Loose belts would cause a printer to malfunction and prevent proper printing. It can cause Layer shifting, Ghosting, or other print abnormalities like getting an irregular shape instead of a perfect circle when printing a cylinder. The Y-axis belt is located under the heatbed, X-axis belt moves the print head. All adjustments are done with the 2.5mm Allen key.

Checking belt tension

New procedure - Belt tuner app

Follow the instructions in the video below, to adjust the belt tightness using our belt tuner.

Old procedure

On MK3/S/+, it is possible to check the Belt Status numbers via LCD Menu -> Support -> Belt Status.

While there is not a precise ideal value, from our experience, the best approximate value is around 250 on the X-axis, and 275 on the Y-axis, with an optimal range at +-15 from these values on either axis.

The value does not represent a physical quantity, but an arbitrary number inversely proportional to the motor load. The values are with the consideration that the assembly is good and that the parts are in good condition and properly lubricated. Values may not be accurate if there are other problems.

- If your value is under (or close to) 240, you need to loosen the belt

- If your value is over (or close to) 290, you need to tighten the belt

- The values are updated every time you run the Selftest or run the belt test in LCD menu -> Calibration -> Belt test.

Other MK-series models do not have the belt status option. The clue we can give you is that the belt should sound roughly like a low bass string when plucked. It should be possible to pinch the two sides together with your thumb and index finger, but you should feel a little bit of resistance.

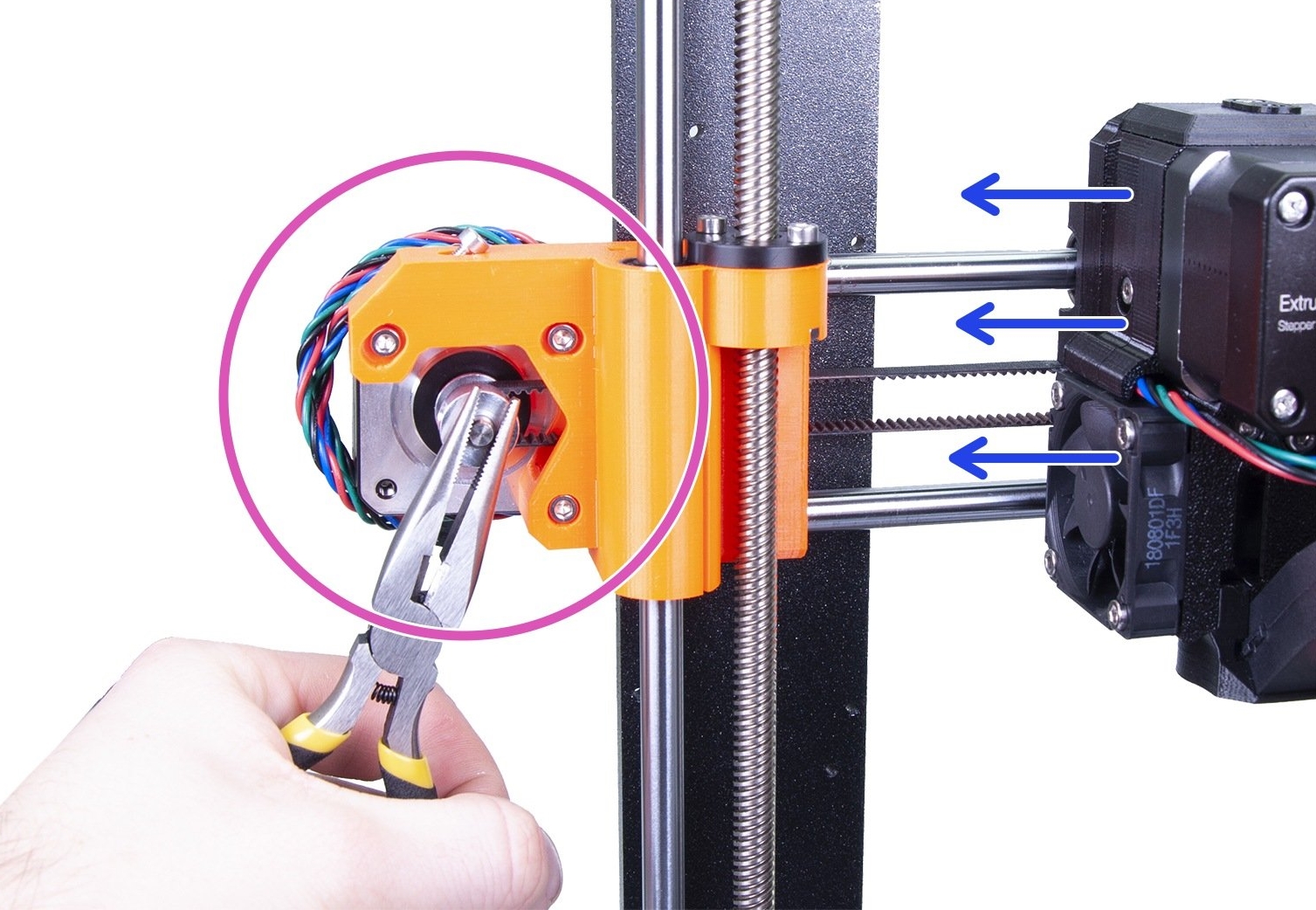

Another way is to use the technique described in this step of the assembly manual to test if the pulley is correctly tightened and if the belt is not too loose. Hold the X-axis motor shaft with pliers (take advantage of the flat part of the shaft) to fix it in place (purple circle), then try to move the extruder by hand. You should see no slack on the belt as a result of pushing on the extruder. The same procedure can be applied to test the Y-axis pulley and belt.

X-axis belt

Slight adjustments MK3S

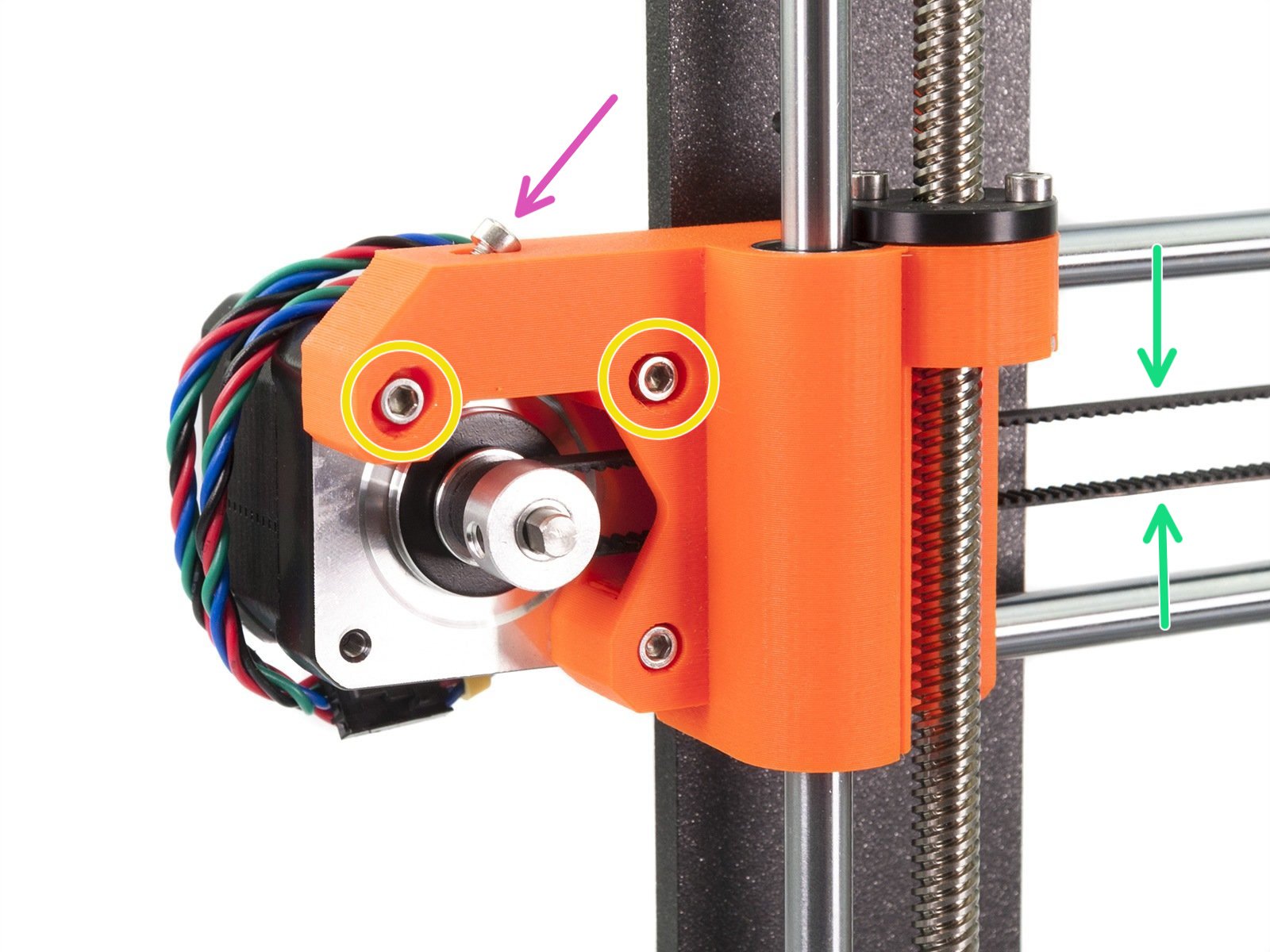

Loosen the two front-facing screws and make sure they have space to their right to move (yellow circles). While assisting with the rotation of the motor with your hand, tighten the M3x18 screw on top of the X-end-motor (purple arrow).

After each turn or two check the tension in the belt by pressing them together. For optimal performance, the belt must need some force to press together with your fingers (green arrows). Move the extruder all the way to the X-end-idler and try the belt tension in the middle of the X-axis.

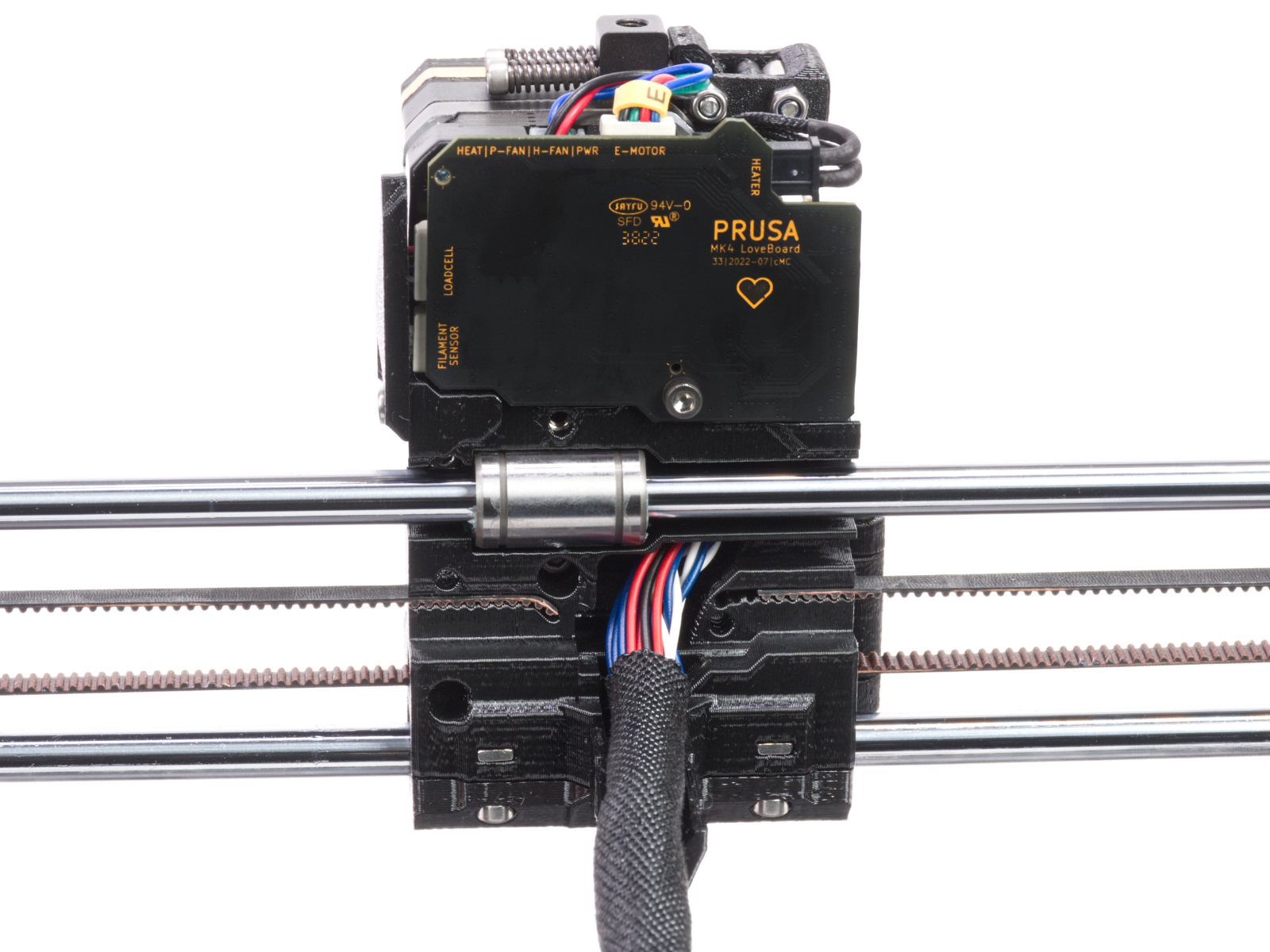

Slight adjustments MK3S+, MK3.5/S, MK3.9/S, MK4/S

- Slightly release all the screws holding the motor, otherwise, the "tensioner" won't work as the motor must be able to move (left picture).

- Using the ball end of the Allen key, start tightening the screw on the rear side of the X-end-motor, but after each turn or two check the tension in the belt (right picture).

- When you achieve optimal tension, please tighten the screws again (left picture).

|  |

Large adjustments MK3/S/+ or MK3.5/S

If a slight adjustment is not sufficient you must adjust it at the belt holder. This is found on the back of the extruder and requires a little disassembly.

First, remove the two top screws from the motor-holder to let the belt have some slack in order to easier manipulate the belt.

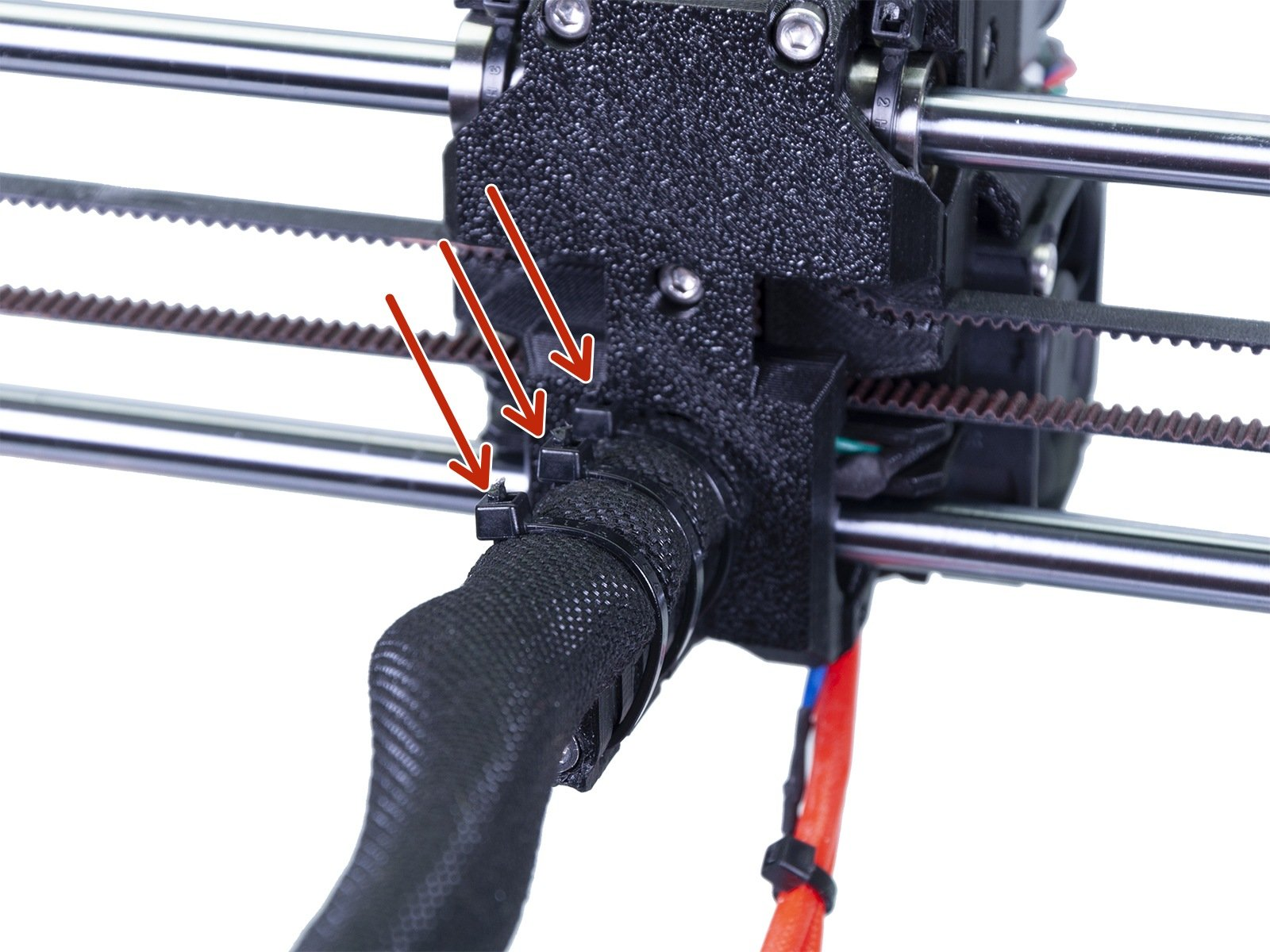

- Snip the zip-ties on the back of the extruder (red arrows), which are securing the hotend wires and the ones securing the cable wrap.

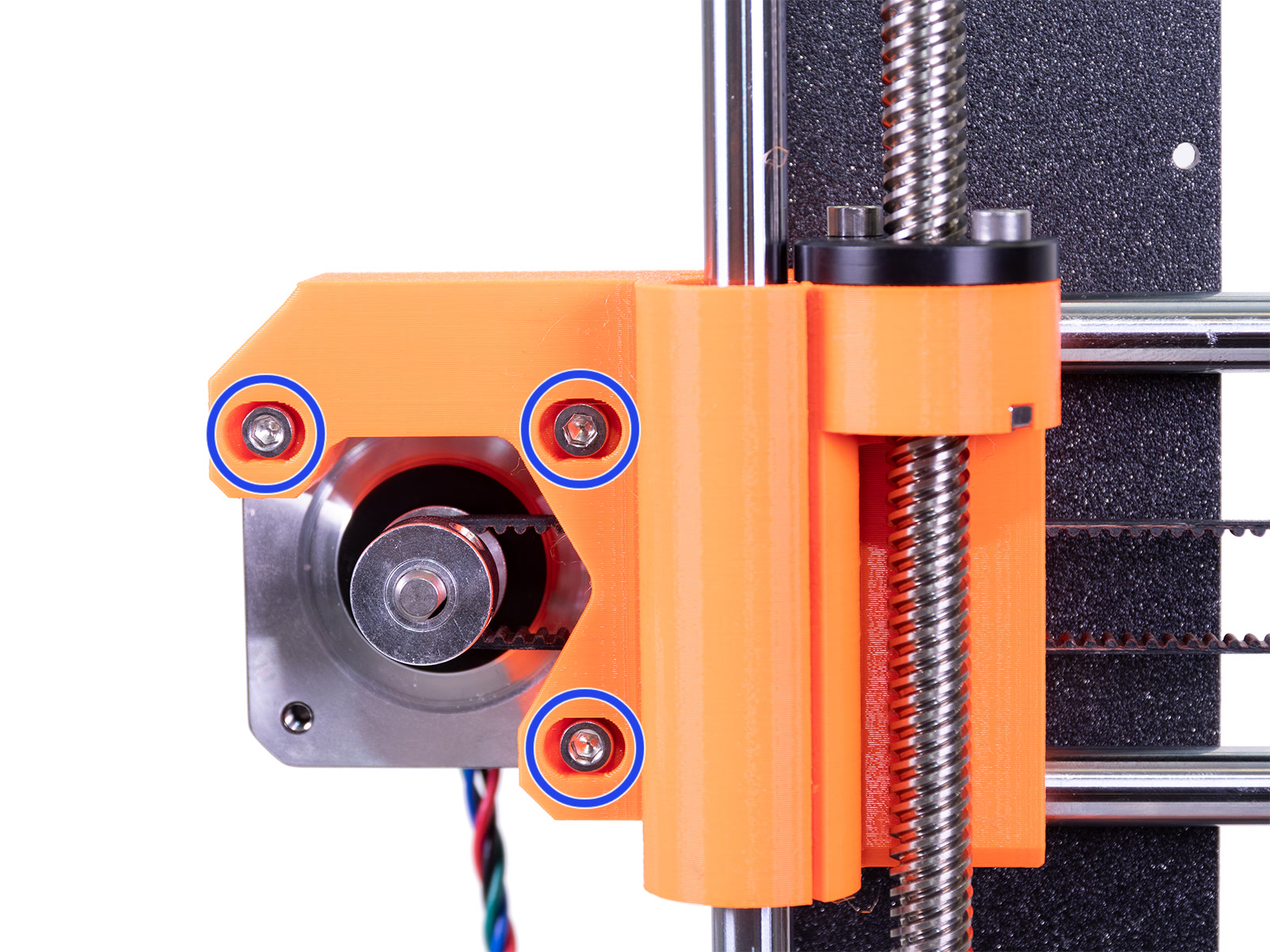

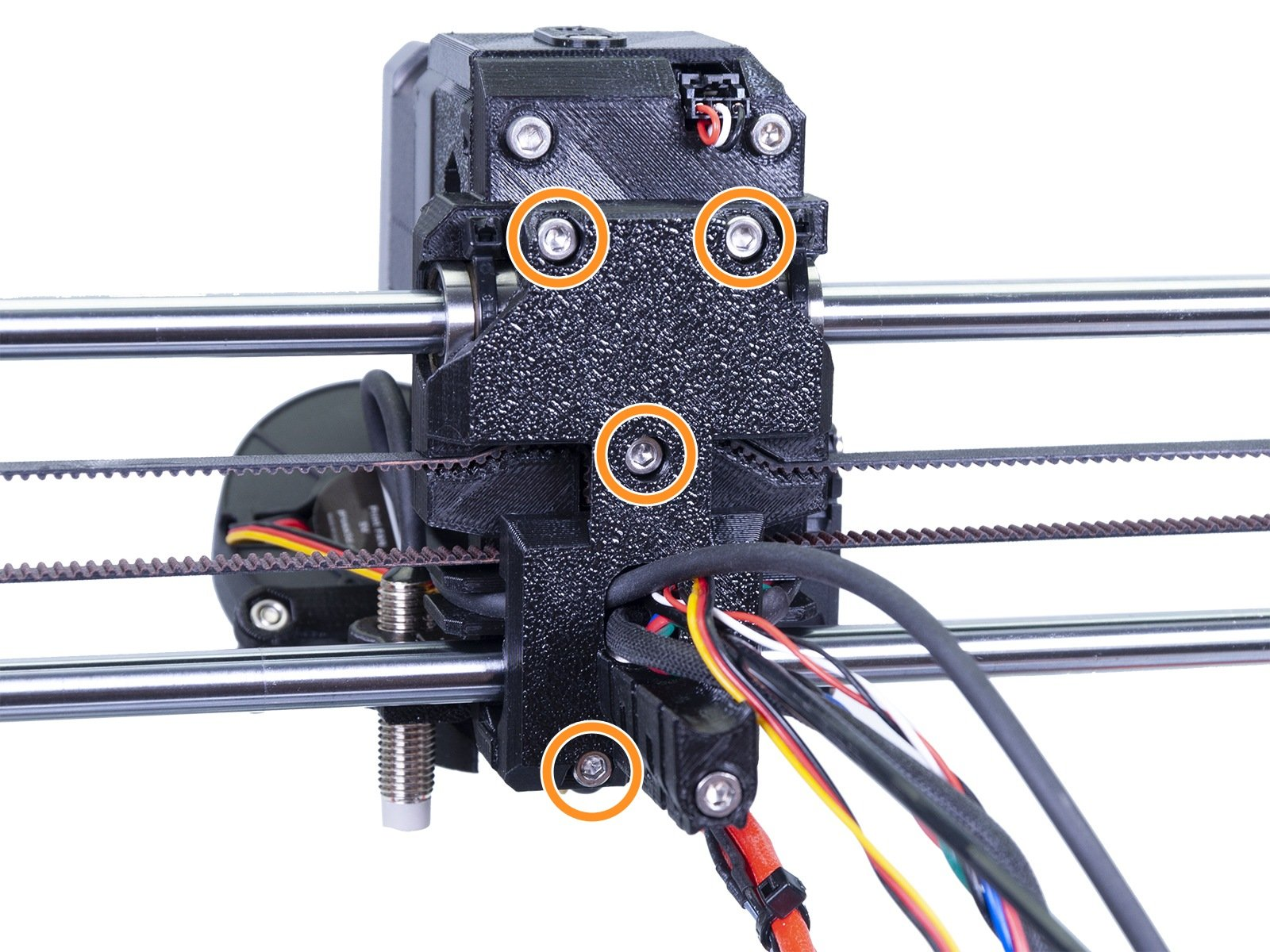

- Unscrew the 4 screws circled in the picture below.

- Carefully pull the back plate loose, making sure the wires are safe, and turn the whole plate to the left or right.

- You now have access to where you mount the belts. Put a mark on the belt with a pen or marker as close to the plastic part as possible, so you know how it was adjusted. Now, take out the belt from the mount and move it in 1-2 teeth.

- Place the back plate back on, secure the screws, starting with the center one for alignment, then put on new zip-ties.

- Re-tighten the screws on the x-motor, securing it. Adjust it tighter if needed.

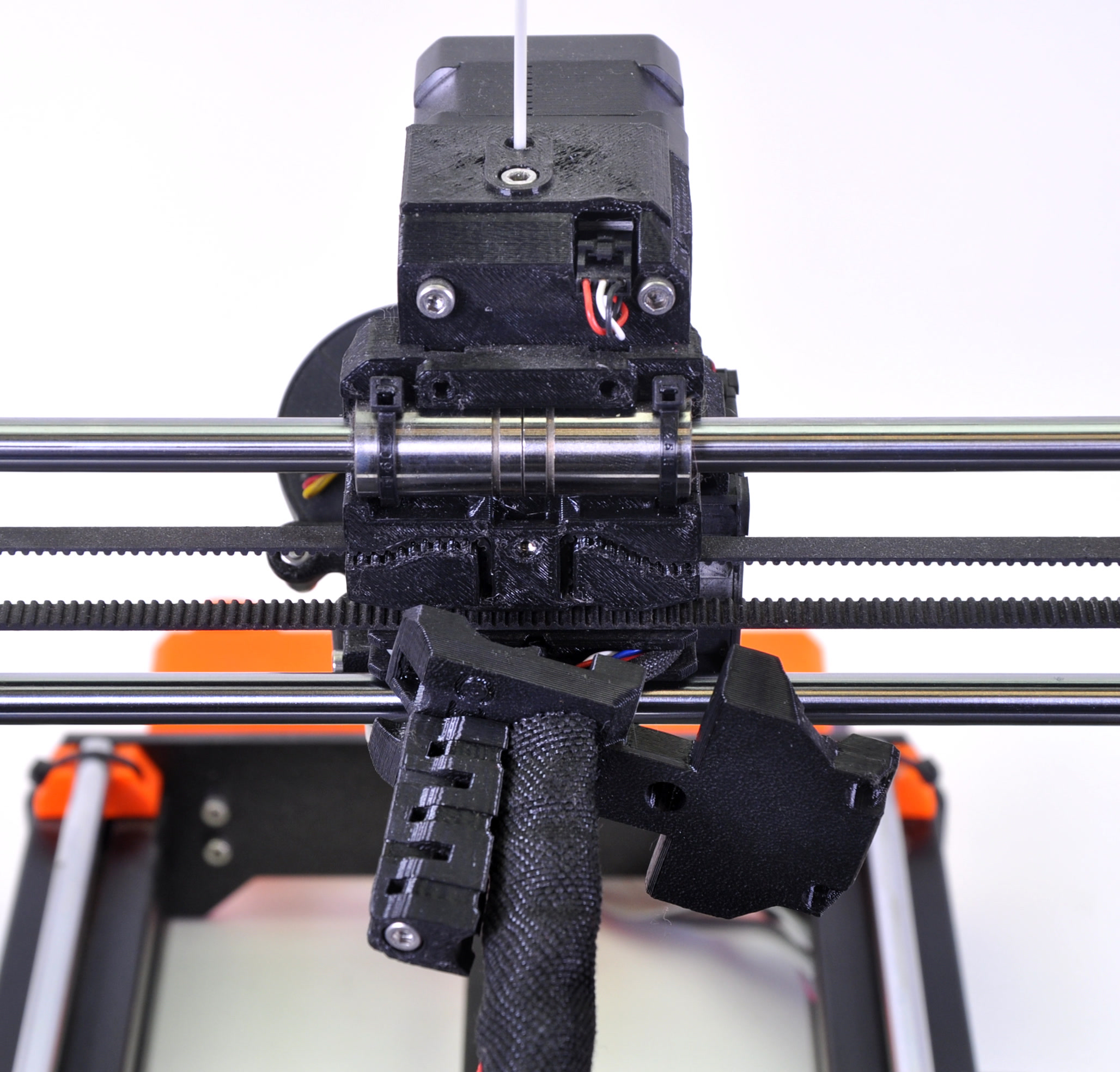

Large adjustments MK4/S, MK3.9/S

- Loosen the three indicated screws covering the X-carriage. Carefully take out the X-cover-back.

- You now have access to where you mount the belt. Put a mark on the belt with a pen or marker as close to the plastic part as possible, so you know how it was adjusted. Now, take out the belt from the mount and move it in 1-2 teeth.

Y-axis belt

Slight adjustments

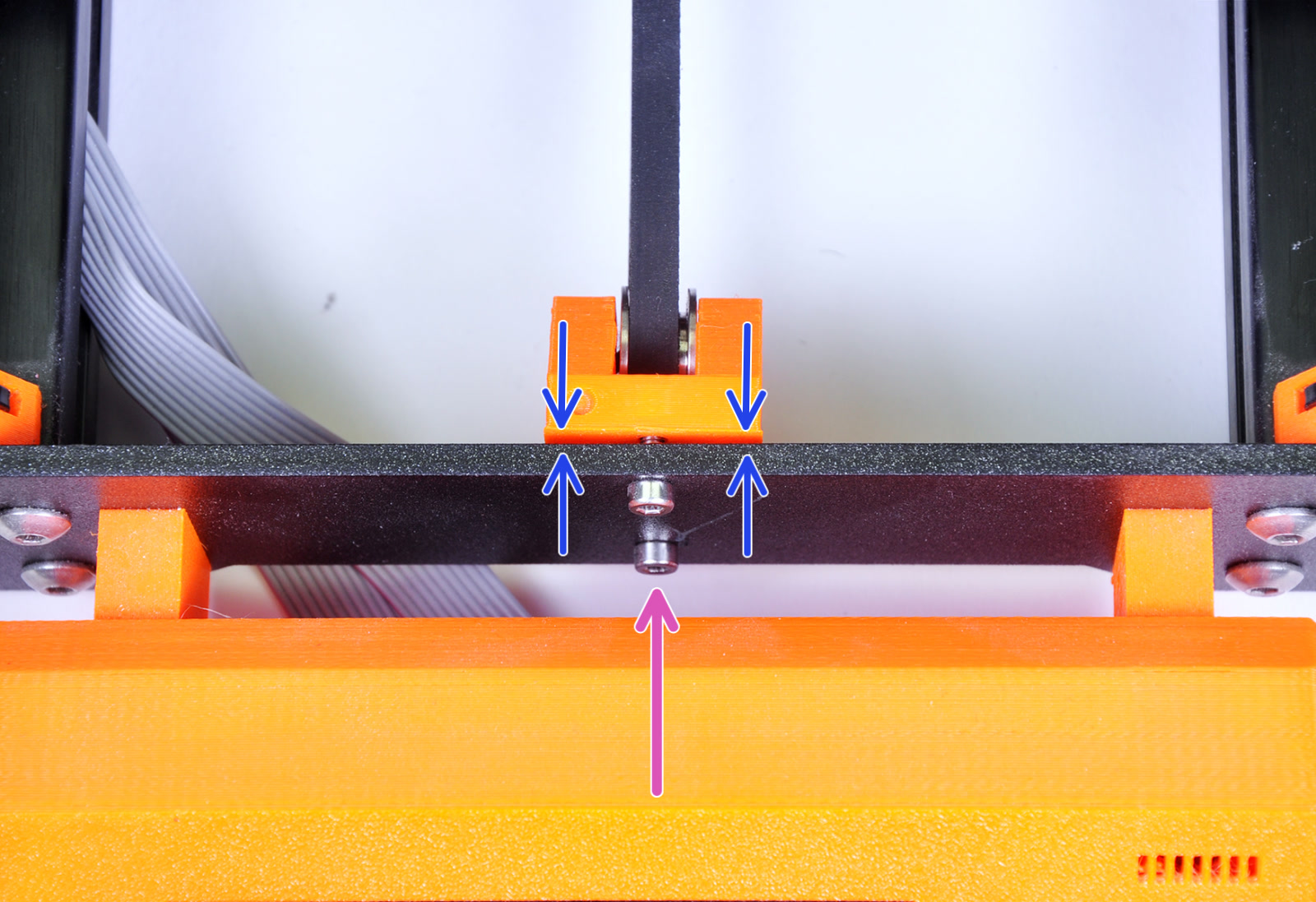

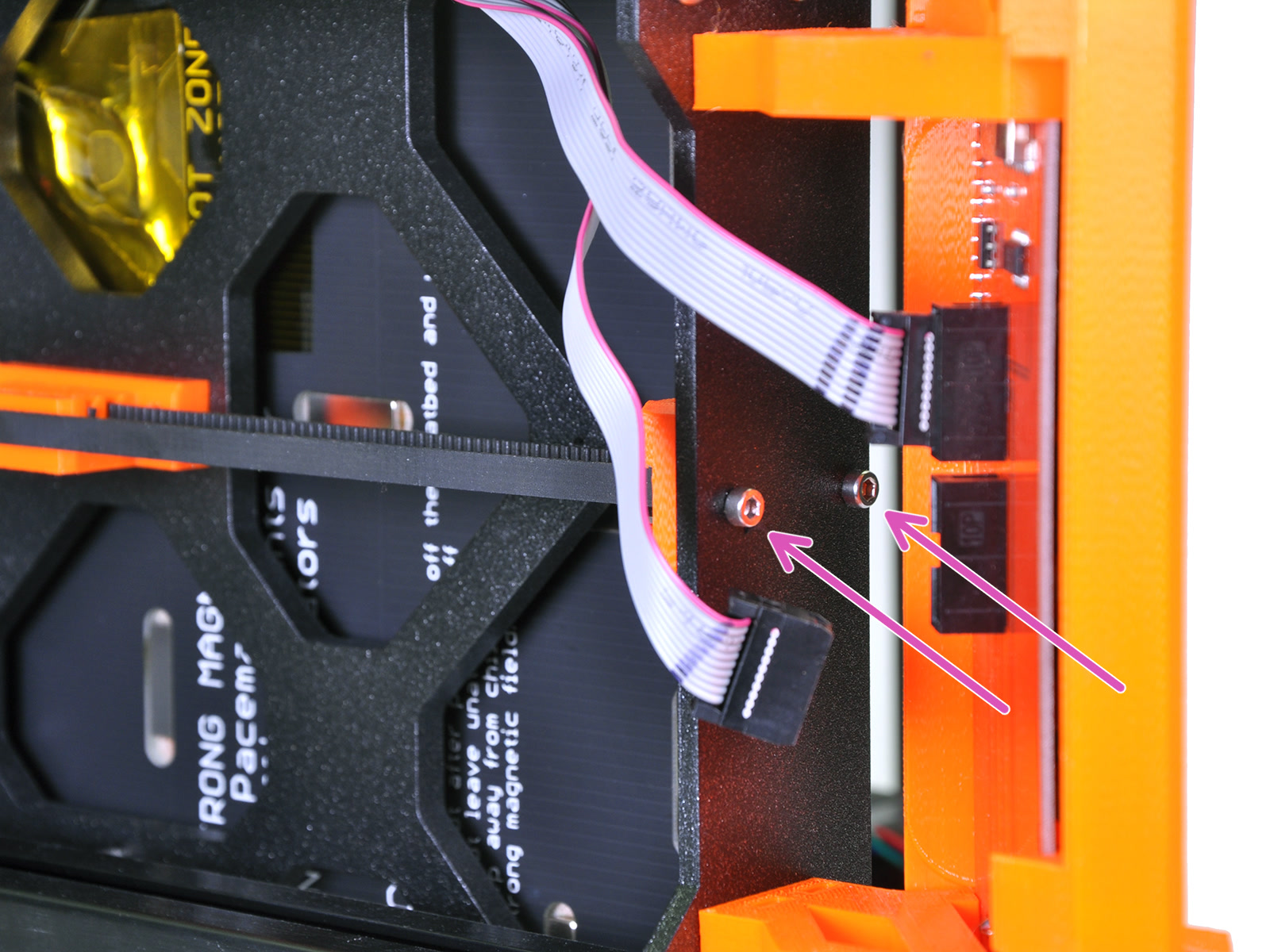

On the front plate of the printer's frame, behind the LCD module, you will find the printed Y-axis belt idler. This is held by two M3X10 screws (purple arrow), going through the front plate.

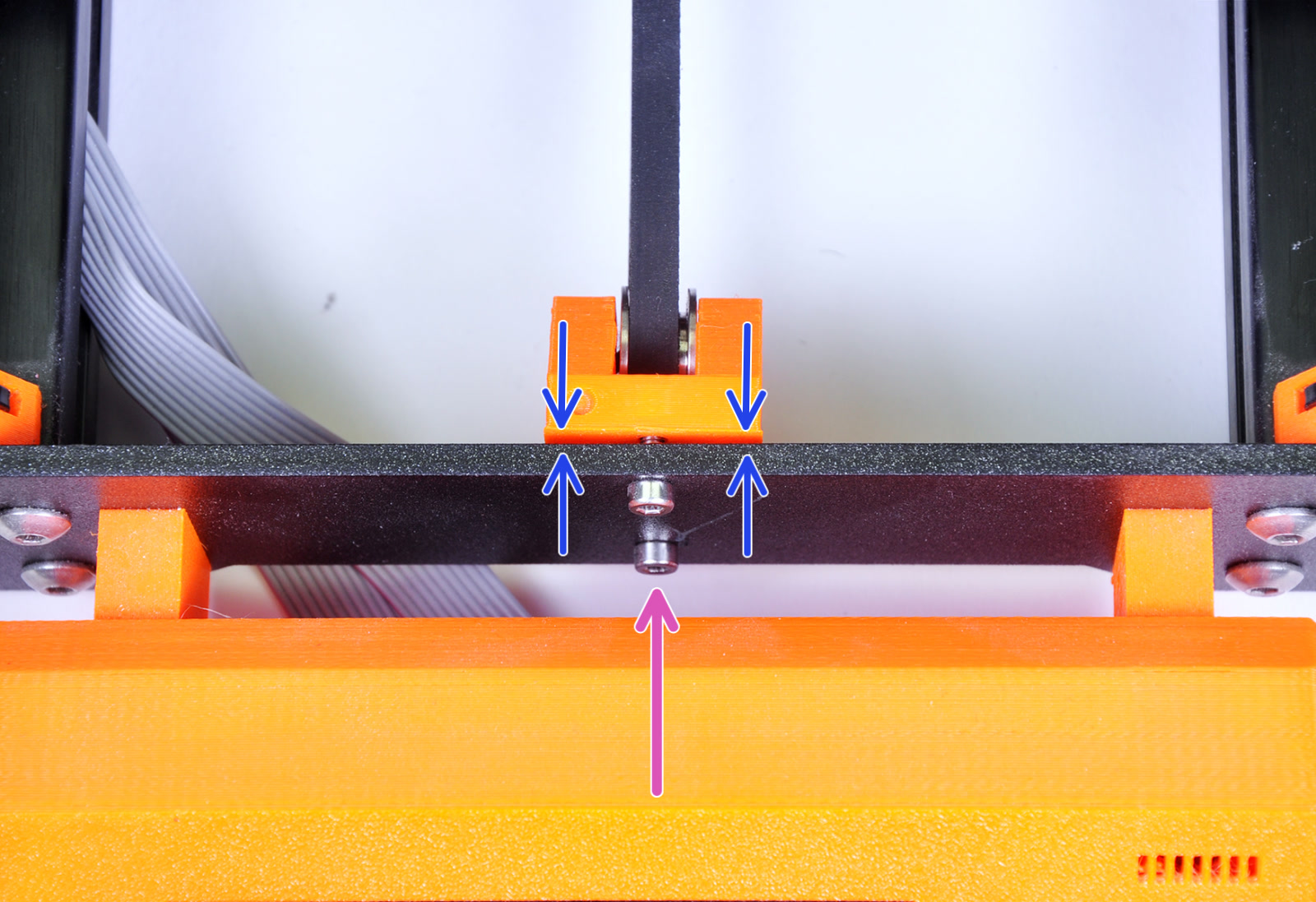

If you have a gap between the idler part and the front plate of the frame (blue arrows) you can tighten the belt by using your 2.5 mm Allen key to turn the screws clockwise (purple arrow), closing the gap.

The easiest way to access the screws is from below, by moving the printer to the edge of its table, with the LCD module sticking out. You now have access to the bolts from below the LCD module.

Large adjustments

If a slight adjustment is not sufficient you must adjust it at the belt holder. There are two main types of the Y-axis belt holder, one adjustable and one fixed. The adjustable belt holder was introduced in the first quarter of 2019, with the S-upgrade for the Original Prusa MK3, and is also featured on the Original Prusa MK4. Adjustments for this are explained in 'Method 1'. For an earlier Original Prusa MK3, follow 'Method 2', for the fixed belt holder.

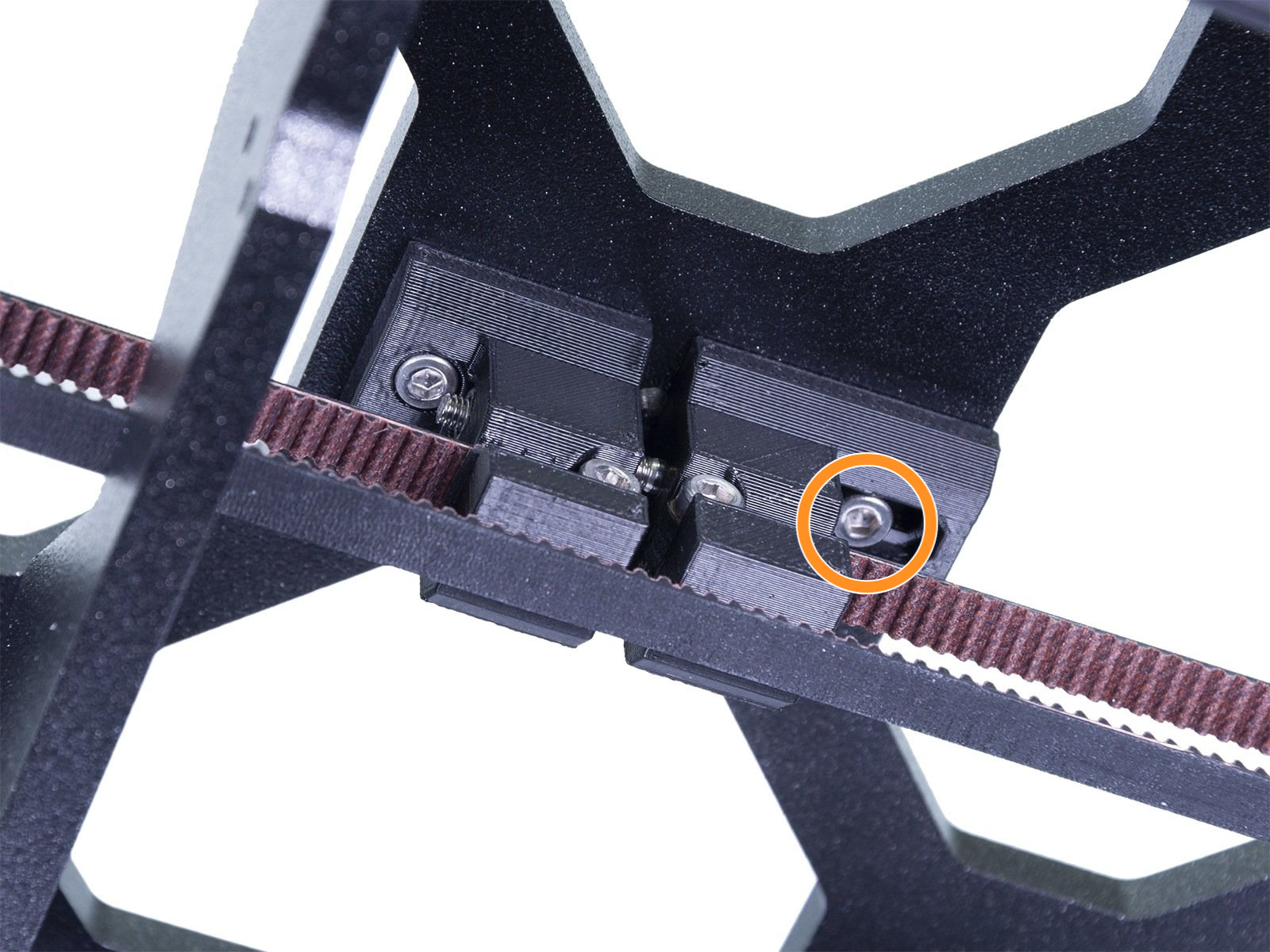

Method 1 - Adjustable belt holder

- Unplug the printer and lay it over on the side of the PSU.

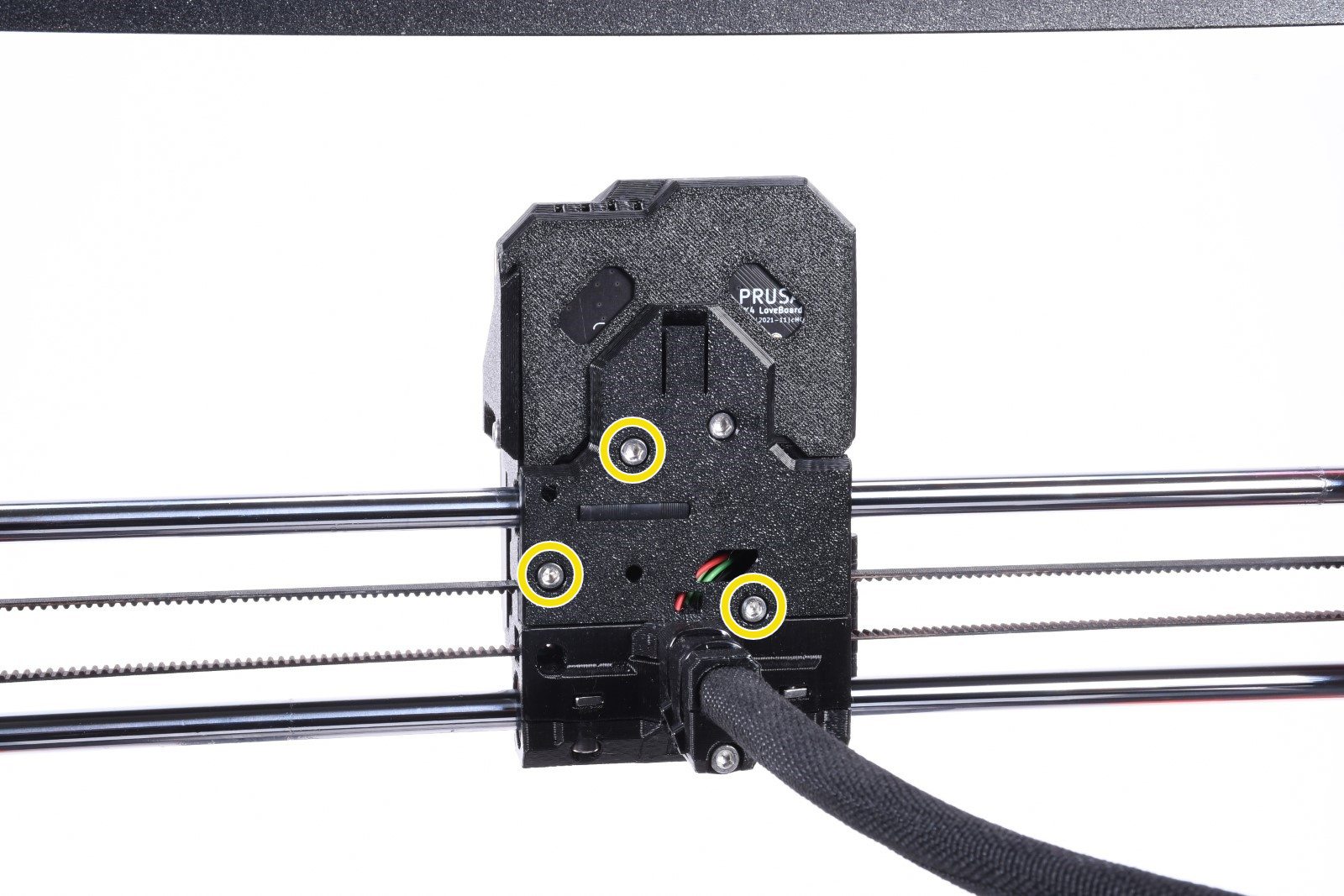

- Below the bed carriage, you will find the belt holder. Loosen the right screw by turning it counterclockwise (orange circle left picture).

- Turn the screw going through the two halves of the belt holder (purple arrow right picture). Turn clockwise to tighten the belt, moving the two halves together (blue arrows).

- When at the correct tension, secure the right half of the belt holder again by turning the screw from step 2 clockwise (orange circle left picture).

|  |

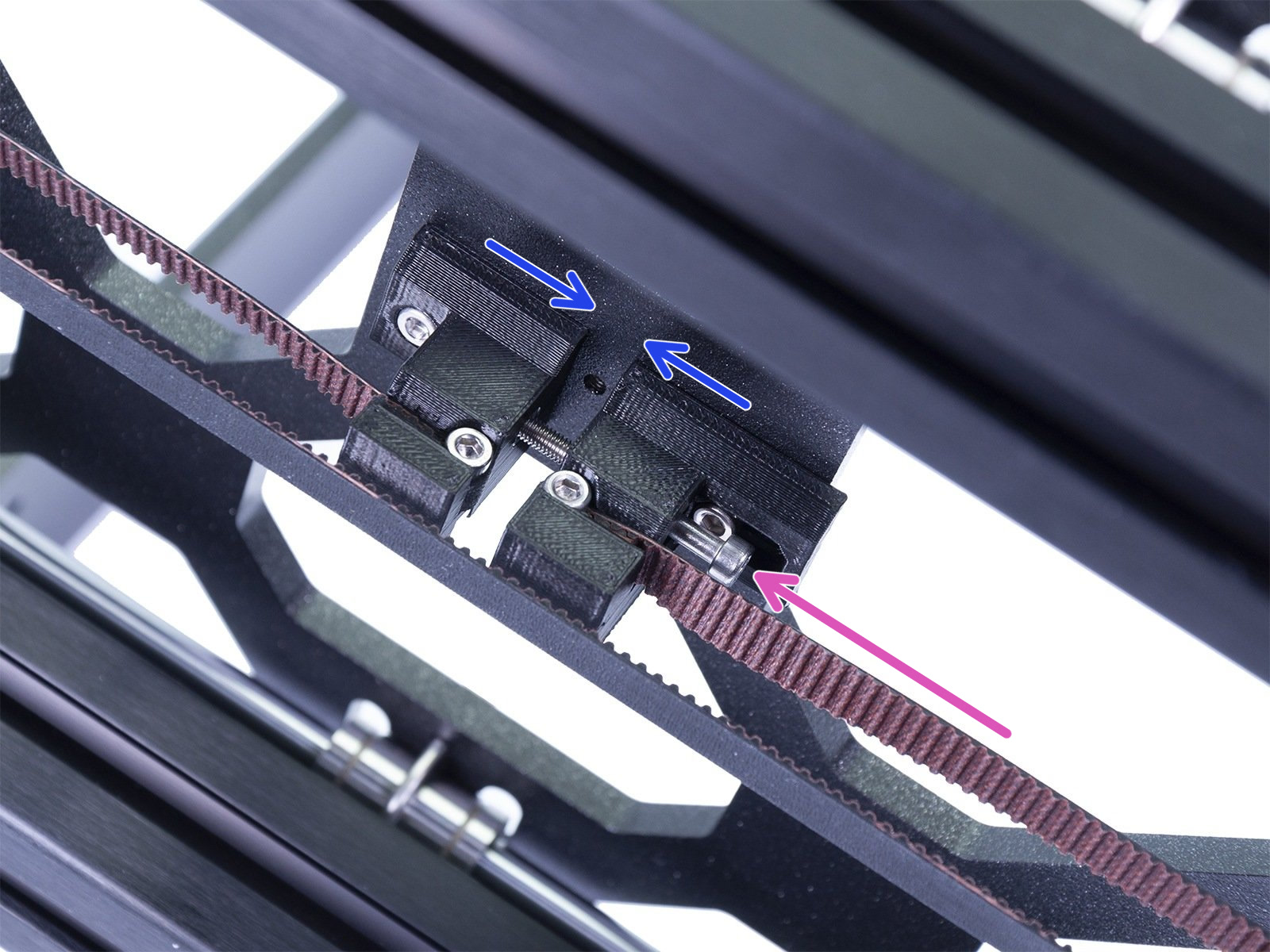

Method 2 - Fixed belt holder

- Unplug the printer and lay it over on the side of the PSU.

- Detach the belt-idler in order to easier manipulate the belt (purple arrows). Detaching the idler completely may not be necessary, but will make it easier to adjust the belt in the next step.

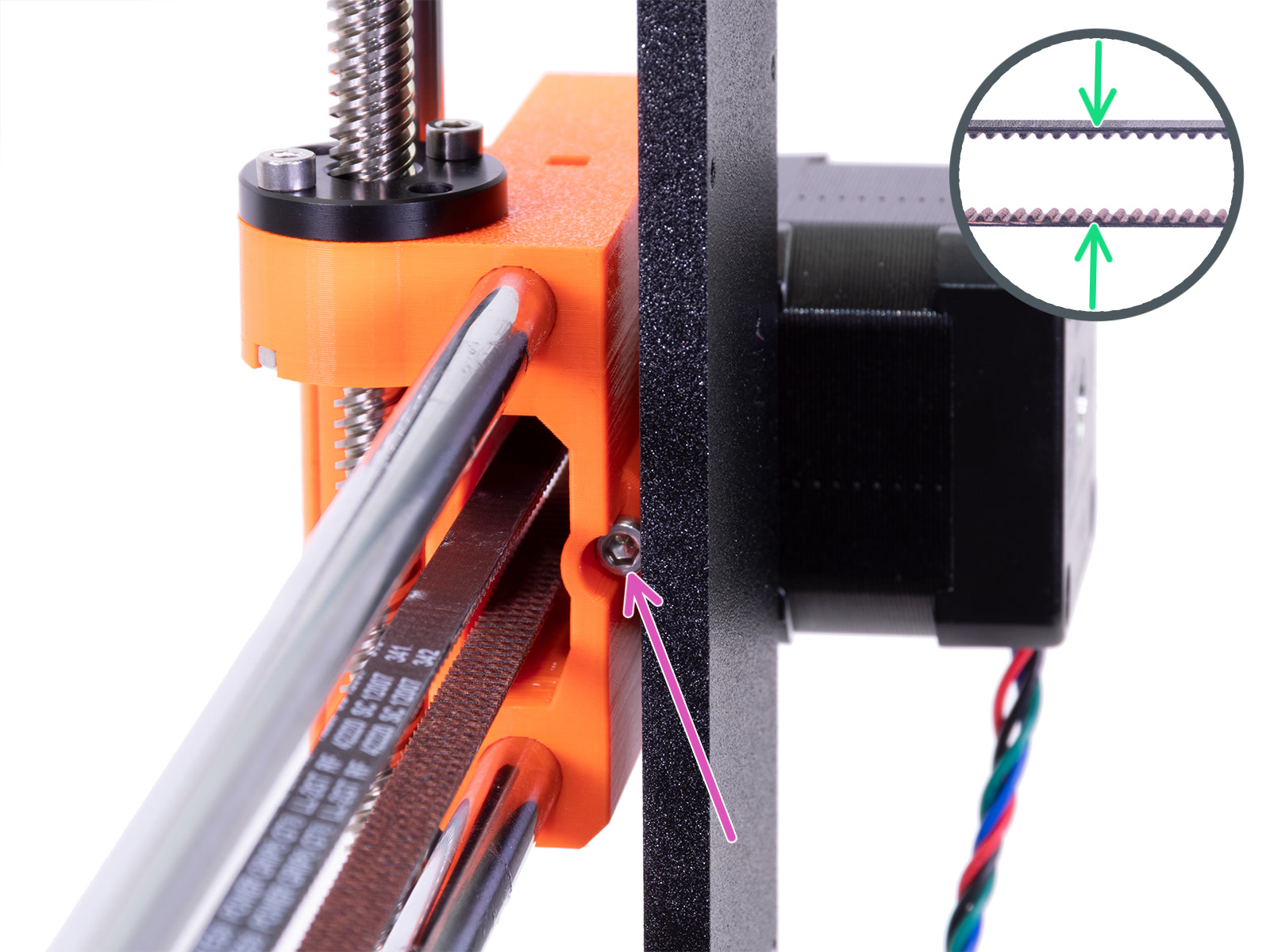

- Set a mark on the belt so you know how much you are moving it. Now take out the belt of the top slot, and move it in 1-2 teeth (blue arrow) before pushing it back into the slot (green arrows).

Your belt mount may look slightly different, being another iteration, but the procedure remains the same.

Your belt mount may look slightly different, being another iteration, but the procedure remains the same.

- Re-attach the belt-idler with its two M3x10 screws through the frame (purple arrow). Leave a gap with the frame, for slight adjustments (blue arrows).

40 comments

Finally, the adjustment procedure should be modified to: First set the large adjustment such that you have a 2-3mm(?) gap between the idler and the frame, then fine tune using the fine tuning procedure.

Thank you good sir.

This tool was pretty handy, though I did have to hover over the pause button with my mouse and carry the mouse over to the printer while I strummed.

Comparing the results from the belt tension measurement app and the printer's built-in belt test, I found discrepancies, which is quite confusing.

Belt tension measurement app results: X-axis 110~130 / Y-axis 140~180 → Slightly/Very tight

Printer belt test results: X-axis 240~260 / Y-axis 260~275 → Similar to the recommended values on the website (X: 250 / Y: 275)

I understand that belt tension naturally loosens over time with printer usage. However, since the app indicates that the tension is still tight, should I follow the app's values and loosen the belt tension?