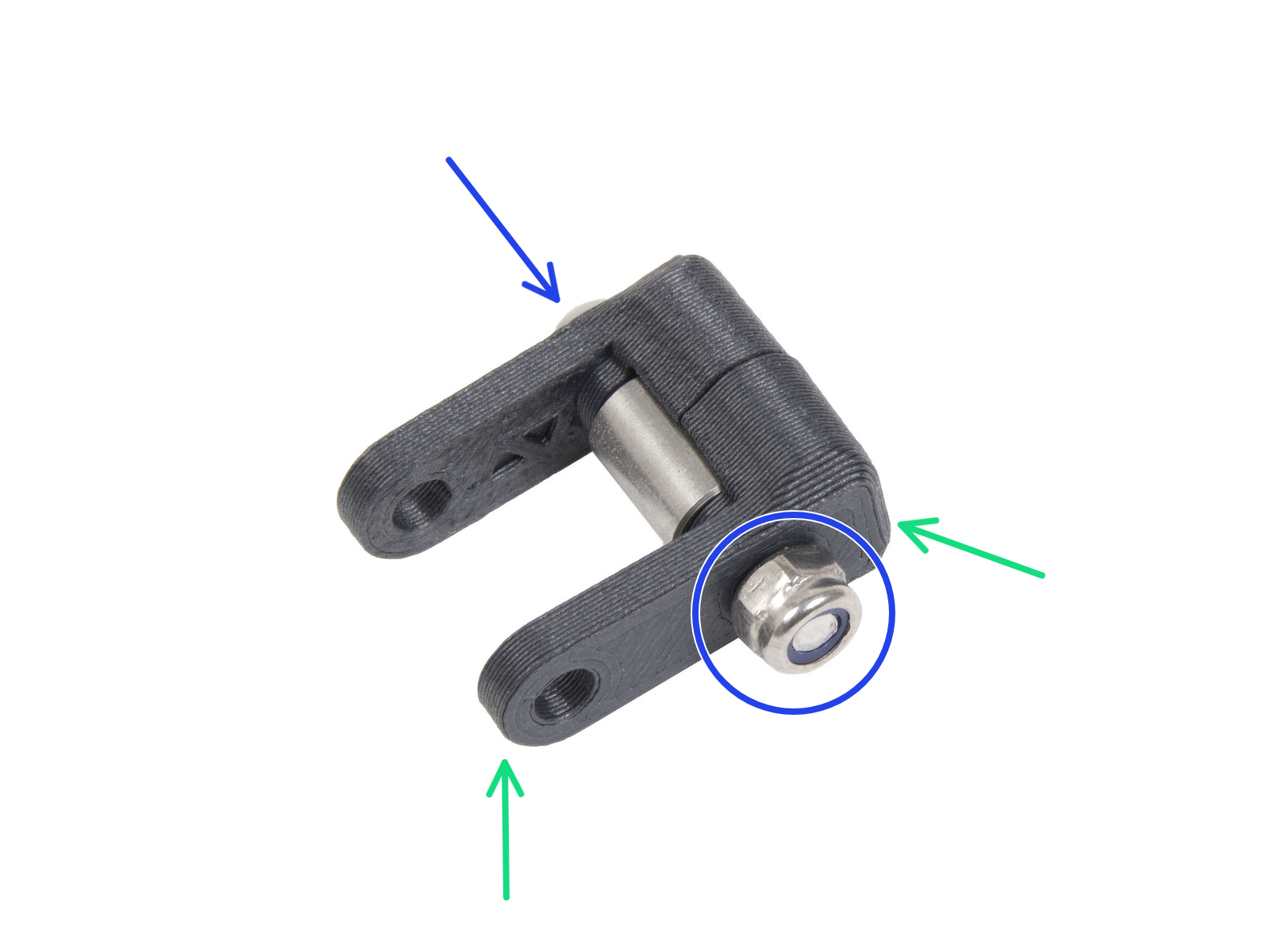

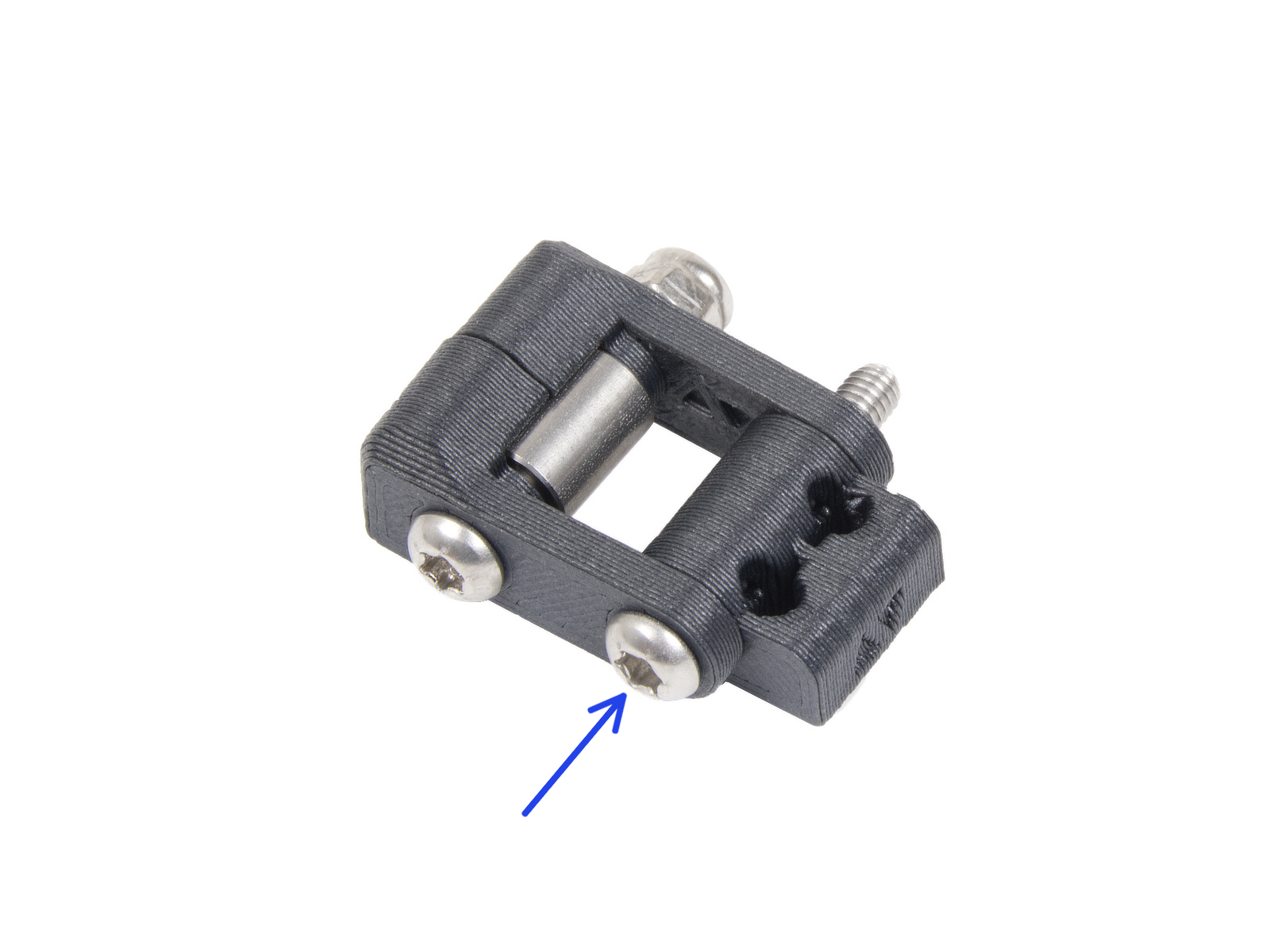

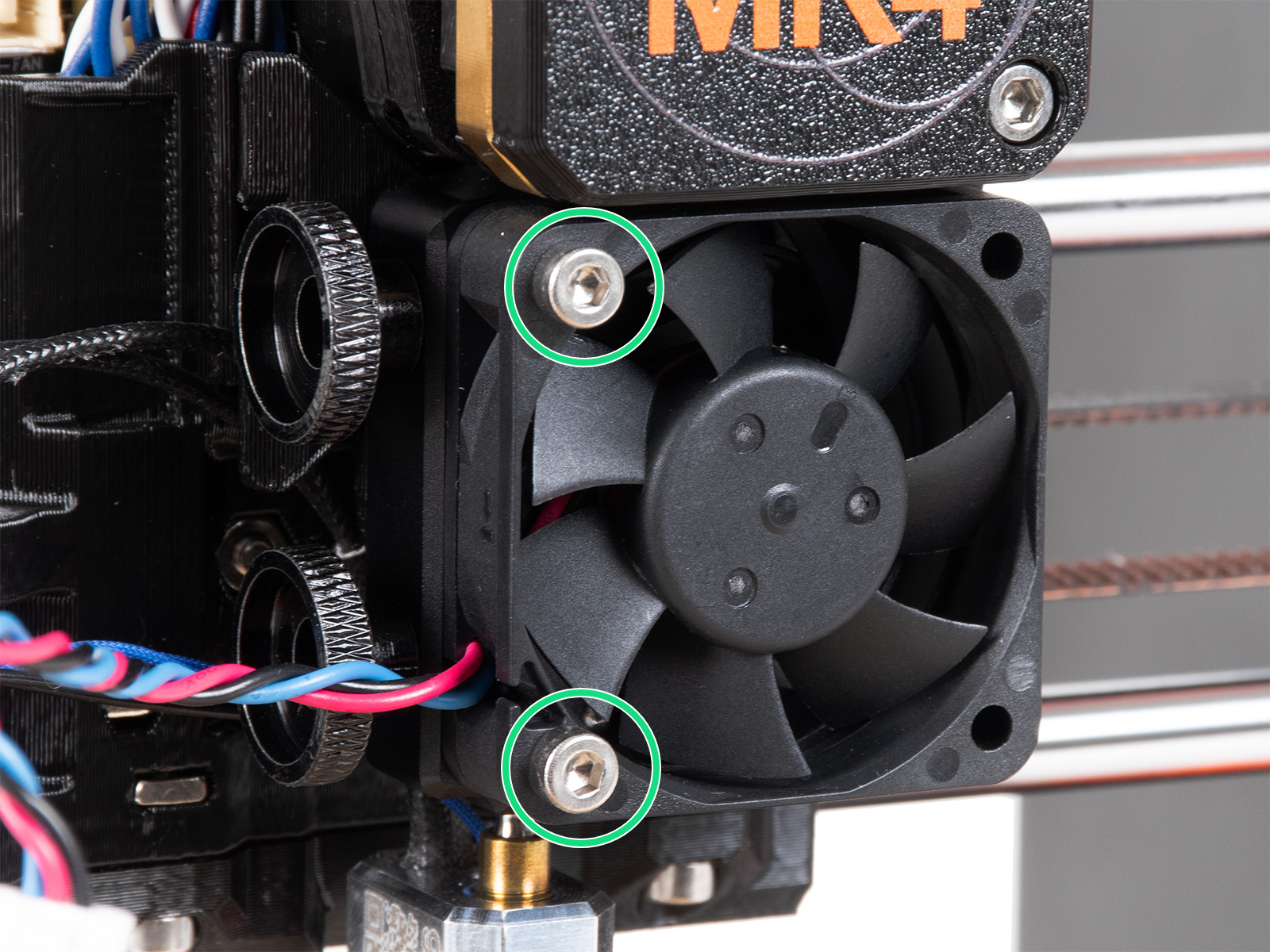

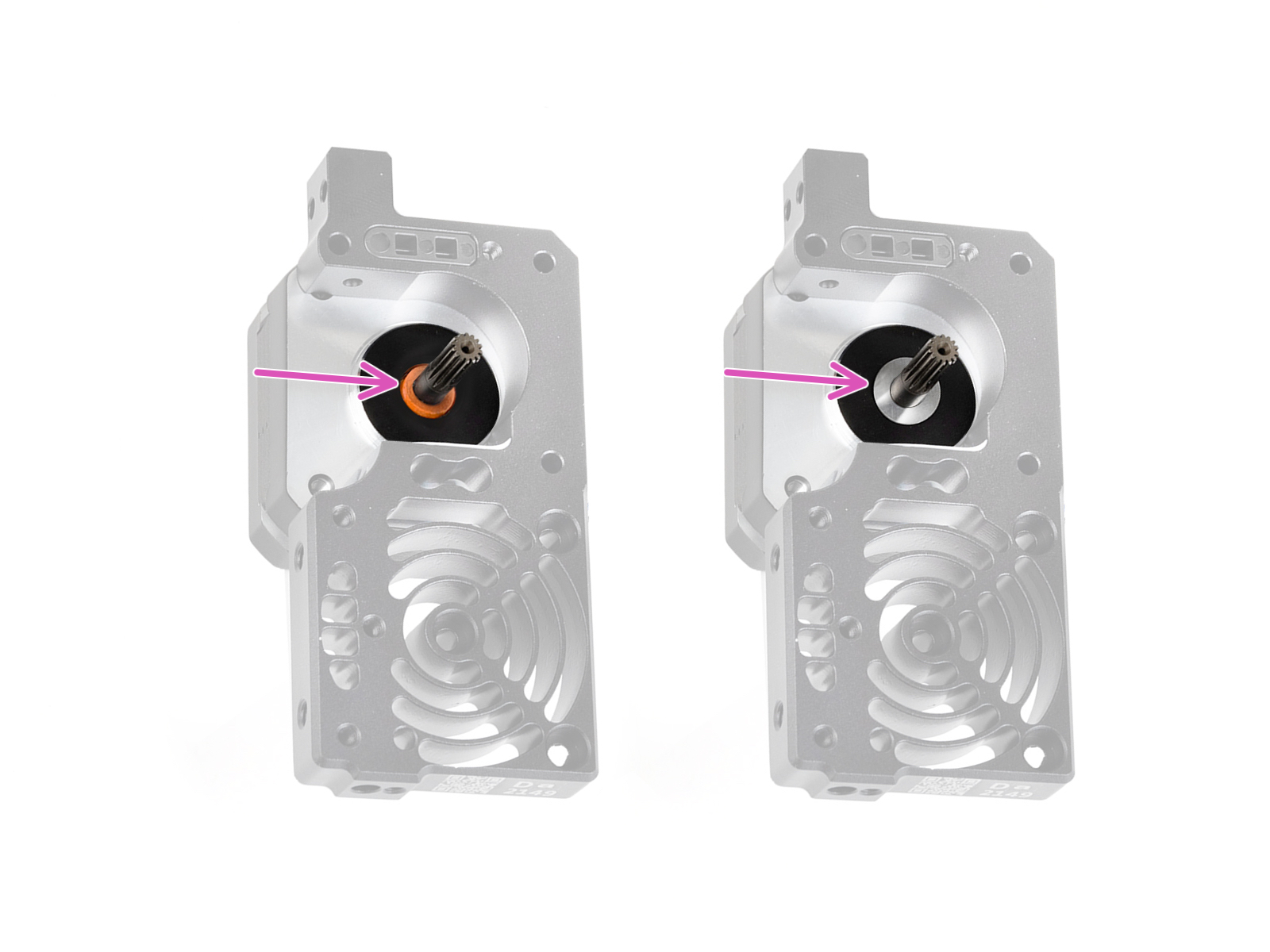

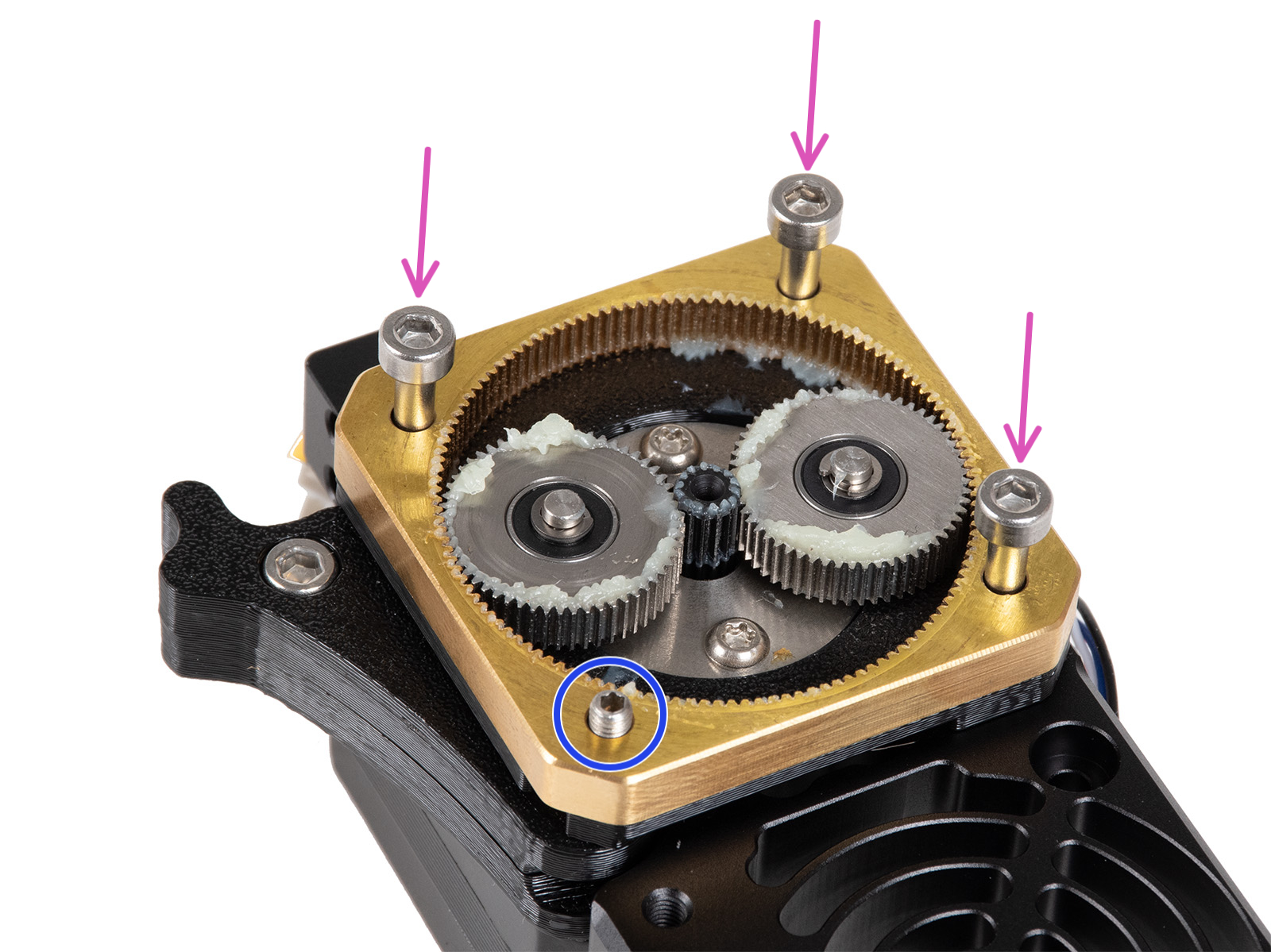

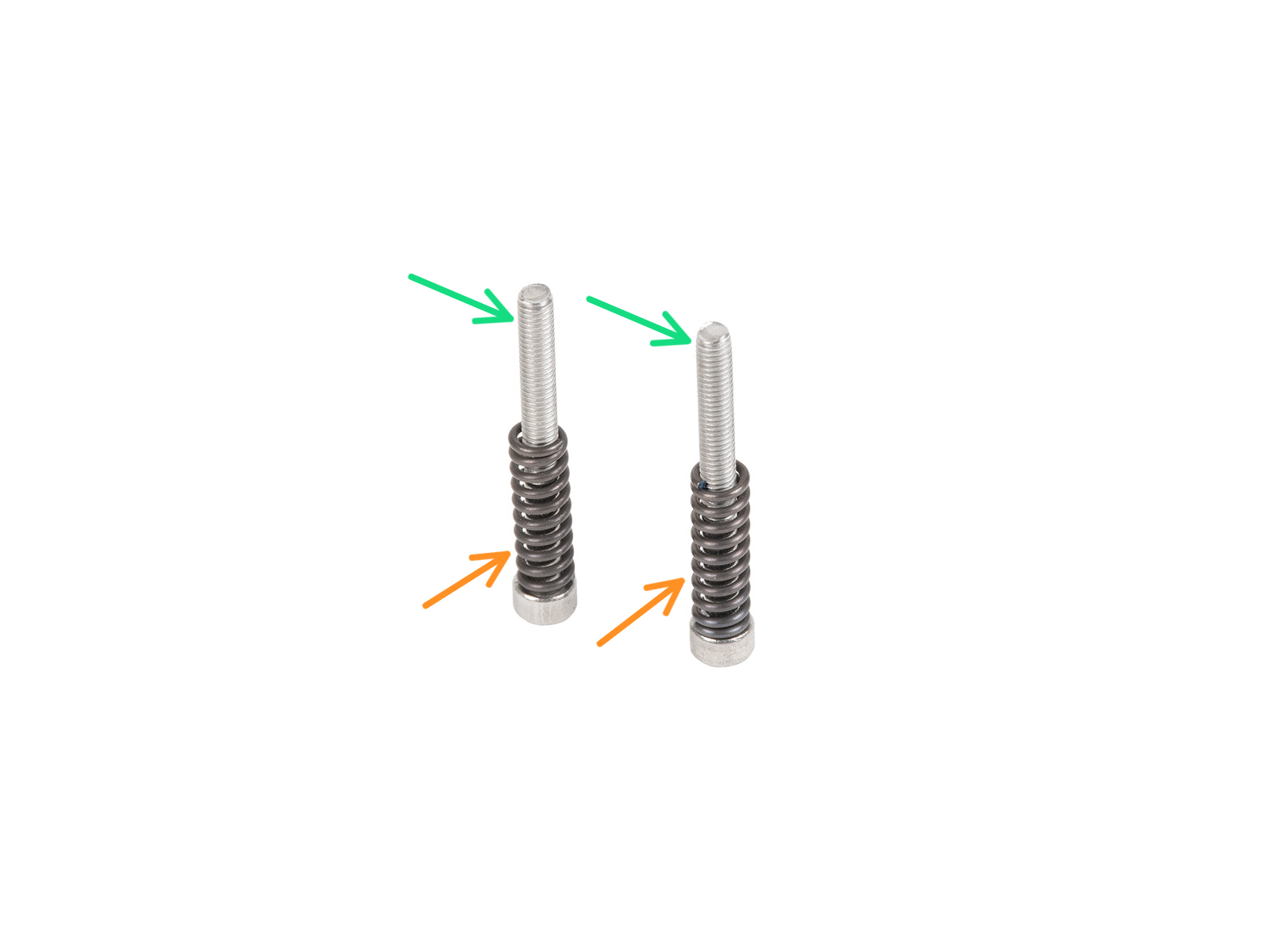

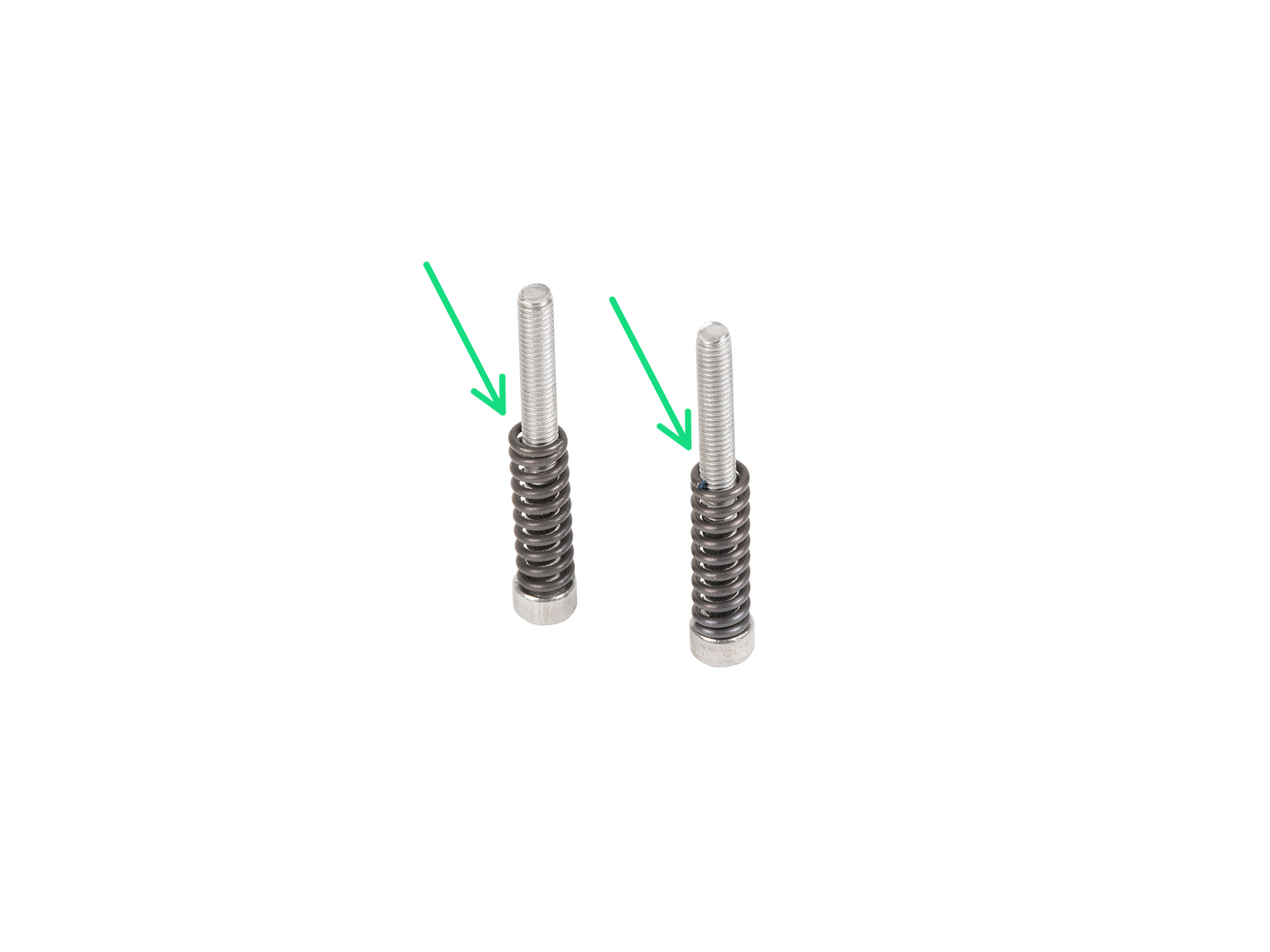

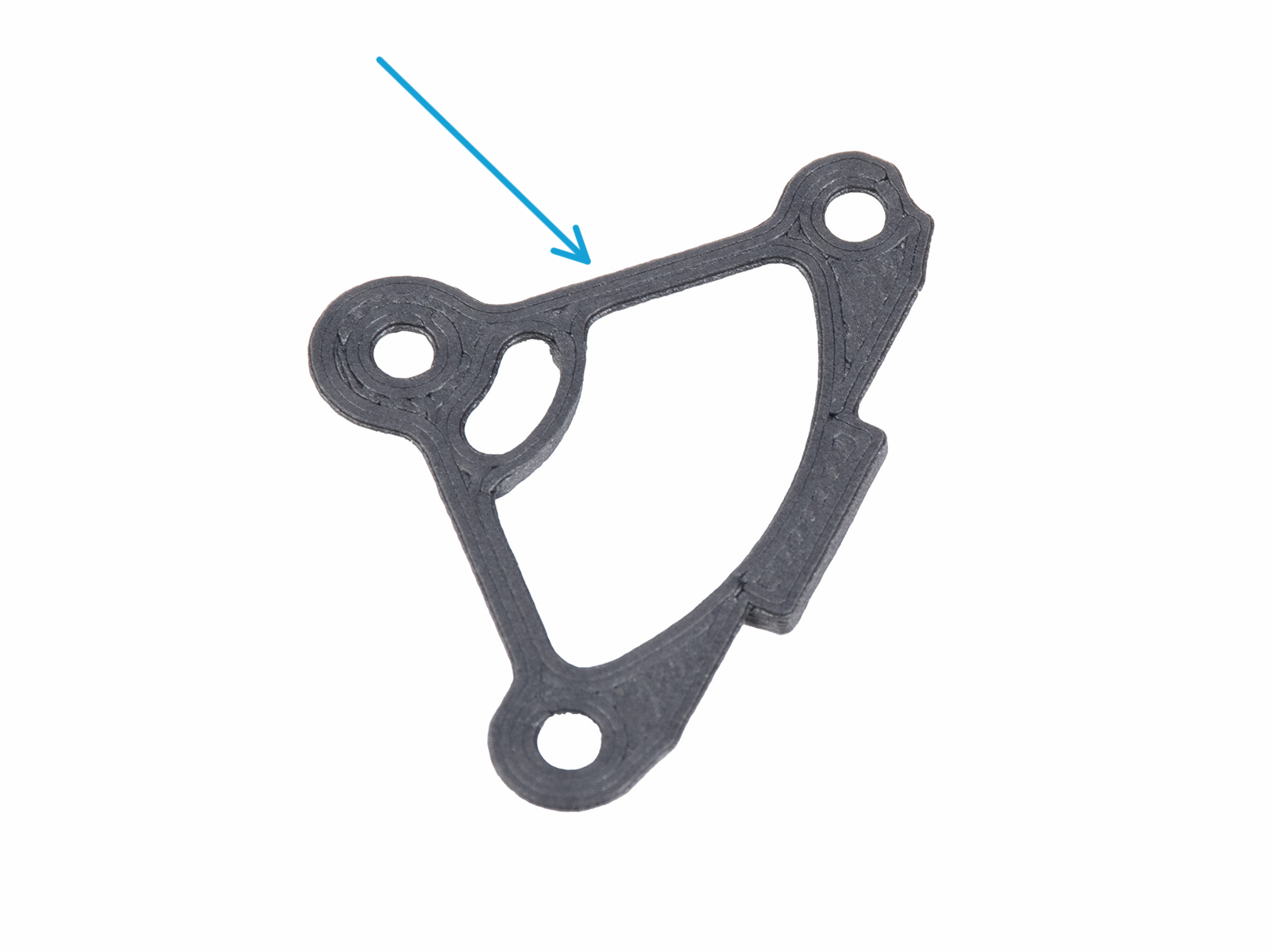

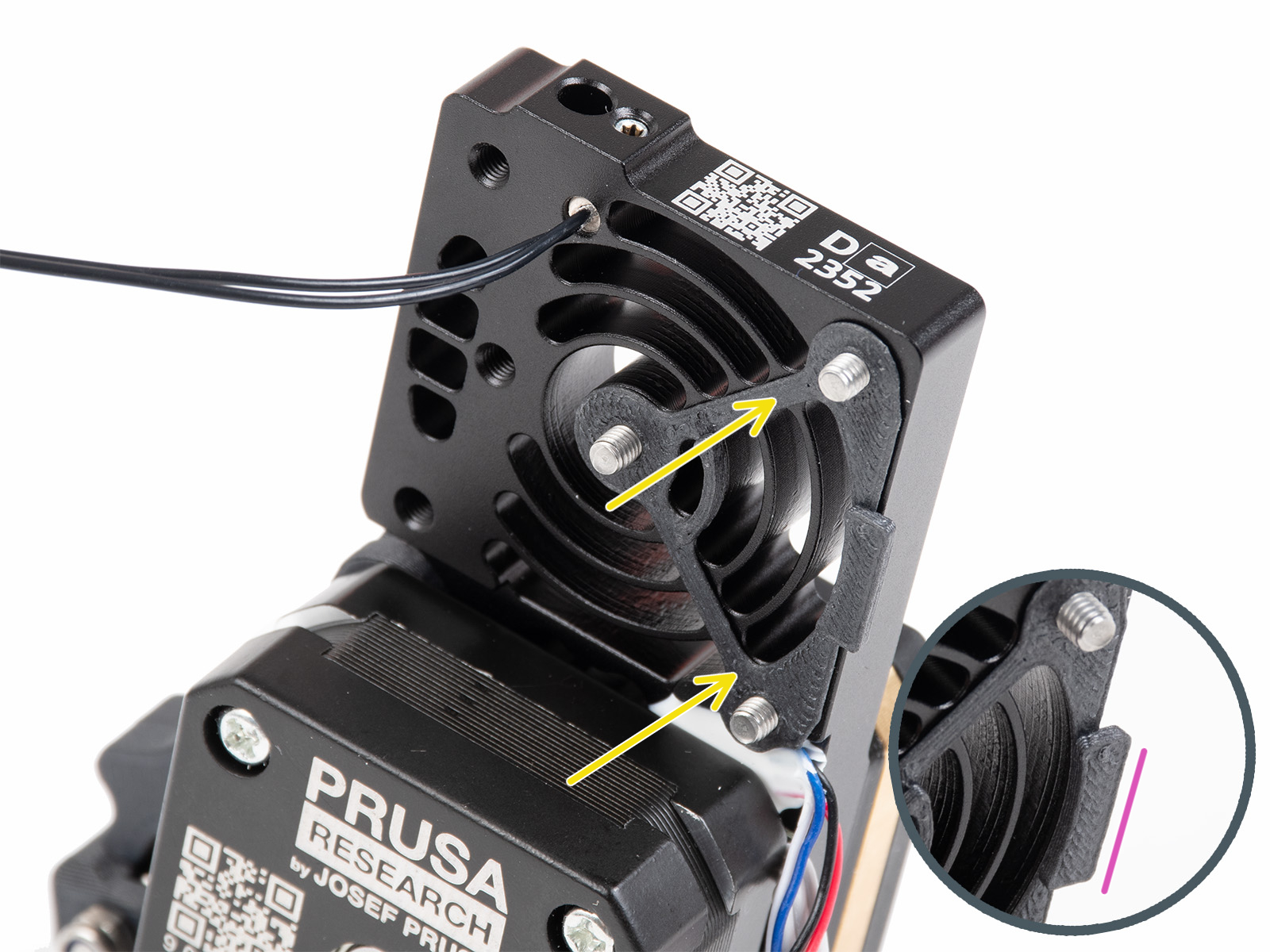

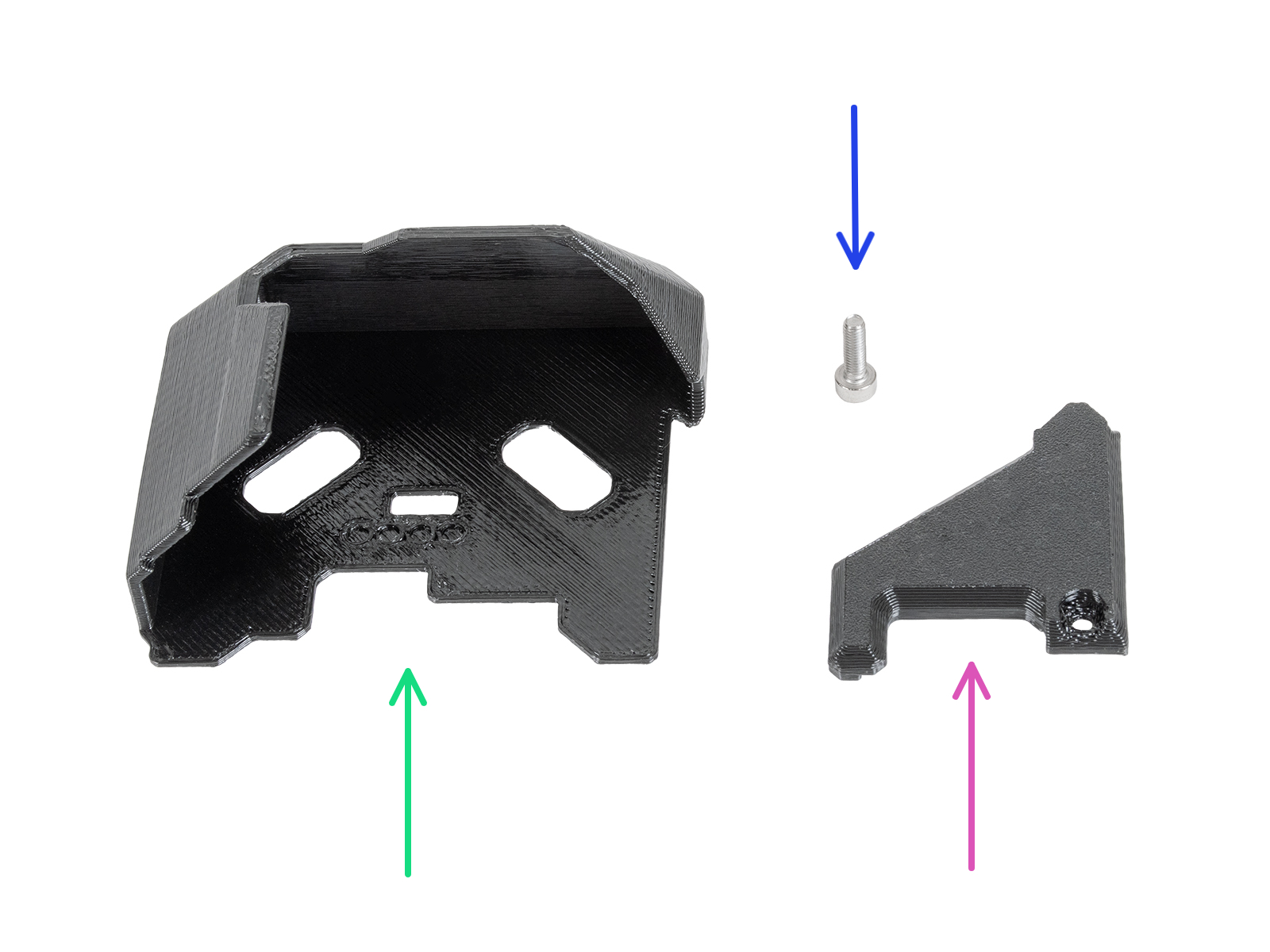

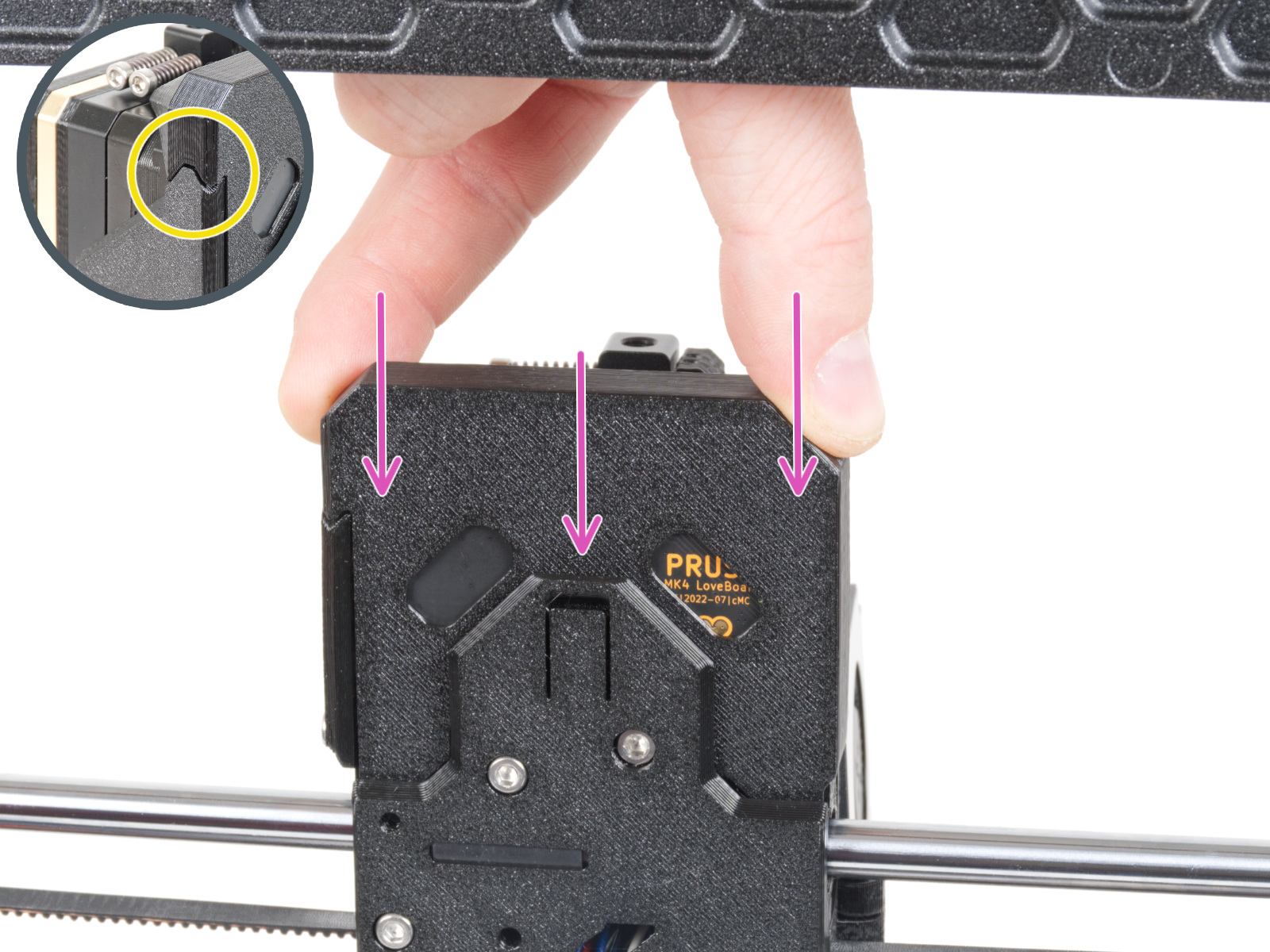

Another difference is that the older gearbox uses a plastic spacer, while the newer one has a metal washer. Replacing it isn't necessary, as it as it requires a full gearbox teardown and offers no functional advantage.

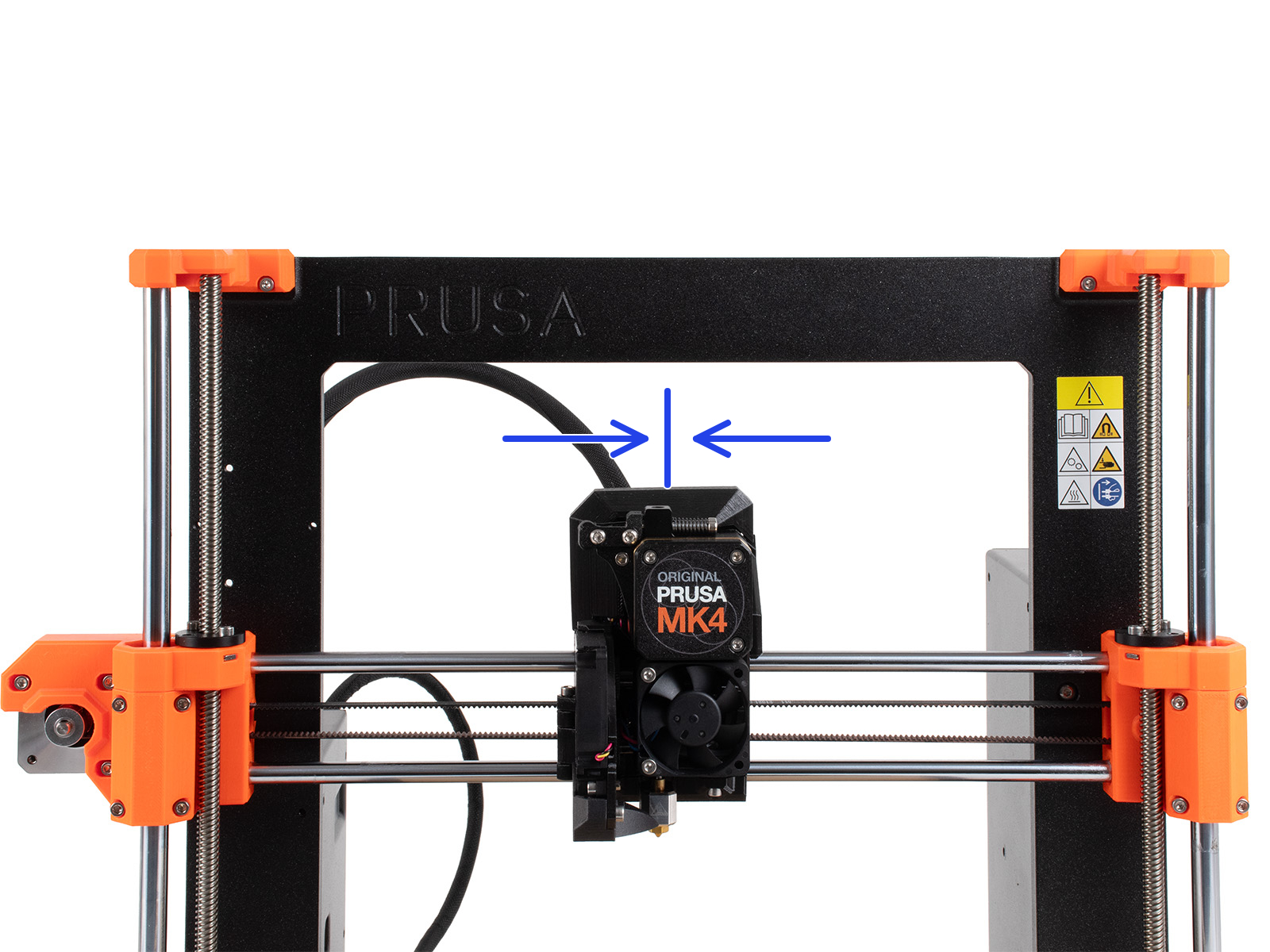

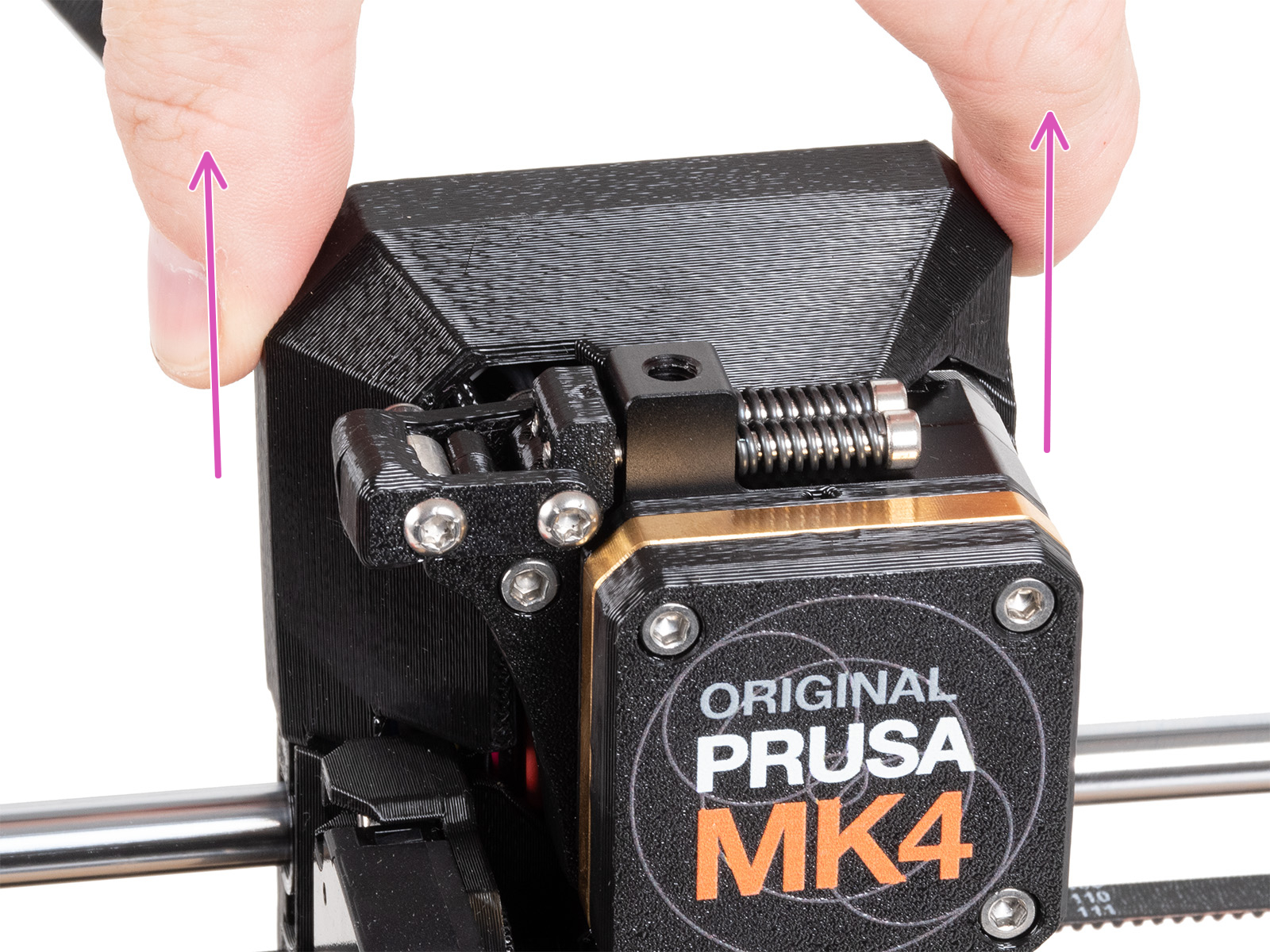

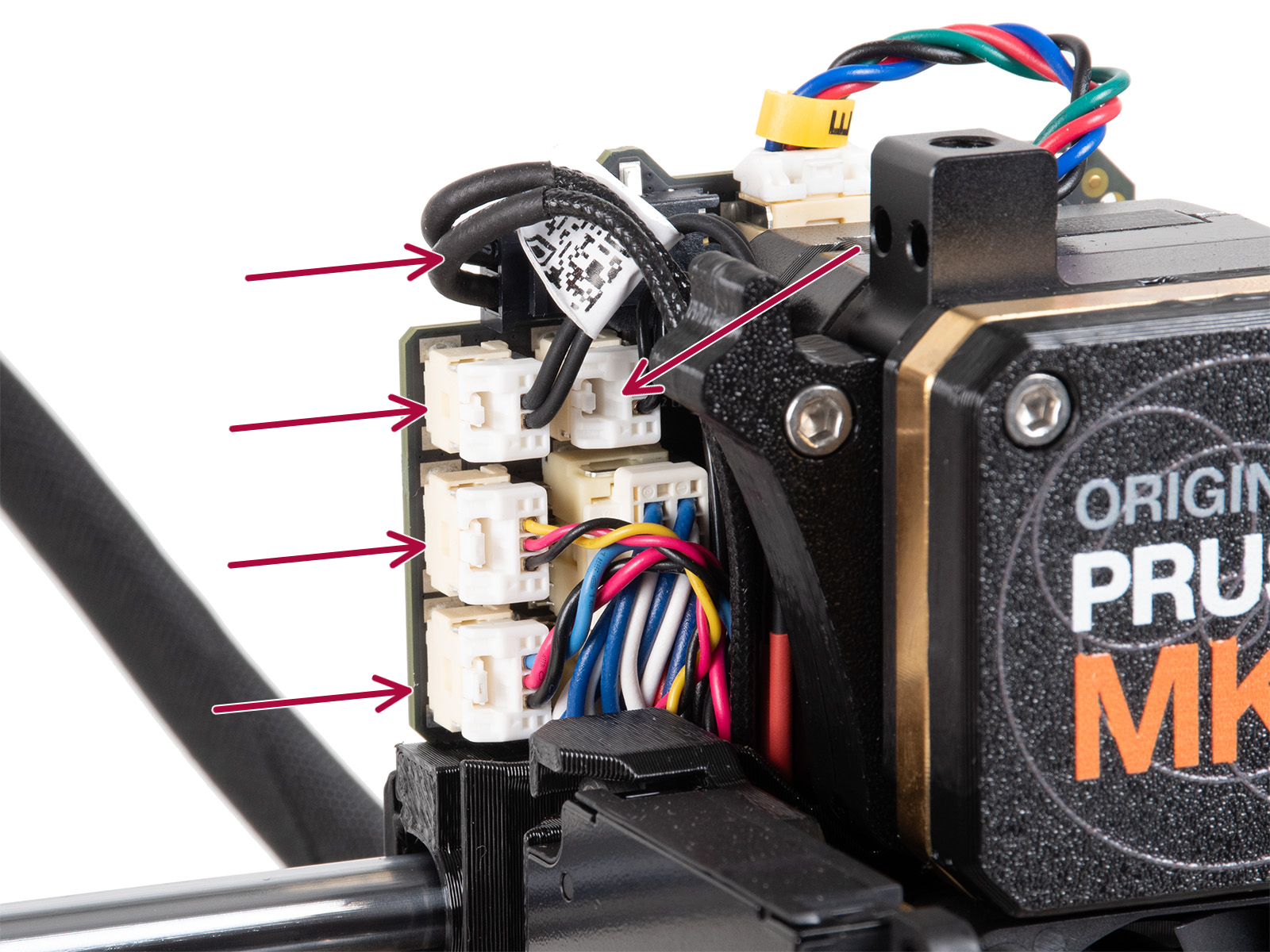

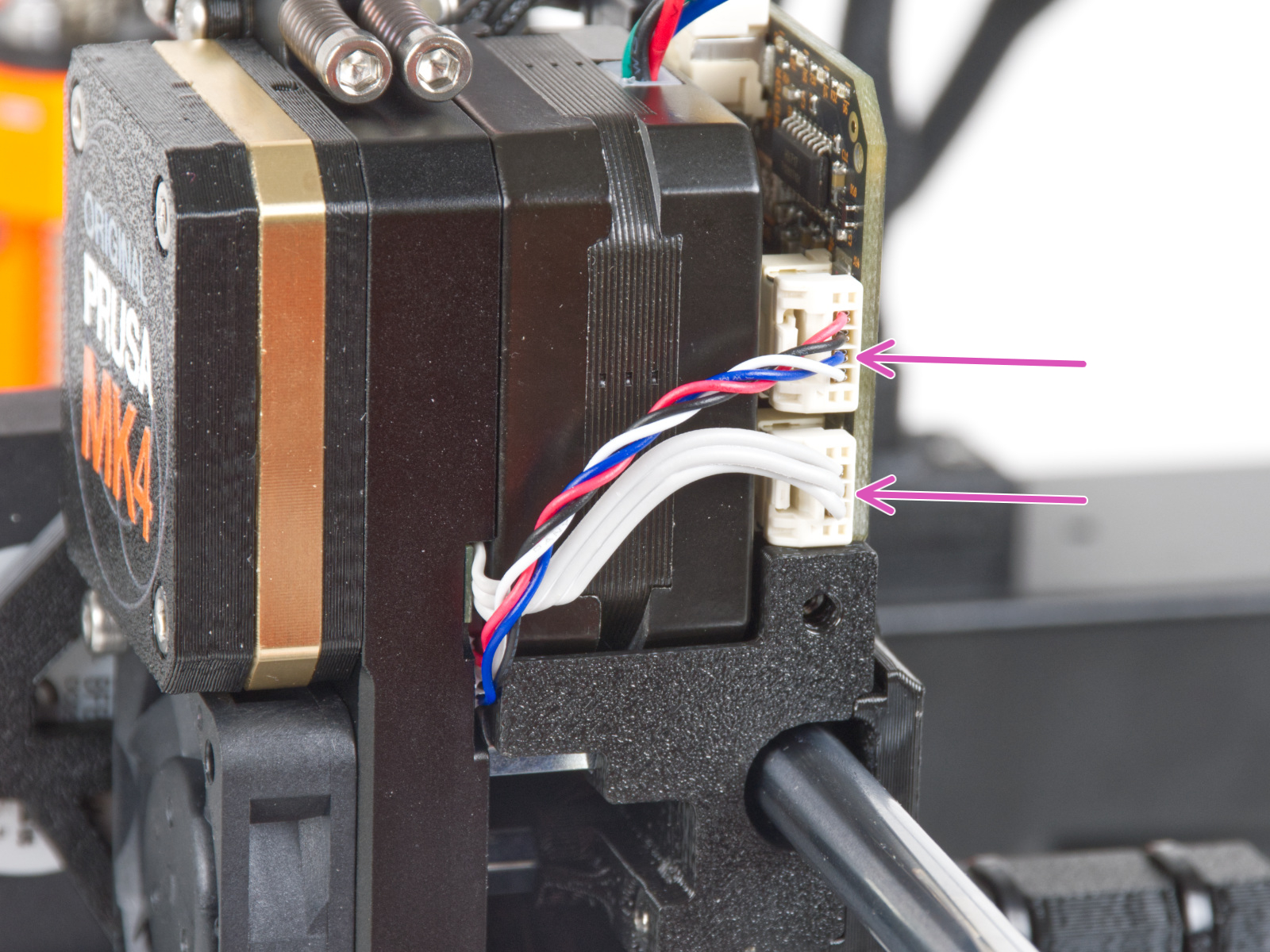

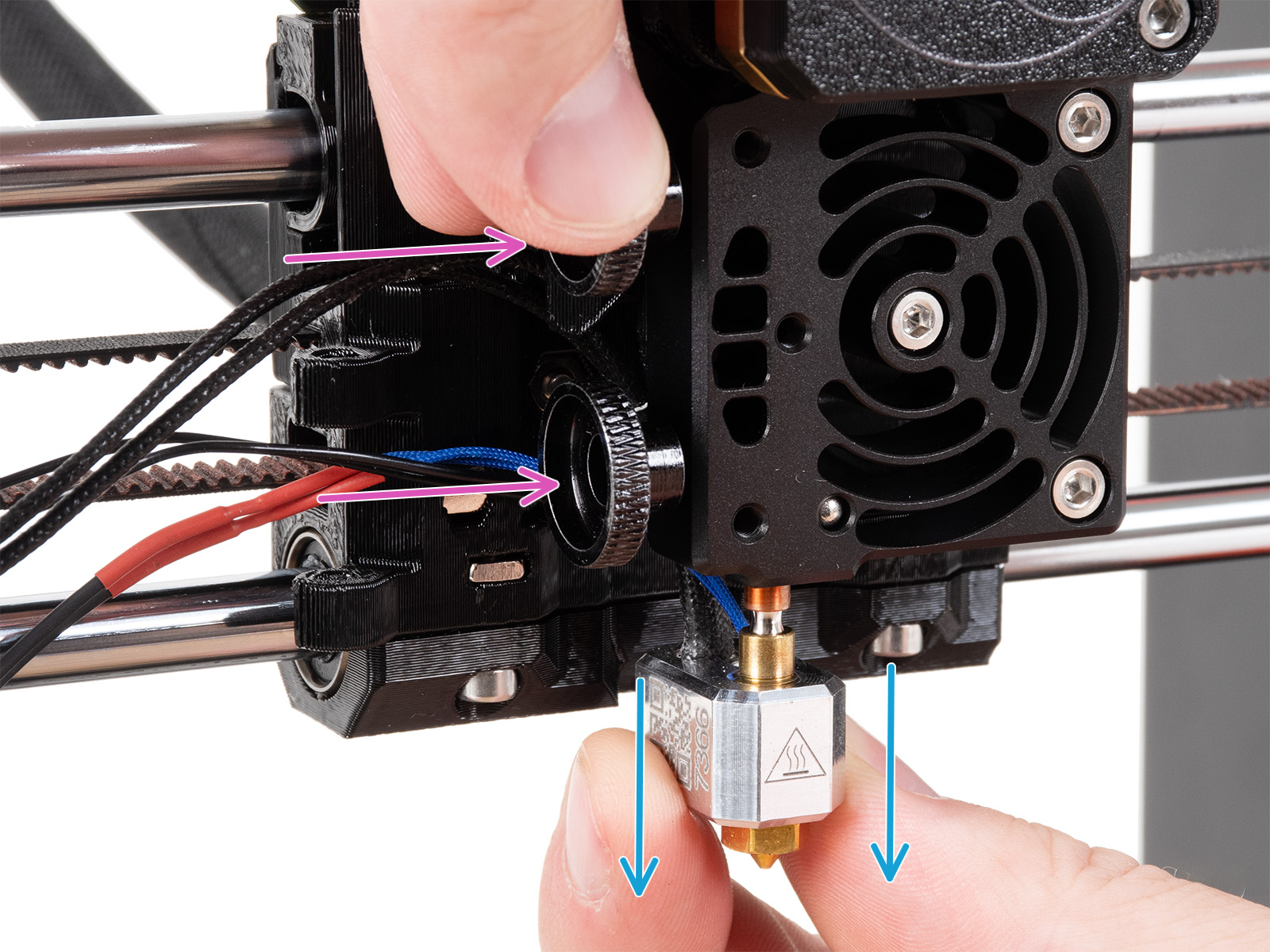

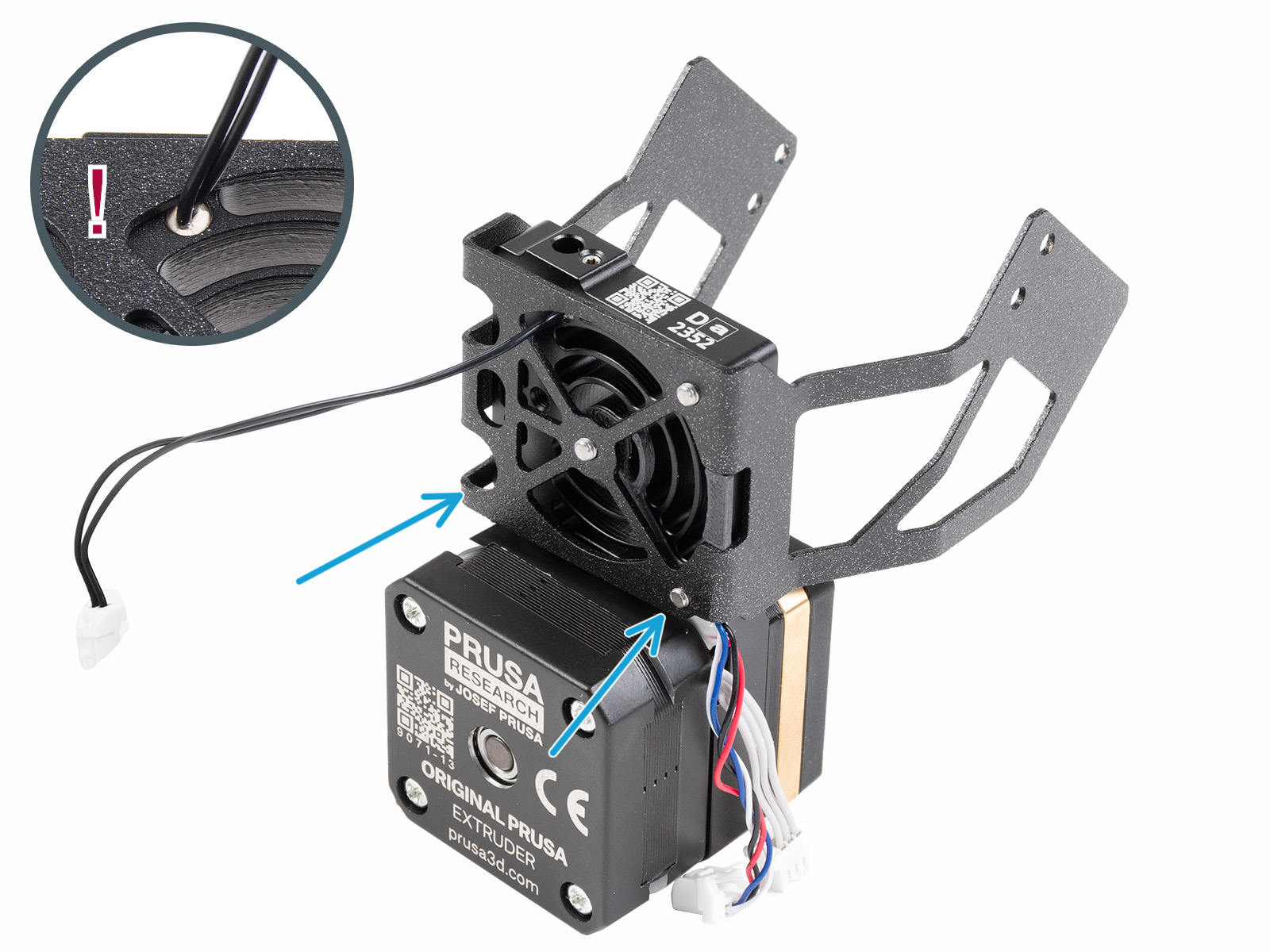

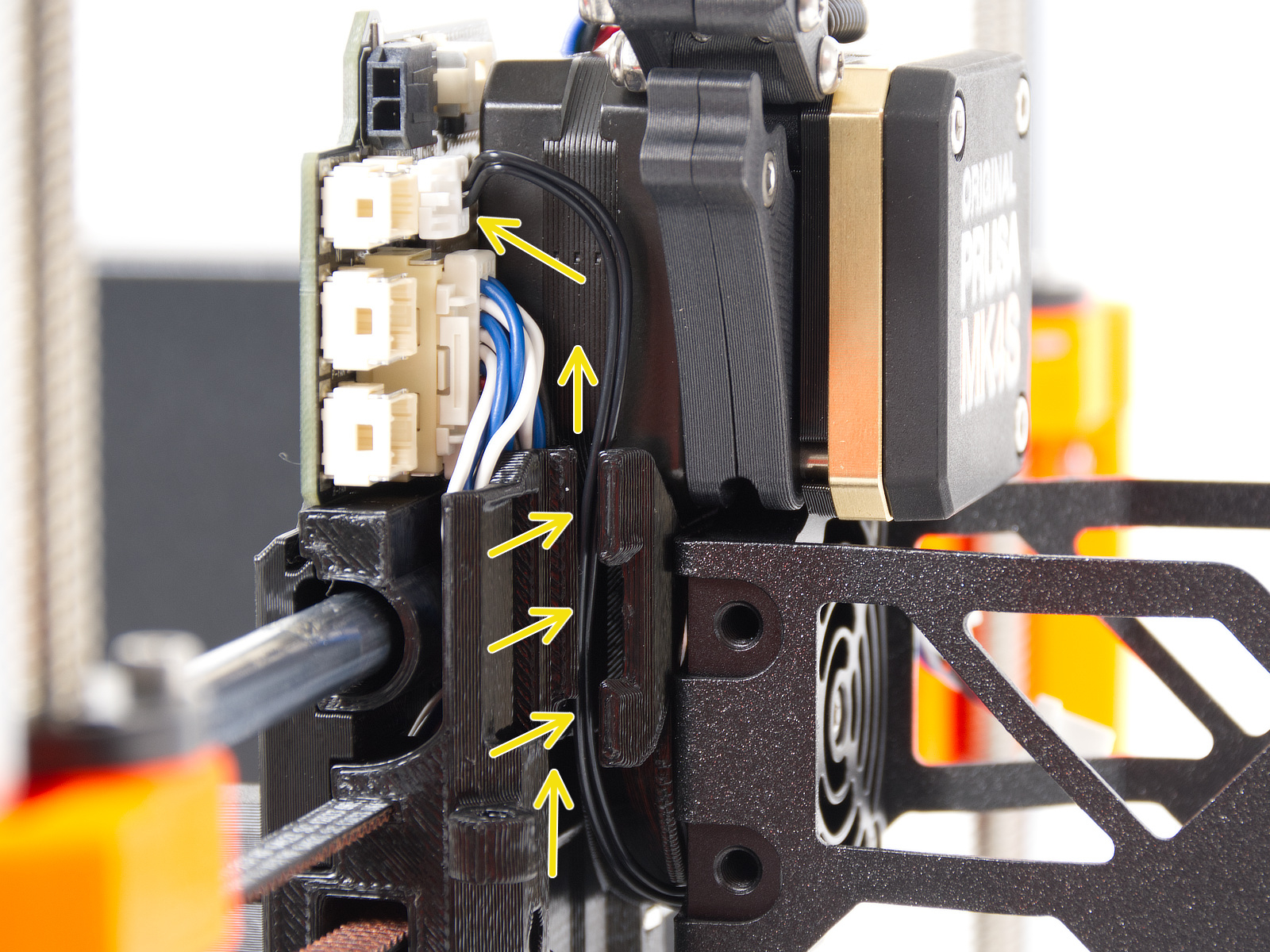

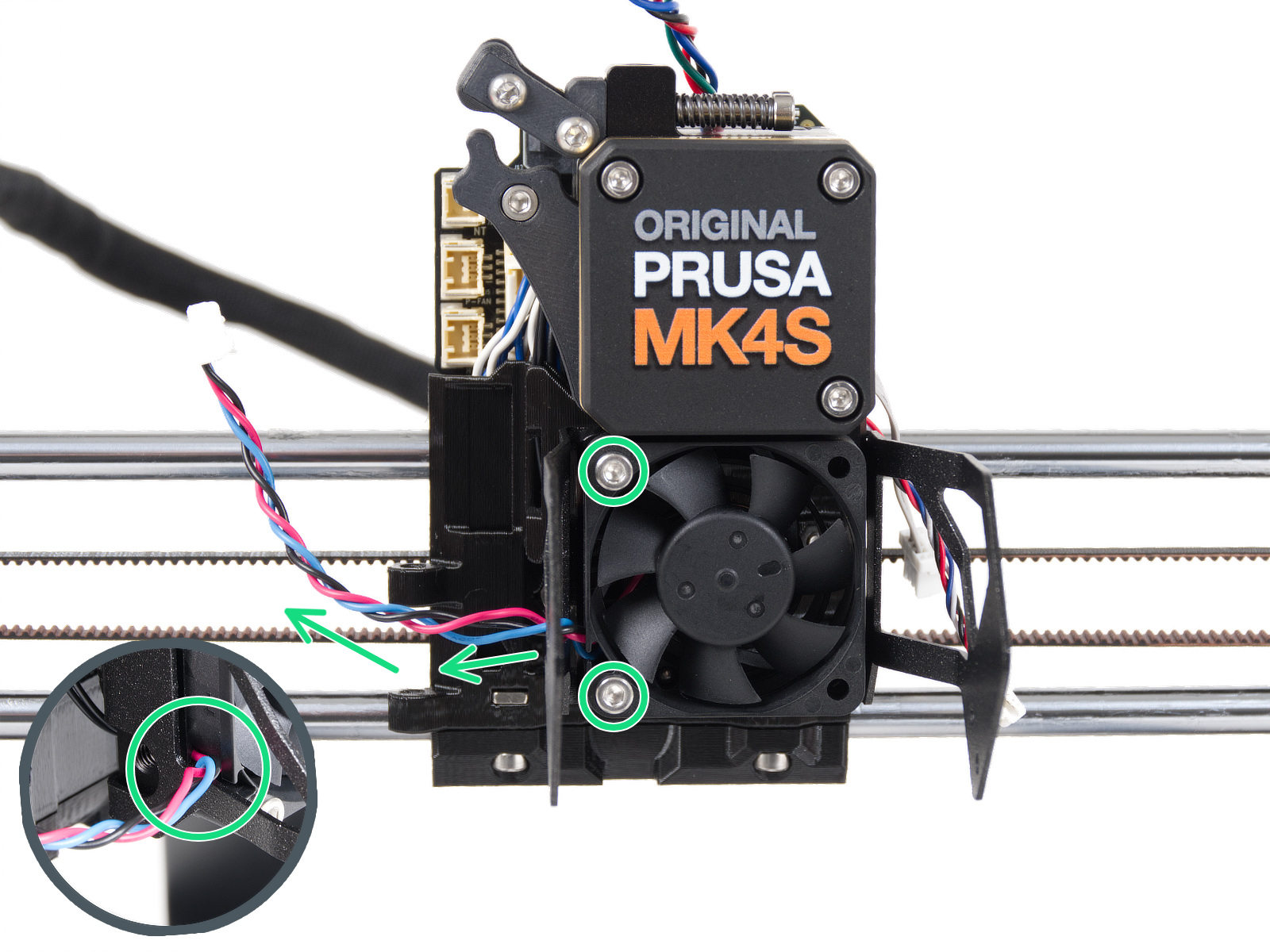

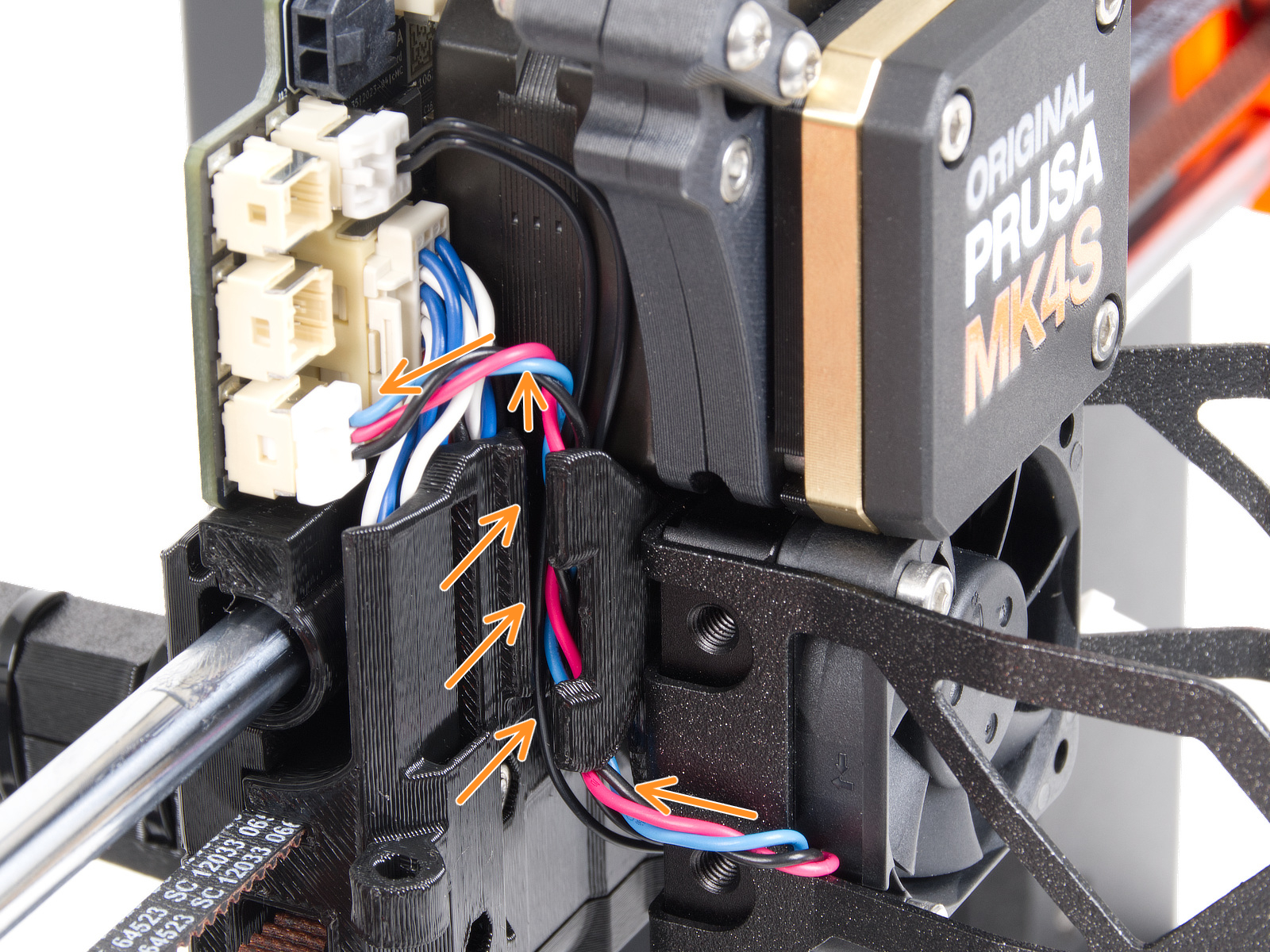

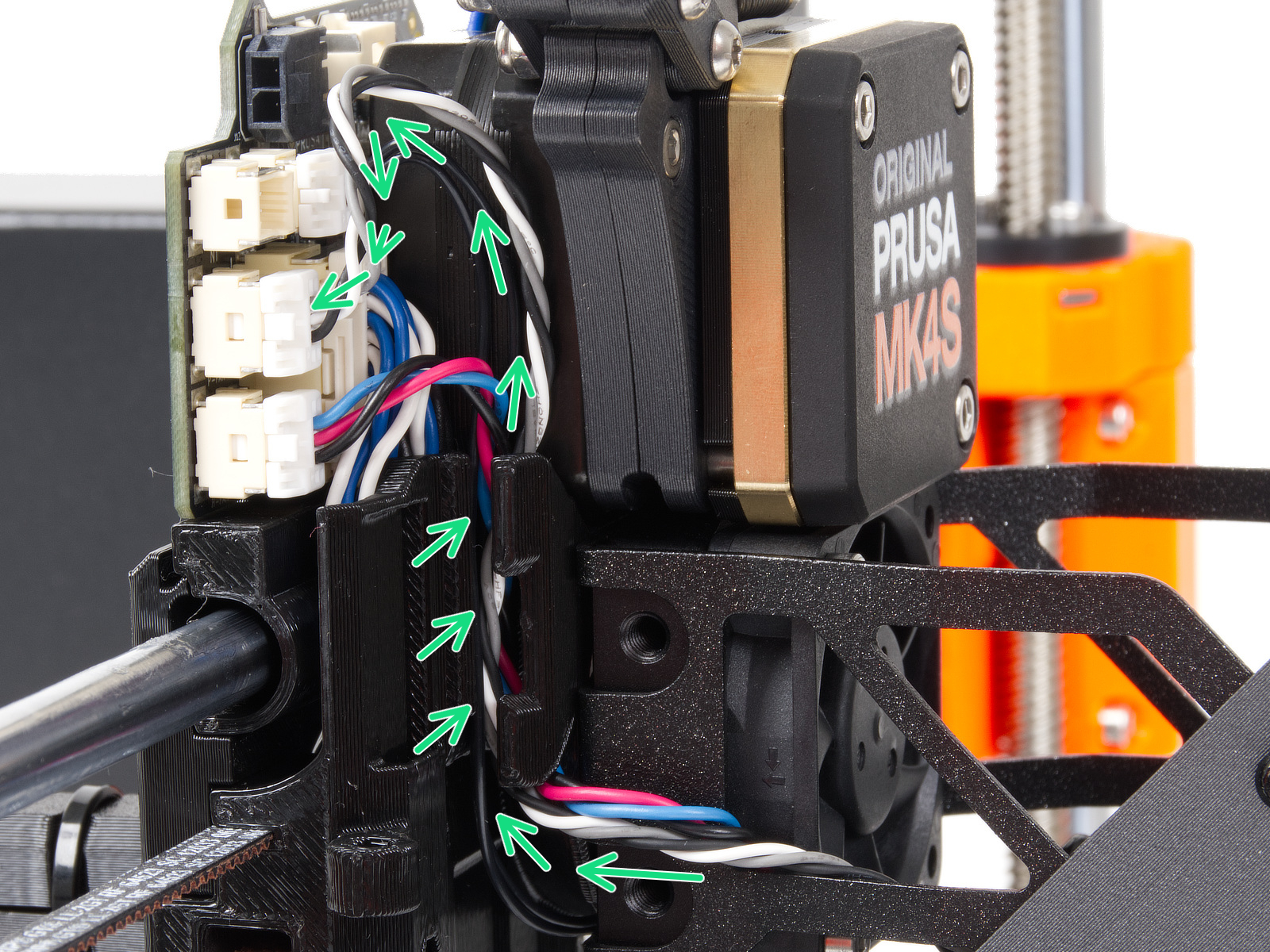

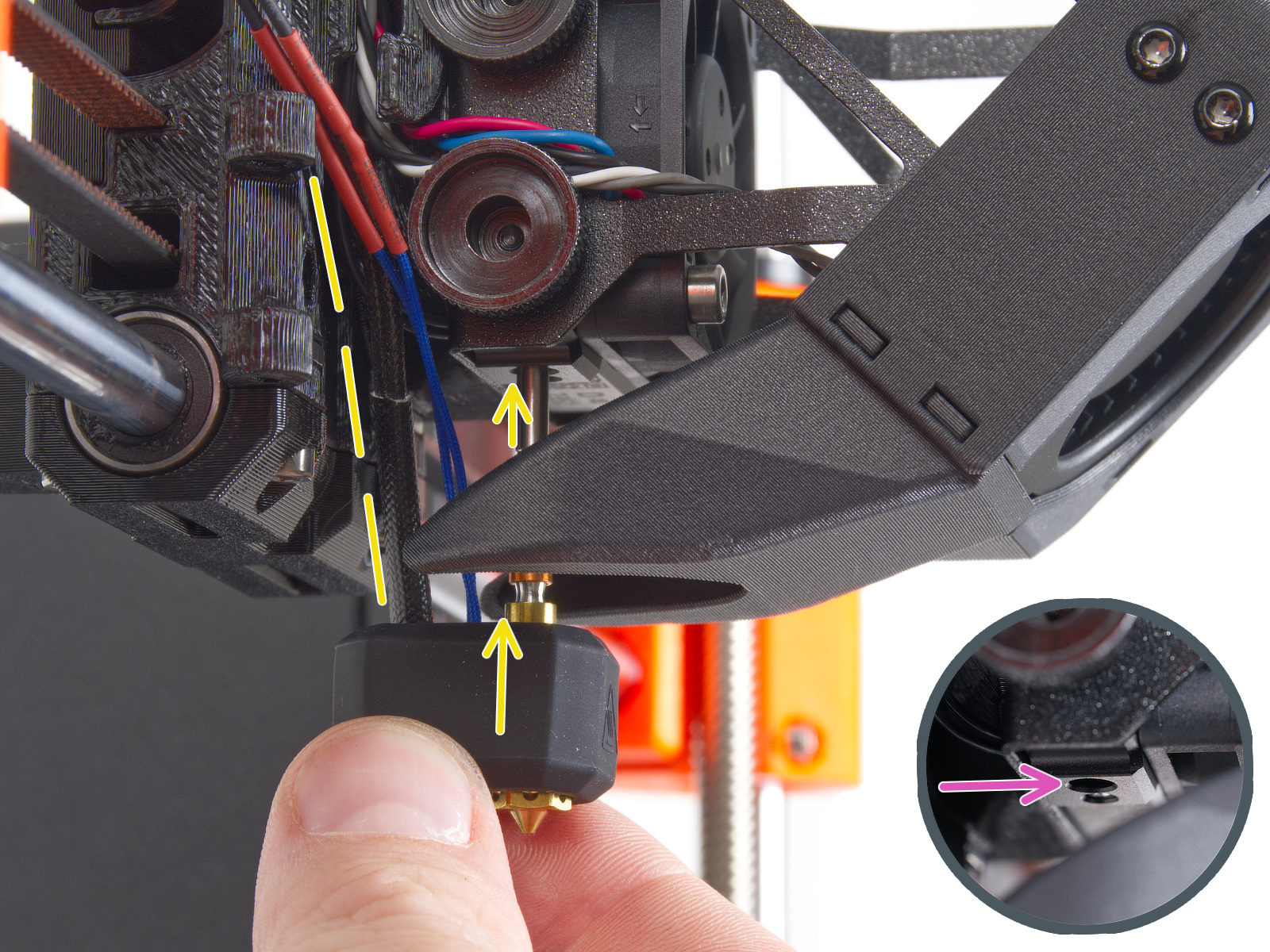

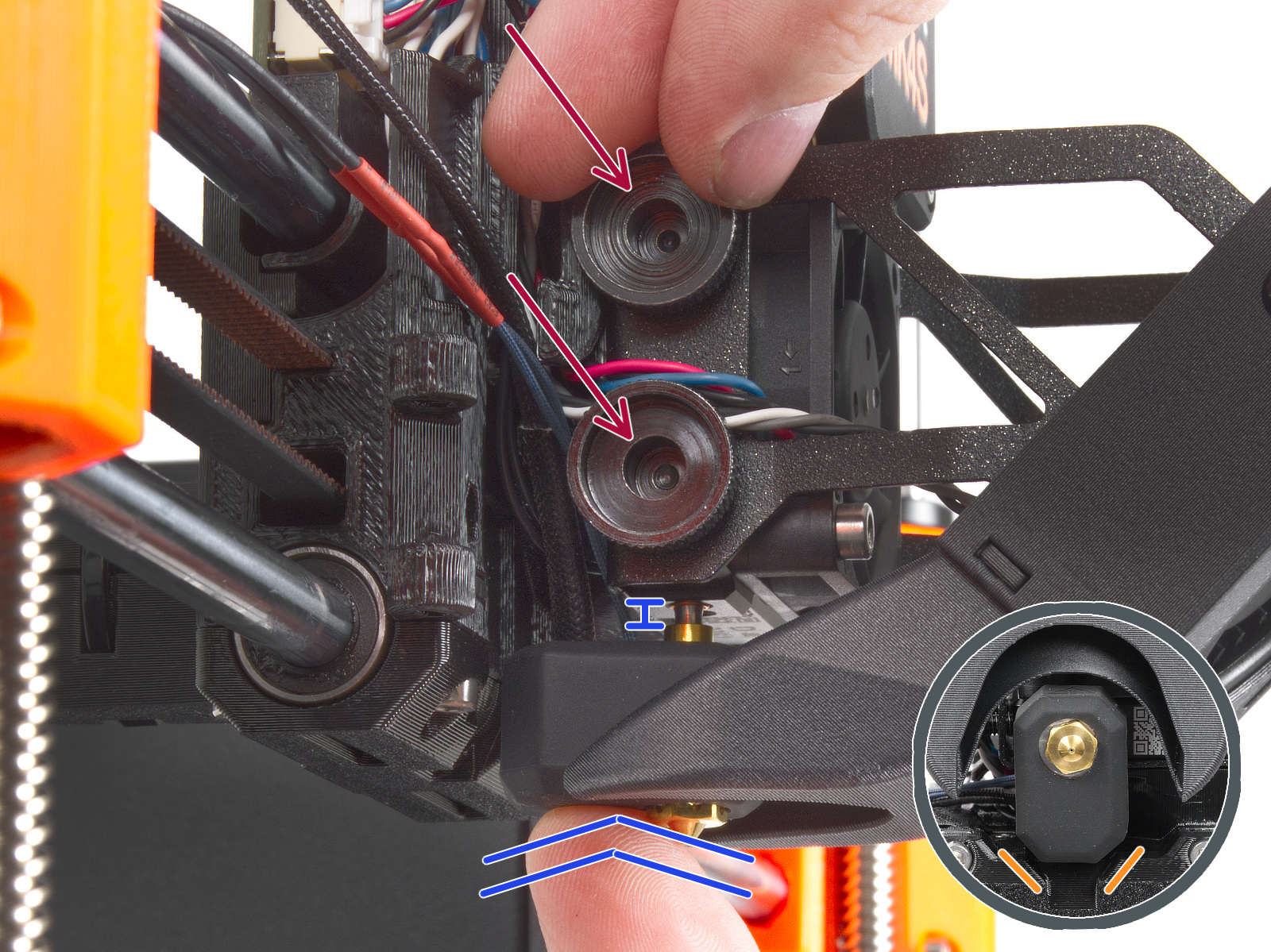

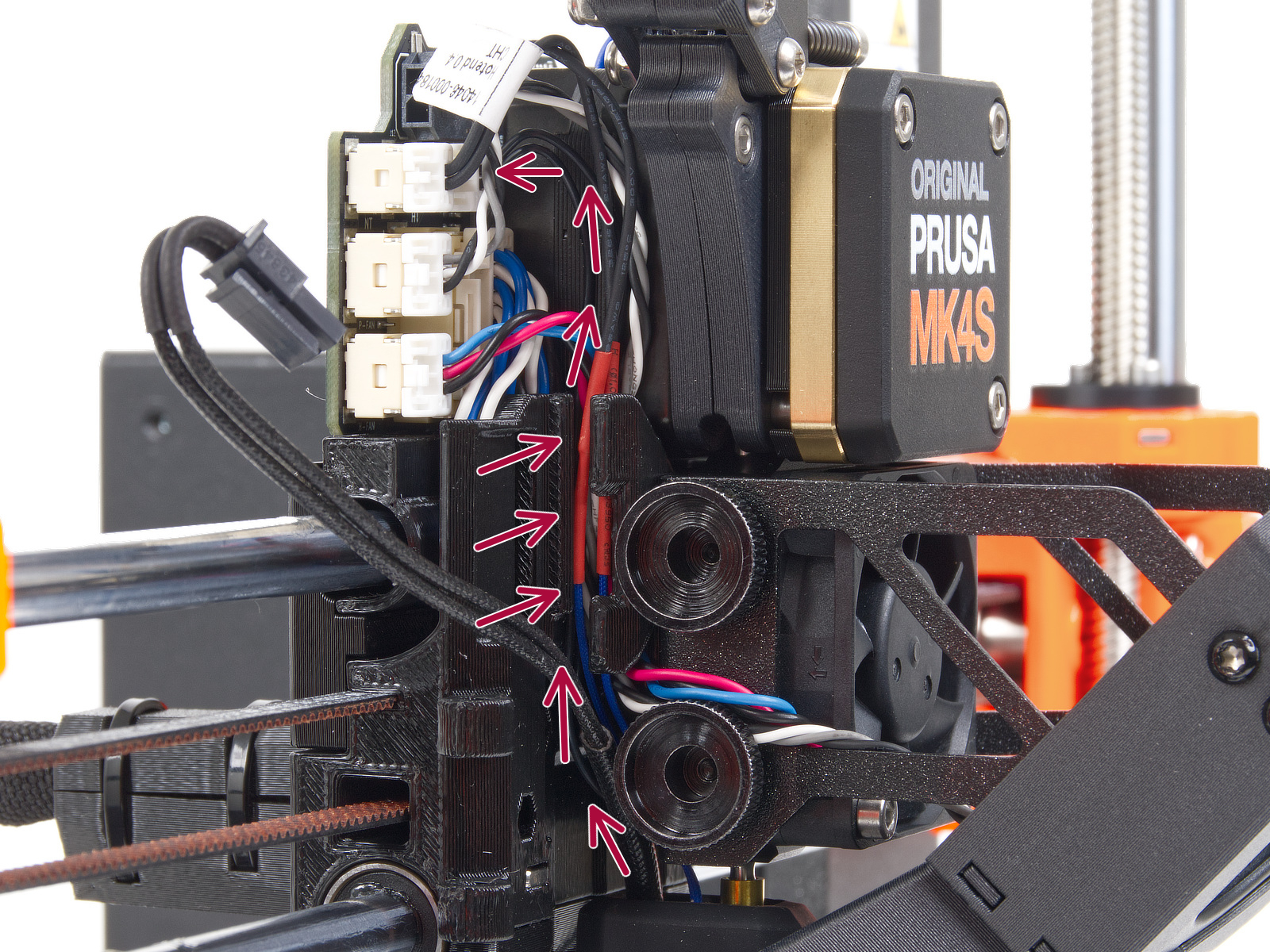

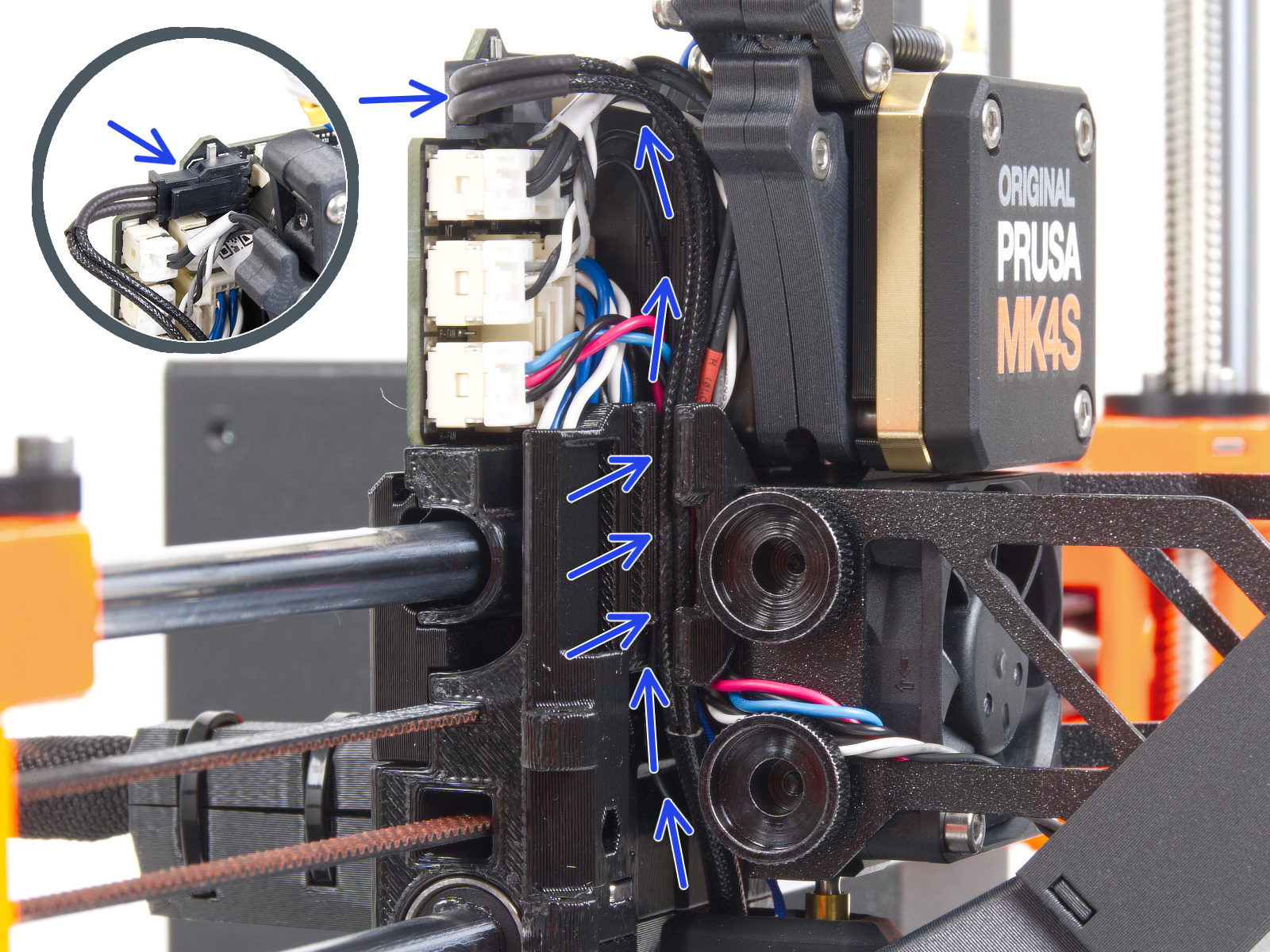

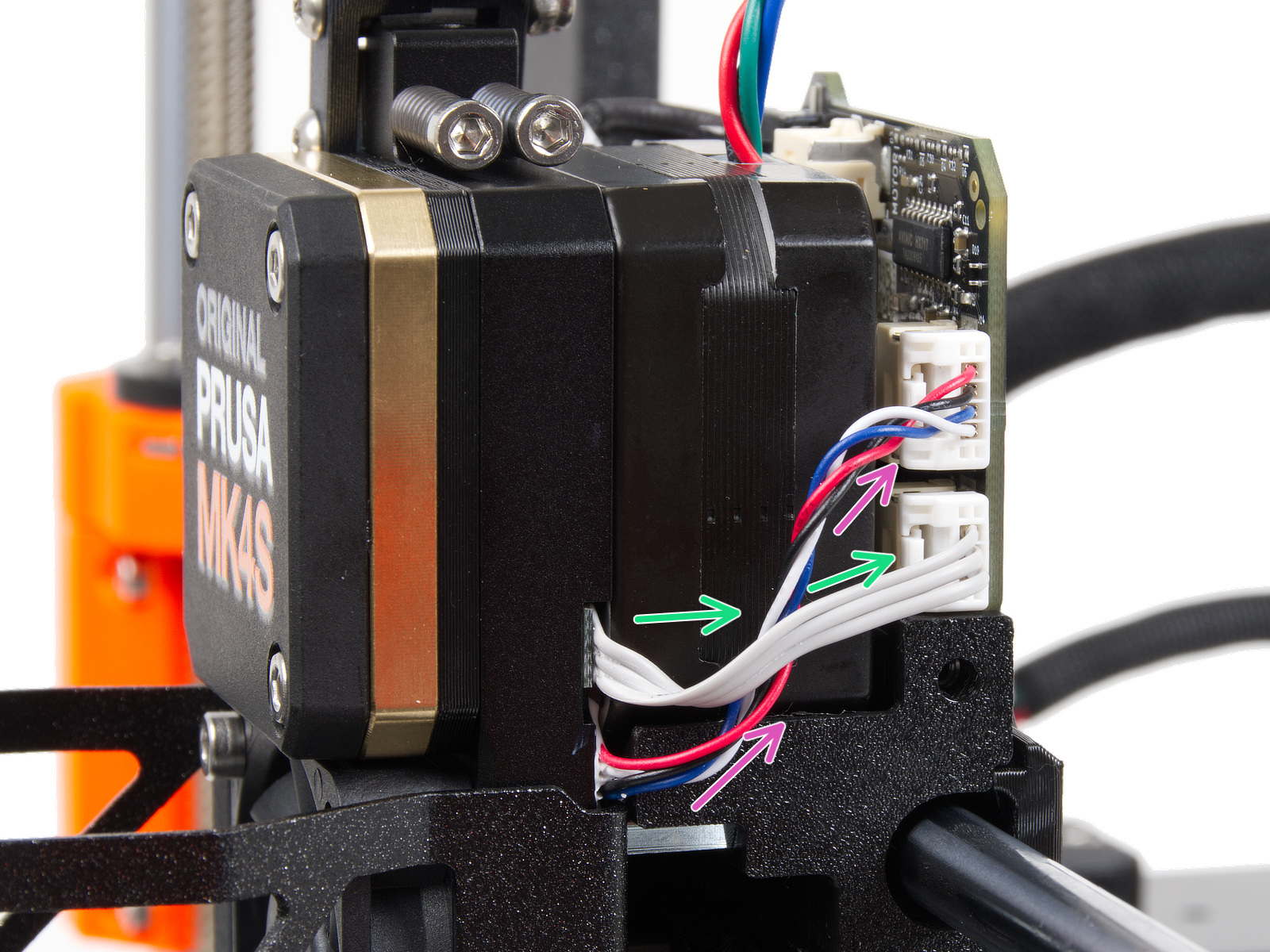

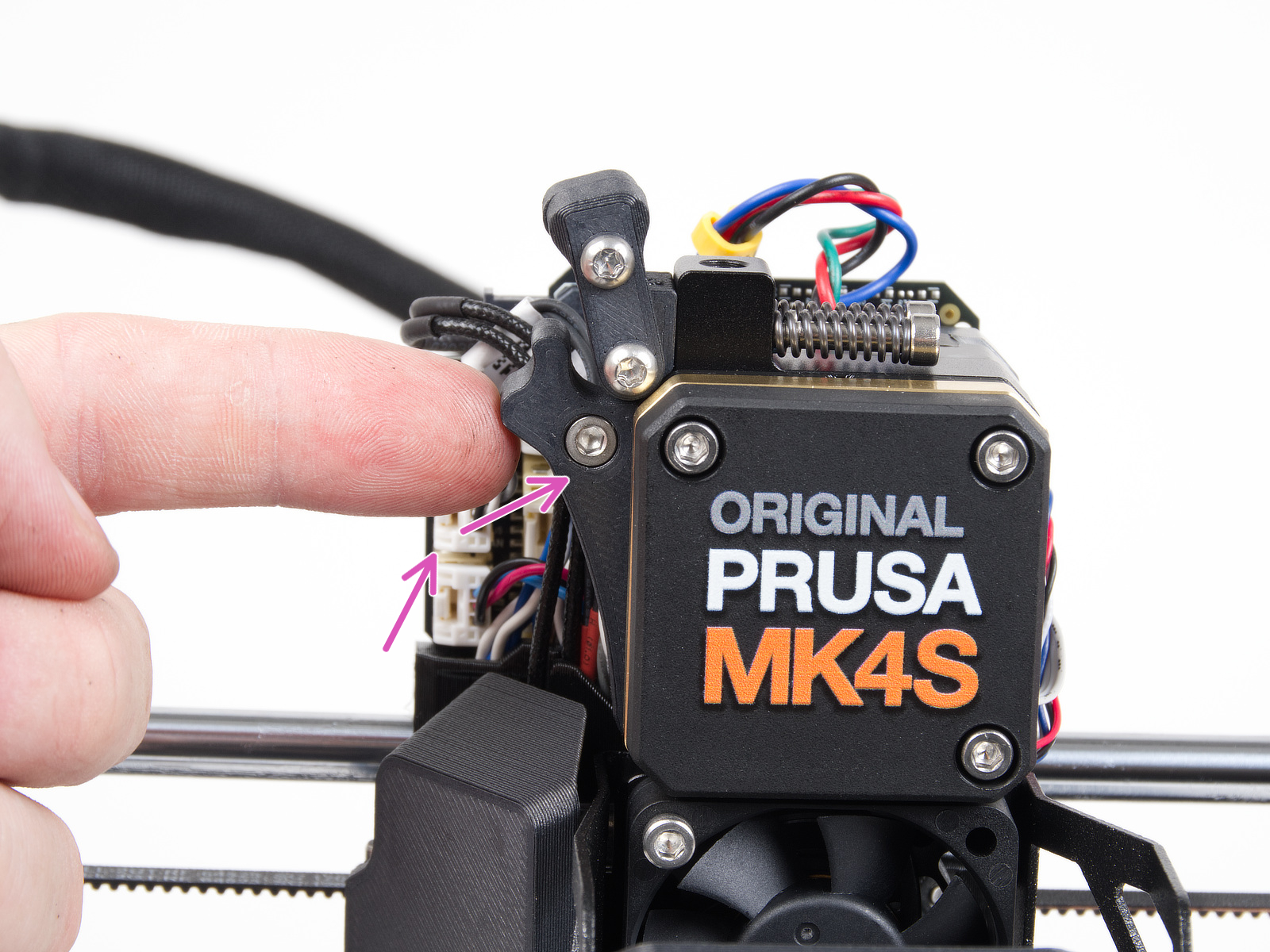

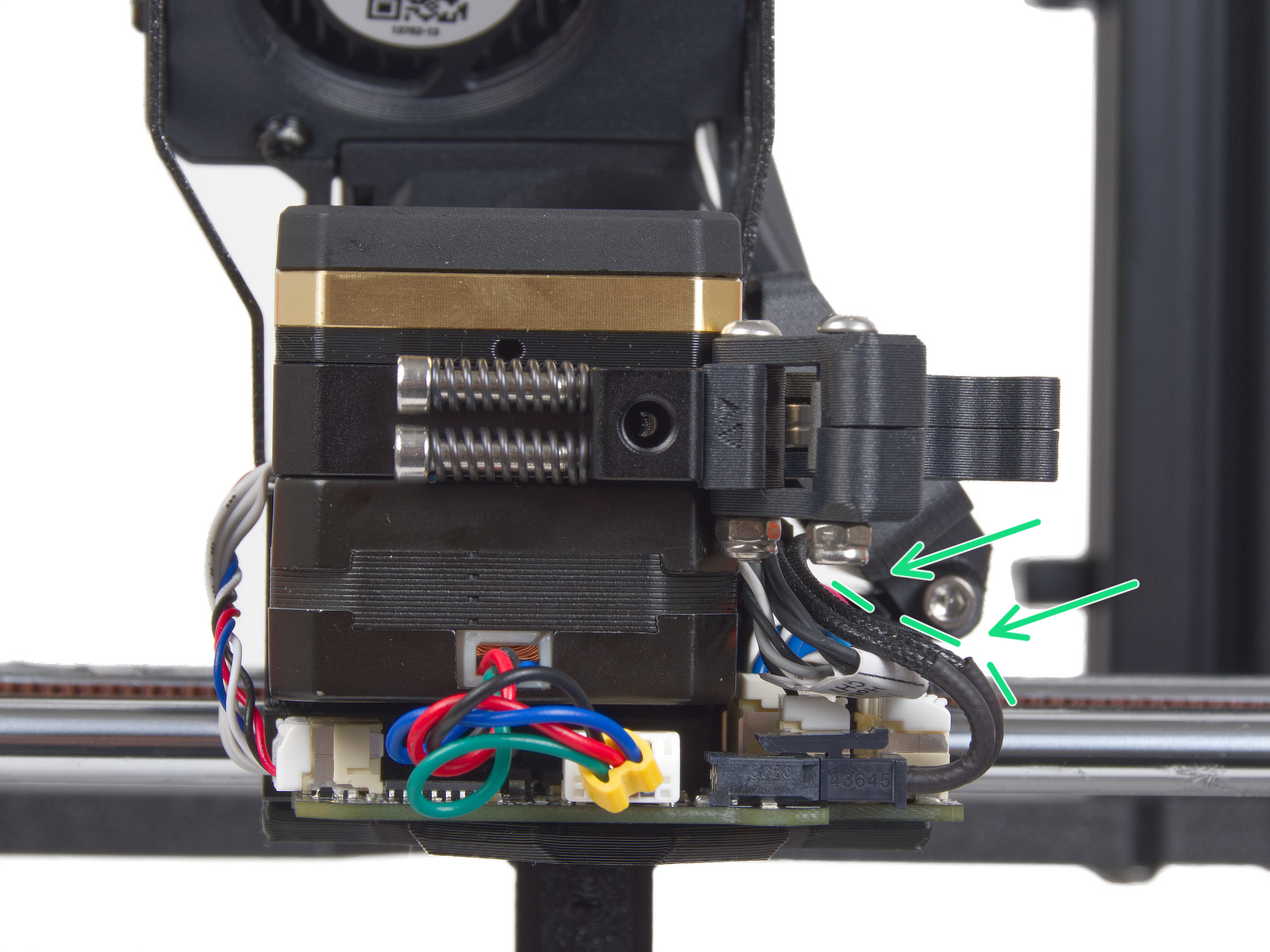

DO NOT PINCH ANY OF THE CABLES!

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.