The XYZ calibration is a process, which checks, whether the printer was assembled correctly and the axes are perpendicular to each other. It measures the skew of your X/Y axis and applies compensations for any imperfections. It may indicate two sets of error messages compromised/failed. See below for a detailed description.

XYZ calibration is a part of the Wizard, which will appear on the first boot or after a factory reset. In case you have skipped the Wizard, you can start it manually from the LCD Menu - Calibration - Wizard.

If you wish to redo the XYZ calibration and you have finished the Selftest successfully, you can start the XYZ calibration separately through the LCD Menu - Calibration - XYZ cal.

Calibration walkthrough

- The printer will start the calibration by aligning the Z-axis. Make sure that both ends of the X-axis reached the top.

- In the next step, the printer asks whether you have the steel sheet on the heated bed. Remove the steel sheet for the upcoming initial 4 point calibration now and select No.

- Check that the nozzle is clean and confirm the on-screen prompt.

- Place a sheet of paper (e.g. the included cheat sheet) between the nozzle and the heatbed. If the nozzle catches the paper, immediately press the Reset button. Your P.I.N.D.A. sensor is probably set too high. Lower it down by 2 - 3 threads and run the XYZ calibration again. More info below.

- Once the first routine finishes, place the steel sheet on the heated bed and confirm the on-screen prompt. The printer will perform a full 9 point mesh bed leveling. All of the measured compensations will be stored in non-volatile memory.

Troubleshooting the XYZ calibration

Click here for explanations of XYZ-calibration error-messages (MK3/MK3S/MK3S+).

If you encounter any error messages, there is most likely something wrong with the assembly of your printer.

Please perform the following tasks:

- Make sure you followed the instructions on the LCD precisely. Especially make sure that the X-axis moved to the very top. Otherwise, the Z-axis might be misaligned.

- Make sure that the cable harness leading from the extruder, or zip ties securing it, does not hit the cover of the EINSY RAMBo board before it reaches the end of the X-axis.

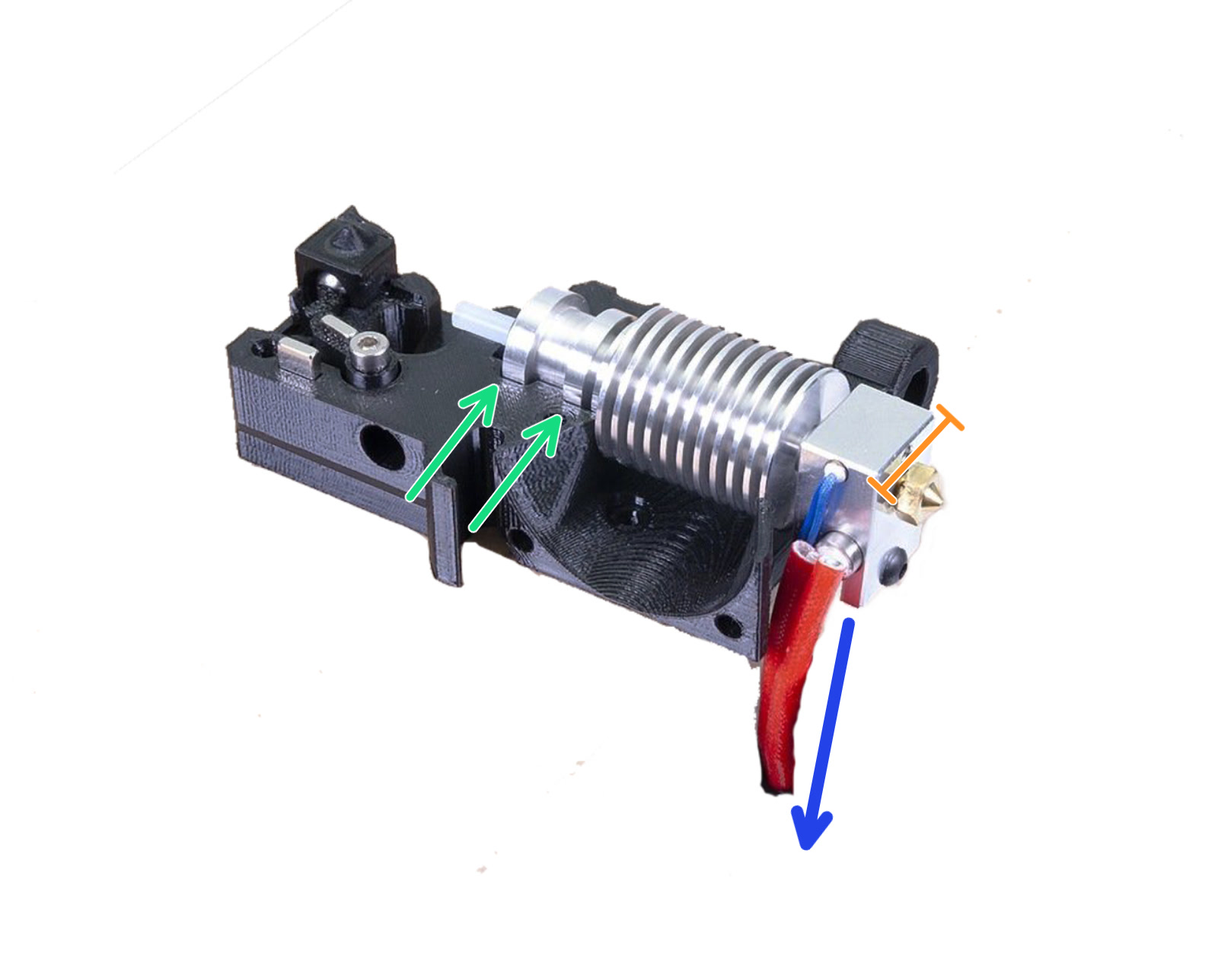

- Check the E-axis assembly. Make sure that the hotend is perfectly inserted in the extruder.

Make sure the heatsink is slotted into both slots (green arrows), the short side of the heaterblock is facing forward (orange ruler), with its wires running back alongside the left side of the heaterblock (blue arrow).

- Make sure nothing blocks the movement of any of the axis. You can easily test that by moving the extruder or heatbed through LCD Menu - Settings - Move axis (X/Y). Simply move it from one end to the other and inspect the movement.

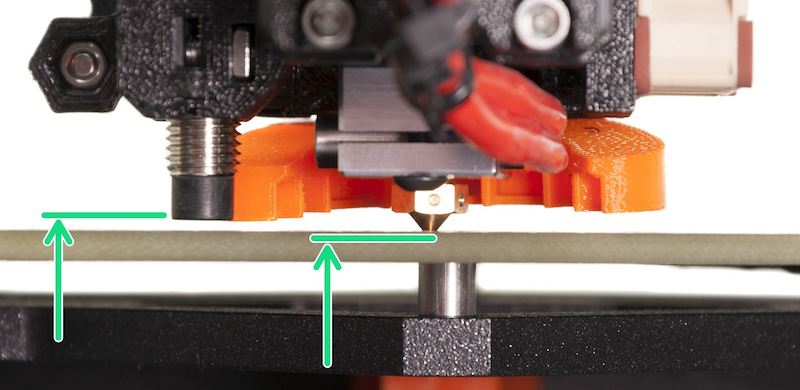

- Make sure that your P.I.N.D.A. or SuperPINDA sensor is roughly 1 mm higher than the tip of the nozzle. Distancing the P.I.N.D.A. sensor is covered in the assembly manual Part 9. Preflight check.

- There is also a small possibility that your P.I.N.D.A. sensor could be defective. The easiest way how to check that is to navigate to LCD Menu - Support - Sensor info.While placing anything metal (e.g. a spatula) under the P.I.N.D.A. sensor. The P.I.N.D.A. value should change from 0 to 1. More information can be found in P.I.N.D.A./SuperPINDA Sensor testing.