Do you need to send your printer back for a refund or repair? Unlike when returning a single part or component, when returning an assembled Original Prusa i3 printer (MK2/S, MK2.5/s, MK3/S/+) you must follow some guidelines to prevent any damage during the transport.

Returning for refund

No matter the reason for returning the printer, if you are not sending it back for repair, you must include all of the tools and accessories that came with it. That includes:

- Flexible magnetic steel sheet

- Spool of grey filament and spool holder (even if it has been opened and less than half is used)

- SD card, power cable, USB cable

- Pliers, spatula, screwdriver, Allen keys, spanner

If we have sent you some replacement parts earlier, don't forget to send us back the original (broken) parts too.

Returning for repair

When returning the printer just for repair, you do not have to include everything.

You can keep:

- Tools (pliers, spatula, screwdriver, Allen key, spanner)

- Cables

- Spool holder

You must include:

- Flexible magnetic steel sheet. If you have more sheets, always include the one that you are using when the problem happens.

- 1 meter (40 inches) sample of the filament giving you trouble. This is sufficient to check moisture content and diameter to eliminate these variables.

- SD card with the G-code and original STL file that you had trouble printing.

Documentation

We require some documentation of the refund in the form of the following:

- Pictures of the packing process to have approved by our shipping department.

- Prusa Service List: Download the Prusa Service List PDF and fill out the form. It can be edited from the browser and should be sent with the photo documentation.

Serial number

All printers have a serial number to identify them. This must be filled in when completing the Prusa Service List. This silver sticker is either on the back of the printer's frame or in the box that the Einsy board was sent. If you are missing this sticker and/or the serial, please contact support.

List of packaging material

Cardboard box

If you bought the printer assembled, please re-use the box in which you have received it. If it was a kit, please find another suitable box. The printer's dimensions are 420 × 420 × 380 mm (height). To accommodate for padding material and accessories the box must be a bit larger.

The box should have a minimum volume of:

540 x 510 x 475 mm (height) / 21.5 × 20 × 18.5 inches.

Make sure you use a box with thick enough cardboard. For reference, the walls of our boxes are 4 mm (~1/8 inch) thick.

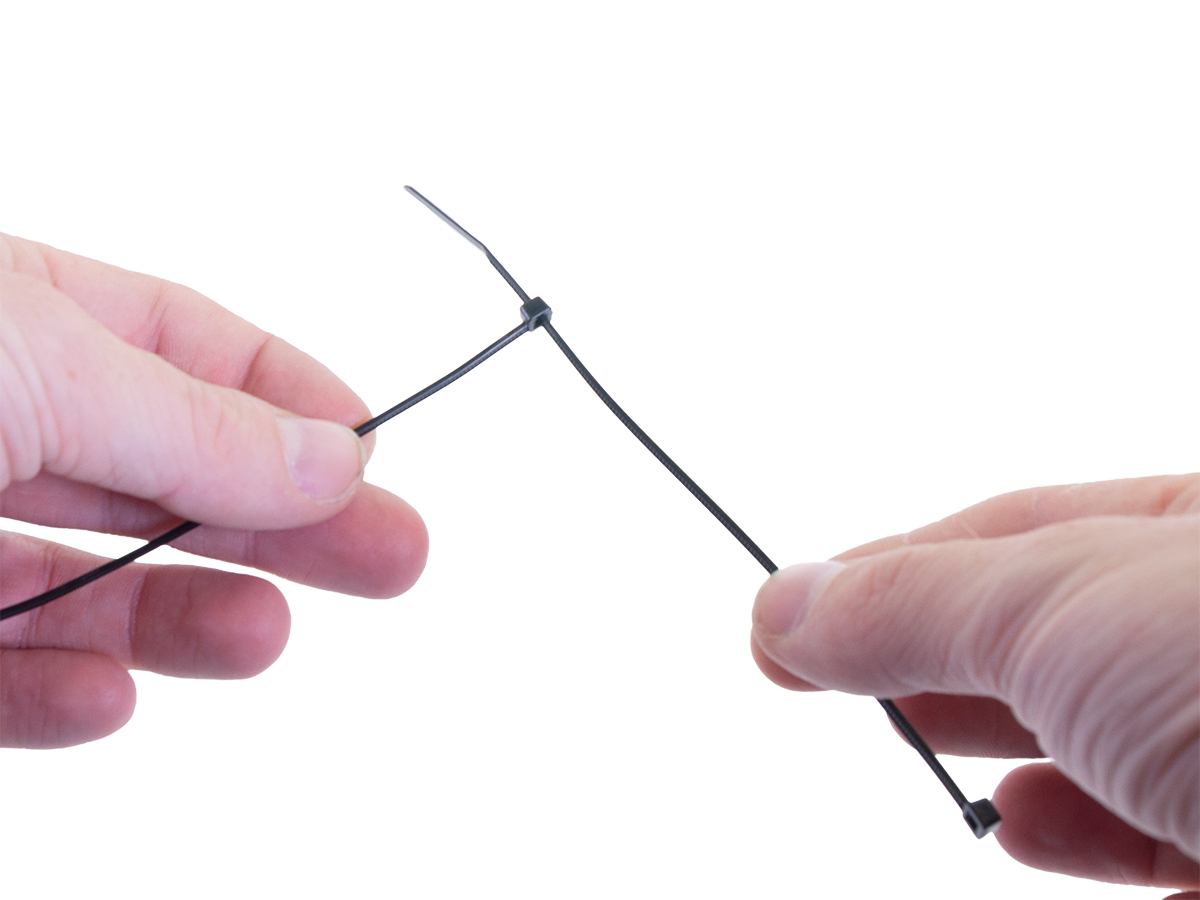

Zip ties

You will also need some zip ties (also known as hose ties/cable ties) or similar fasteners. The smaller the length, the more you will need. We are always sending a full pack of zip ties with printer kits and upgrades.

Packaging material

Protective padding material is important. Besides the official padding, the best is bubble wrap and crumpled-up paper, like old newspapers or ads. Layer this on top and around each component being packed.

To secure the nozzle, you will need a small piece of packaging foam of 50 × 100 × 100 mm / 2 × 4 × 4 inches. For example, you can cut a piece of the white foam that was used in the original box. Even if you purchased the printer as a kit, packaging foam can be found in the box where the motors were stored.

How to pack the printer

Do not disassemble the kit! Do not try to cram the assembled kit into its original box! If you send us your kit for repair, partially (or fully) disassembled, you will be asked to pay the price difference between the kit and the assembled printer. Moreover, it can double the time needed to settle your claim.

MMU2S

If you have a Multi-Material Upgrade, follow the guide linked below to correctly pack it before starting on the printer. Add it to the printer box when instructed to.

Packing Multi Material upgrade for return

I have the original box and padding material

If you have the original box and padding then please follow the guide for official packing linked below.

Packing i3 printer for return - Original Packing Material

I will provide my own box and packing material

If you no longer have the original box and padding material and will provide your own, please follow the guide for the alternative packing method below.

1 comment