To achieve good quality prints, it is fundamental that the nozzle makes the right amount of contact with the print surface. If this is not achieved, your printer will show the message "nozzle cleaning failed". If the message appears, check the items below.

Nozzle cleaning

Check if the nozzle has residue. Debris on the nozzle or heater block can affect its thermal properties. To clean it, heat the nozzle for three to five minutes at 250 °C, as the remains of the filament must be melted slightly so they can be removed easily.

Use a small brass brush to remove any old plastic stuck on the nozzle and heaterblock.

Avoid contact of the brush with the hotend cables, as this could cause a short circuit.

Caution: the printer is still at a hot temperature! Wait until the hot parts are cooled down to ambient temperature. It takes approximately 10 minutes. Do not touch it! Always check the values on the display.

Steel sheet cleaning

Make sure that the steel sheet is clean of any residue. For the smooth, textured, or satin sheet, clean with 90% or higher isopropyl alcohol (IPA).

Also, make sure that there is nothing between the steel sheet and the heatbed.

Filament spool

If the extruder needs to make too much effort to pull the filament, the nozzle cleaning error can be triggered. If this error is being shown when you are using a spool heavier than 2 kg, try changing to a smaller one for testing. Also, if you have a custom setup for your filament path, make sure that the filament is not getting caught anywhere.

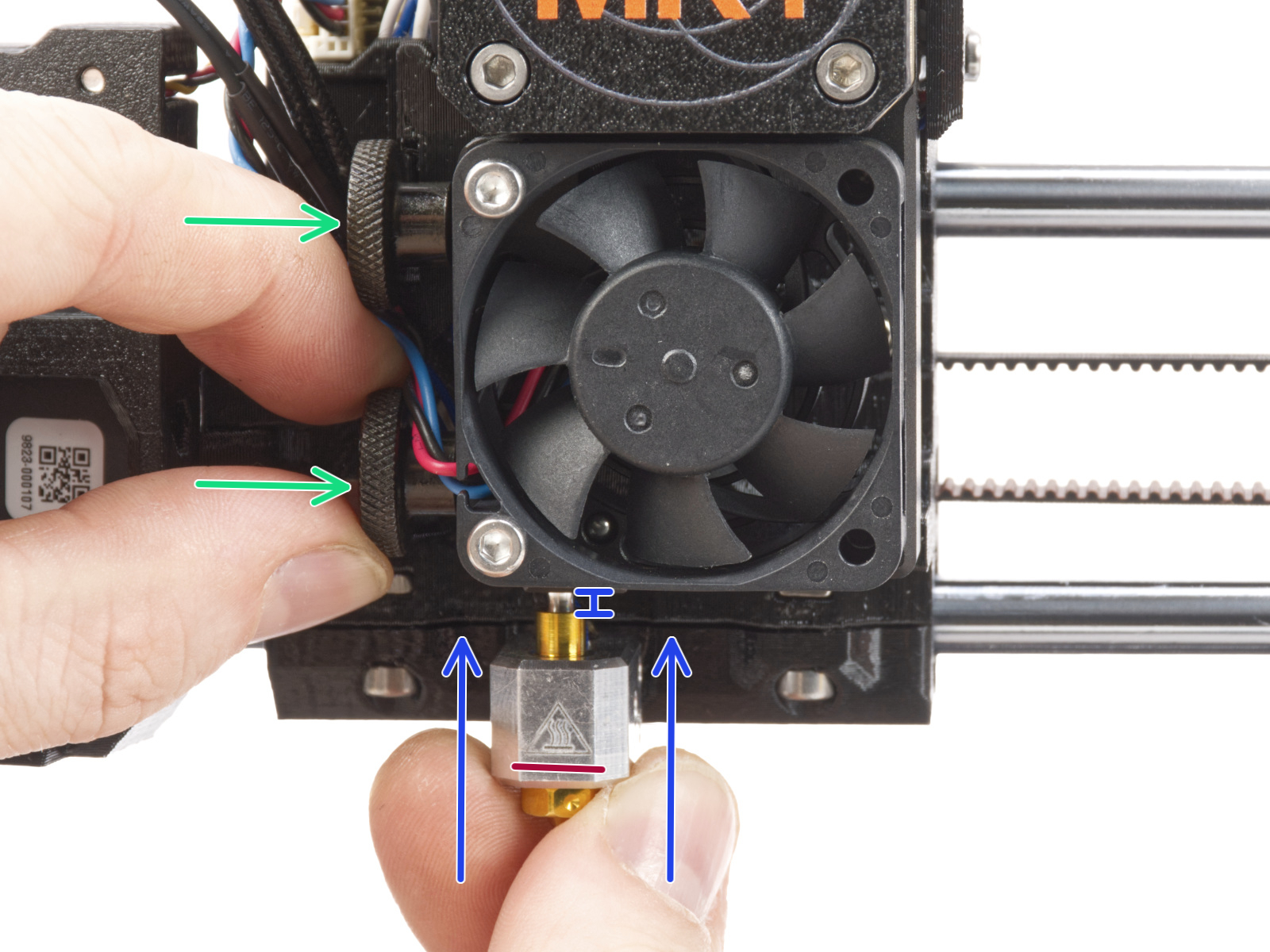

Check if the nozzle is not loose

The nozzle on the Nextruder must be at the correct height and securely tightened. Before proceeding to the next steps, ensure that the nozzle is cooled down. Then, loosen the thumb screws (do not completely remove the screws, a few turns are enough) on the side of the heatbreak, and push the nozzle up. Tighten the thumb screws just by hand, do not use any tools. After tightening the thumb screws, try moving the hotend to the sides and make sure it does not move.

If you have a Nozzle Adapter, check the installation again to make sure that the nozzle has not been lowered or loosened with the installation of the adapter.

|  |

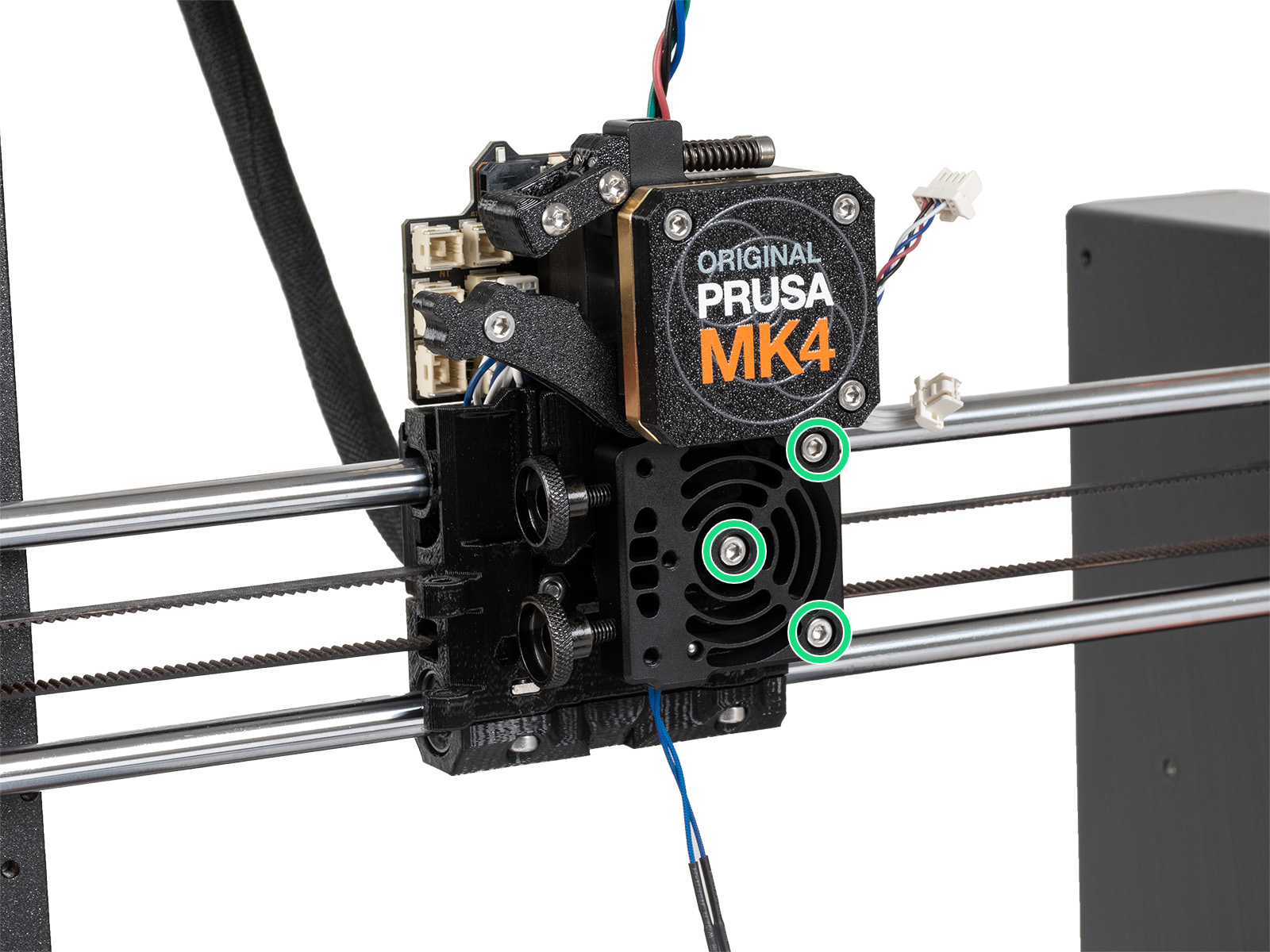

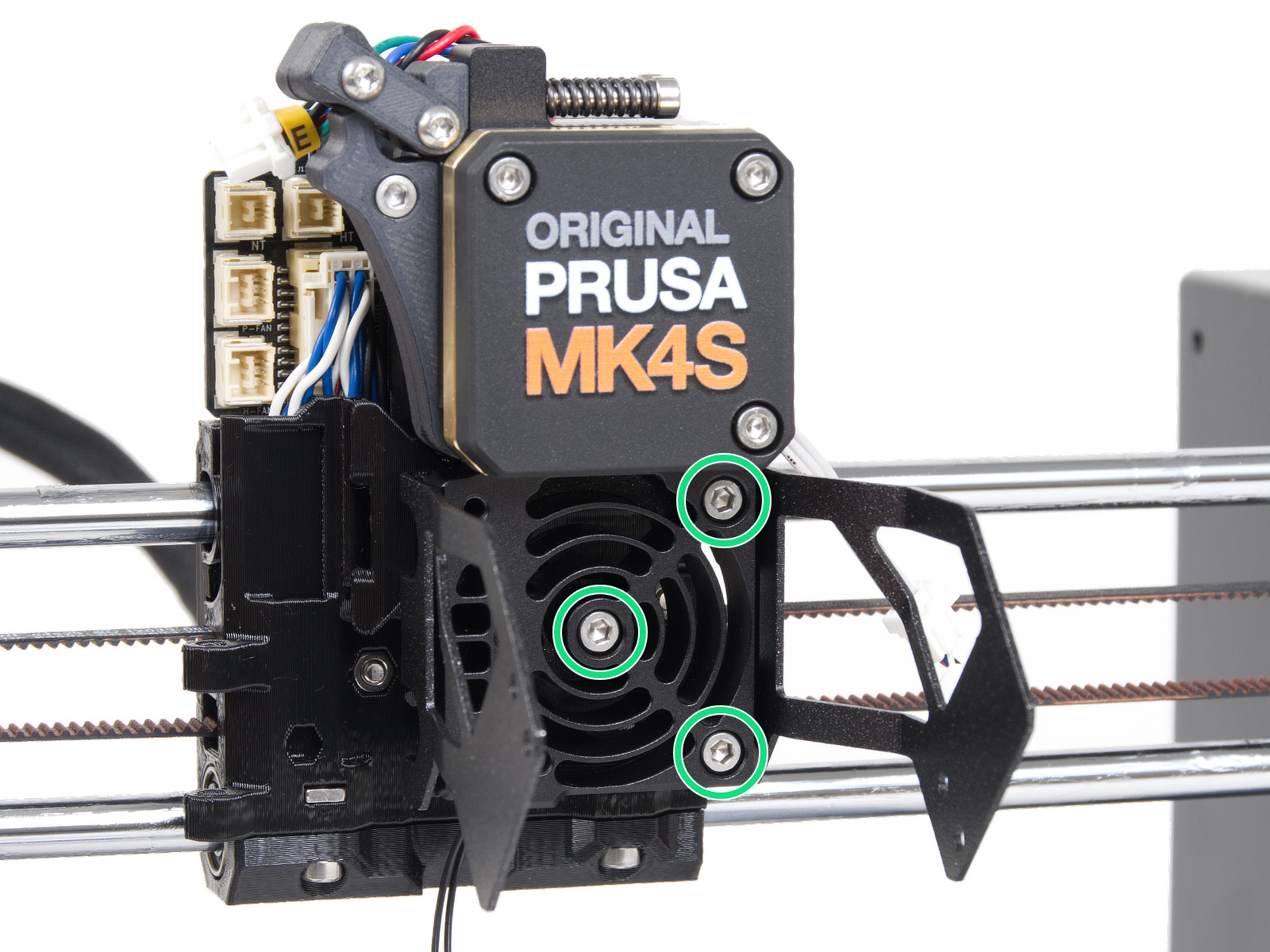

| MK4, MK3.9 | MK4S, MK3.9S |

| |

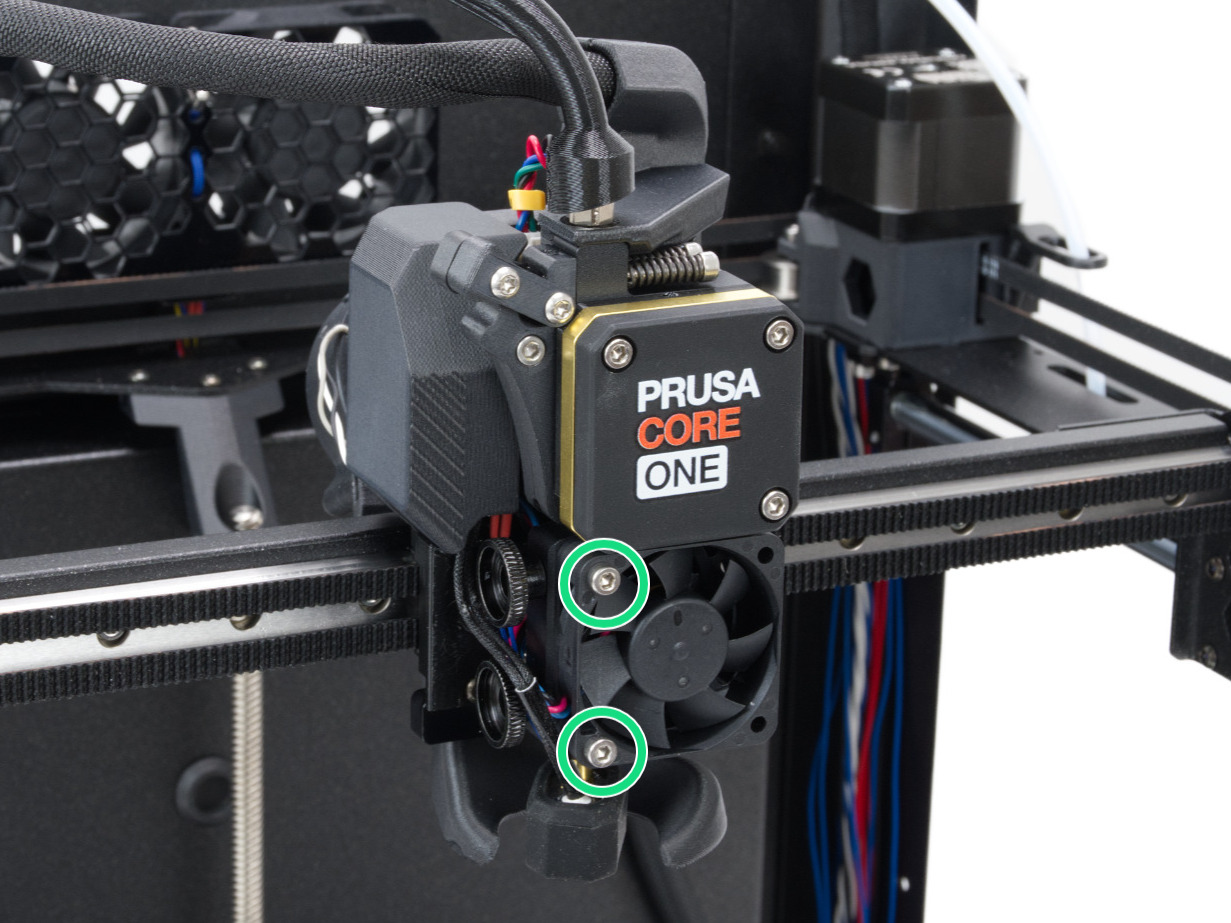

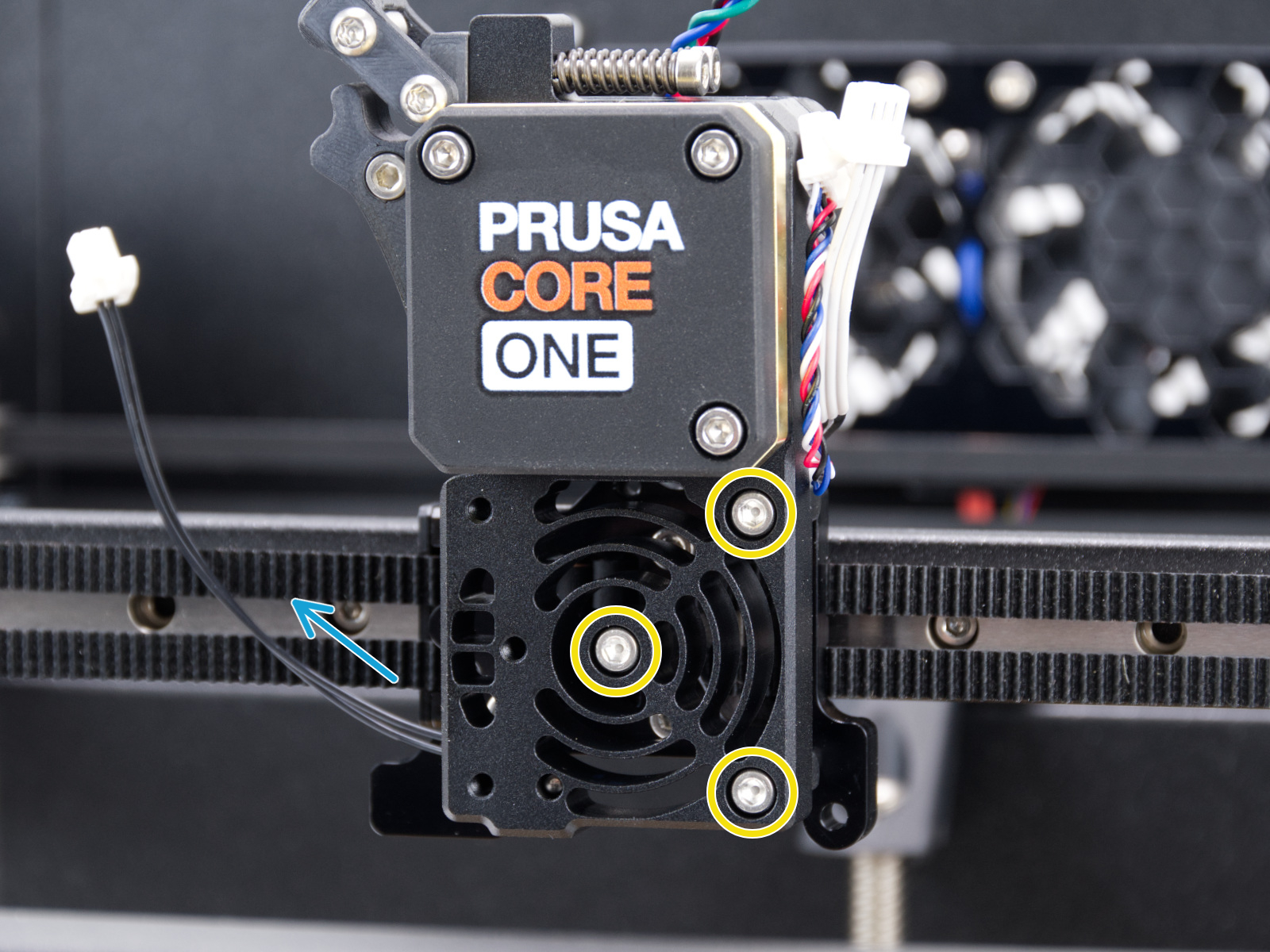

| CORE One | |

Check the bolts that interact with the loadcell

Some of the Nextruder bolts, if too tight, might generate extra forces that can be sensed by the loadcell, skewing its readings, hence potentially causing the issue. Check if slightly loosening the following bolts, while having the parts still tight and secured in place, can solve the issue.

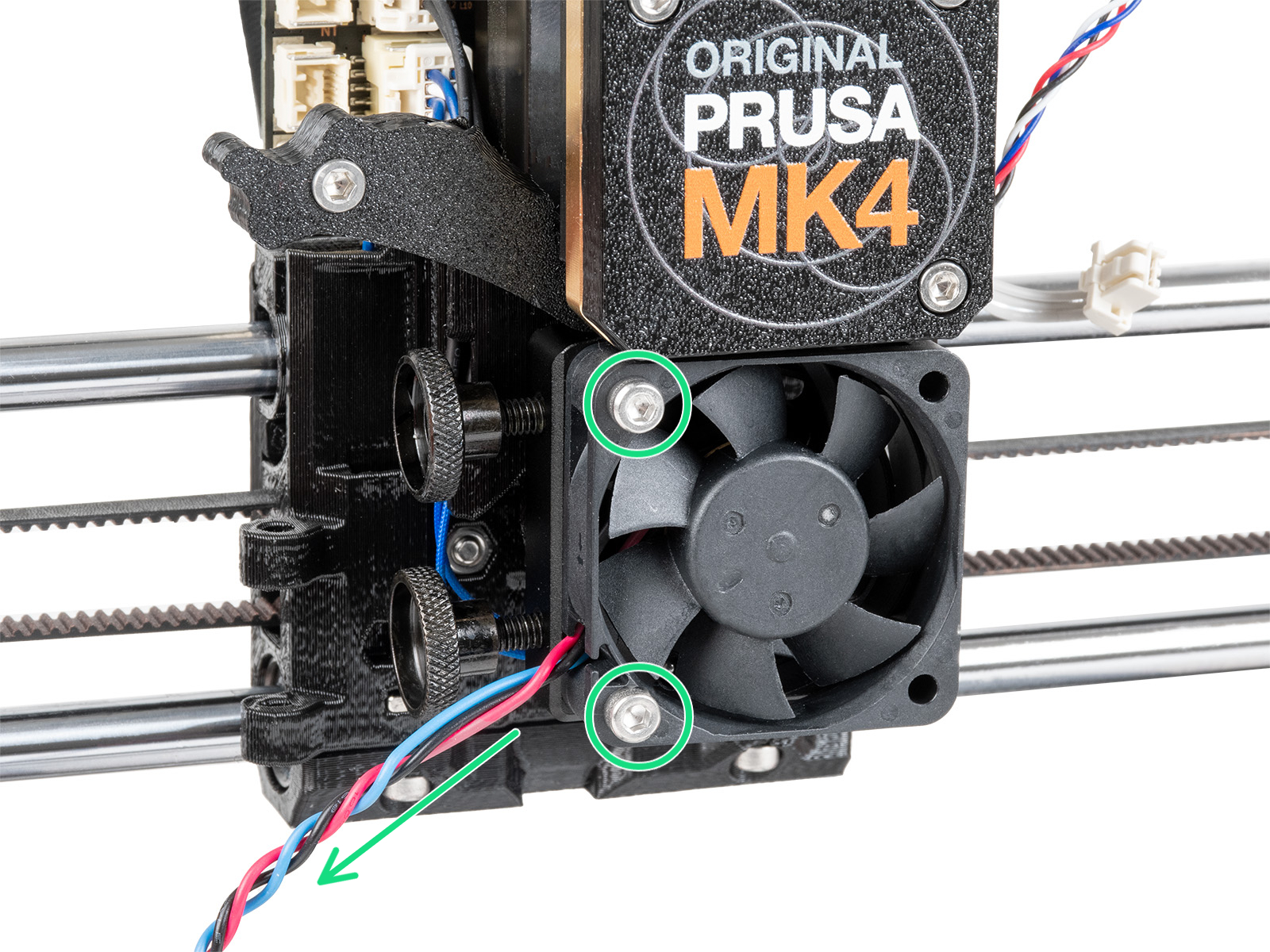

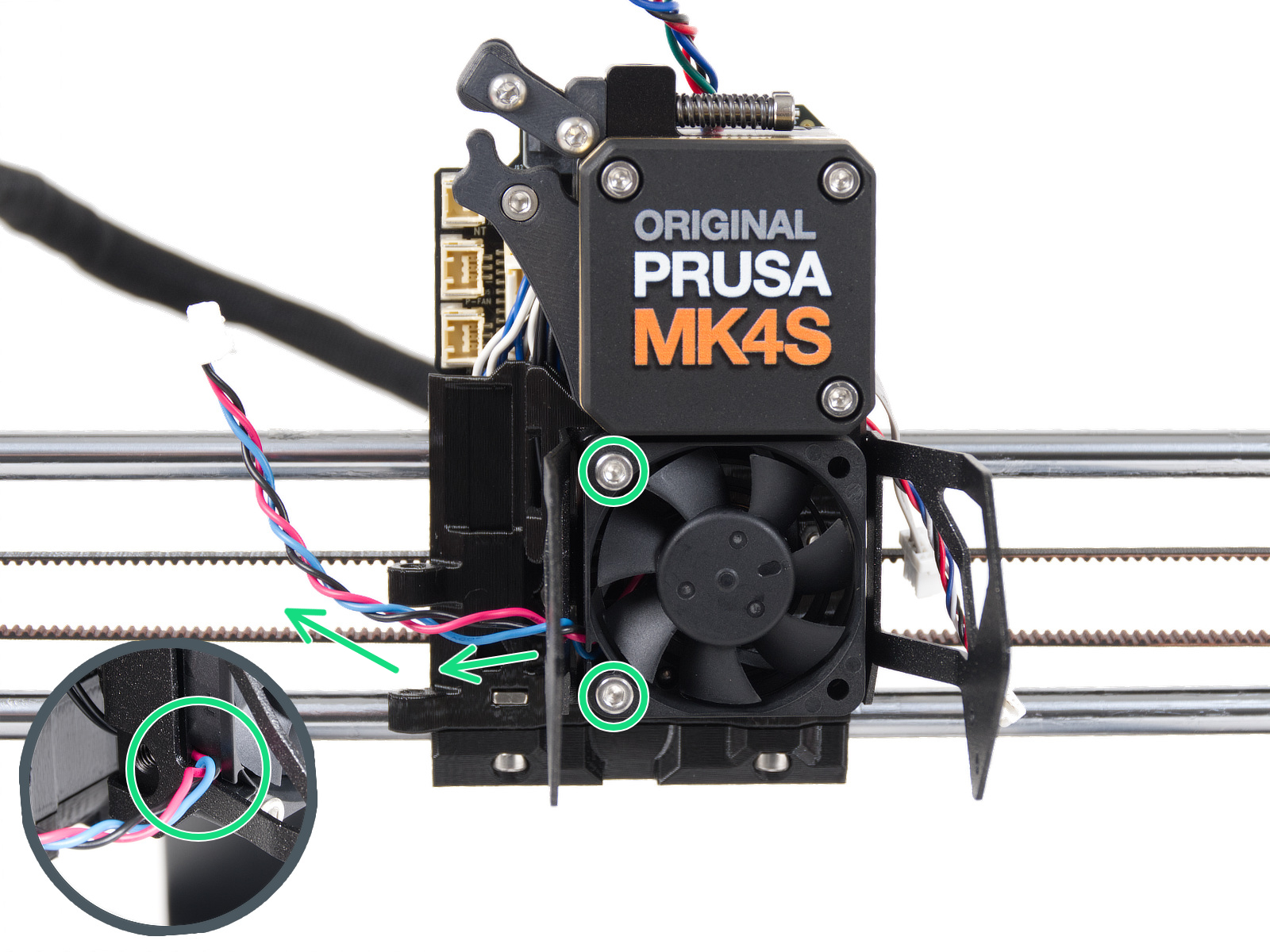

Hotend fan

Check if the hotend fan is not overtightened. You can loosen the screws by 1/2 a turn.

|  |

| MK4, MK3.9 | MK4S, MK3.9S |

| |

| CORE One | |

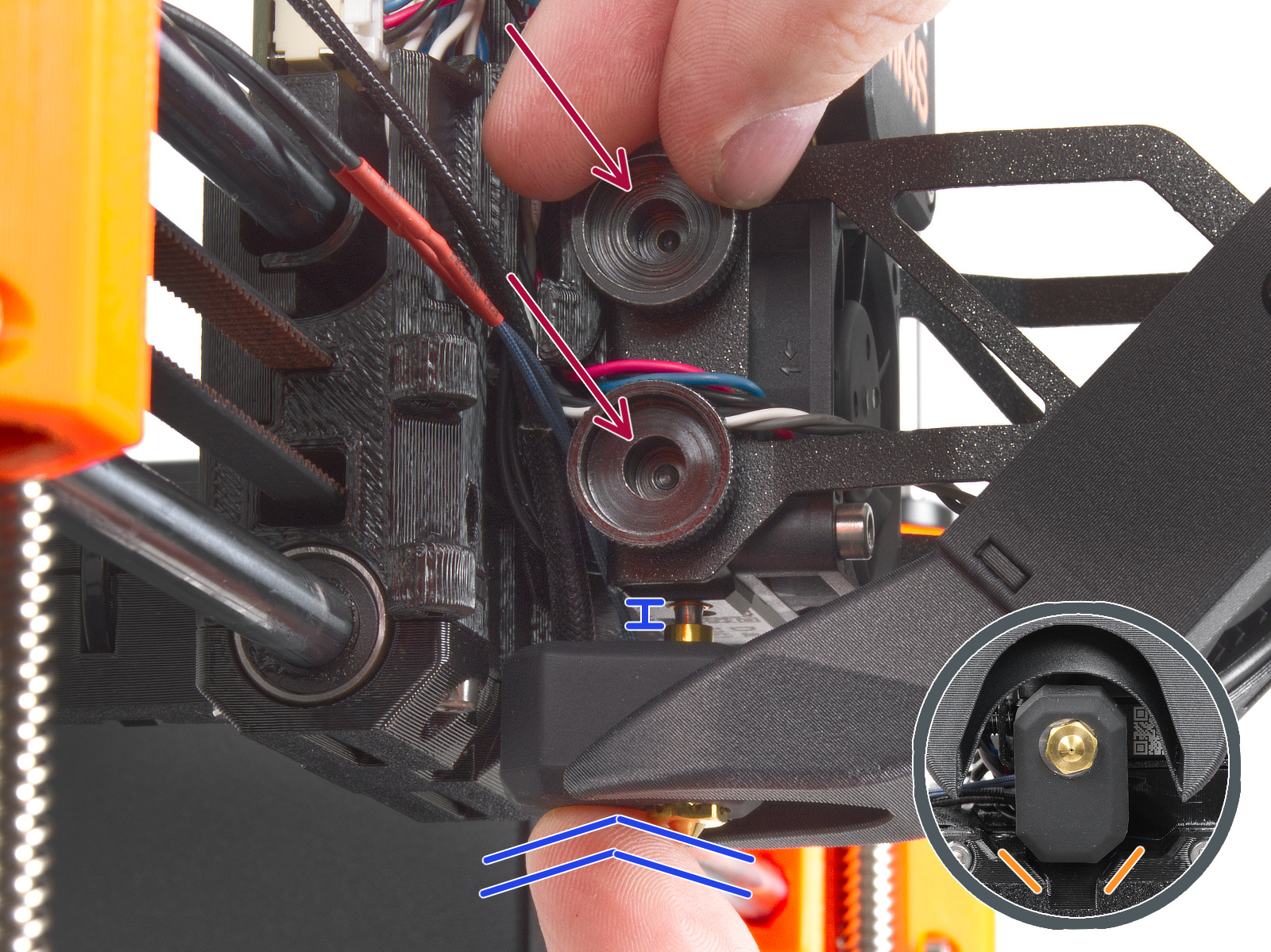

Heatsink

Temporarily remove the hotend fan by removing the previously adjusted bolts. This will expose the heatsink/loadcell. Then, loosen very slightly the three bolts that hold the heatsink/loadcell in place.

|  |

| MK4, MK3.9 | MK4S, MK3.9S |

| |

| CORE One | |

Loadcell seal

The loadcell wires are in the printer's heatsink. The wires and the seal that protect them may get damaged. To access the seal, open the four screws that hold the front case. Then remove the front case, together with the PG-ring, gearbox, and main plate in one piece. Note that the seal might be white or black.

|  |

Expansion joints

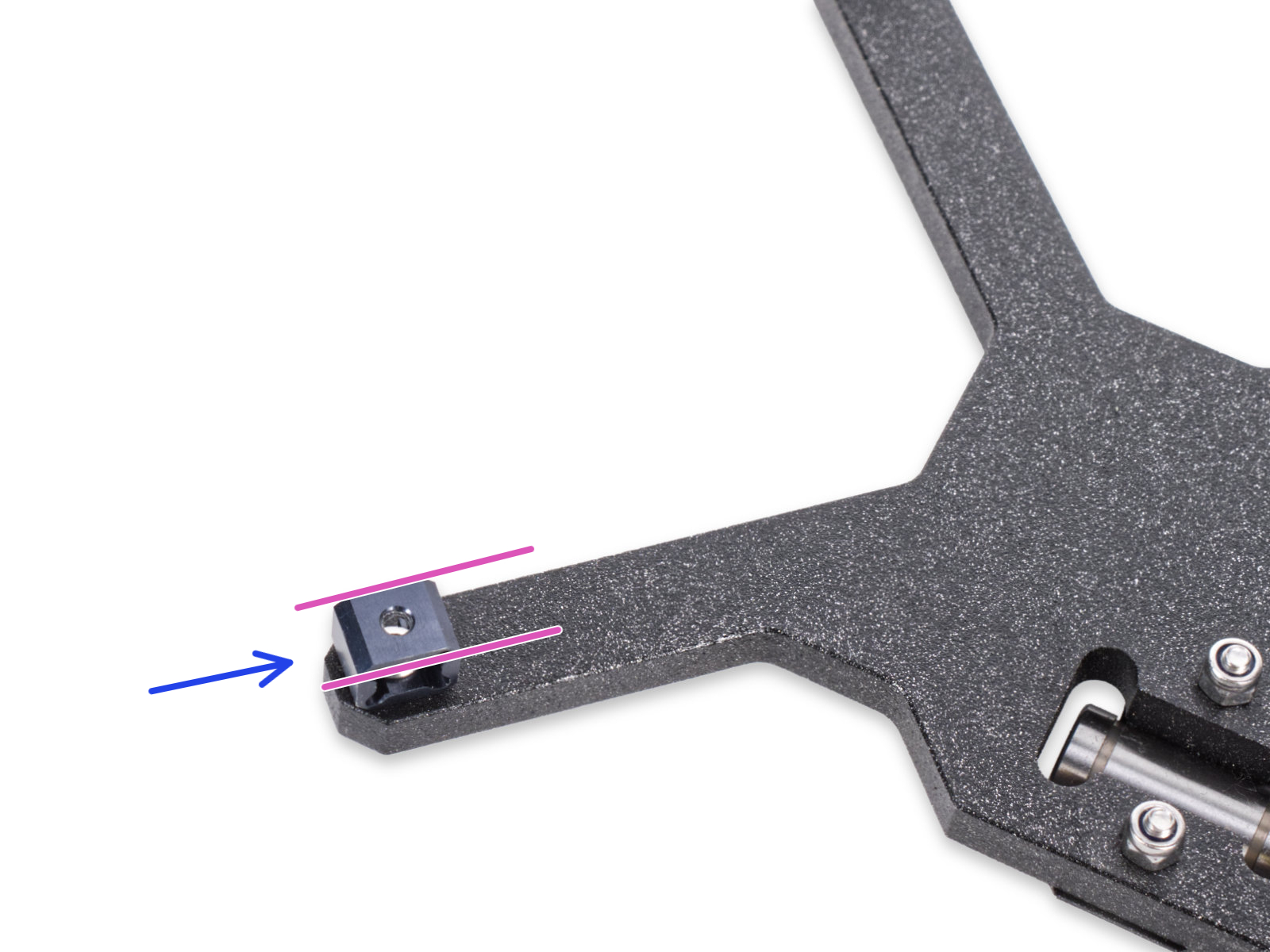

Having the expansion joints in the wrong orientation can cause multiple errors, including the Nozzle cleaning failed. Make sure that all of them have the full side facing the center of the carriage.

2 comments