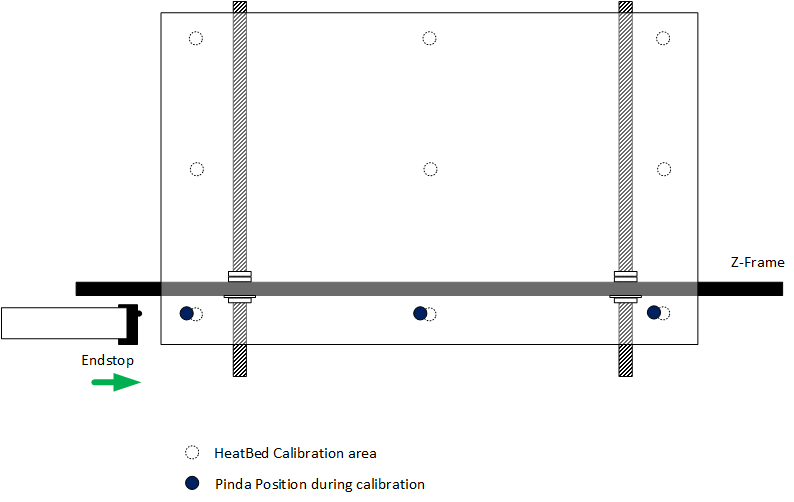

A misaligned P.I.N.D.A. Sensor is an issue that can be fixed by fine-tuning the printer. To do that, you need to calibrate the P.I.N.D.A. sensor position on multiple spots around the heated bed. Once we get the first three right, then you should not experience any calibration errors at all.

Side shift

Side shift is not very common due to the printer's design. However, the endstop can be misaligned during the assembly. To fix it, you must unscrew the Endstop and push it to its proper place. Then tighten the screws again and secure it with screws again, while holding it.

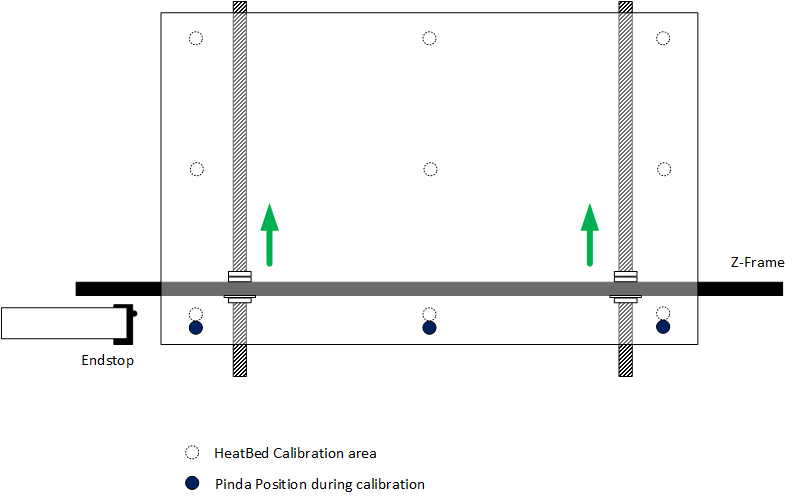

Front shift

The front shift can happen if the frame is not perfectly perpendicular to the Front and the Rear of the printer. In order to fix it, simply unscrew the M12 nuts holding it and move the frame to its designed position (either to the front or back, depending on the relative position of the P.I.N.D.A. sensor).

Make sure the Y-axis is perfectly level - all four corners of the frame must touch the ground.

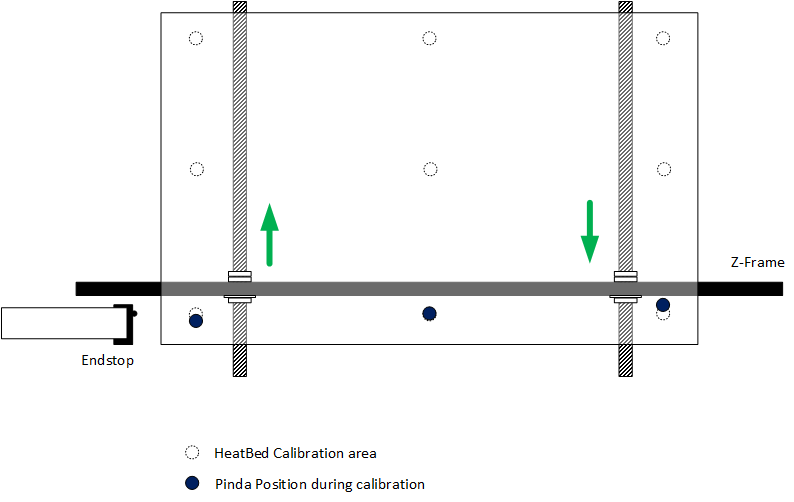

Twist shift

This is probably the most common issue with the Y-axis. Just like with the Front shift, simply unscrew the M12 bolts holding it and move the frame to the correct position.

Usually, it will be a combination of two problems. Take your time with fine-tuning, as it is crucial to achieving a proper calibration of your printer.

4 comments

Hello. Please contact our support team for that.

https://help.prusa3d.com/es/article/resolucion-de-problemas-del-sensor-de-filamento-ir-mk2-5s-mk3s_112226

Si esto no te ayuda, o tienes otro modelo de impresora, contacta a nuestro equipo de Soporte Técnico.

https://help.prusa3d.com/es/article/atencion-al-cliente_2287

Un saludo,