You can recognize under extrusion when there is material missing in your print’s layers. Printed objects with under extruded layers can be fragile and tend to break apart. There could be several causes to under-extrusion and you should also think if you recently did any changes to your printer (or perhaps no maintenance for a long period), as you might find the culprit there.

Example of severe under extrusion (left cube) and a normal print (right cube).

Example of severe under extrusion (left cube) and a normal print (right cube).

Common factors in under extrusions are:

- First layer calibration too close

- Slicer settings

- Nozzle

- Extruder gears

- Insufficient hotend cooling

- Filament

First layer calibration too close

Make sure you have performed the First Layer Calibration correctly. Avoid compensating for a lack of adhesion by squishing the first layer too much. If the nozzle is too close to the build plate, the filament can be obstructed from pushing through. We recommend running the first layer calibration every time you move the printer to a different location or do maintenance on the hotend, like changing the nozzle. Moreover, when you swap the steel sheet from the textured one to the smooth one you must recalibrate due to the sheet's different thickness. That is why we introduced the Steel sheet profiles.

Slicer settings

Each profile in the PrusaSlicer contains settings that determine temperature, speeds, and how much filament the 3D printer should extrude. The printer does not provide any feedback on how much filament actually leaves the nozzle. It can be that less filament is extruded than the firmware expects. If that happens, you may notice gaps in and/or in between printed layers.

Make sure you have set up your printer in PrusaSlicer by running the Configuration Wizard and as a starting point you should use the stock filament profiles which are tailored for your machine, filament type, and nozzle size.

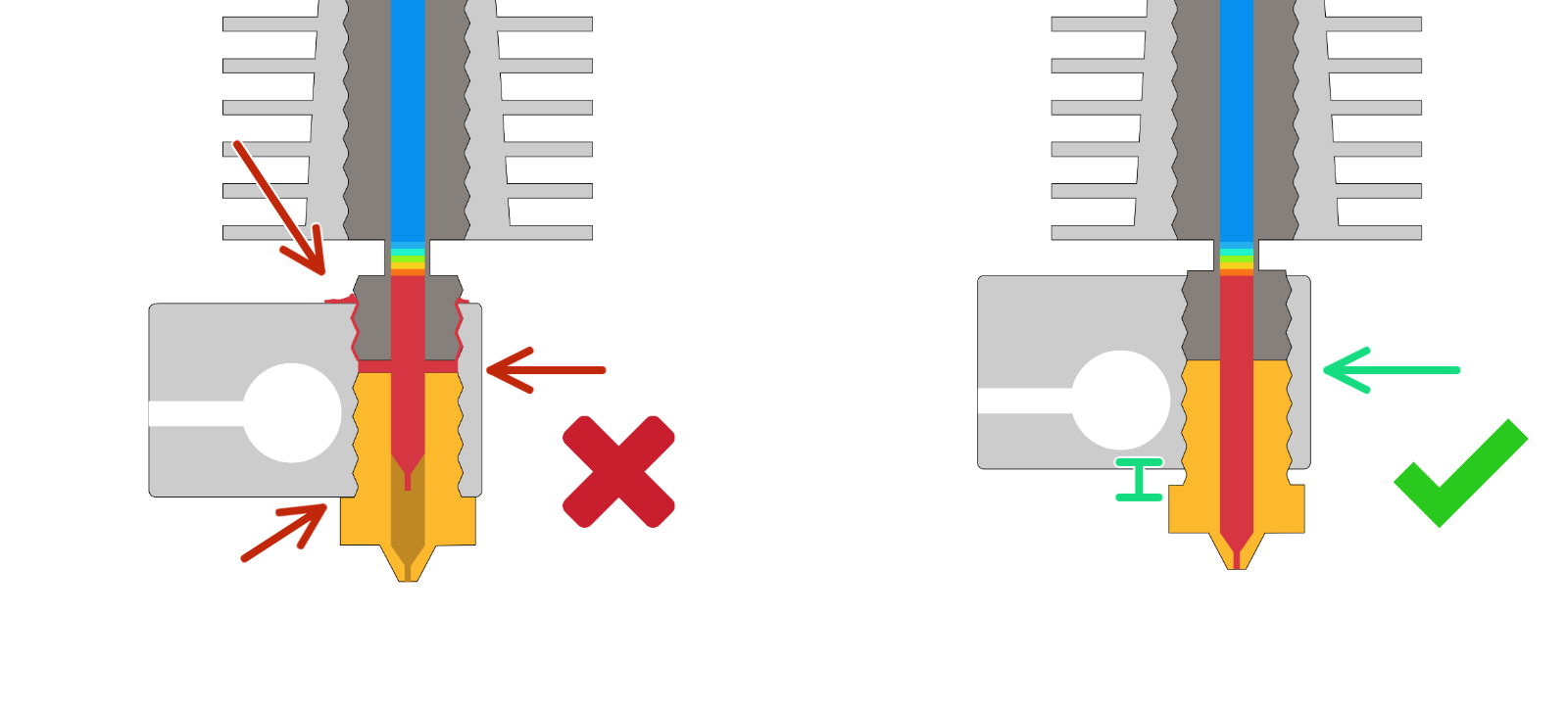

Nozzle

If you had the nozzle removed from the hotend at some point, make sure it has been correctly reinstalled. Please see the dedicated guide for your hotend:

Incorrect installation can cause both clogging and leaks. The nozzle must be tightened when heated and there must be a gap between the nozzle and the heater block. Also, inspect the extruder and hotend for any damage, like the heater element or thermistor's wires or a bent heatbreak (only on V6 hotend).

Using specialty nozzles

If you are using specialty nozzles like hardened steel or stainless steel, etc., you may have to increase the nozzle temperature when printing, usually within a range of 5-10 °C. Steel has different thermal properties compared to a brass nozzle, which can affect print results, mainly the inter-layer adhesion. But remember that higher temperatures can also lead to increased stringing. If the issue persists, try replacing the nozzle with the original 0.4mm brass nozzle and see if it makes a difference.

Furthermore, not all nozzle sizes will be suitable for all filaments. Filament that contains particles of wood or metal will most often be unsuitable for nozzles with a diameter below 0.4, and some will require an even larger nozzle, like 0.6 mm or 0.8 mm. For more information, please see Different nozzle types.

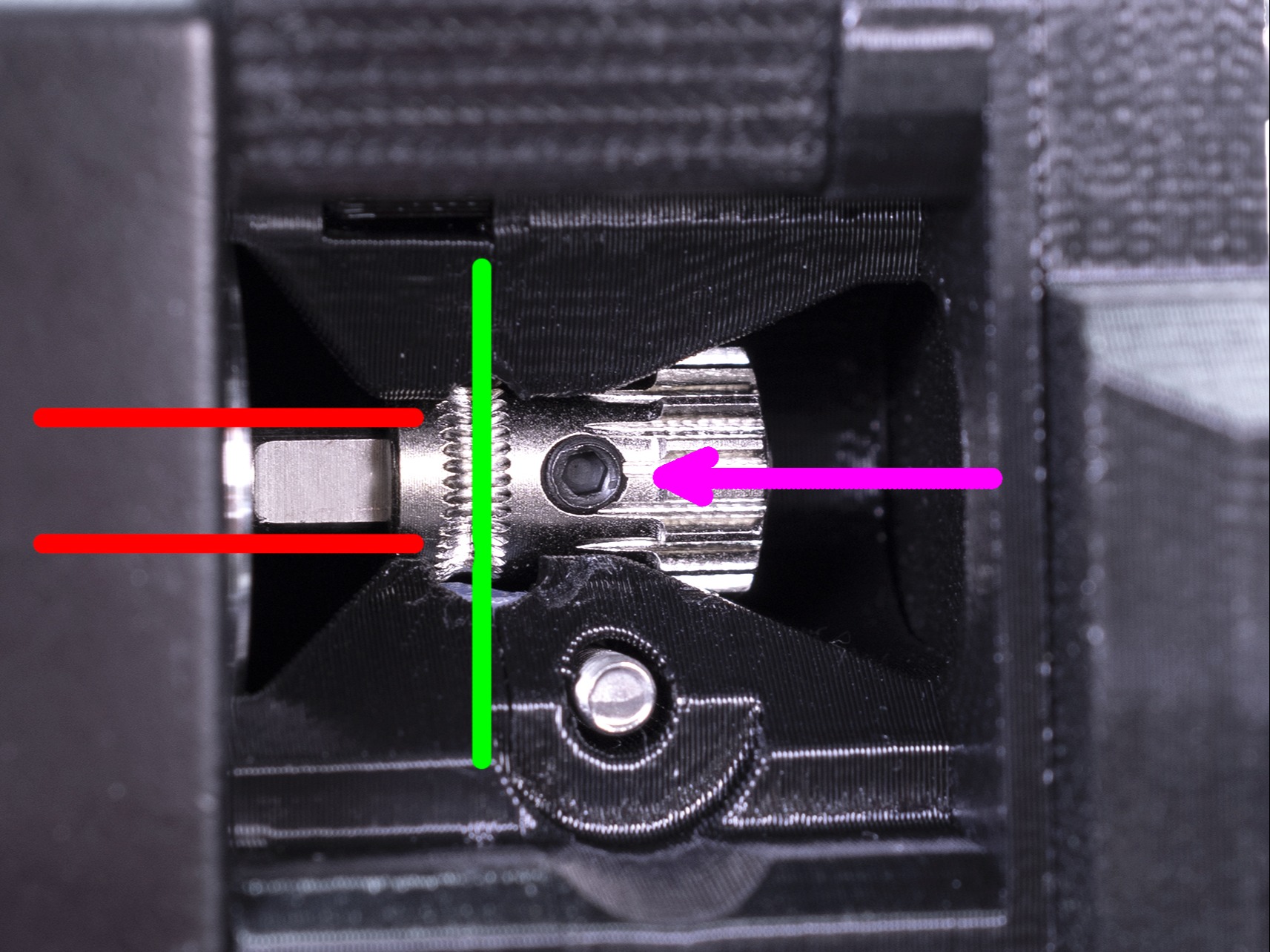

Extruder gears

Check both Bondtech gears for any dirt or misalignment so they are able to push filament through. Please see Checking/re-aligning the Bondtech gear (MK3S/MK2.5S) for details.

Additionally, make sure that your printer’s extruder idler is at the correct tension. Having the idler screw too loose or too tight can cause under extrusion.

|  |

Insufficient hotend cooling

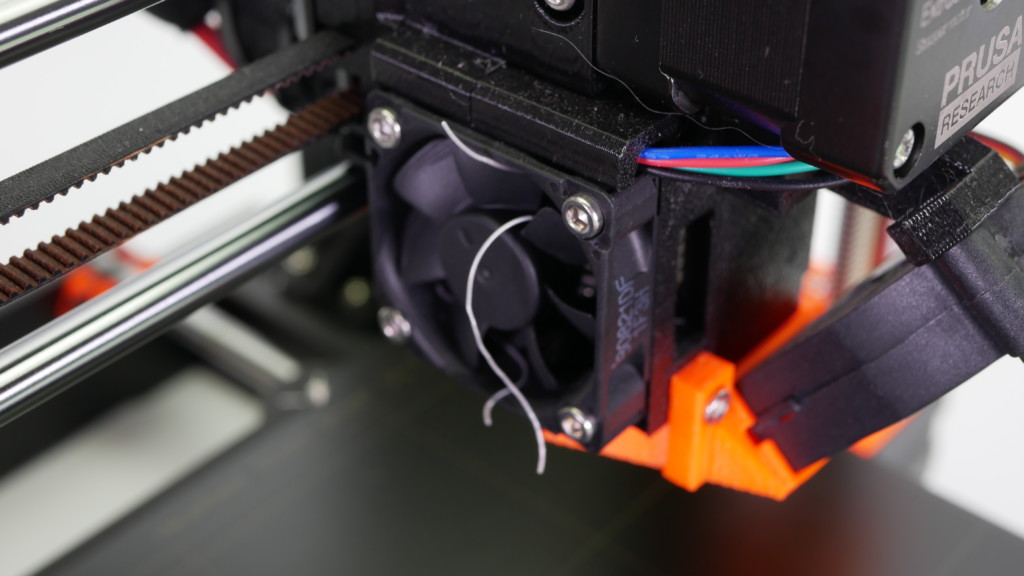

Controlling the "melt-zone" of the filament is very important. With insufficient cooling, the filament can start melting too far away from the nozzle. Check that your extruder fan is installed in the correct orientation and whether the fan is blocked by a piece of filament or some other debris.

If you are using your printer in an enclosure, make sure the temperature inside is not too hot, as overheating can result in Heat creep, where the filament will start melting before it reaches the nozzle

Example of a blocked fan by a strand of filament.

Filament

Too low or too high printing temperature can cause print issues as well. If your filament brand and type is not listed in PrusaSlicer, you can try to adjust the print temperature by +/- 5-15°C to see if this resolves the issue.

Some specialty materials, like Flexible materials, may require many adjustments and tweaks to print them successfully. Composite materials, like Woodfill filament, may require at minimum a 0.6 mm nozzle, and 0.2 mm layer height to prevent clogging. If there are composite materials like kevlar or carbon fiber, a hardened nozzle is required.

Some filaments can also have a varying thickness, due to quality or infused materials like wood, which will cause unexpected changes in the volume of extruded filament. The industry standard of variations in diameter is +/- 0.05 mm.

Keep your filament dry, free of moisture because damp filaments have a negative impact on printing, especially soluble filament, PETG, and ABS. We highly recommend putting spools back inside their original bag when it’s not in use, along with a silica gel. We recommend storing your filaments in a dry area or ideally in a “dry box”.

Incorrect loading/unloading

When loading a new filament with a lower specified temperature, preheat the nozzle to the temperature required by the previous filament type you have used. In other words, always the highest temperature filament, as its remnants are most likely still in the hotend. For example, if you have printed with ABS or PETG and want to print with PLA now, load the PLA filament at the ABS or PETG temperature. This way, the newly introduced filament can push the old one out.

9 comments

I am using a MK4. I am now experiencing under extrusion when printing, it happens with every model. I have tried using exactly the same settings (0.2mm SPEED preset in PrusaSlicer) as previous successful prints, but it is under extruding. I have tried all the suggestions above, but still not working. Using different PLAs, also trying different temperatures, it keeps under extruding. Any suggestions?

Hi. Assume, were talking about the V6 hotend.

If there is a gap between the heatbreak and the nozzle (the nozzle isnt tightened up against the heatbreak properly) resulting in molten plastic oozing on top of the heaterblock, you might need to:

- loosen the nozzle slightly,

- partly dismantle the extruder to gain better access to the hotend,

- tighten the heatbreak into the heaterblock some more,

- heat up the hotend and then tighten the nozzle so that it seals against the heatbreak.

Hello, thank you for your comment. It's a fair point, though in the cases where an under-extrusion wasn't related to aspects of the printer hardware or filament, we generally suggest, instead of modifying the e-steps, going for the Extrusion Multiplier Calibration which has the same effect.

Once again, thanks!