The Maximum volumetric speed setting (MVS) is one of the most powerful features in PrusaSlicer. The MVS setting essentially creates a manager for the maximum amount of filament that the slicer will attempt to push through your 3D printer’s hotend.

This gives PrusaSlicer users a huge advantage. Rather than trying to calculate a range of speeds for combinations of different nozzle sizes, layer heights or extrusion widths, you can simply specify the speeds and settings you desire, then let MVS regulate speeds at slice time when and only if necessary.

Max volumetric speed = Layer Height × Extrusion Width × Speed

Independent MVS values can be set under both Print settings and Filament settings. In your print profile, you'll typically have an all-around default value based on your hotend hardware. In filament profiles, you can adjust MVS as needed to account for filament characteristics, e.g. decrease it for FLEX filaments (so you won't have to create a new print profile for flexible filaments, just a filament profile).

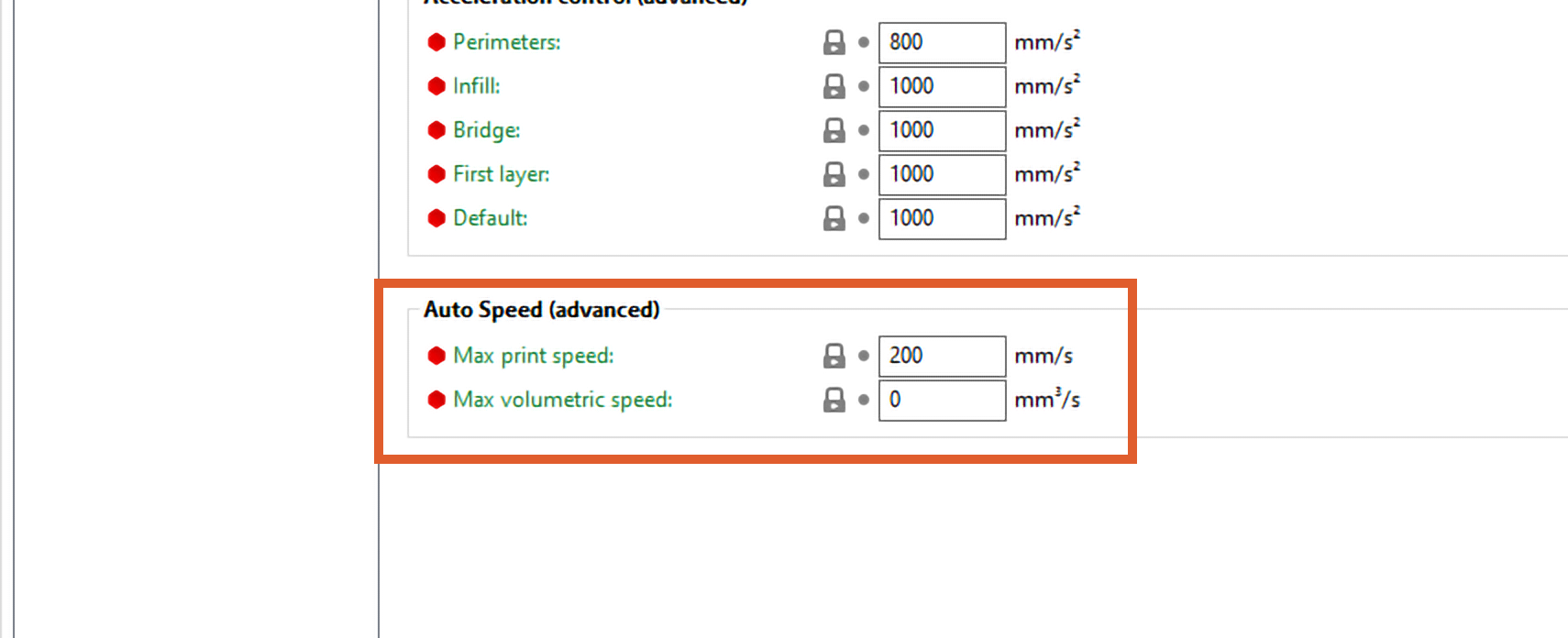

MVS in Print settings

Print settings - Speed - Max volumetric speed (Expert mode)

This value sets the overall maximum volumetric speed. Even if you set MVS to a higher value in filament settings, it will never exceed this value.

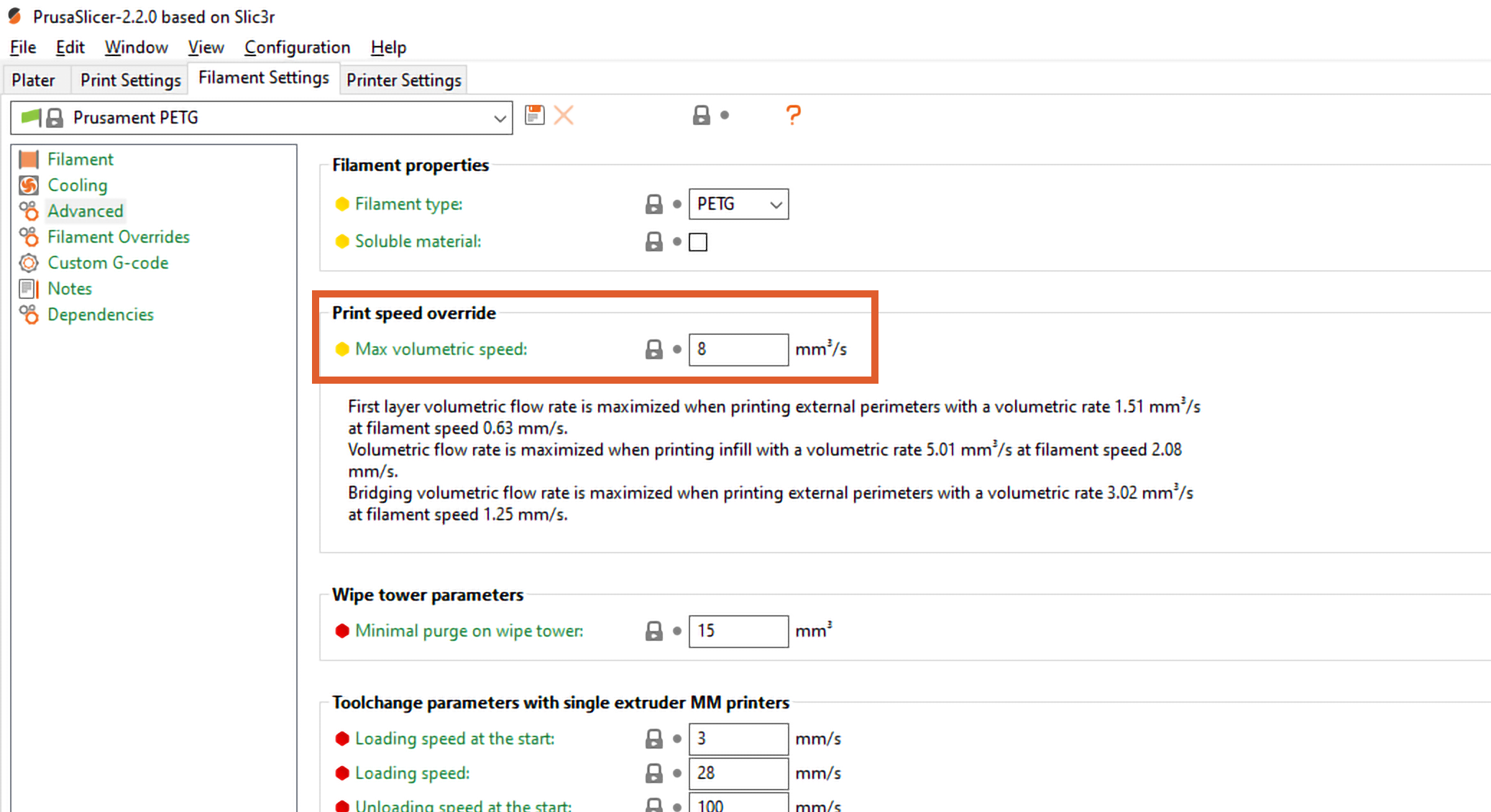

MVS in Filament settings

Filament settings - Advanced - Max volumetric speed (Advanced mode)

This value is capped by MVS set in the Print settings, you can, however, override it to a lower value.

Choosing MVS

Filaments

Different filament materials have different characteristics. Viscocity, stiffness and other factors may greatly reduce effective throughput.

Examples:

| Filament | Max volumetric speed (approx.) |

|---|---|

| PLA | 15 |

| ASA/ABS | 11 |

| PETG | 8 |

| BVOH/PVA (soluble supports) | 4 |

| FLEX (TPU/TPE) | 1-2.5 |

Hotends

The overall maximum volumetric speed you should use depends on your hotend. The E3D V6 hotend that ships with the Original Prusa i3 MK3/S is advertised with a rate of 15 mm3/s. A safe value that leaves some space for imperfect setup (idler tension, slightly jammed nozzle) of 11.5 mm3/s is realistic.

If you need to push more filament, a more powerful hotend will be necessary. The Volcano hotend from E3D increases this to roughly 25 mm3/s but does require modding the printer and the firmware. Other hotend designs allow even higher flow rates.

Nozzle diameter

Intuitively, it may seem that the nozzle diameter shouldn't affect the maximum amount of plastic that the hotend can heat in a given amount of time. However, with bigger nozzles, you can slightly increase MVS due to lower mechanical resistance - basically, it's a bit easier for the filament to get pushed through the nozzle.

And vice-versa, with smaller nozzles, you'll have to decrease MVS a bit.

This is an often-overlooked consequence of MVS. When you use a large diameter nozzle and very tall layer height, e.g. 0.8 mm nozzle and 0.5 mm layer height, your print speed is indeed going to be capped by MVS. That is unless you install a more powerful hotend on your printer. If you notice in the preview, that your speed is limited by MVS, you can try increasing the nozzle temperature and raising MVS a bit. However, it may be time to simply lower the layer height, you'll get more detail without increasing the print time because the printer will be able to print faster.

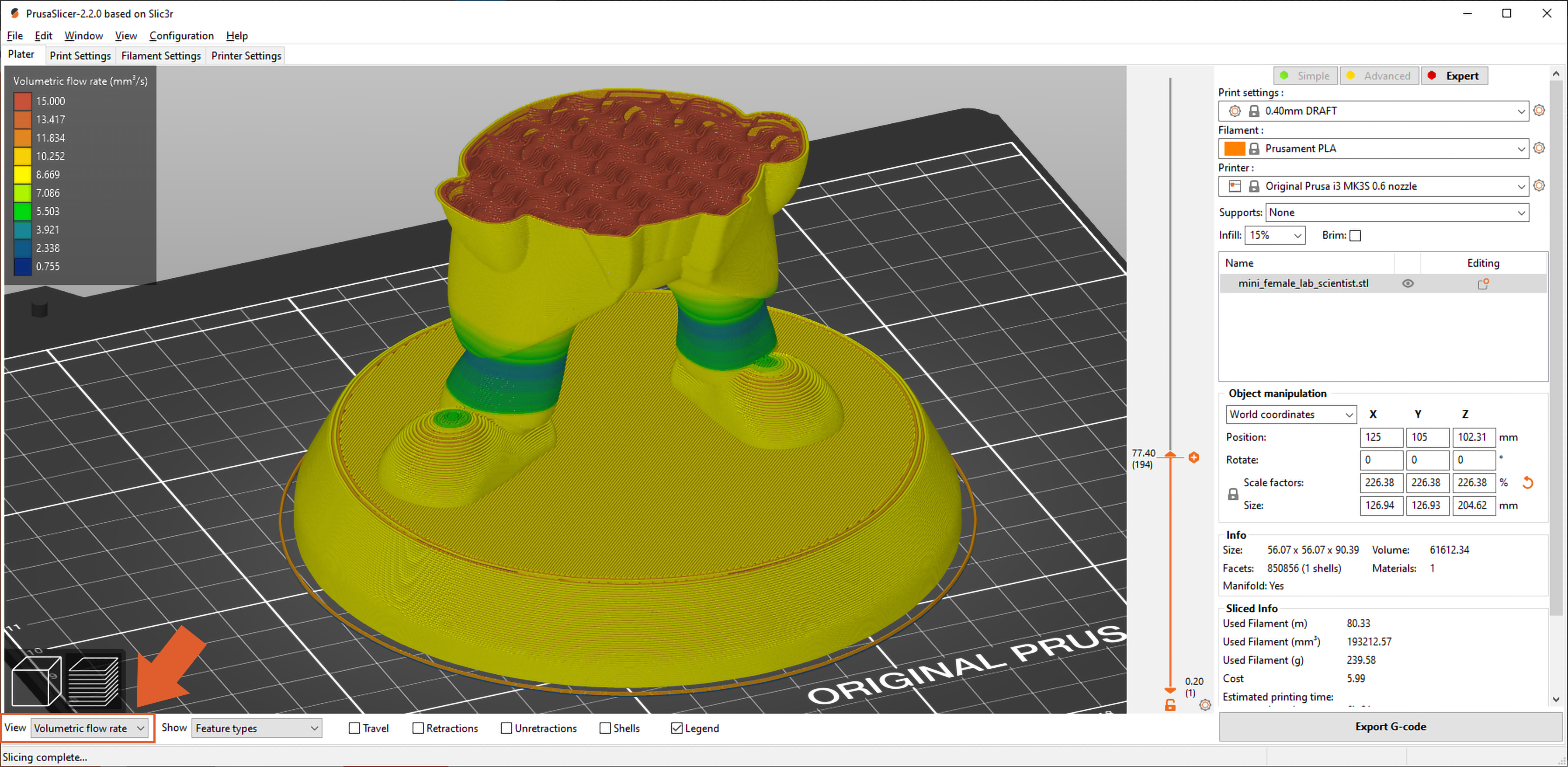

Preview MVS

Once you slice your model, you can switch the preview mode to Volumetric flow rate using the select box in the bottom left corner.

On smaller models, you'll notice you're not being capped by MVS at all. Likewise, if you're printing with small layer height, you're most likely not going to be capped by MVS.

On the other hand, when printing bigger models with tall layer heights, you may notice the speed being limited by MVS, especially when printing infill. If the majority of your model is being printed slower due to the MVS limit, consider lowering the layer height, you'll get more detail "for free".

Big thanks to Bob George for his help on this article

11 comments

a Bondtech CHT nozzle that increases Volumetric Flow. The new nozzle pushes ordinary Prusament PLA out with a volumetric flow of 24mm³, which is a 50% increase from the MK4 standard of 16mm³

It would also be useful to know how Prusa Slicer arbitrates between Print Profile Autospeed settings (Max volumetric speed) and Filament Profile MVS.

Because I found it easier and more efficient to print in 15mm^3/s like PLA, but I might be wrong.

And I couldn't find any totorials for it, only revieves and tests with no Prusa slicer setting showed...

Thx

Where can I change this parameter???

I can't get volumetric speed more than 11mm3/s in slicer at 100mm/s

I want to get 20mm3/s. I have a Vulcan hotend. RepRap printer.

The MVS based on the hardware can be adjusted in PrusaSlicer on the Print settings tab - Speed, and scroll down to Auto Speed (advanced). The setting for Max volumetric speed is there. If you do not see this option, make sure you are in the Expert mode on the top right.