En la Prusa CORE One y CORE One L, ajustar la correa a la tensión óptima es crucial para conseguir una buena calidad en las impresiones. Una correa floja puede causar Saltos de capa, Ghosting, u otras anomalías de impresión, como obtener una forma irregular en lugar de un círculo perfecto. Una correa demasiado apretada puede provocar un movimiento irregular en los ejes X e Y.

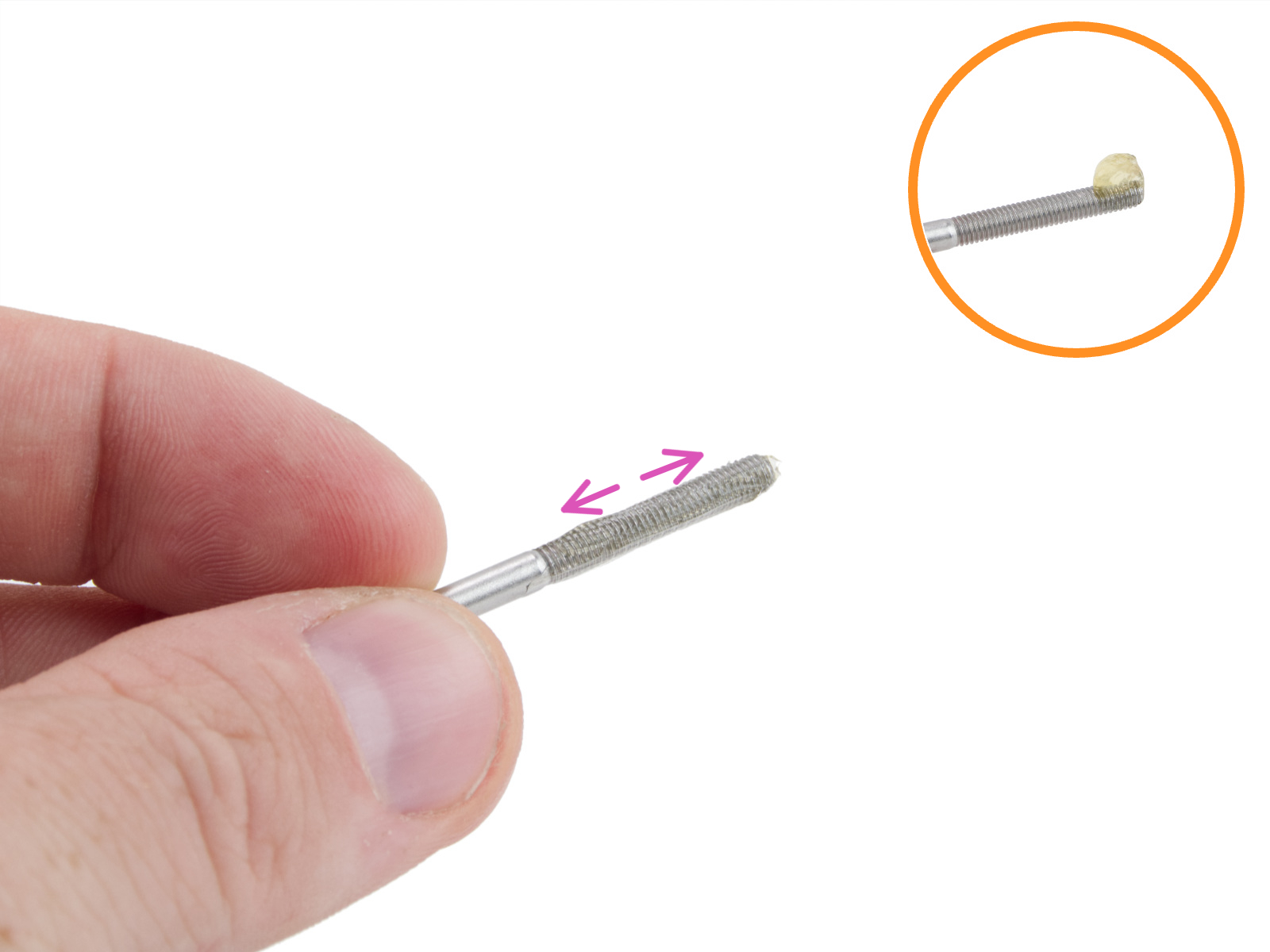

Recordatorio en el montaje - lubricar los tornillos tensores (kit de CORE One).

La siguiente comprobación se aplica exclusivamente a los kits de CORE One y CORE One+. Las CORE One, CORE One+ y CORE One L preensambladas ya tienen este paso realizado en fábrica.

Durante el proceso de montaje, indicamos que se aplique una pequeña cantidad de lubricante Prusa en la punta de ambos tornillos M3x30 para las piezas del tensor de la correa. Si esto se ha hecho durante el montaje del kit, no es necesario volver a hacerlo, pase directamente a los siguientes pasos.

Sin embargo, los primeros kits de CORE One no incluían este paso recomendado en nuestro manual. Si este es el caso y los demás pasos no han funcionado, es posible que sea necesario sustituir los tensores de correa derecho/izquierdo y las poleas tensoras de correa acopladas a ellos.

- How to replace the Belt Tensioner Left (CORE One) [Traducción en desarrollo]

- How to replace the Belt Tensioner Right (CORE One) [Traducción en desarrollo]

- How to replace the Belt Tensioner Pulley (CORE One) [Traducción en desarrollo]

|  |

Alineación

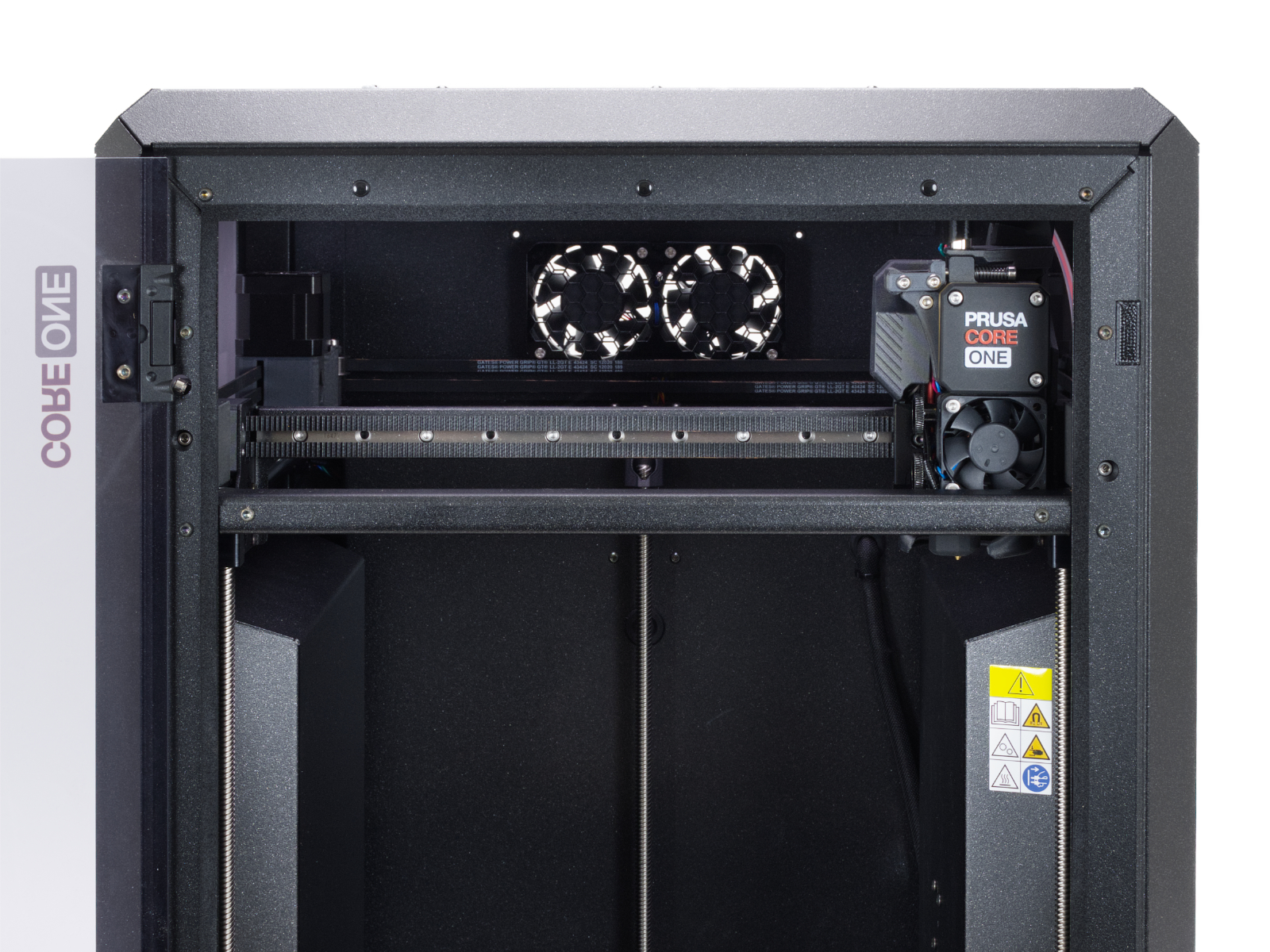

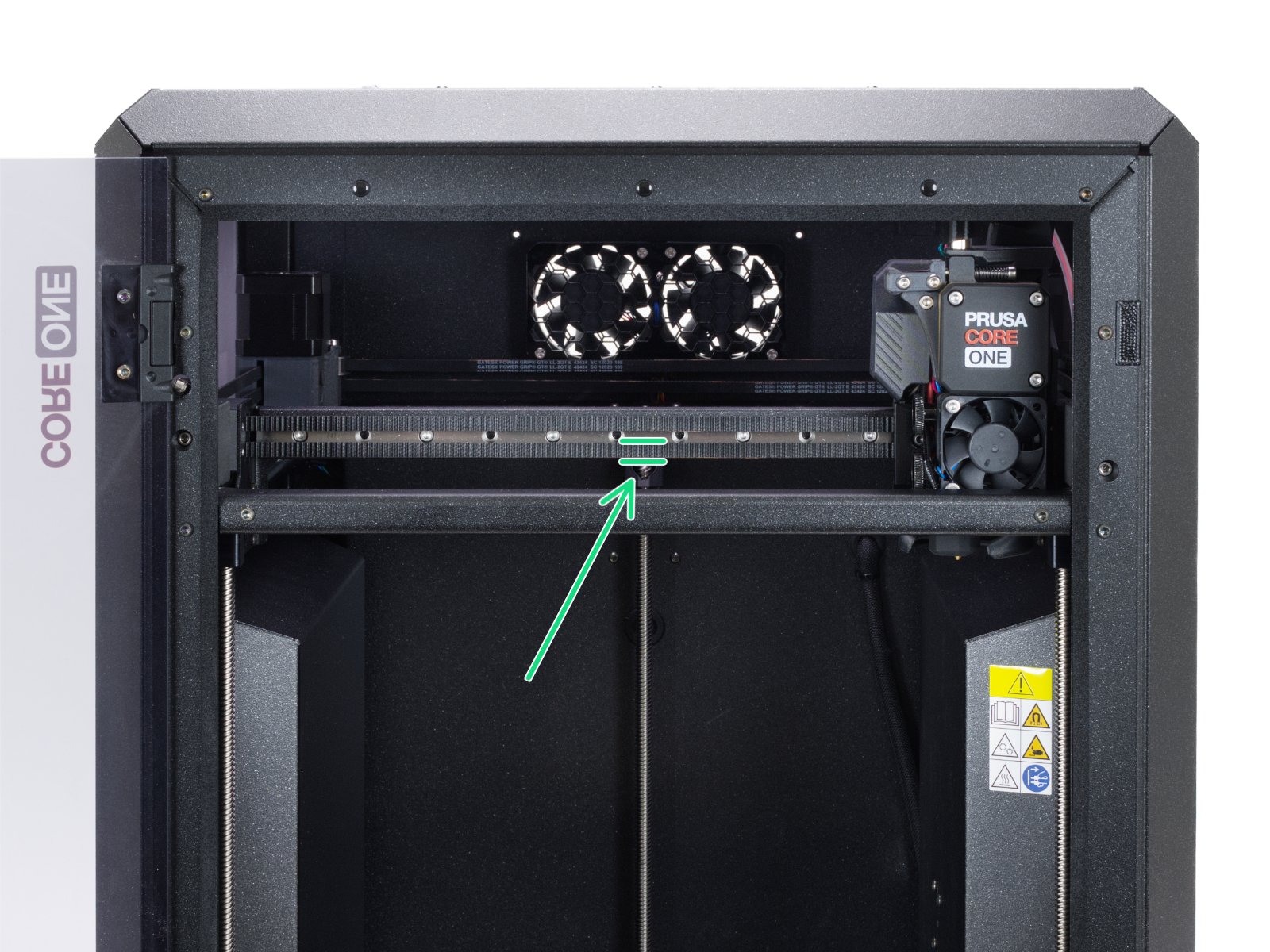

Antes de ajustar la correa, asegúrese de la correcta alineación de la estructura CoreXY.

- Asegúrate de que los motores paso a paso están desactivados. Esto se puede hacer apagando la impresora, o a través del menú LCD -> Control -> Desactivar Motores.

- Con la mano, mueve el Nextruder a la posición más frontal del eje Y y al centro del eje X.

- Presiona la esquina del gantry contra la parte delantera del CoreXY, y asegúrate de que no hay holgura. Realiza este procedimiento en ambos lados. Si hay alguna holgura en cualquiera de los lados, aún no se ha logrado la alineación perfecta.

Alineación rápida del gantry

Alineación rápida del gantry

Si hay un espacio en cualquiera de los lados del gantry, puedes intentar forzarlo manualmente en la dirección opuesta:1. Afloja completamente ambos pernos tensores, esto permitirá el movimiento libre del gantry.

2. Mueve el gantry a mitad de camino por los raíles.

3. Agarra el gantry firmemente por ambos extremos y aplica una suave fuerza contraria en la dirección opuesta de la inclinación hasta que se enderece.

4. Compruebe la alineación con las correas aún flojas y empuje con cuidado el gantry hacia delante. Dado que las correas flojas no lo tirarán completamente, es posible que tenga que guiarlo con la mano. Compruebe que no haya ningún espacio a ambos lados en la posición delantera.

5. Apriete ambos pernos tensores gradualmente, alternando entre ellos, apretando cada uno en la misma medida para mantener el gantry recto. Puede sujetar el gantry en su sitio con la mano mientras aprieta. Después de apretar ambas correas, asegúrate de que no haya vuelto a aparecer ningún hueco.Nota: Aplica la fuerza con cuidado para evitar dañar las correas o los rodamientos.

- Afloja un poco ambos tornillos tensores de la correa. Afloja el tornillo de la esquina con menos juego que el otro.

- Repite los pasos 3 y 4 hasta conseguir una alineación perfecta. No te preocupes si la correa está floja en esta etapa, el ajuste de la tensión de la correa se realiza en un paso posterior.

Asistente para ajustar la correa

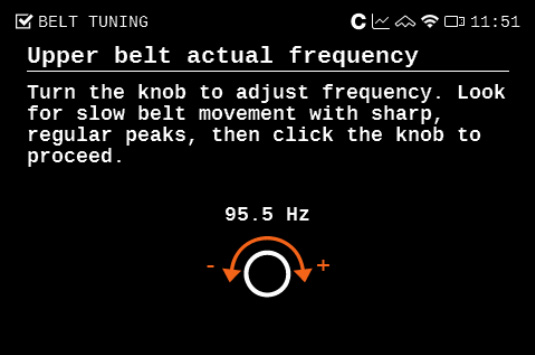

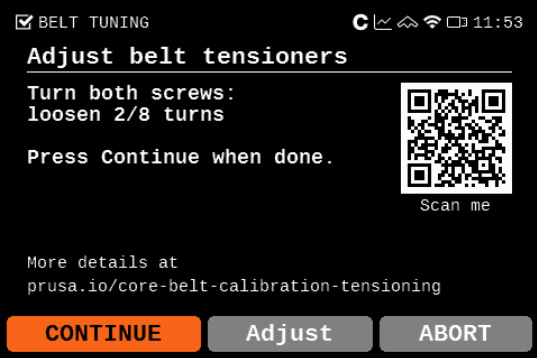

A partir de la versión 6.4.0 del firmware, hay disponible un asistente de ajuste de la correa en el menú de la impresora, al que se accede desde Menú LCD -> Ajustes -> Ajuste Correas Manual. La impresora utiliza una excitación controlada de la correa combinada con retroalimentación estroboscópica para visualizar la resonancia de la correa.

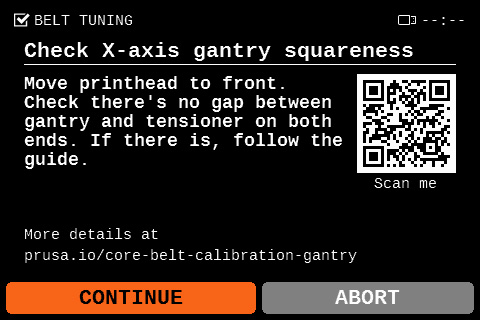

El asistente comienza solicitando al usuario que compruebe que el gantry está correctamente alineado, ya que una desalineación puede afectar la precisión de la medición. Sigue las instrucciones que aparecen en pantalla para verificar la alineación del gantry y, en caso de desalineación, sigue los pasos descritos en el párrafo anterior sobre alineación.

A continuación, el asistente mide la frecuencia de vibración de ambas correas y recomienda si es necesario tensarlas o aflojarlas. Sigue las instrucciones que aparecen en pantalla para girar el dial y variar la frecuencia de vibración y, al mismo tiempo, observa el movimiento vibratorio que realiza la correa seleccionada a medida que se modifican las frecuencias.

Busca un movimiento lento, prolongado y constante de resonancia en la correa seleccionada. Una vez que observes ese movimiento en la correa seleccionada, selecciona la frecuencia actual en la pantalla de la impresora.

|  |

| Upper belt resonating movement | Lower belt resonating movement |

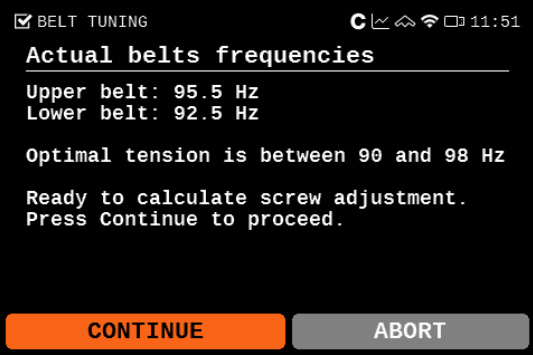

En la CORE One, el rango de frecuencia ideal es de un máximo de 98 Hz para la correa superior y un mínimo de 90 Hz para la correa inferior.

En la CORE One L, el rango de frecuencia ideal es de un máximo de 95 Hz para la correa superior y un mínimo de 85 Hz para la correa inferior.

Una vez completada la prueba de resonancia, el cuadro de diálogo de la impresora muestra las frecuencias de resonancia encontradas y el ajuste sugerido.

Importante: apriete siempre ambos tensores de manera uniforme y alterna. Esto garantiza que el gantry permanezca en posición perpendicular durante el ajuste.

|  |

Belt tuner (CORE One)

Tenemos nuestro propio afinador de correas, disponible en nuestra página de ajuste de correas. También se puede acceder al afinador de correa en nuestra App de Prusa, navigando a >Menú >Belt Tuner.

El afinador de correas utiliza el micrófono de tu dispositivo y determina la tensión de la correa midiendo la frecuencia de la vibración generada al tocarla.

Selecciona la CORE One, y luego selecciona la XY-belt, and follow the instructions shown on your device. When ready to measure the belt frequency, tap on Start listening to use your device's microphone.

Ajustando las correas

En la CORE One, el rango de frecuencia ideal es de un máximo de 98 Hz para la correa superior y un mínimo de 90 Hz para la correa inferior.

En la CORE One L, el rango de frecuencia ideal es de un máximo de 95 Hz para la correa superior y un mínimo de 85 Hz para la correa inferior.

Si tu gantry está desalineado, es posible que no pueda alcanzar estos valores exactos. En algunos casos, la correa inferior puede incluso mostrar una frecuencia ligeramente superior a la de la correa superior. Esto es aceptable siempre que la diferencia entre ambas no supere los 8 Hz y ambos valores se mantengan dentro del rango de 90-98 Hz (CORE One) y dentro del rango de 85-95 Hz (CORE One L).

Si no puedes conseguirlo, deberás cuadrar el gantry manualmente antes de ajustar la tensión de la correa. Consulta las instrucciones en “Alineación Rápida del Gantry” de encima o “Ajuste exhaustivo del gantry y las correas” al final de este artículo.

Importante: Aprieta siempre ambas tensores de manera uniforme y alterna. Esto garantiza que el gantry permanezca en posición perpendicular durante el ajuste.

Pequeños ajustes

-

- Asegúrate de que los motores paso a paso están desactivados. Esto se puede hacer apagando la impresora, o a través del Menú LCD -> Control -> Desactivar Motores.

- Con la mano, mueve el Nextruder a la posición más adelantada del eje Y y a la posición más a la derecha del eje X.

- En la parte delantera del gantry, toca el centro de la correa superior. Coloca tu dispositivo junto a la correa durante este paso para medir la frecuencia en Hz del sonido de la correa. La frecuencia ideal para la correa superior son 96Hz.

- En la parte delantera del gantry, toca el centro de la correa inferior. Coloca tu dispositivo junto a la correa durante este paso para medir la frecuencia en Hz del sonido de la correa. La frecuencia ideal para la correa inferior son 92Hz.

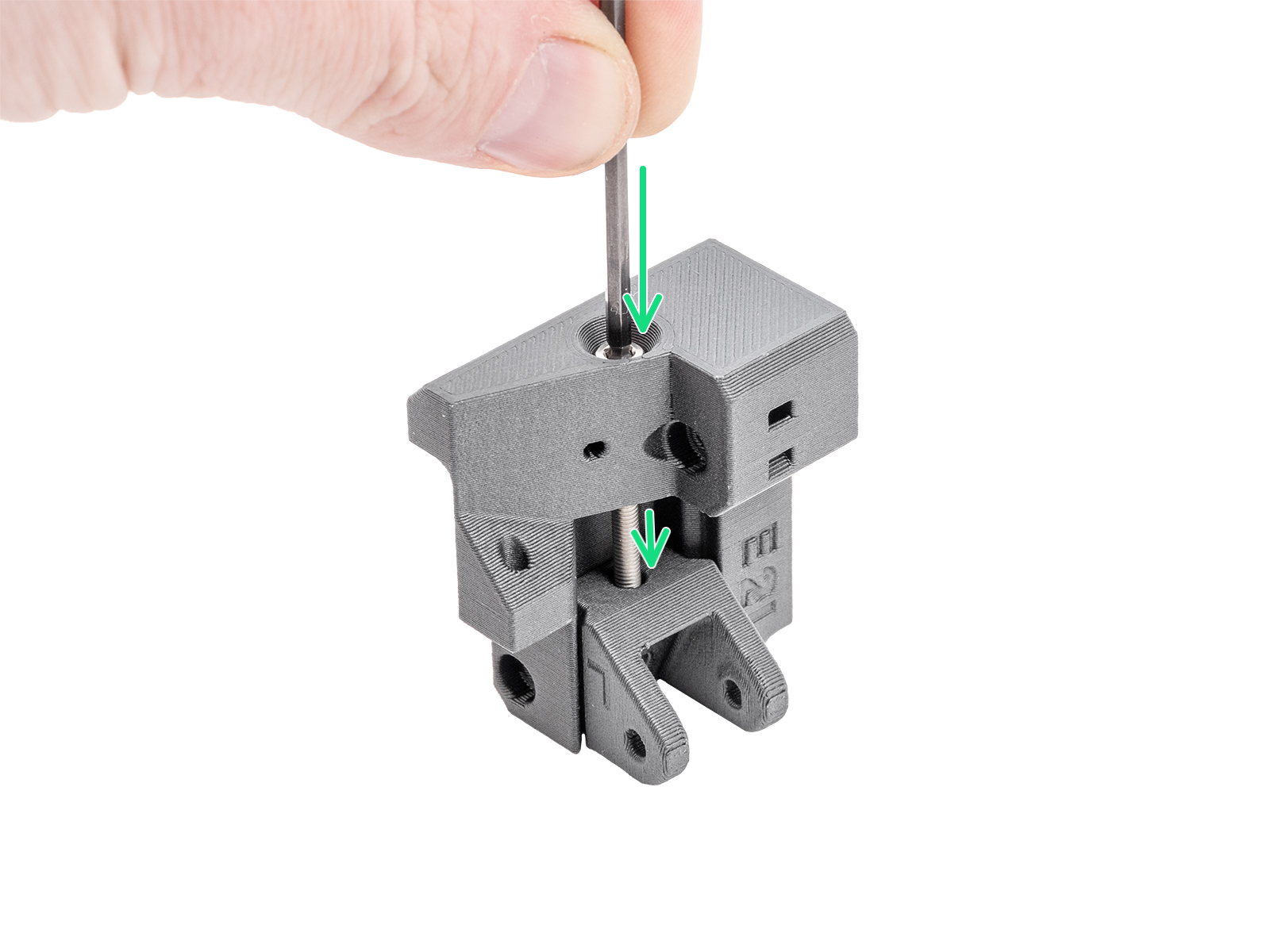

- Ajusta las correas apretándolas o aflojándo los tornillos del tensor de la correa la misma cantidad. Un tornillo más apretado provoca una frecuencia más alta, y viceversa.

|  |

Ajuste exhaustivo del gantry y las correas (CORE One)

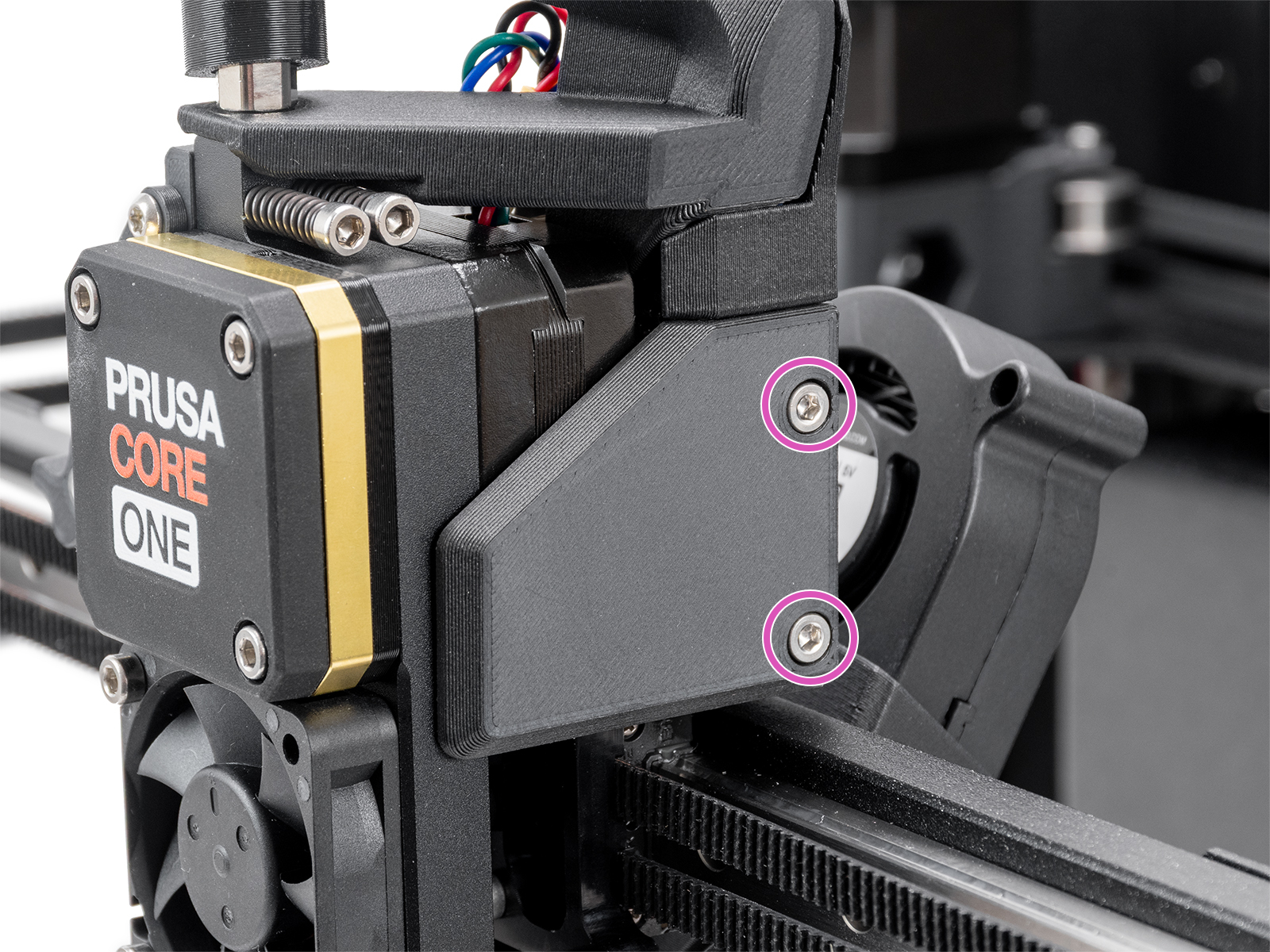

Los tensores de correa deberían resolver la mayoría de los problemas relacionados con las correas. Sin embargo, si necesita realizar un ajuste mayor debido a un problema realmente grave, gantry desalineado o una correa que se ha salido del soporte, sigue los pasos que se indican a continuación para acceder a la correa.

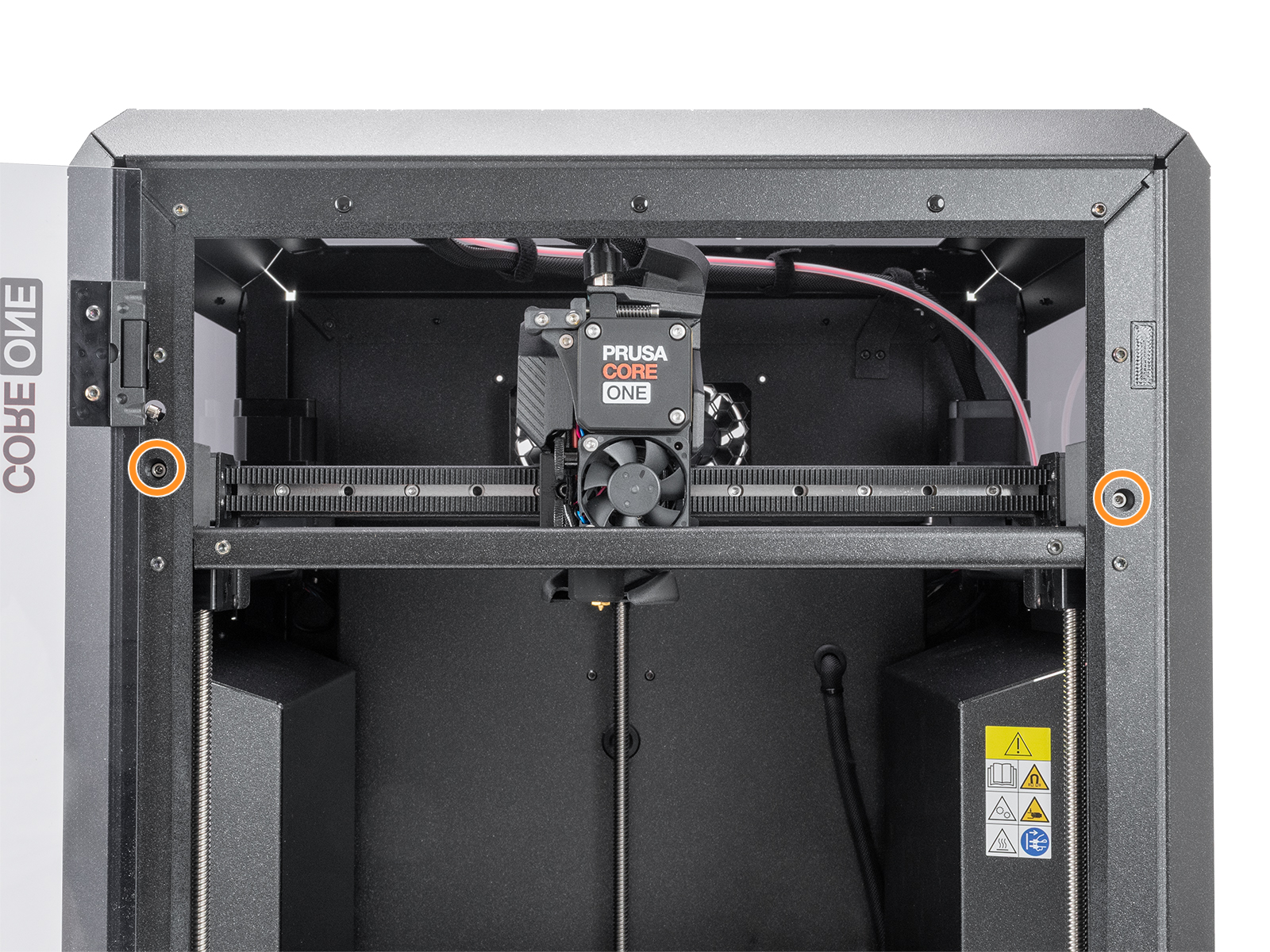

- Mueve manualmente el Nextruder hacia delante y colócalo en el centro para permitir el acceso desde ambos lados.

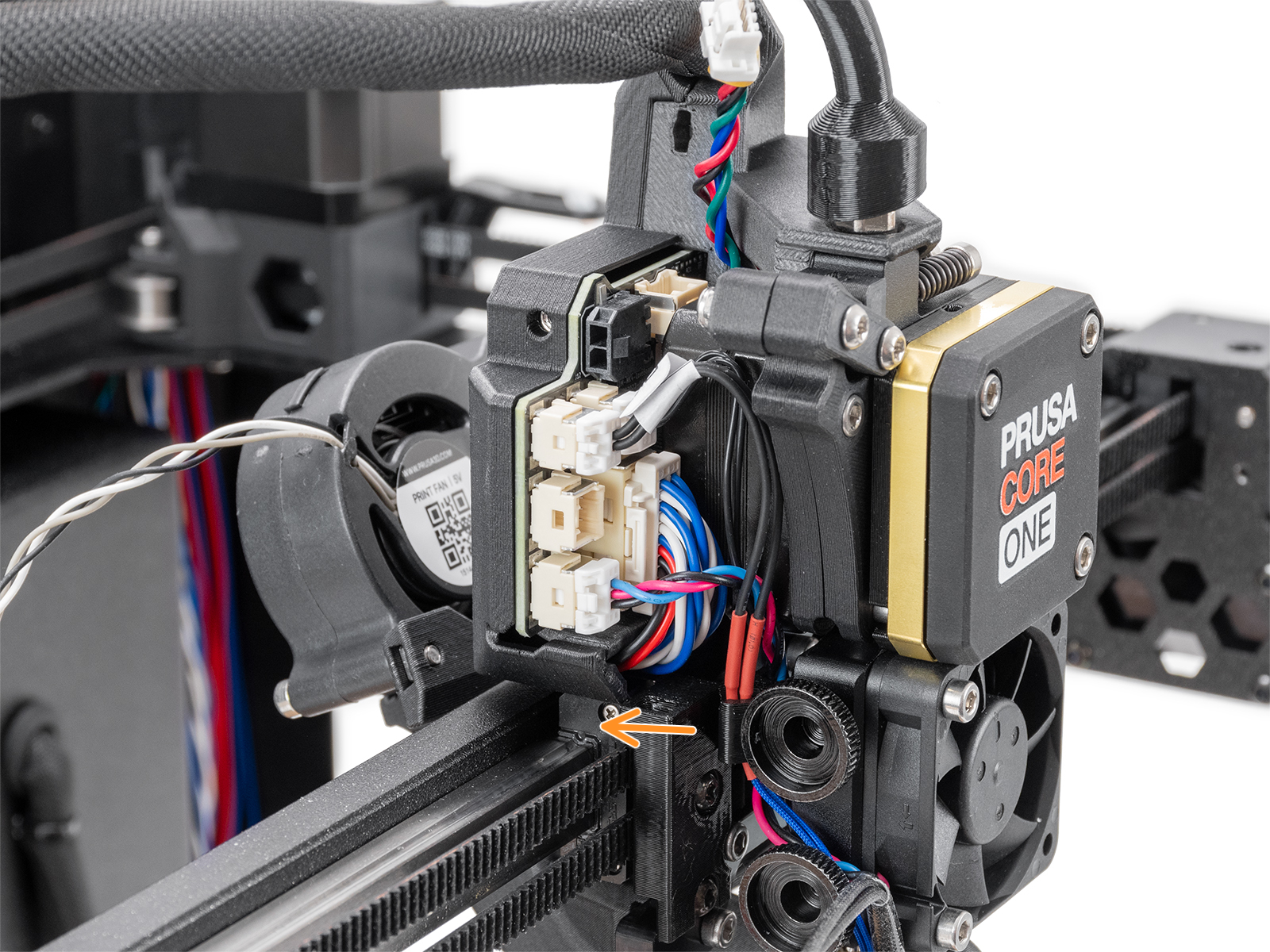

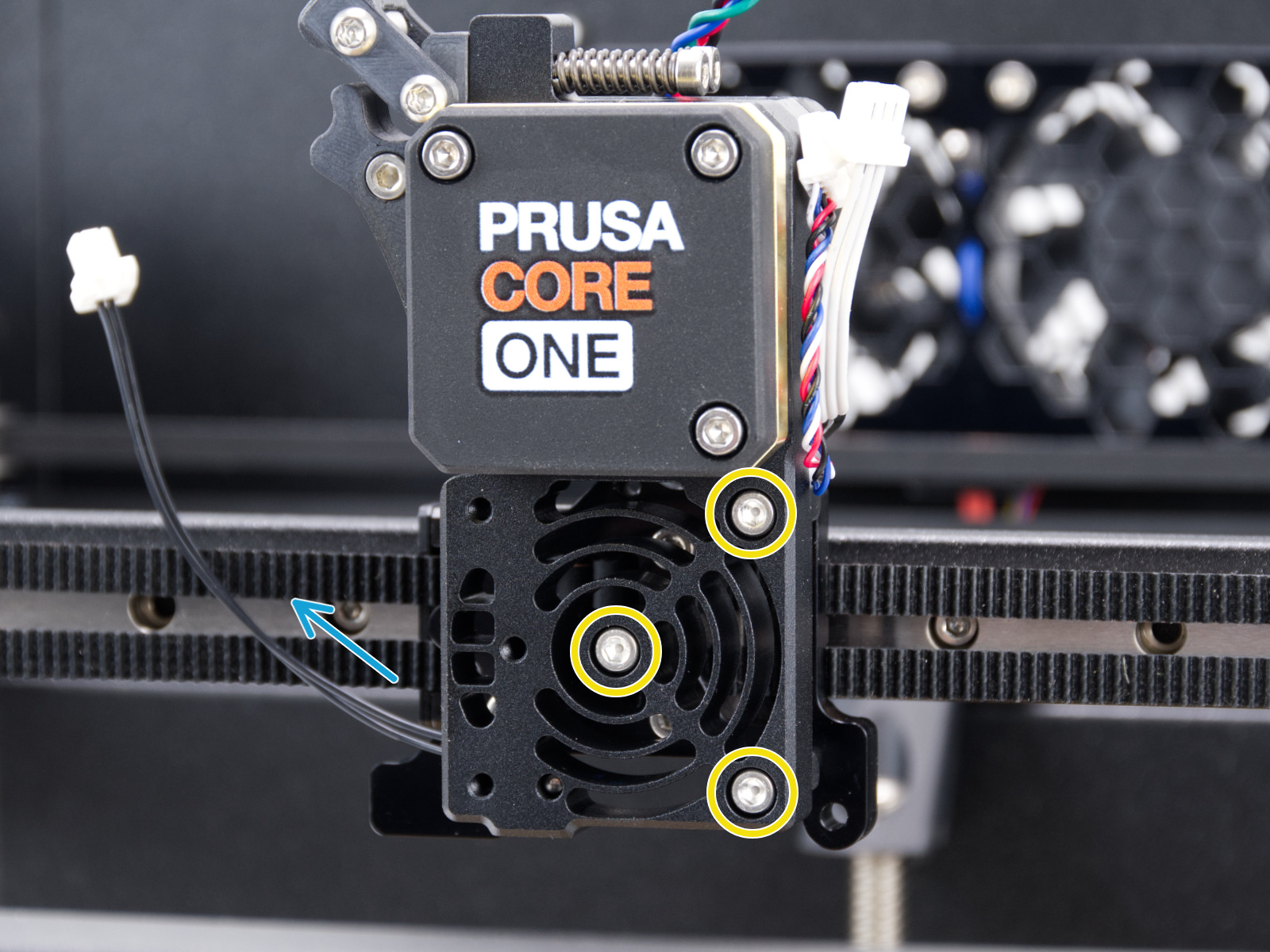

- Retira la cubierta izquierda y derecha del cabezal de impresión quitando los tornillos M3x10 que se muestran a continuación.

|  |

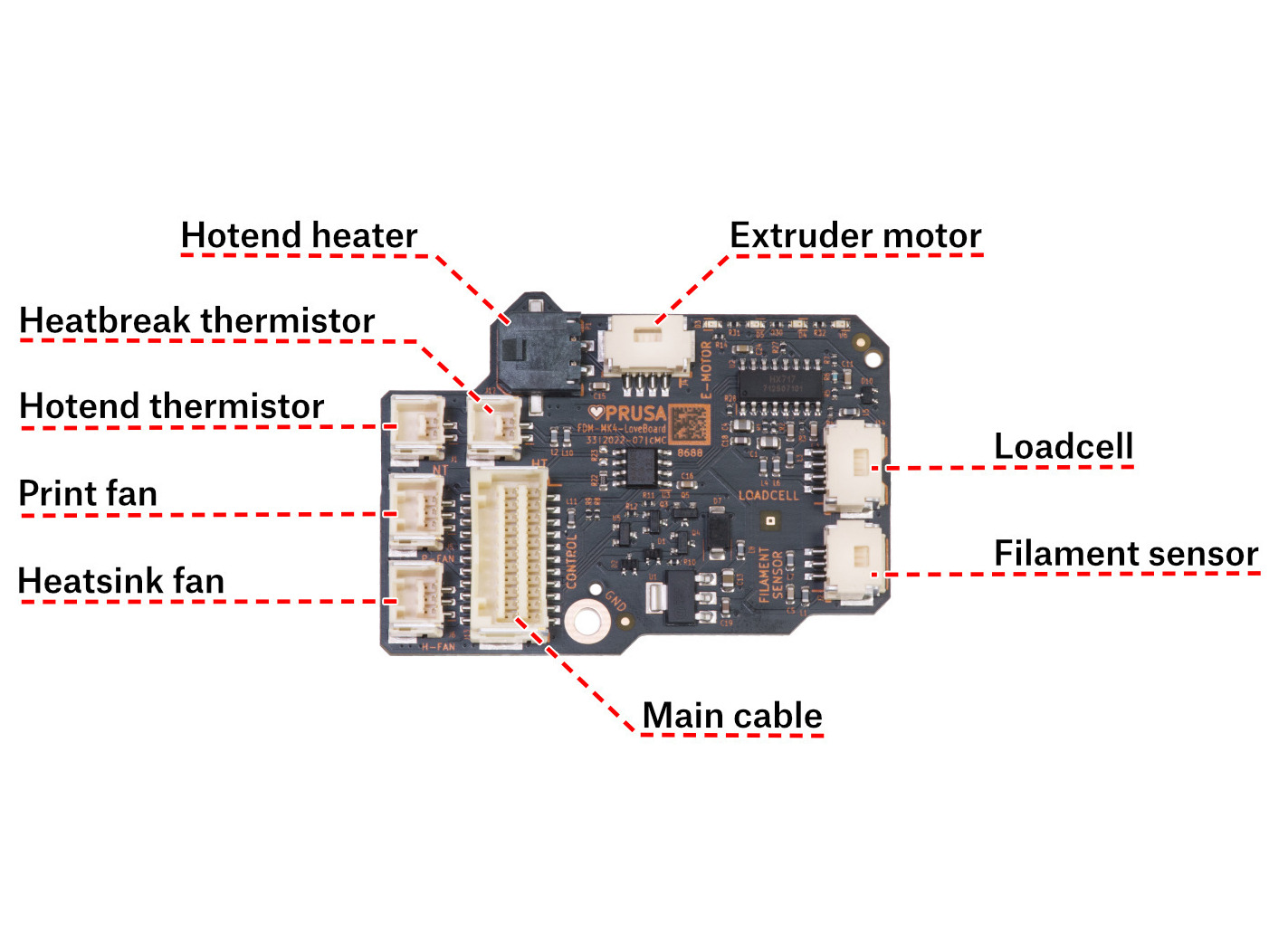

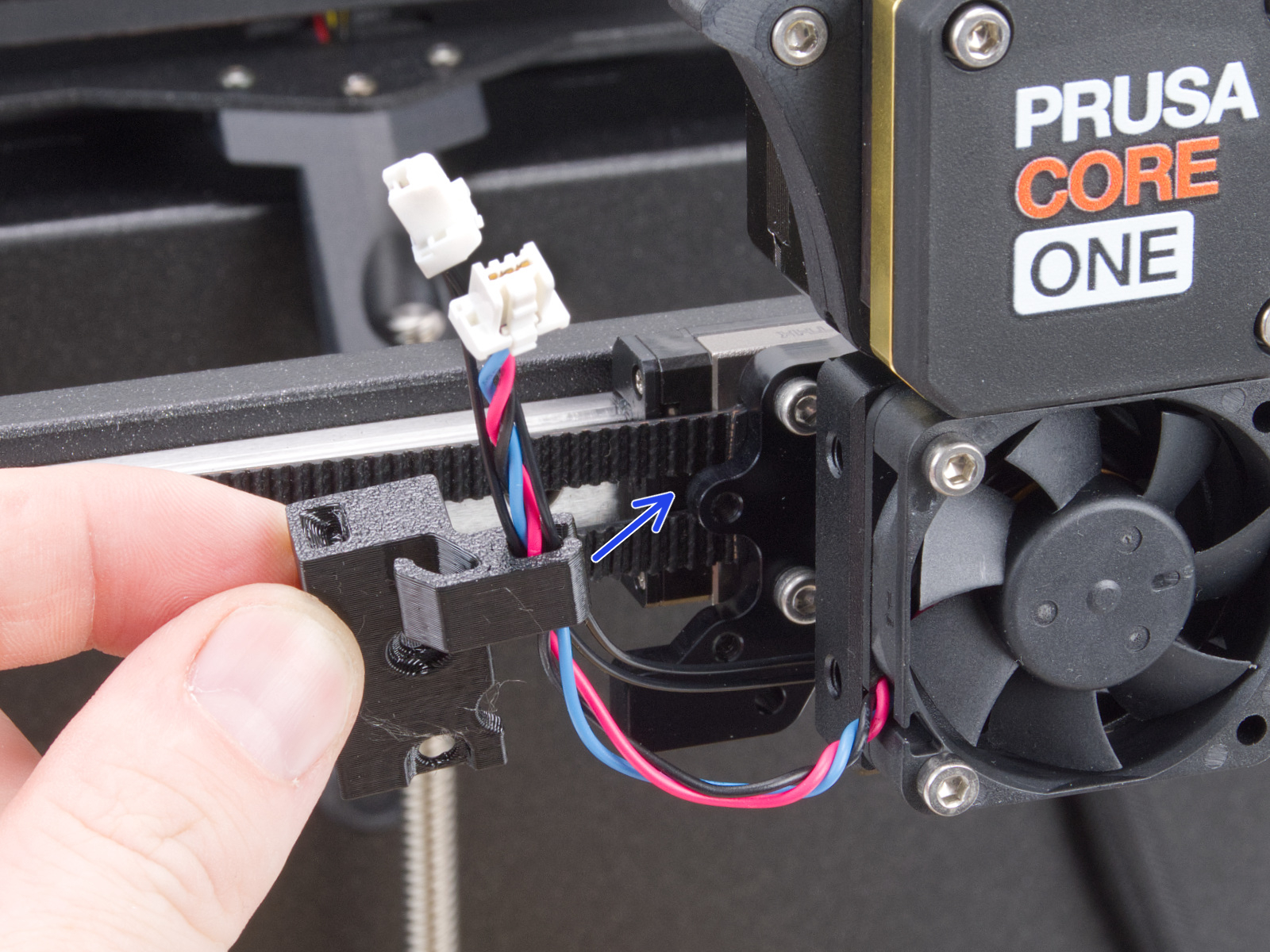

- Desconecta todos los conectores de la LoveBoard, excepto el cable principal.

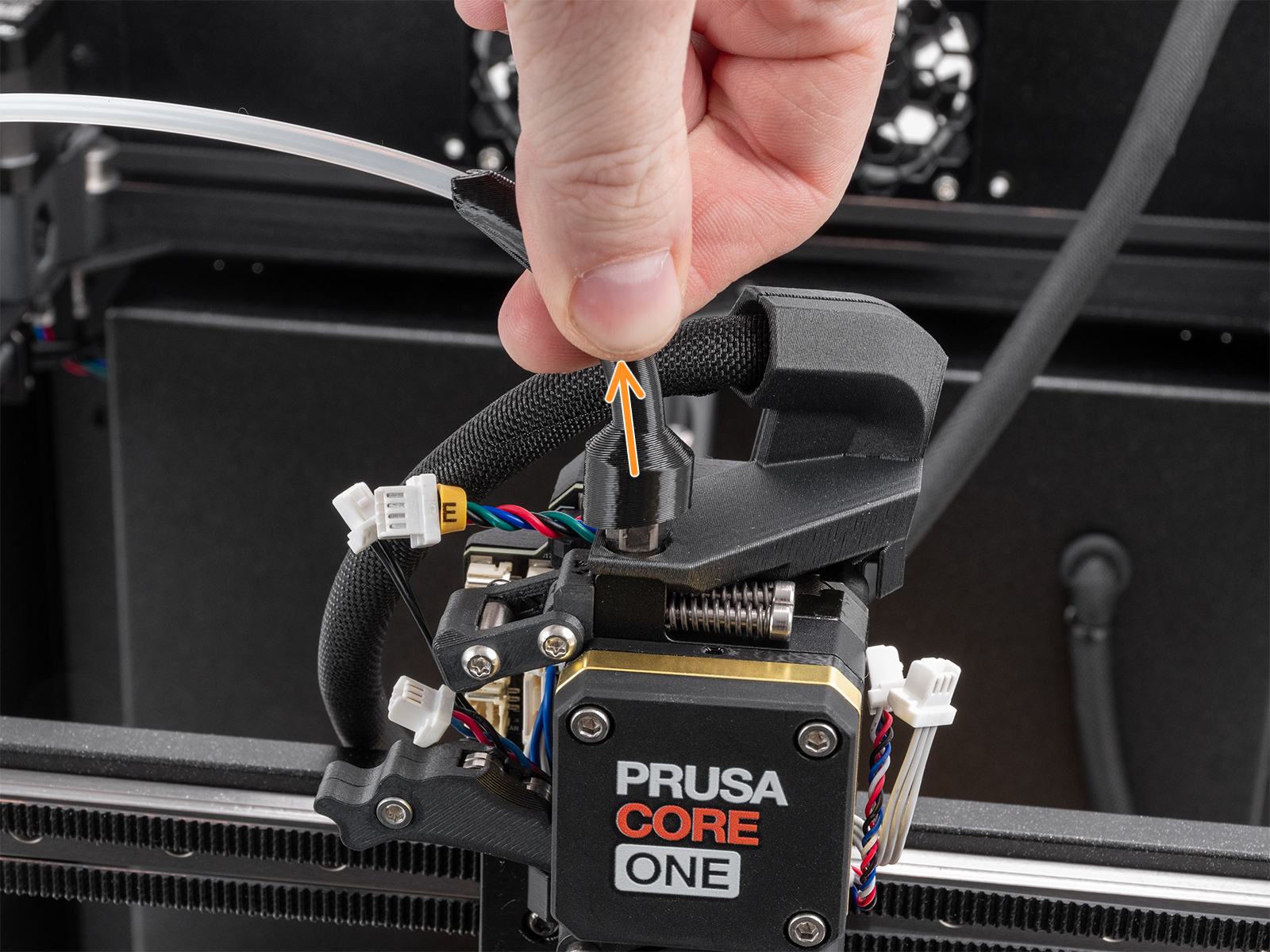

- Saca el Bowden-bend desde el racor situado en la parte superior del extrusor, desenrosca el racor. A continuación, abre los tornillos M3x10 que sujetan el conjunto LoveBoard.

|  |

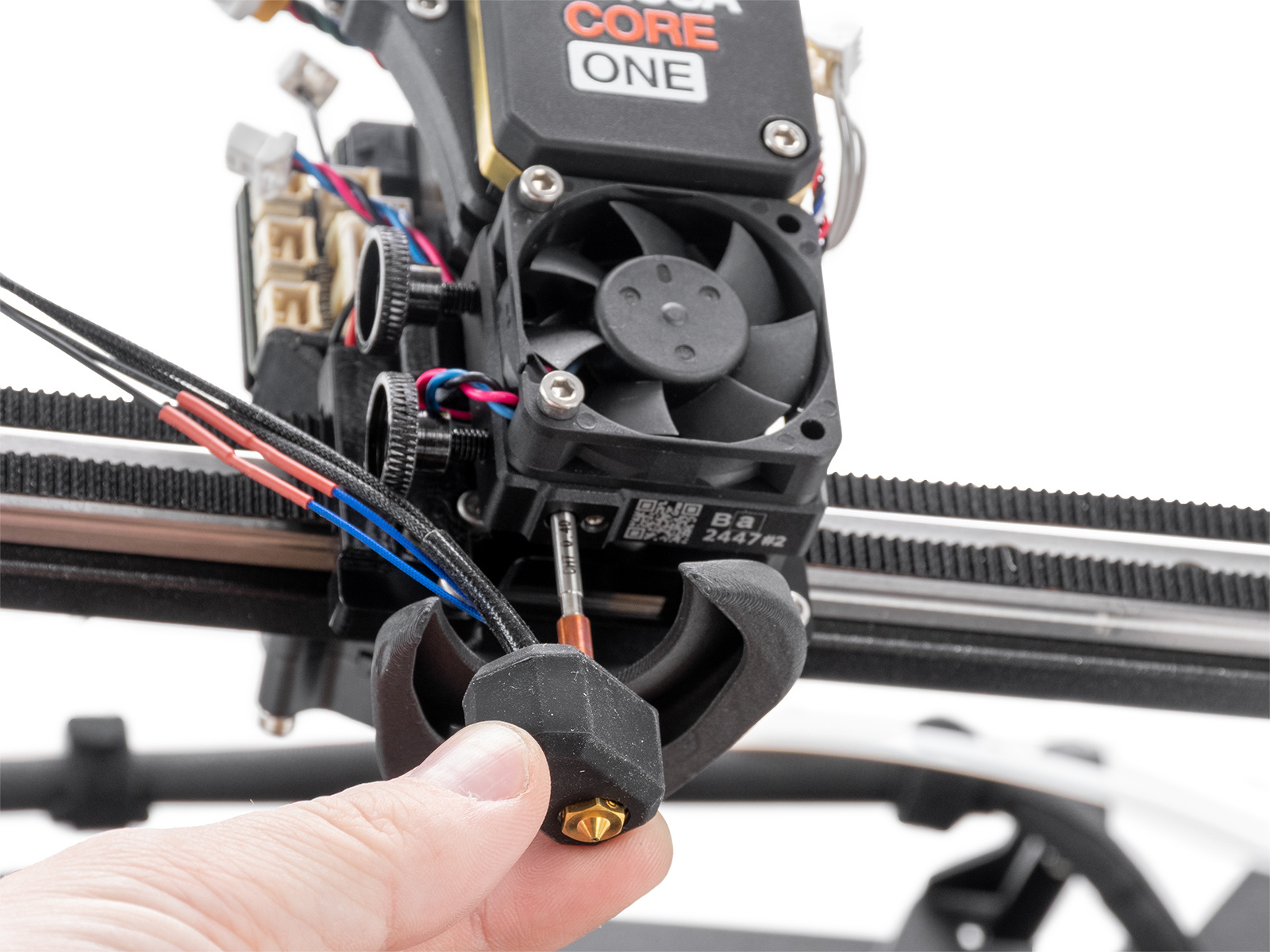

- Retire el termistor del hotend y los cables del calentador del clip para cables. Abre los tornillos de mariposa y retira el hotend, teniendo cuidado con los cables.

|  |

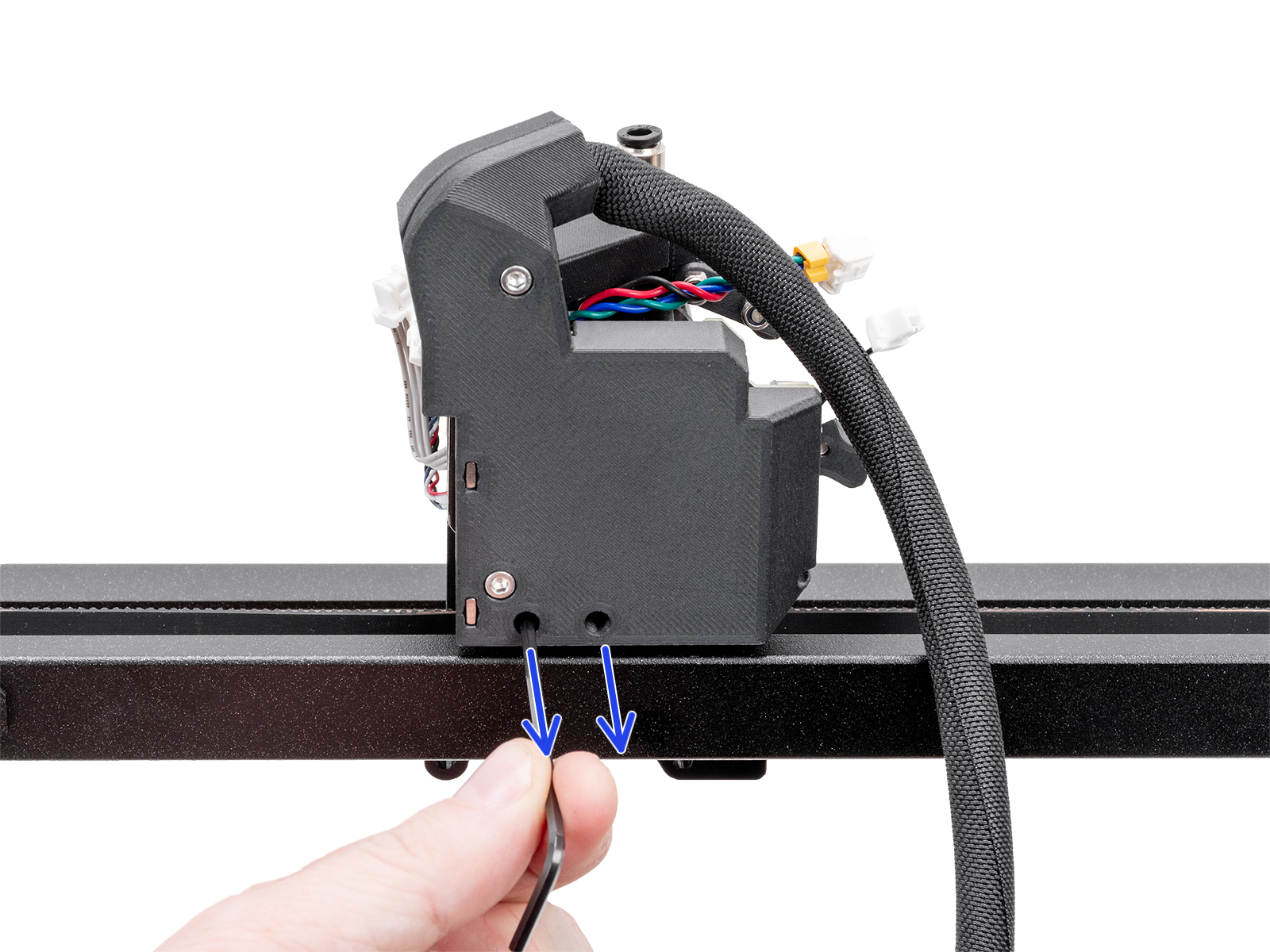

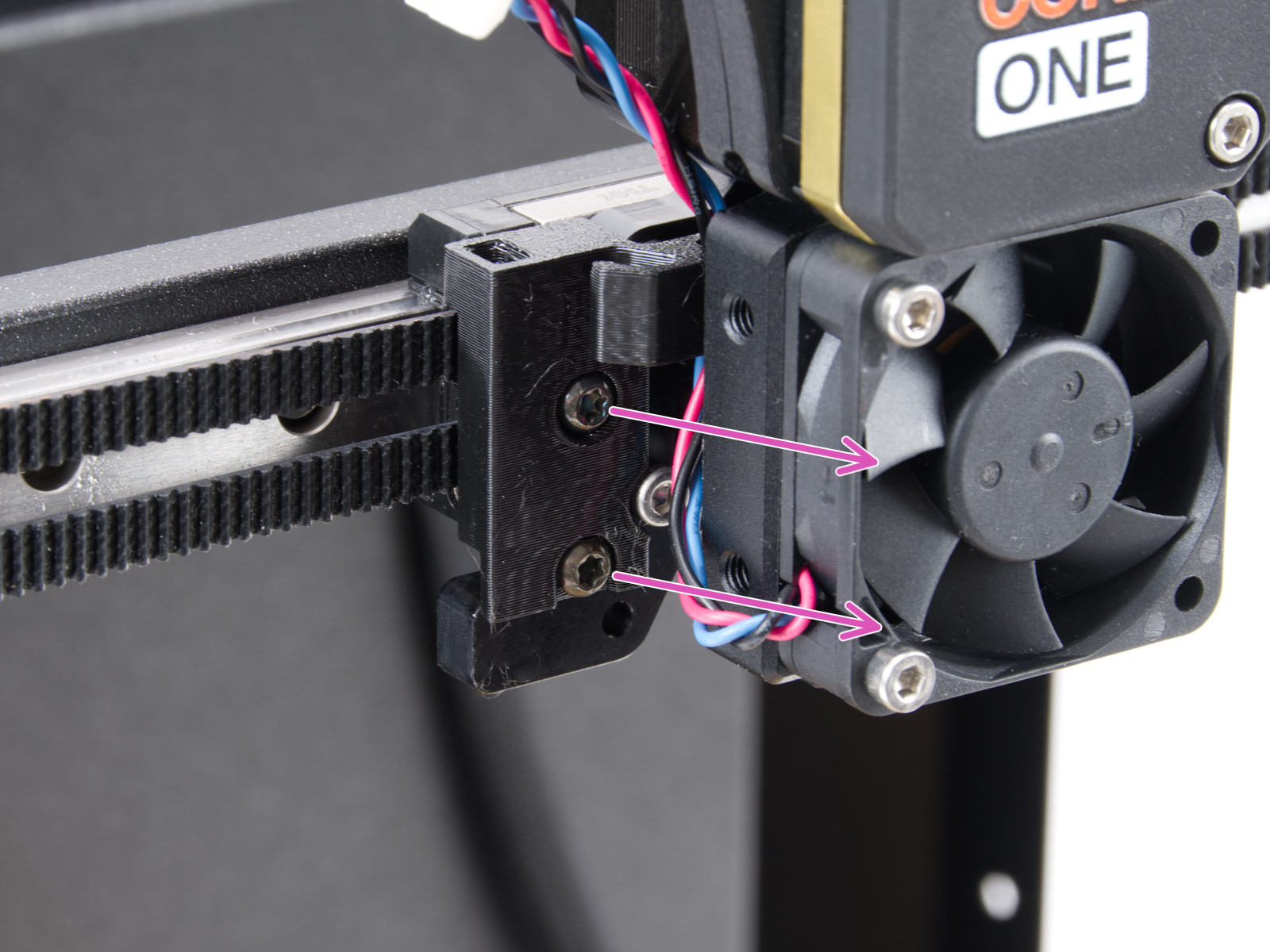

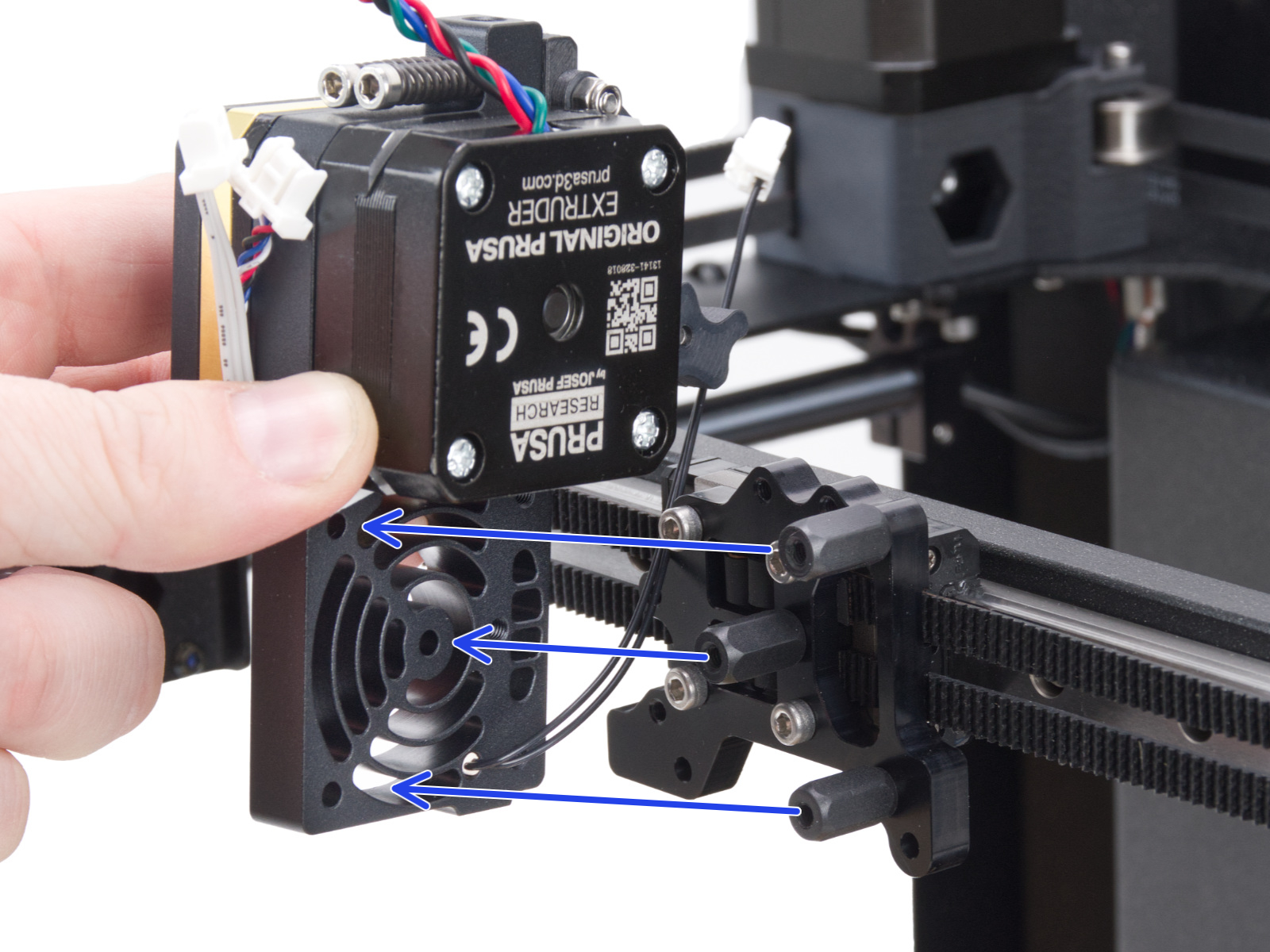

- Desatornilla los dos tornillos M3x4rT del clip del cable del hotend y tira de él para retirar el ventilador del disipador térmico y los cables del termistor del disipador térmico.

|  |

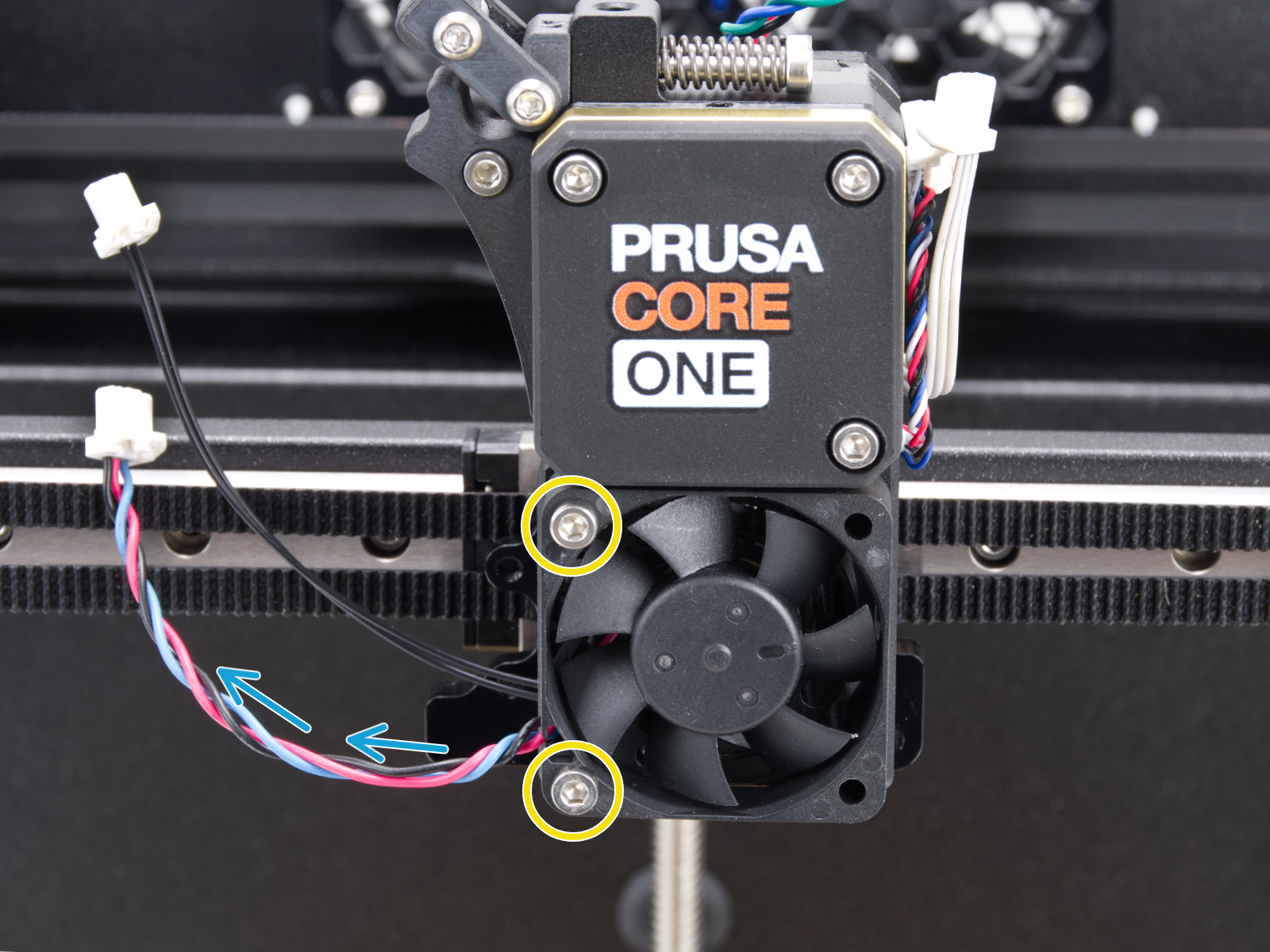

- Desatornilla los tornillos M3x18 del ventilador del disipador térmico para retirarlo.

- Desatornilla y retira los tres tornillos M3x10 que sujetan el disipador térmico y extráelo. Ten cuidado con los cables.

|  |

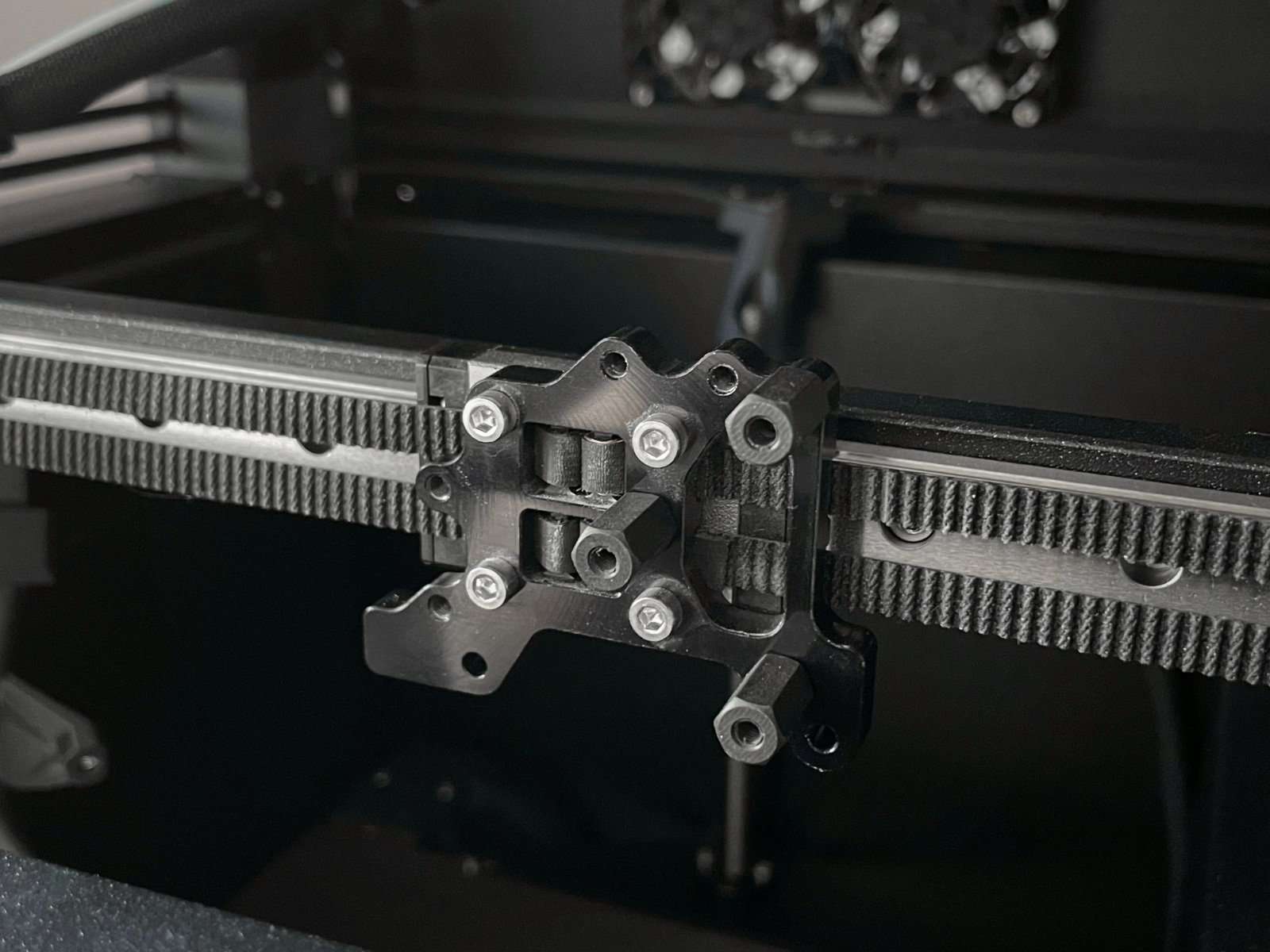

- Ahora tienes acceso al soporte Nextruder con las correas. Asegúrate de volver a colocar las correas que se han salido o ajusta las que estén demasiado flojas. Si te resulta difícil volver a colocar la correa, intenta aflojar los tornillos tensores de la correa. Si necesitas más acceso, desatornilla los cuatro tornillos que fijan el soporte al carro.

- Para volver a montar, sigue el Manual de montaje y vuelva a ajustar la correa con la aplicación del afinador de la correa.

1 comentario

https://help.prusa3d.com/es/article/atencion-al-cliente_2287

Un saludo,