In case there is a clog in your hotend, the filament might grind against the Bondtech-gears and be damaged enough so it can't be unloaded. It might snap right above the PTFE-tube when you try to pull it out by hand. In this case, the filament will need to be removed manually.

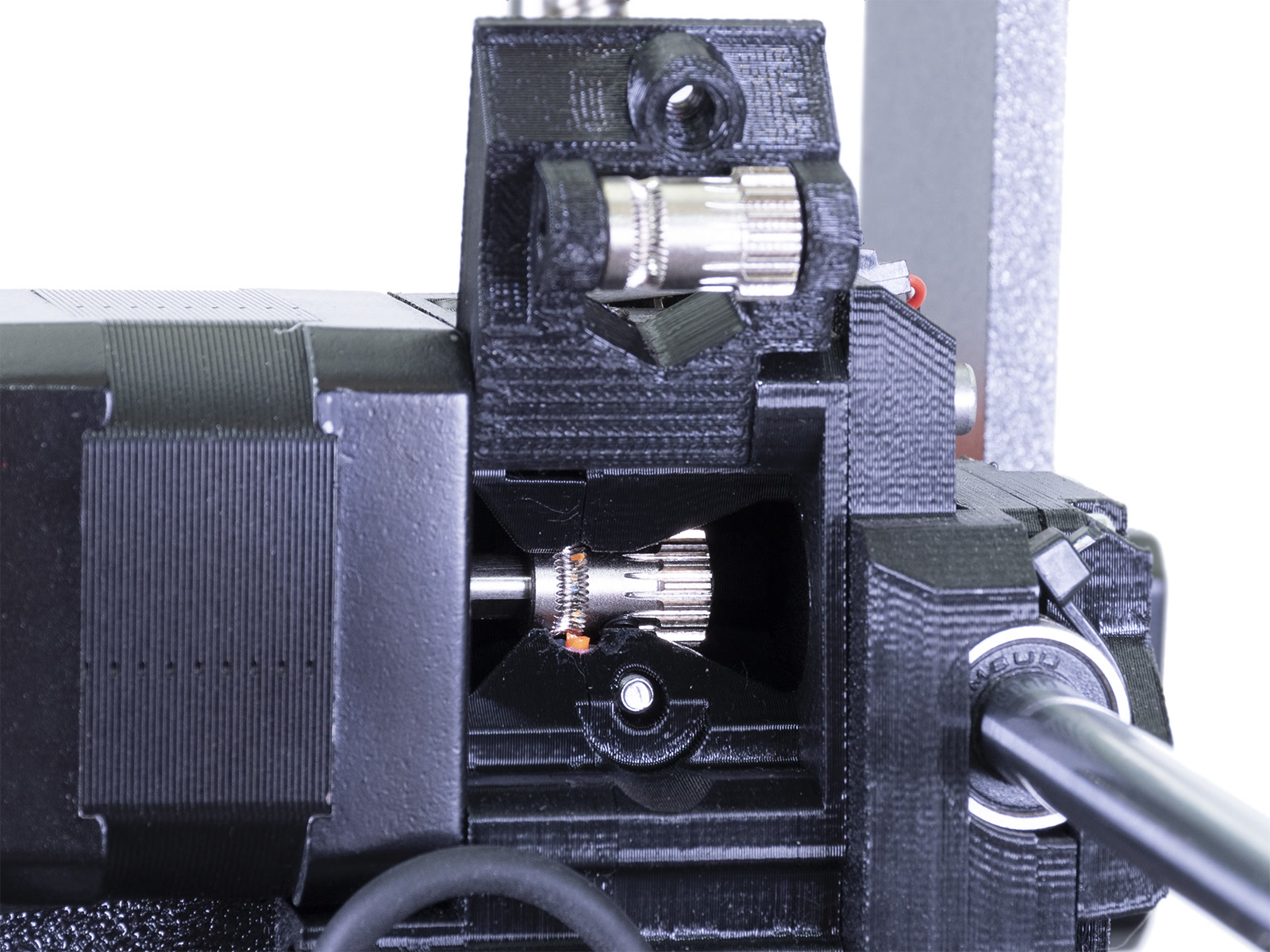

Idler door open

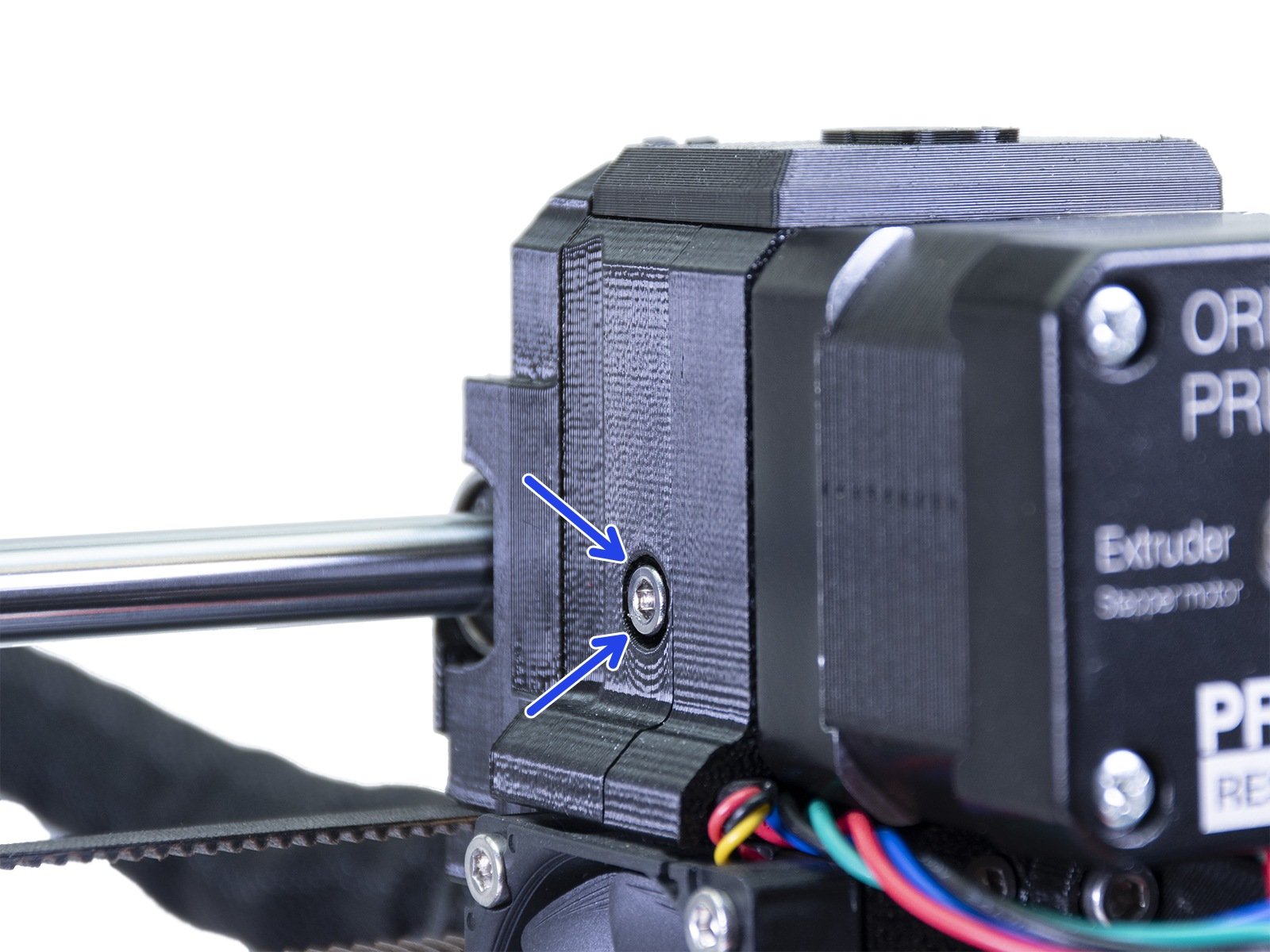

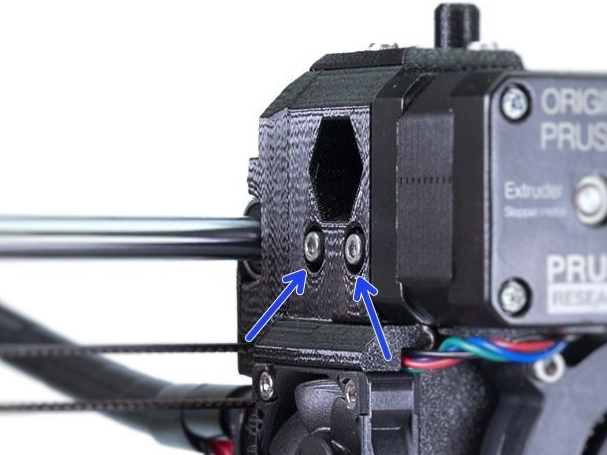

Open the idler door by removing the spring-loaded tension-screw(s), on the left side of the extruder.

|  |

| MK3S, MK3S+, MK3.5/S extruder (single idler screw) | MK3 extruder (two idler screws) |

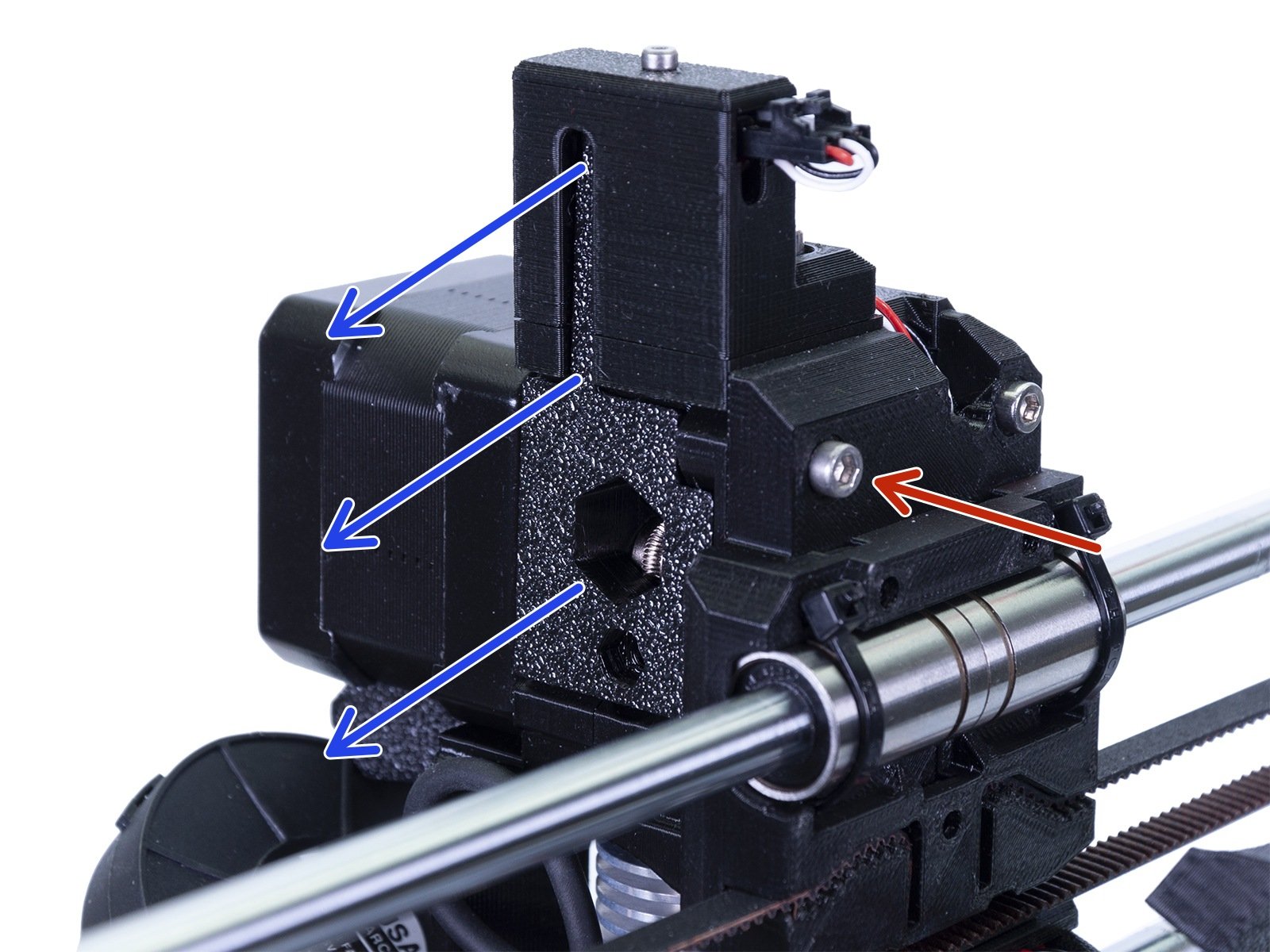

MMU2S/MMU3 idler door

Where did it break?

|  |

| Use Method 1 | Use Method 2 |

If the filament snapped right at the edge of the PTFE you should start with Method number 1, where you try to push the filament through the hotend. If there is 0.5-1cm sticking out of the filament, reaching the Bondtech filament-pulley starts with Method number 2, pulling it out with pliers.

Setup

- Go to the LCD Menu -> Settings -> Temperature -> Nozzle and set the temperature to 280º C. Wait for 3-5 minutes with the hotend at this temperature.

- In the LCD menu in Settings, select Disable steppers.

- Go to the LCD Menu -> Settings -> F. Autoload, so A<em>utoload will not interfere.

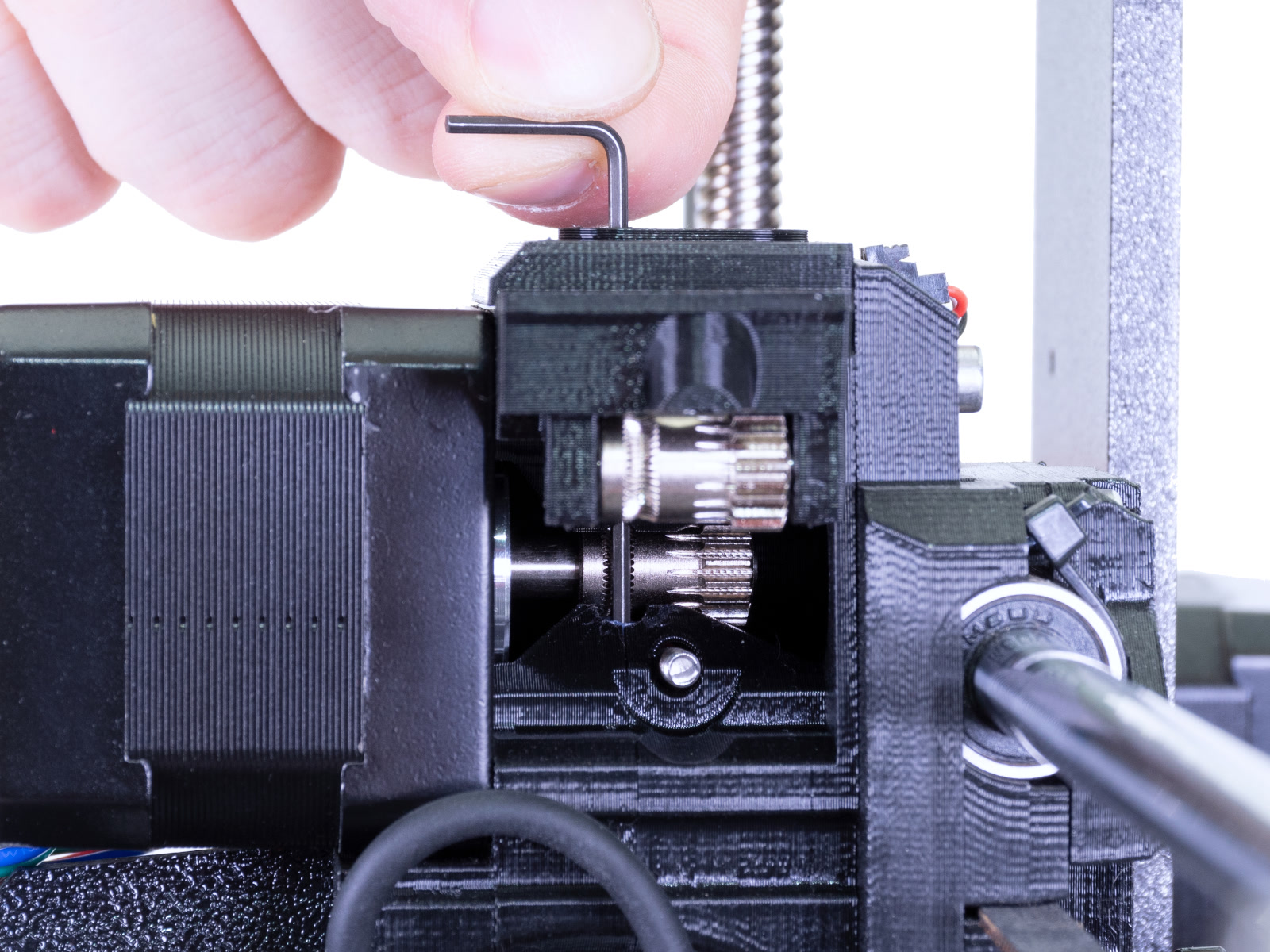

Method 1: Pushing the filament through the hotend

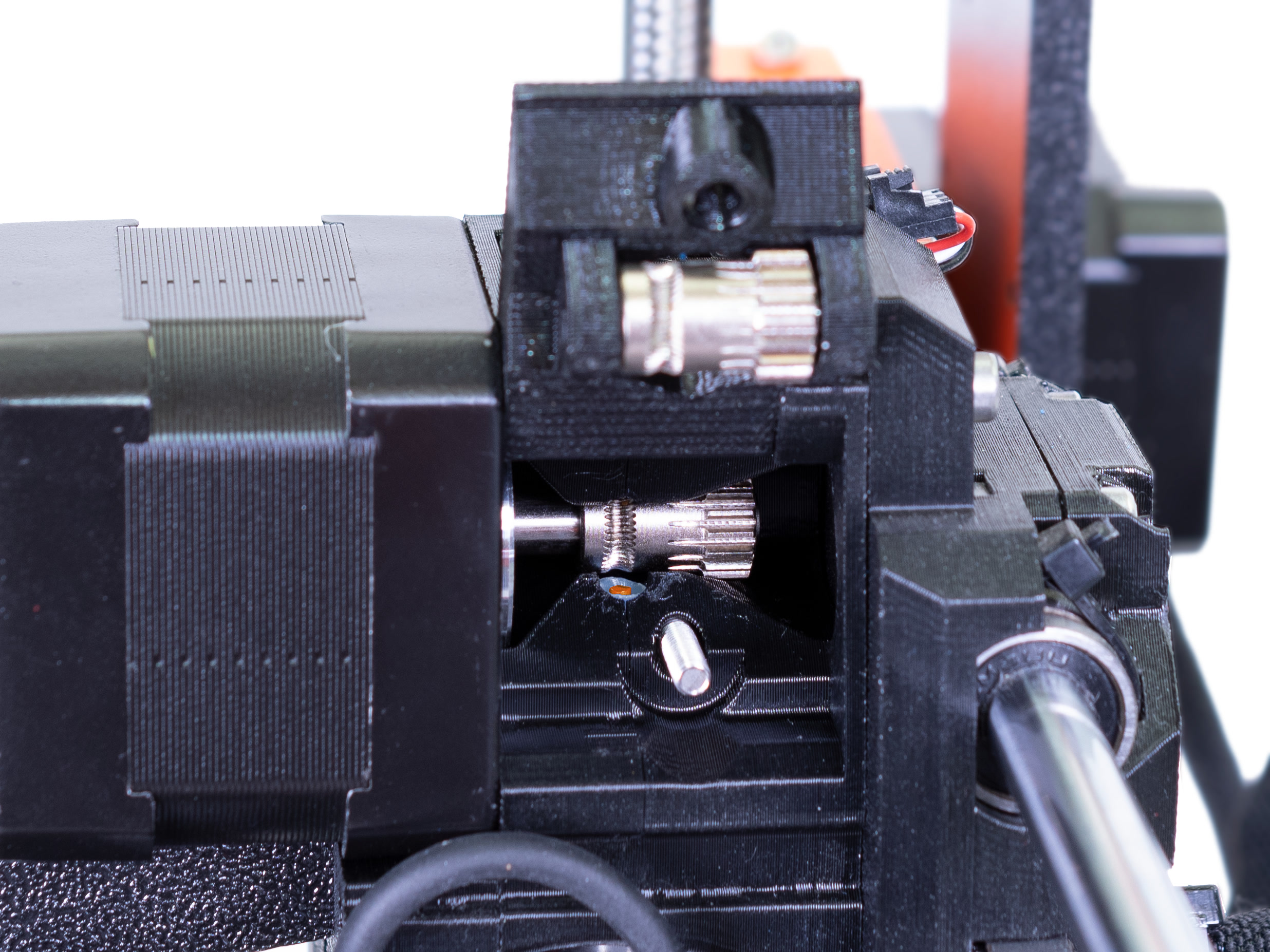

Using another piece of filament, a thin (1-1,5 mm) Allen-wrench or same diameter wire, at least 4.5 cm long for the MK3(s) and 6 cm long for the MMU2s, you are often able to simply push it through.

- Feed in from the top of the extruder your tool of choice, down past the Bondtech-gear, and on top of the stuck filament.

- In case the filament starts being extruded from the bottom, Keep pushing the filament to clear the nozzle and see the color change.

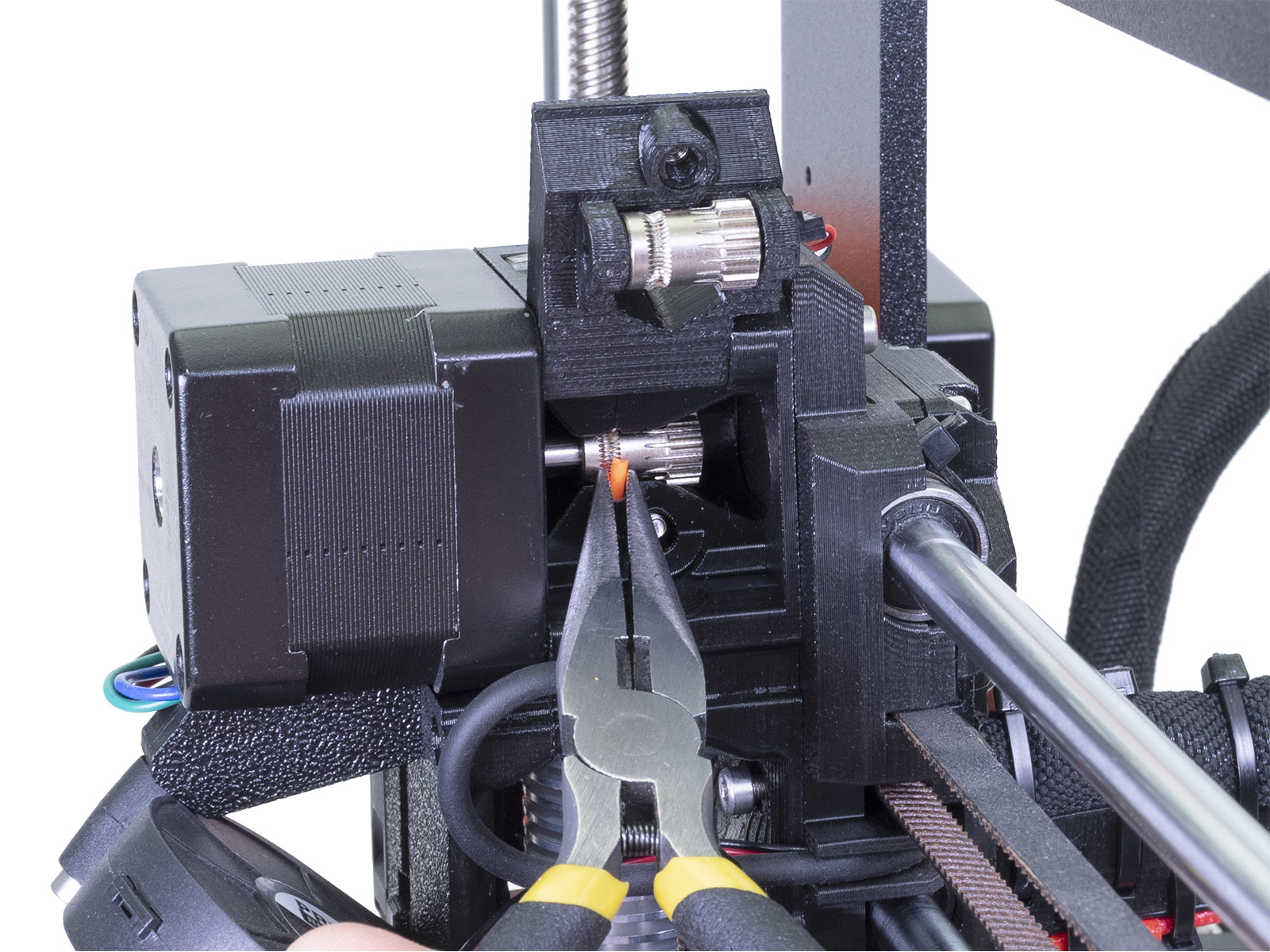

Method 2: Pull out filament with pliers

While hotend is heated to 280° C, firmly grab the filament with the needle-nose pliers that came with the printer. Slowly drag/feed the filament upwards, bit by bit, through the top of the extruder body, until it is completely removed from the PTFE-tube.

The filament can get stuck on geometry on the path up through where it is fed. It is also possible to pull it out of the idler door.

Nope, it is still stuck

If none of these methods work, it means that the tip is not touching the part of the hotend that is heated and is stuck in the PTFE-tube. In this case, you must extract the PTFE-tube. Follow the guide linked below to resolve it.

8 comments

Good procedure!

In the LCD menu in Settings, select Disable steppers.

Go to the LCD Menu -> Settings -> F. Autoload, so Autoload will not interfere.

I have the CORE One and no such settings exist.

Please add a feature to re-home the print head after manual filament removal.