The Input Shaper functionality on the Prusa CORE One/+, and on the Original Prusa MK4/S, MK3.9/S, and MK3.5/S can be calibrated using an optional accelerometer.

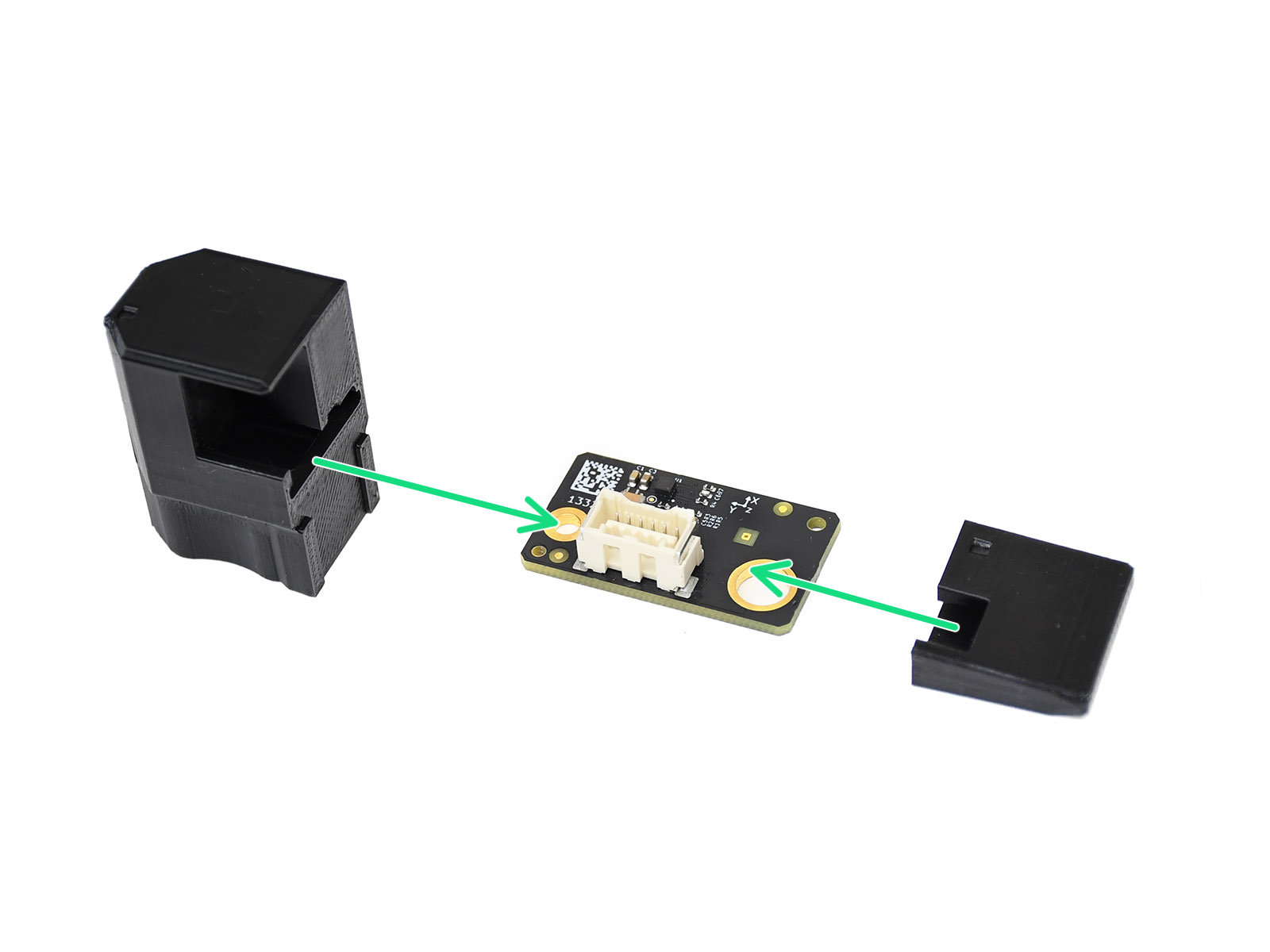

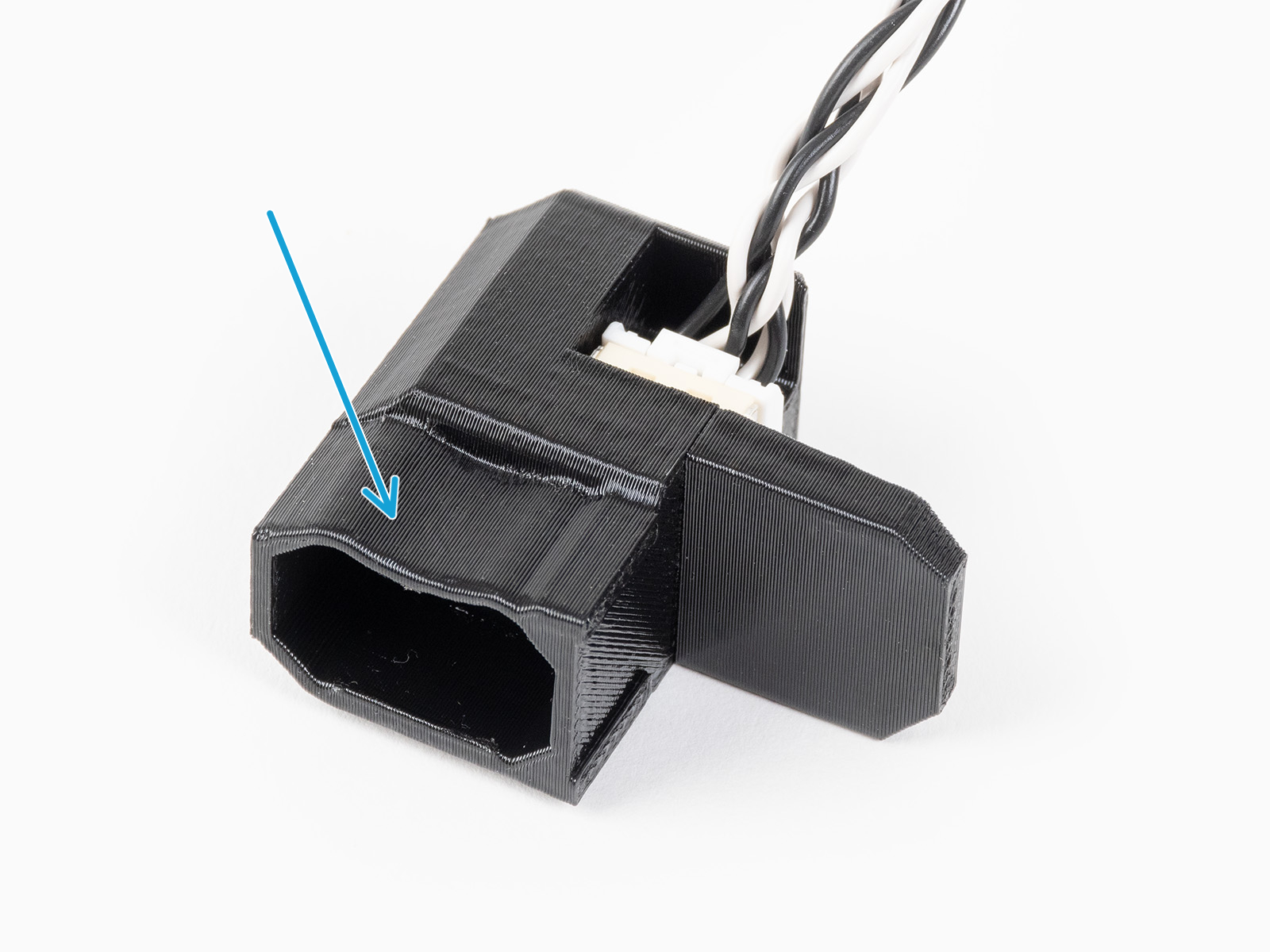

The accelerometer assembly consists of a small PCB enclosed in a printed cover, which connects to the printer. Please note that using the accelerometer requires partial disassembly of the printer.

The input shaper is pre-calibrated from the factory, so this calibration is usually unnecessary on a stock printer. However, if you've made any modifications to the printer hardware, it may be beneficial to recalibrate the settings using the accelerometer.

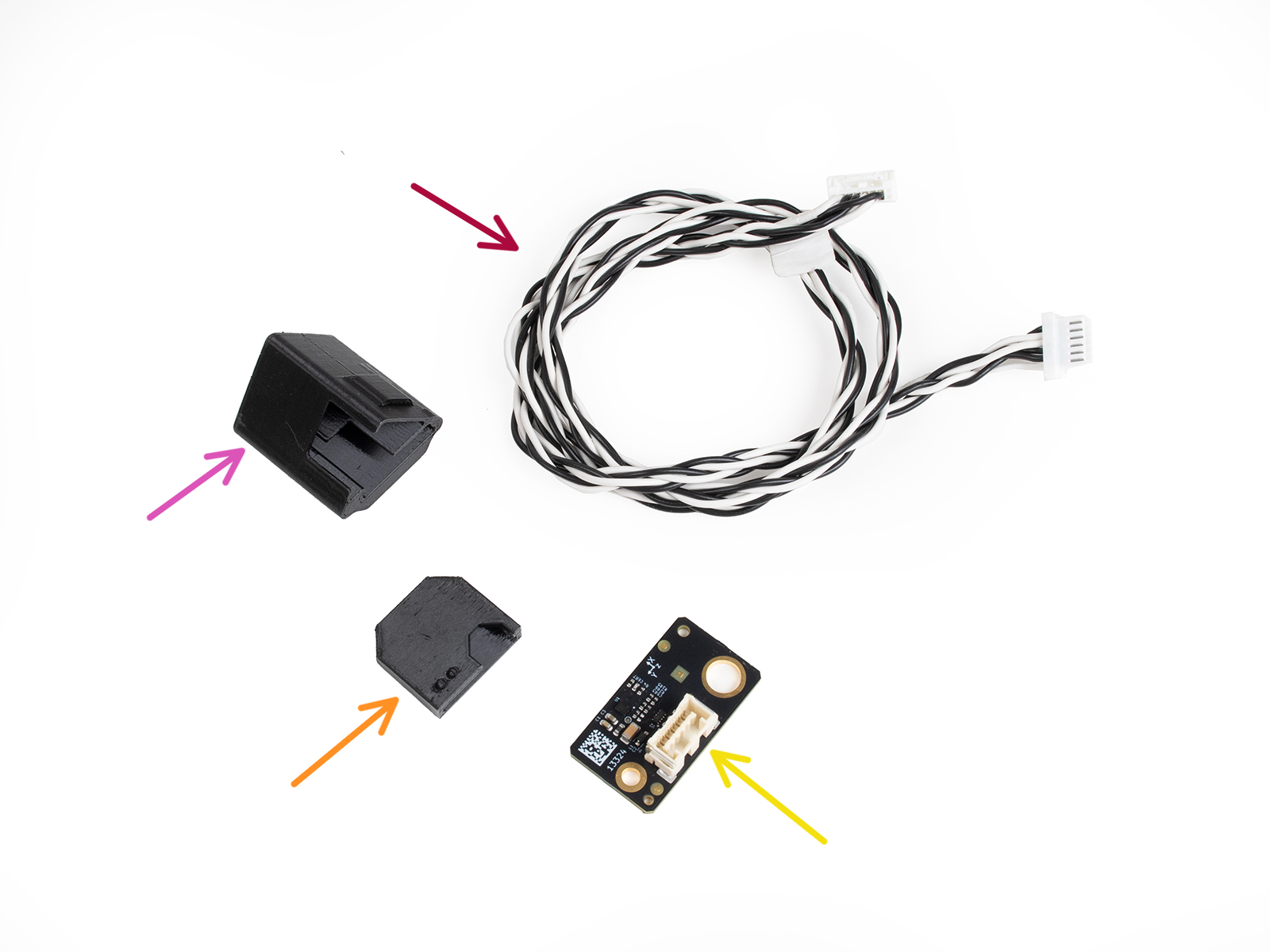

Contents of the accelerometer set.

Contents of the accelerometer set.

|  |

| Assembling accelerometer for CORE One/+, MK4/S, MK3.9/S. | Assembled accelerometer for CORE One/+, MK4/S, MK3.9/S. |

|  |

| Assembling accelerometer for MK3.5/S | Assembled accelerometer for MK3.5/S |

Prusa CORE One/+

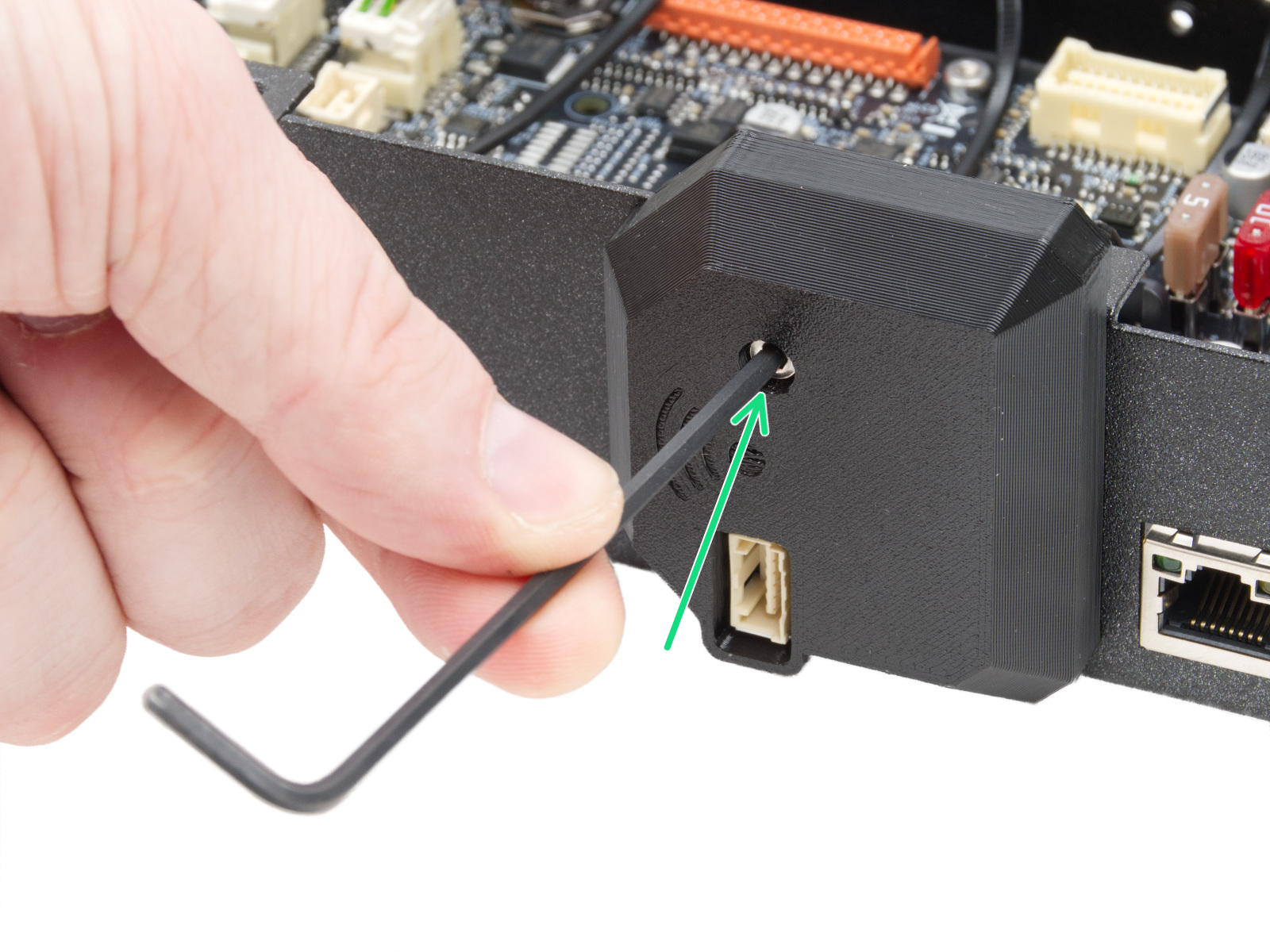

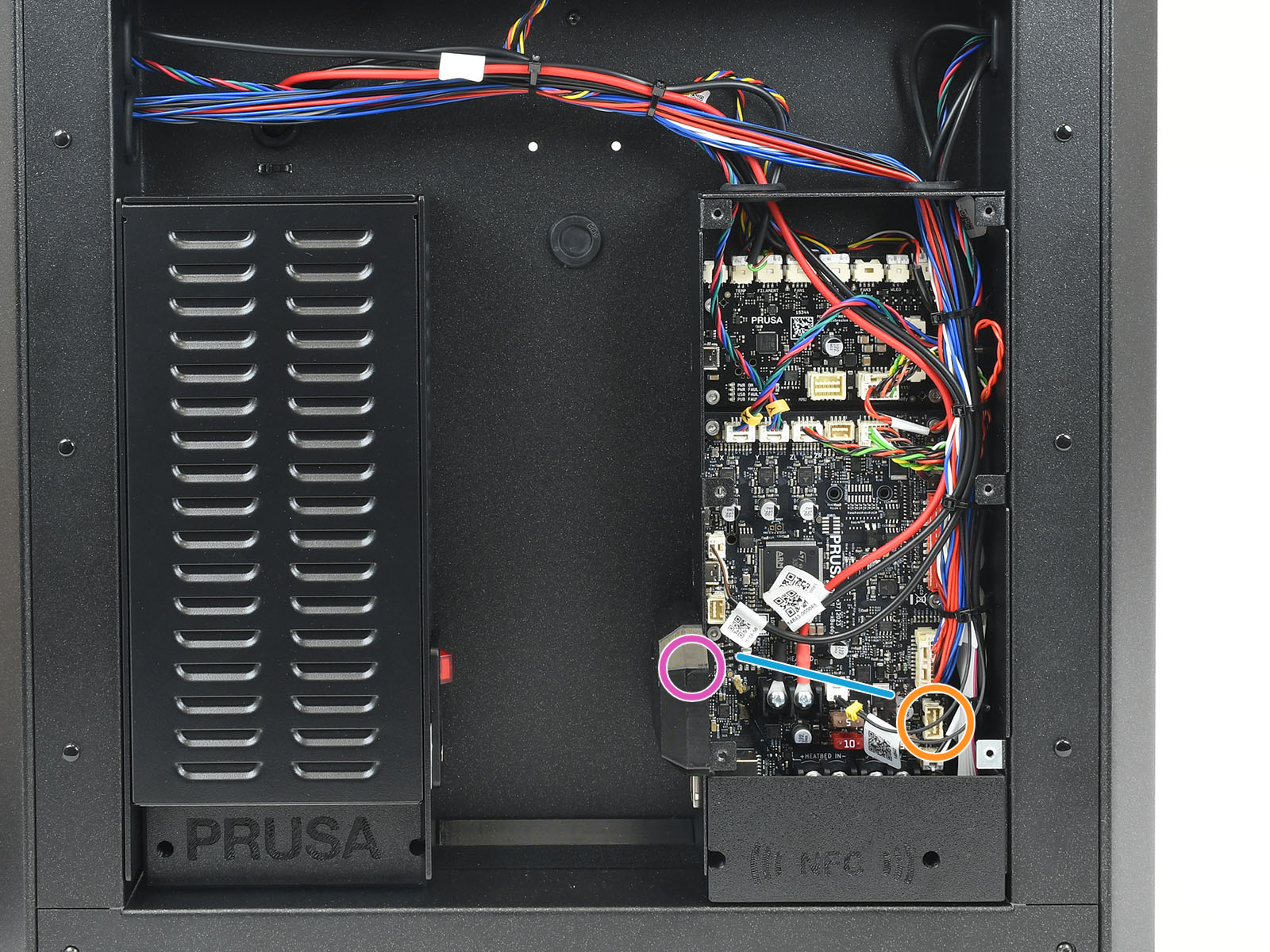

Temporarily remove the Wi-Fi board cover, by loosening its M3x12 screw.

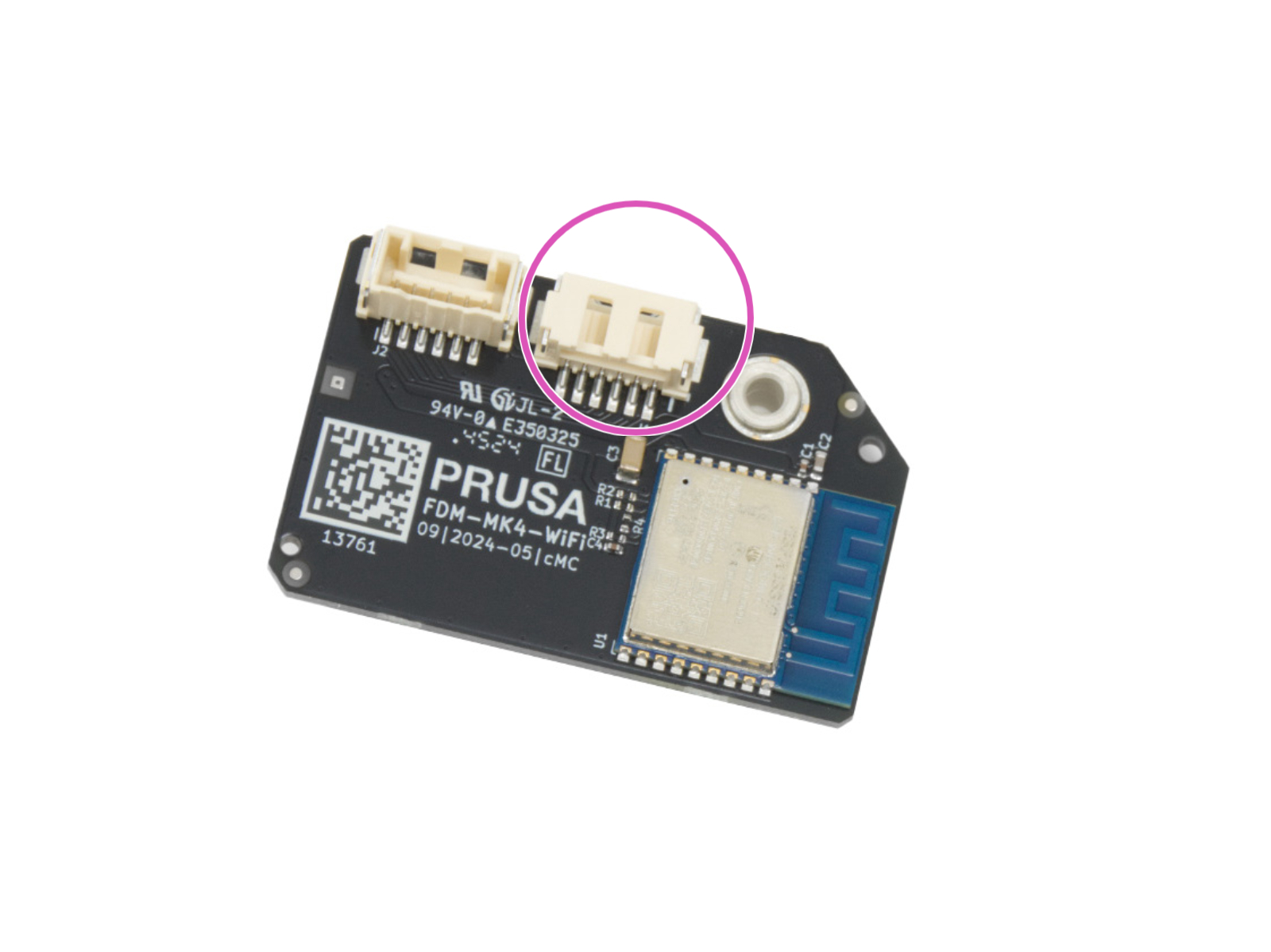

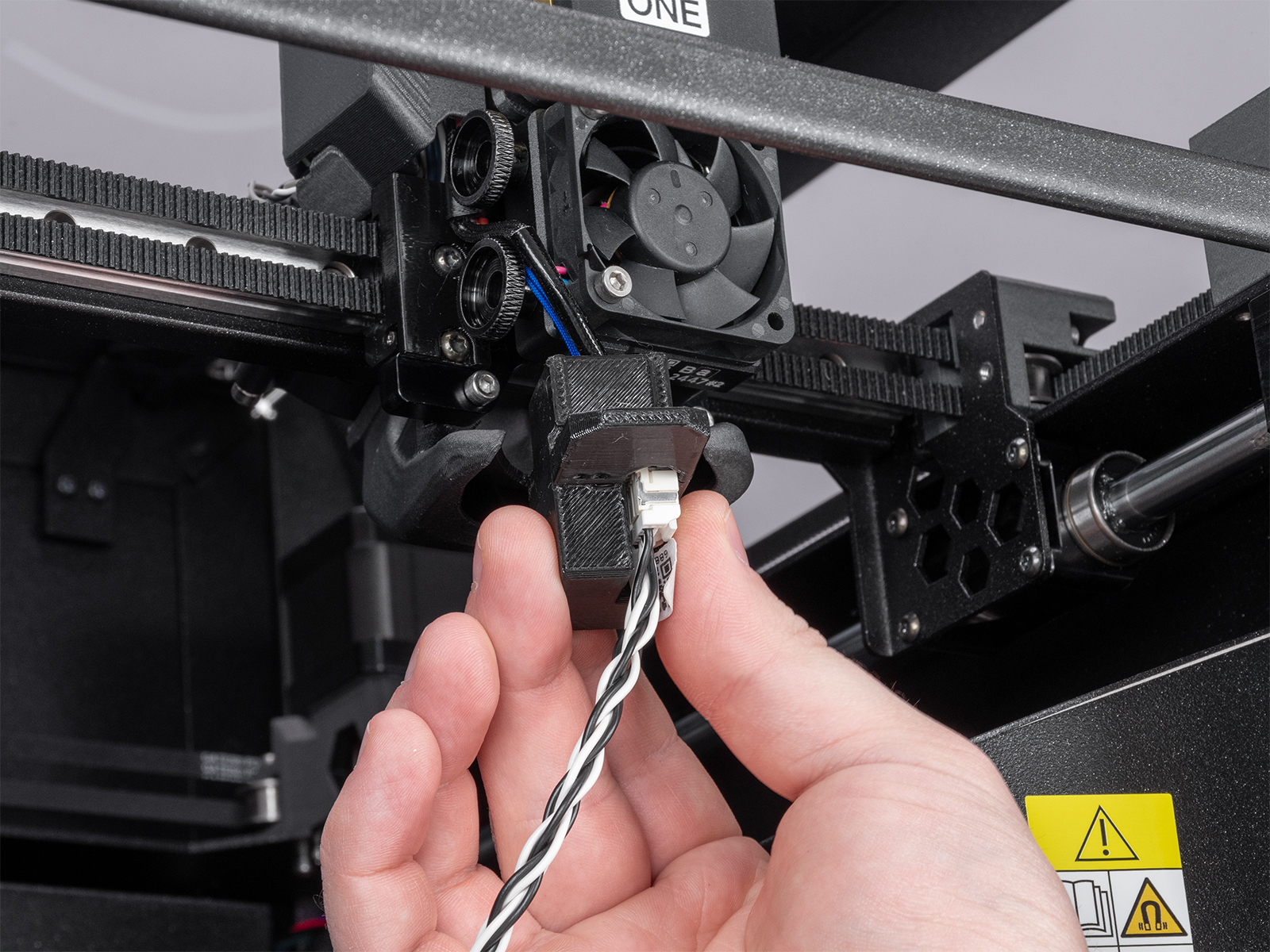

Connect the jumper cable between the xBuddy connector and the Wi-Fi module connector.

|  |

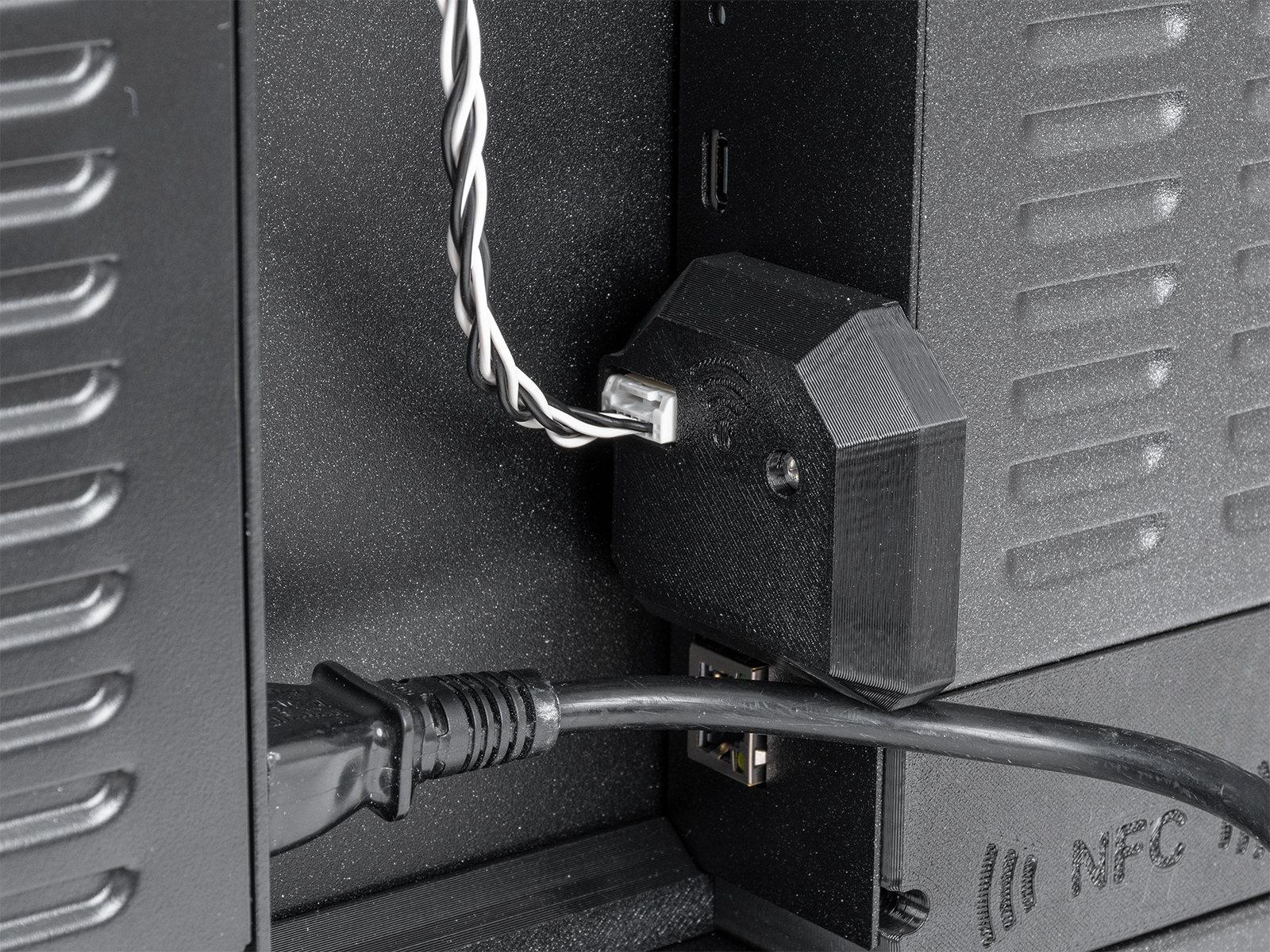

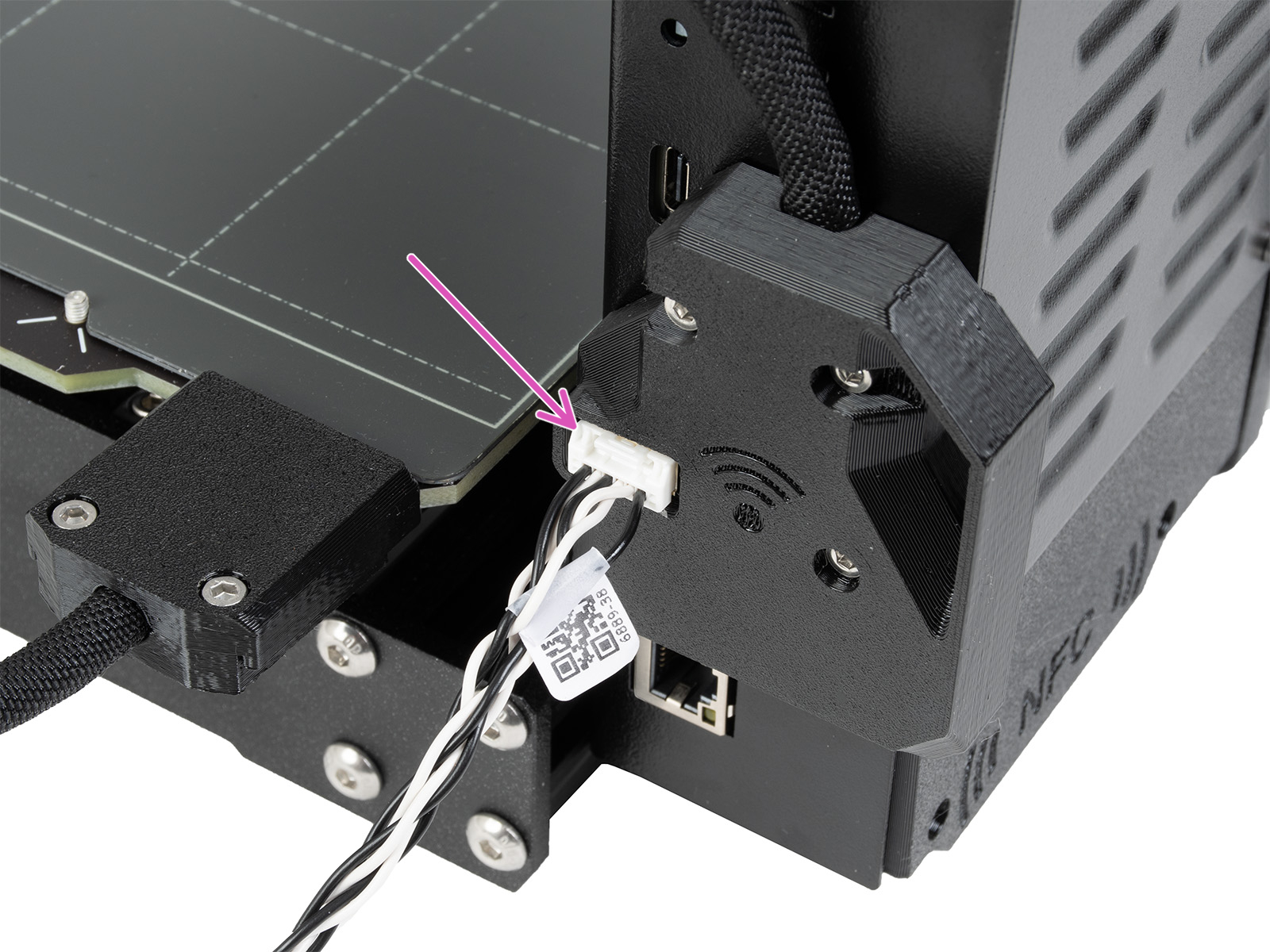

Remove the circular cover on the back. Then, route the accelerometer cable in the hole.

|  |

Connect the accelerometer cable to the connector at the back of the printer.

Original Prusa MK4/S, MK3.9/S

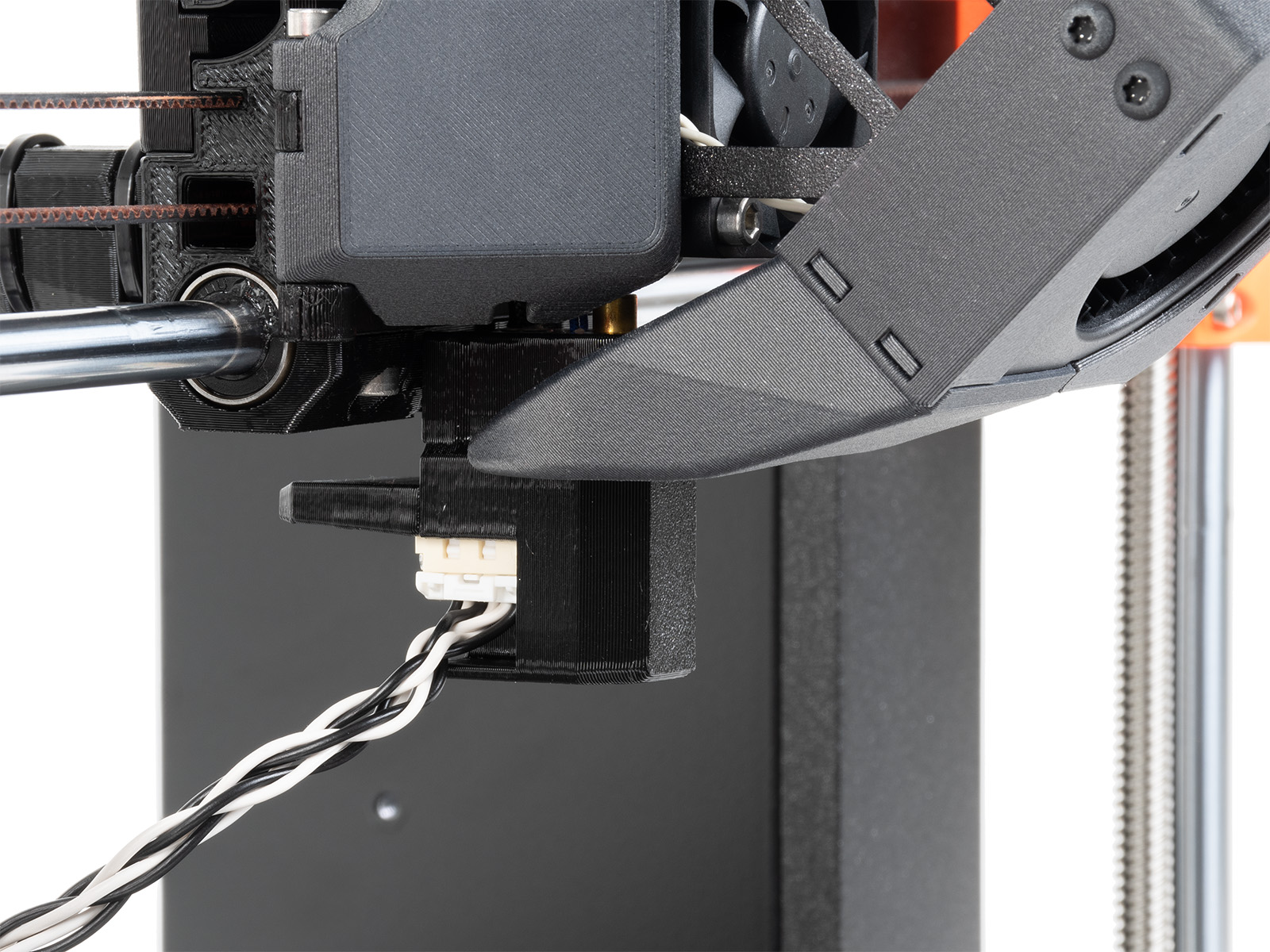

On MK4S and MK3.9S, connect the accelerometer to the dedicated port on the xBuddy board.

Alternatively, you can install a short jumper cable between the xBuddy and the Wi-Fi module on the back of the printer. Then, you can connect the accelerometer to the connector on the back of the printer.

On MK4 and MK3.9, connect the cable to the accelerometer's PCB and attach the printed covers. The accelerometer connects directly to the dedicated port on the xBuddy board.

|  |

Accelerometer connection on MK4S and MK3.9S

Original Prusa MK3.5/S

For MK3.5 or MK3.5S, please visit the dedicated guide.

Calibration

The accelerometer is used to calibrate the input shaper parameters. You can launch the calibration from the LCD Menu -> Settings -> Input Shaper -> Calibration.

X-axis

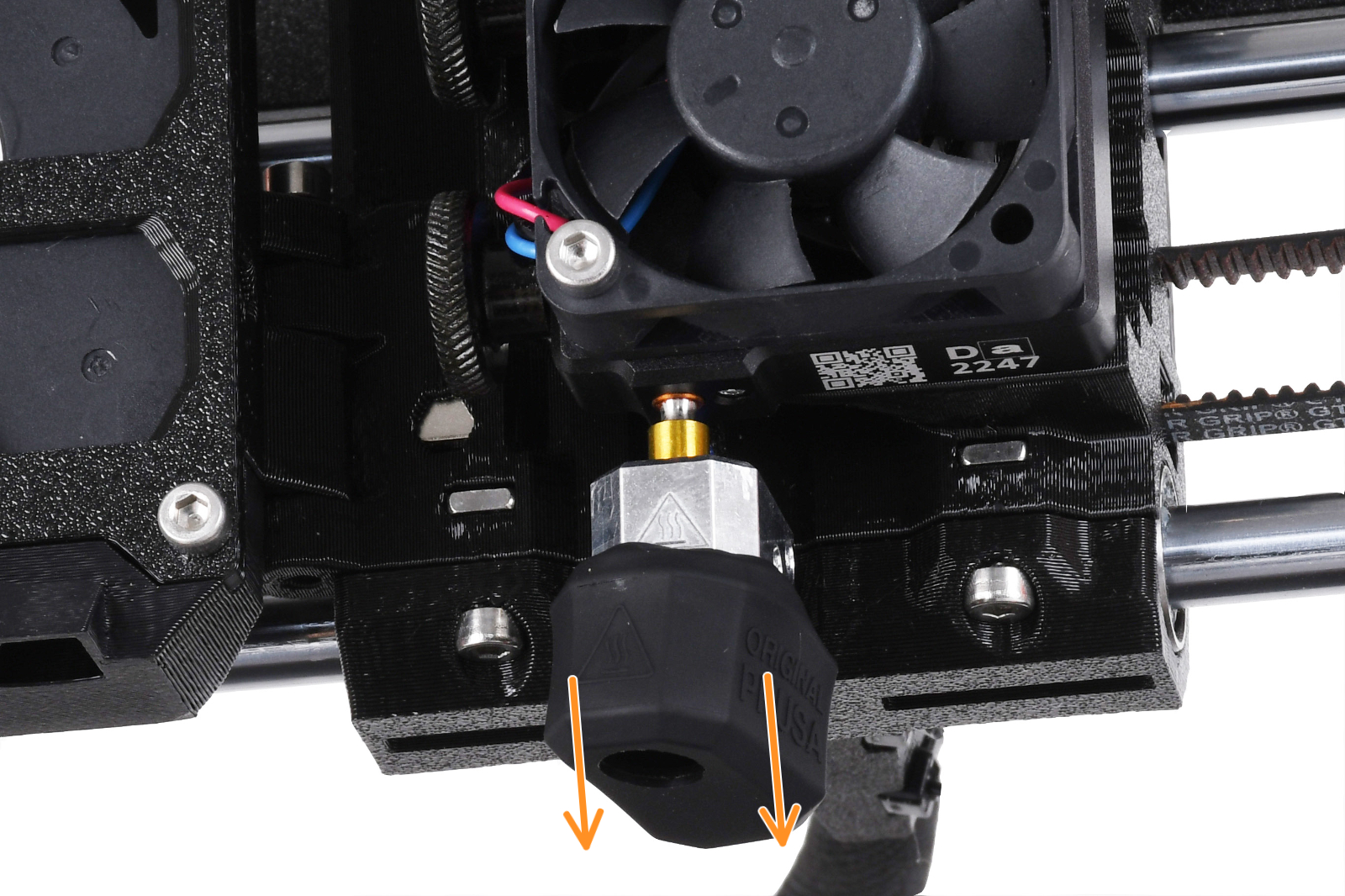

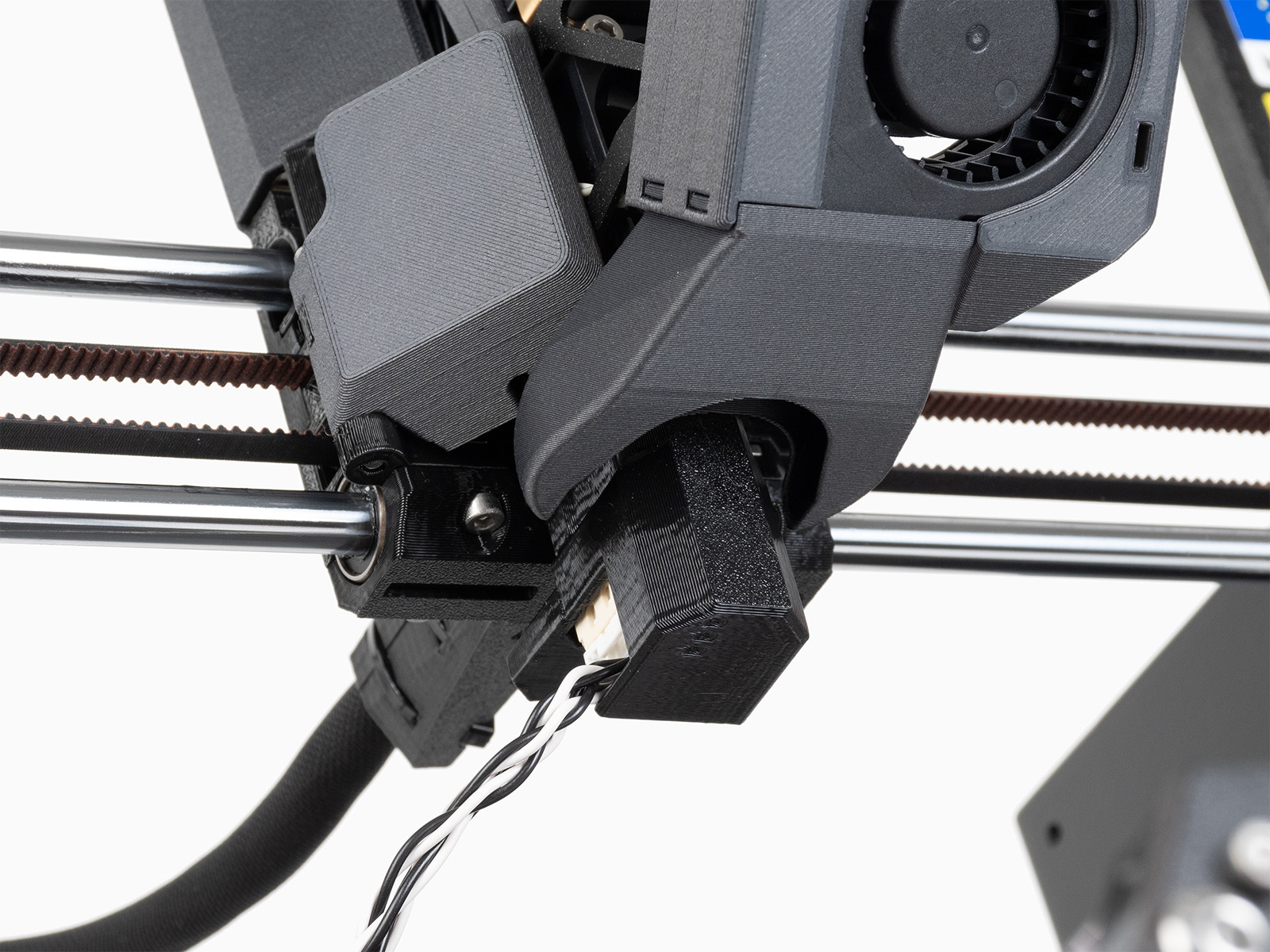

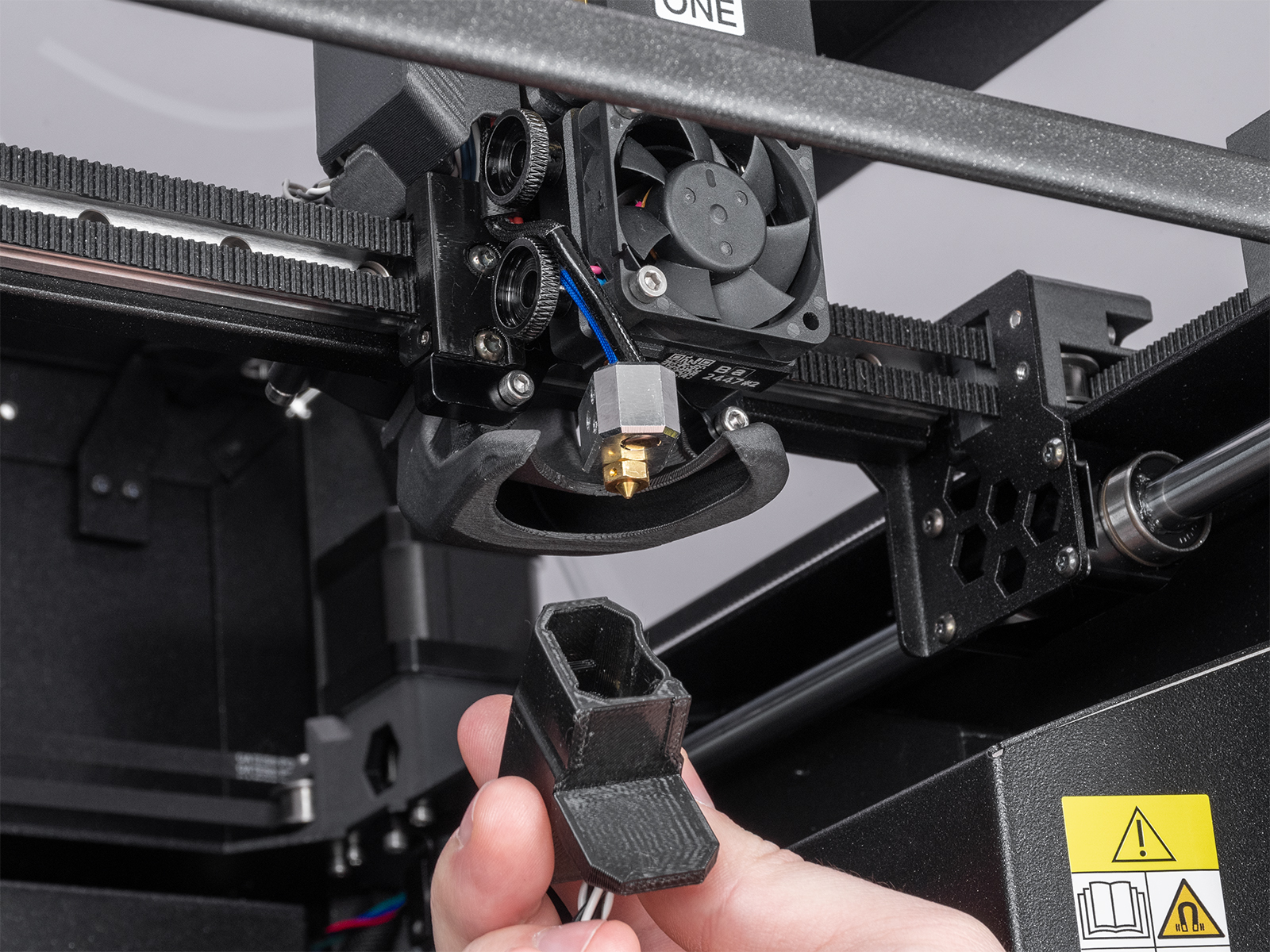

On MK3.9 or MK4, open the fan-door completely before the procedure. Remove the silicone sock, if installed. Identify the part of the accelerometer that is in the shape of the heater block.

|  |

Fit the accelerometer to the heater block, by pushing it from the bottom of the hotend. If there is any resistance, do not attempt to push the accelerometer harder, as excessive force might bend the heatbreak.

|  |

|  |

Y-axis (MK4/S, MK3.9/S, MK3.5/S)

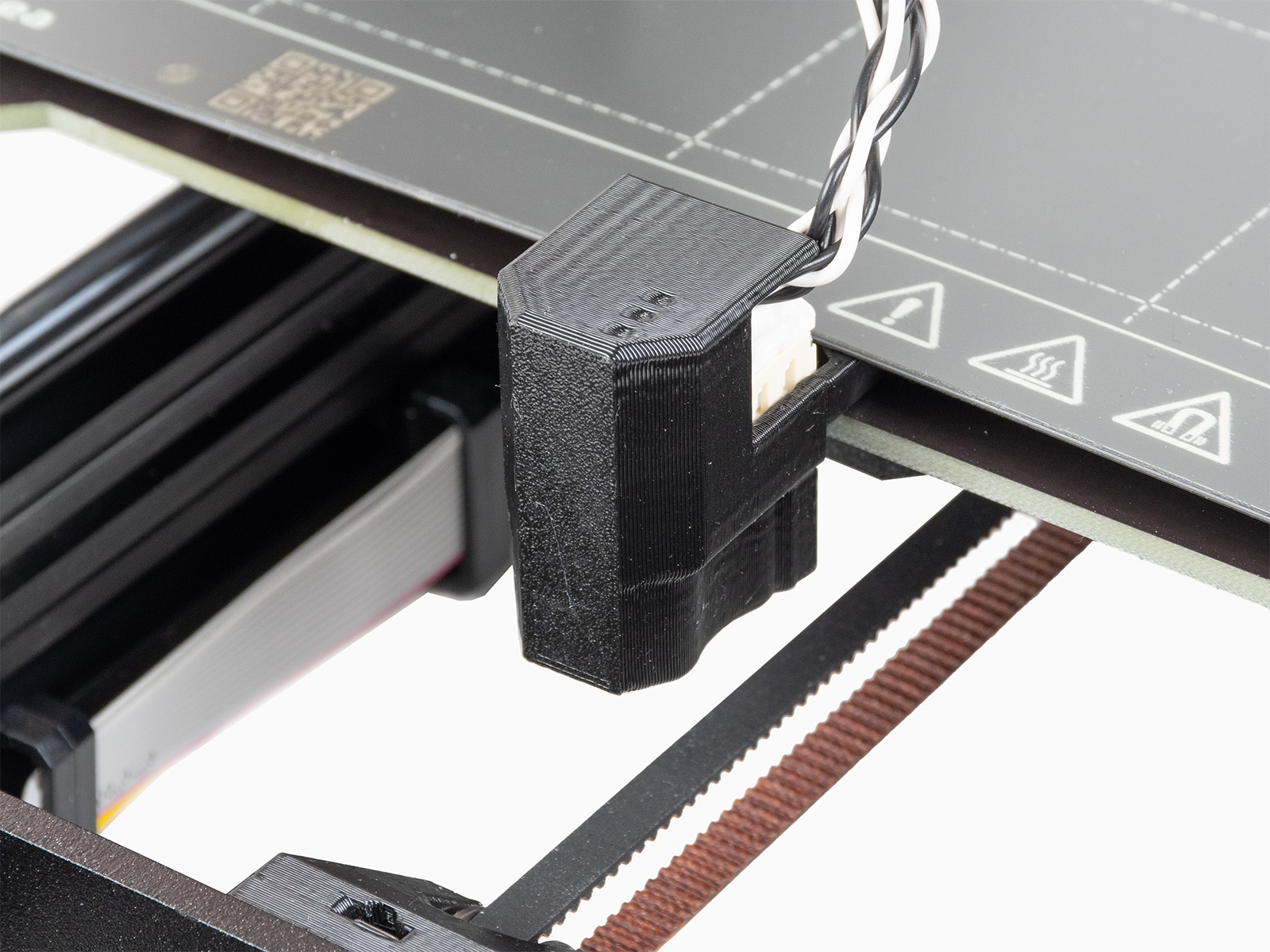

Identify the part of the accelerometer that protrudes from the rest. On the front side of the Y-axis, place the protrusion between the steel sheet and the heatbed.

|  |

Results

The results shown on the printer's display at the end of the calibration indicate the optimal input shaping type and frequency found with the calibration.

44 comments

These instructions are not up to the quality standards of other articles. I have a Core One and tried to follow the instructions. These were the issues I encountered:

- The kit ships with two cables of different lengths. The instructions don't mention which cable to use in the first step. It only becomes clear after reading all the steps and returning to the first one.

- The diagram depicts inserting the accelerometer board into the two plastic housings before attaching the cable. However, this makes inserting the cable subsequently very difficult because the cable has to be bent at 90deg while somehow applying force into the mating connector. Disassembling the plastic pieces is also very difficult because of the tight tolerances. I had to rip them apart with pliers, insert the cable, and reassemble it.

- The instructions state to *loosen* the M3x12 screw, however the screw must be *removed*.

- The body of the accelerometer housing was too big and crashed into the hot end fan shroud. I had to force it on by pushing the fan shroud out of the way.

- Once the accelerometer is installed, there are no further instructions for the Core One. All instructions are for MK4.x/MK3.x. I had to find instructions on YouTube (https://www.youtube.com/watch?v=U7Iantbv4kE).

Now I can't use the accelerometer.

I attempted to plug the cable directly into the main board, but the cable doesn't reach the port on the main board.

If I connect the two cables using the Wi-Fi module as a bridge, it can reach the main board.

On their product page, they advertise, "The Wi-Fi module can be easily unplugged for environments with the highest level of security.

But that doesn't mean "You can calibrate Input Shaper without the Wi-Fi module."

If your environment doesn't allow Wi-Fi, the module may have already been discarded or stored in another location.

I didn't think about the relationship between the Wi-Fi module and the accelerometer. Now I need to find an alternative.

I'm going to solve this problem by connecting the two cables with insulating tape.

https://www.prusa3d.com/product/accelerometer-set/