Español

Welcome to the MMU3 guide! There were several generations of the Original Prusa Multi-Material printing solution. Verify you are looking at the correct guide for your MMU unit and your printer.

MMU1 for MK2 and MK2S printers (introduced in 2016-2018)

It used four separate extruders feeding one nozzle.

MMU2 for MK2.5 and MK3 (2018-2019) Five filaments feeding one direct-drive extruder.

MMU2S for MK2.5S, MK3S, MK3S+ (2019-2023)

Introduced a chimney on the extruder with the IR-filament sensor.

And finally, the latest model:

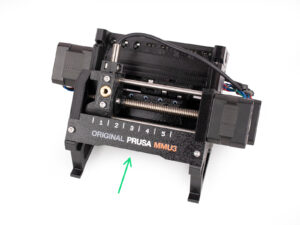

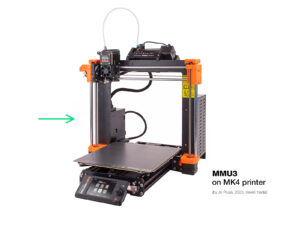

MMU3 for MK3S+, MK3.5/S, MK3.9/S, MK4/S and CORE One.

MMU3 is the one we will be dealing with in this guide.