It is recommended to take some time to maintain your Original Prusa MINI/+ regularly. This should be done even if the printer is working perfectly.

Clean the sheet

If the printed objects have trouble adhering to the print sheet surface, you need to wipe the sheet clean. Choose the right cleaning product for your sheet (IPA, Windex, etc.), pour a small amount of it onto an unscented paper towel, and wipe the print surface.

The sheet should be cleaned while cold to achieve the best results - cleaning it when hot can lead to potential injury, either from the heated bed or nozzle. When cleaning at higher temperatures, the alcohol will also evaporate before it can clean anything. More details can be found in the First layer issues.

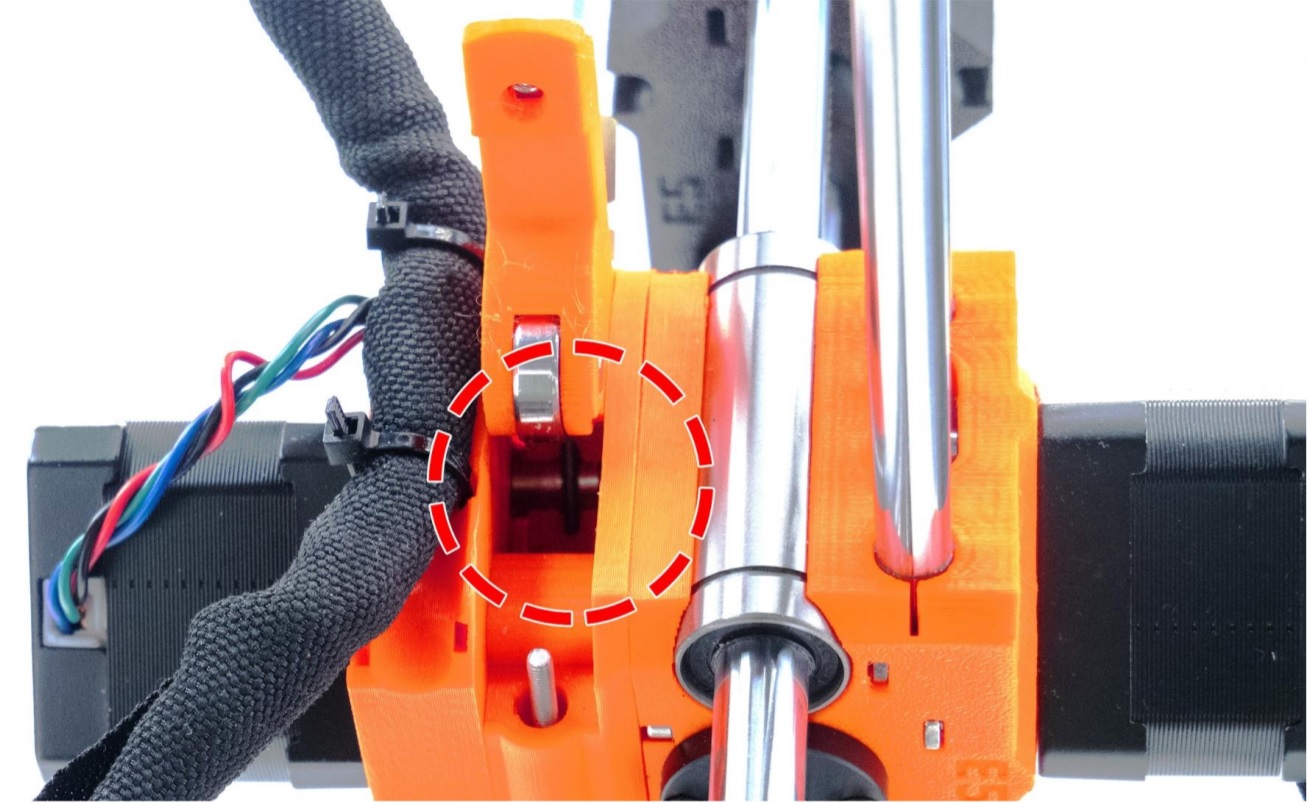

Bearings maintenance

After ~200 hours of printing, the smooth rods should be cleaned with a paper towel. You can buy a lubricant (any good super lube will do) and apply it onto the smooth rods (XYZ axes). MINI/+ is supplied with a tube of Prusa lubricant and it is also available in our eshop.

With the printer turned off, move the X-axis (extruder) and Y-axis (heatbed) by hand back and forth a couple of times. If you feel that one of the axes doesn’t move smoothly anymore, the bearings can be taken out and greased on the inside (they should be removed from the axis because the plastic lip-seal will prevent most of the grease from getting inside).

For our detailed maintenance guide, please see Maintenance tips.

Fans

Both fans should be checked and cleaned every couple hundred hours. Computer cleaner spray (compressed air) will get the dust away and tweezers can be used for little plastic strands. Always hold the blades when cleaning the fan with compressed air.

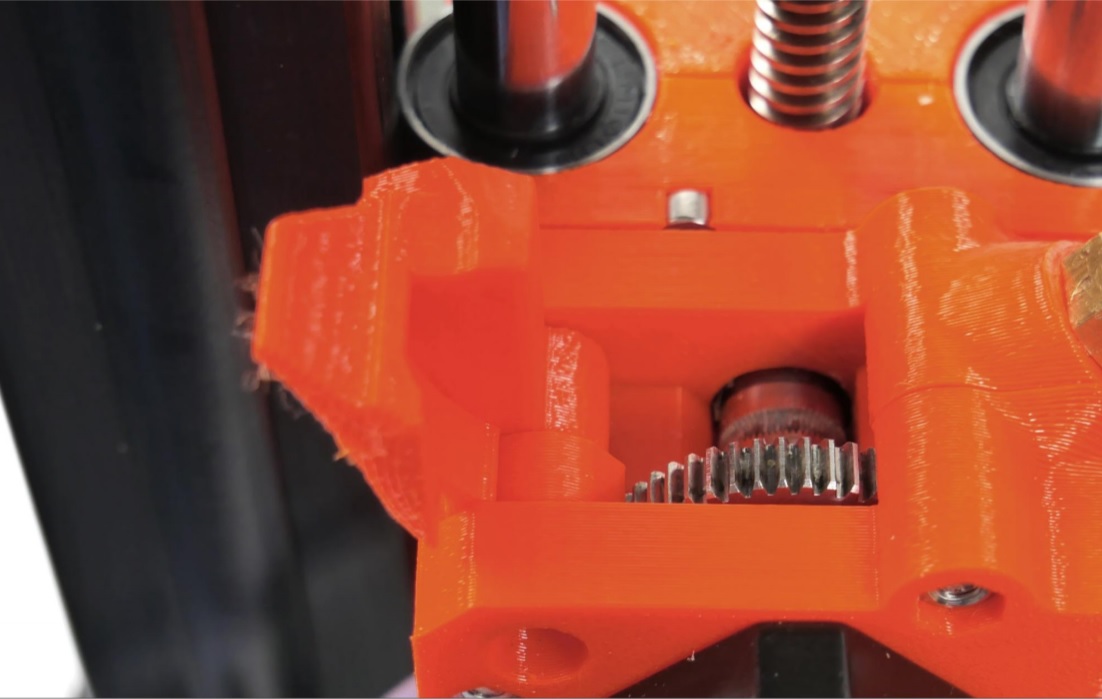

Extruder driver gear cleanup

The extruder gears do not need any lubrication. However, over time they can suffer from a build-up of filament shavings in the grooves, and loose gripping force that can cause under-extrusion. Use compressed air to blow the debris out or use a small brass brush to clean the grooves, a regular toothpick will do the job as well. Check and clean from the access window on the top of the extruder assembly. Clean what you can, then rotate the gear and repeat. A very small amount of lubricant on only the drive teeth does not hurt but can cause problems if it reaches the filament teeth or starts to collect debris.

For more extensive disassembly, see How to access and clean the extruder-pulley (MINI/MINI+)

Opening the idler will enable you to clean both gears and/or remove any filament leftovers caught in the extruder gears. It’s advised to inspect the gears from time to time and remove any debris caught in the extruder.

PTFE tubes

The MINI has four PTFE tubes, two external and two internal, that may need a basic level of attention from time to time. PTFE tubes are used to lead the filament strand from the spool, through the extruder, all the way to the nozzle. Over time, filament debris can accumulate in the PTFE tubes.

These tubes should be clean and uniform. If they are deformed or look worn they should be replaced. Use a can of compressed air to clean them. Using a piece of solid wire can damage them on the inside.

The leftmost tube has a regular inner diameter, while the rightmost tube has a deformed, worn tip.

The leftmost tube has a regular inner diameter, while the rightmost tube has a deformed, worn tip.

Accessing the PTFE tubes:

External tubes

- The first tube where you load filament, which leads to the extruder, can be pulled out by hand. If you are unable to pull out the first tube by hand, please follow How to access and clean the extruder-pulley (MINI/MINI+) to Step 8 to release the M3x12 screw securing it.

- The second, longer, main Bowden tube leads from the extruder to the print head. Use a spanner (size 10) to loosen the nuts securing it to the fittings, found at each end of it.

- Below each fitting of the main Bowden tube, you will find a PTFE tube. Both should be inspected if you have loading issues. The one located in the extruder is a short tube that assists the filament exiting the extruder.

- The hotend/print head PTFE-tube needs to be clean and slightly compressed when installed inside the heat break. Please see our comprehensive illustrated guide on replacing the PTFE-tube in the MINI.

Nozzle

Inside

If you have a clog or print failure you may need to do a couple of Cold pulls. Also, changing from PLA to PETG, at PLA temperatures can cause issues. Cold pulls should clear any partial or full clog and get you printing again. See our guide on doing a cold pull on the Prusa MINI. When heated, it can also help to use an acupuncture needle (one is included with the kit), to clean the inside of the nozzle.

Outside

If your nozzle is covered with plastic on the outside it can affect its thermal properties. To clean it, heat the nozzle for 5 minutes, and press the reset button.

Immediately after that use a small brass brush to clear away any old plastic stuck on the nozzle and heater block. Be extra careful around the fragile hotend heater and thermistor wires!

Replacement

Nozzles do wear out over time, even when only printing PLA and PETG. If you attempt to print abrasive filaments, like steel-fill, using the stock brass nozzle, the nozzle will be ruined quickly.

Should you need to change the nozzle, you will find a complete guide here, covering the whole procedure, as well as some common mistakes you want to avoid.

Updating the firmware

Keeping your system fresh and up to date is important. The firmware is continuously being developed and new features and operational improvements are implemented regularly, based on testing and feedback from our users. For a complete guide on flashing the firmware, please see Firmware updating (MINI/MINI+).

1 comment