A 3D printer's hotend can get clogged. This article explains the most common causes of this issue, which are usually the same regardless of the printer type or model. We then have a separate article with tips on how to prevent the clog from forming in the first place.

What does it look like

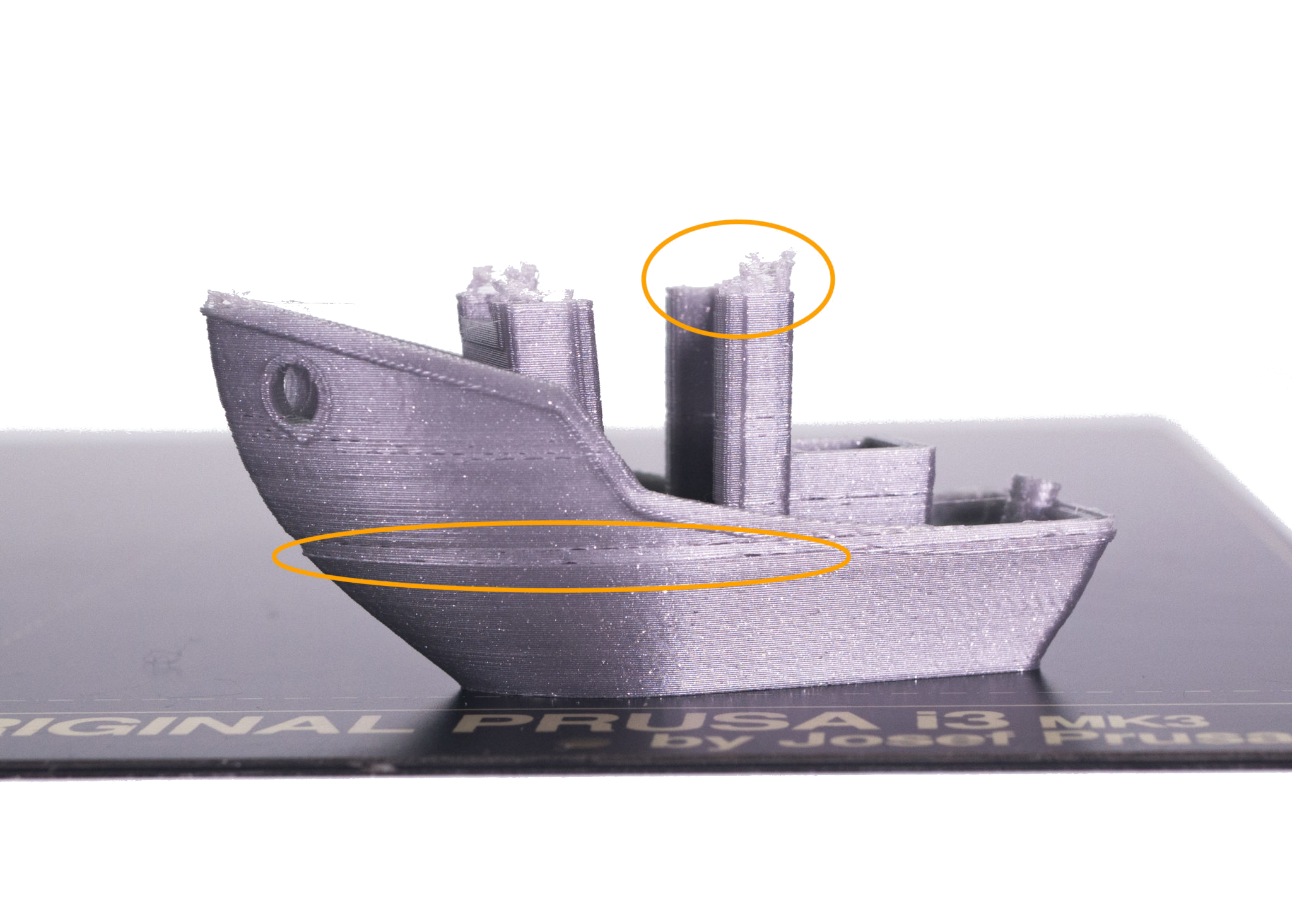

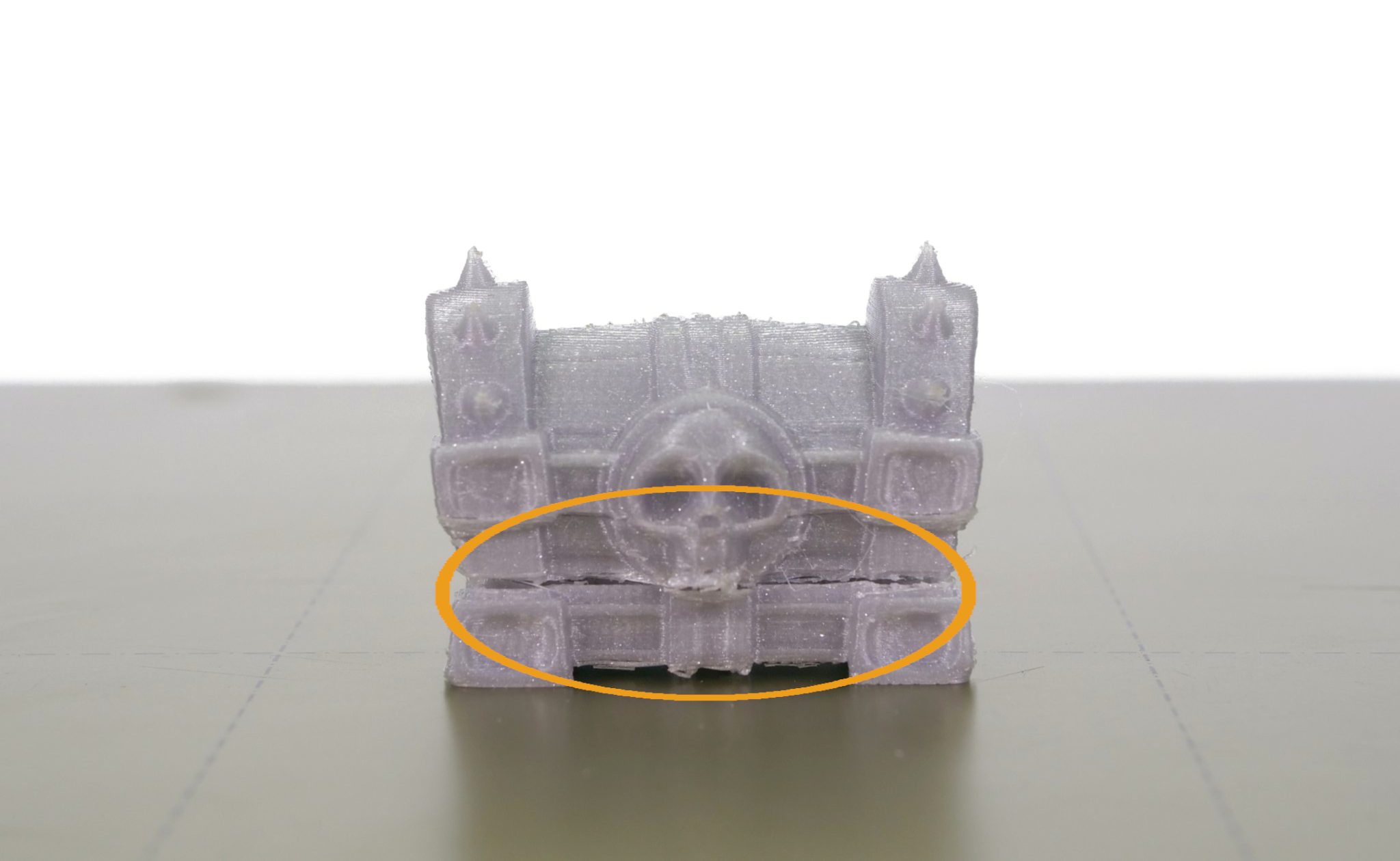

The most obvious symptom is that the filament is not coming out of the nozzle. However, please note that the hotend can also be clogged only partially. Partial clogs usually reveal themselves mid-print, even after you were able to load or unload the filament.

Early signs of the nozzle starting to clog are:

- The filament is not extruded out of the nozzle consistently

- Printed lines look much thinner and sometimes not sticking to the build plate.

- The extruded filament is curling up and sticks to the nozzle when purged.

Another common sign is that you can hear some clicking or ticking sounds from the extruder. The extruder clicking noise means that the stepper motor has to exert more force than a specific preset threshold and it's jumping back by one or more steps (skipping) to relieve the pressure.

|  |

How to fix it

There are three main methods of dealing with this problem. To choose the right method, see whether or not it is possible to load/ unload the filament. Partial clogs can usually be melted or cold pulled, more complex clogs that prevent even loading of the filament call for the third method described below.

Before you begin with any of these methods, unload the filament and remove it from the extruder. To make the work easier, move the extruder head up 10-15 cm from the LCD menu -> Settings -> Move axis -> Move Z-axis.

Cold pull

A cold pull is a good place to start if you experience a clog. If the filament can be loaded and unloaded without any problem, yet it still causes trouble during the print, clean the inside of your hotend using the Cold pull (MK3/S/+, MK2.5/S, MK3.5/S) technique.

Force the clog out

In case it is not possible to load the filament, try to soften the clog by increasing the nozzle temperature and then force it out. This is similar to the cold pull procedure.

To avoid any complication, toggle the Filament autoload OFF in the LCD Menu -> Settings -> F. autoload, before proceeding.

- Go to the LCD Menu -> Settings -> Temperature -> Nozzle. Set the nozzle temperature to 260 °C if you have been using PLA or to 280 °C if you have been using PETG or ABS.

- After the nozzle reaches the required temperature, wait for 2 minutes - the filament should start pouring/dripping out.

- Push the bundled acupuncture needle (0,3 mm to 0,35 mm diameter) into the nozzle from below. Insert it 1-2 cm deep, to help clear the clog. Never feed it in from the top and do not load filament while the needle is inserted.

- If that did not help, try using a 1.5 mm thick 100 mm long, straight, rigid metal wire: insert it into the hotend to see how far it can go and push on it, trying to force the filament down into the nozzle and then out. You can also use the smallest of the bundled Allen keys. It is not very long though, so remove the filament sensor cover to reach further.

- Load some PLA filament. The new string should push the rest of the stuck material from the nozzle.

Clean the hotend parts

If you didn't succeed, it is important to determine where exactly is the clog located. As said earlier, a clogged hotend is not the same as a clogged nozzle: the material can be jammed even above it.

Open the Extruder Idler door and check if you won't see a piece of the filament sticking out of the PTFE tube.

- If you have an MK2/S, unscrew both M3x40 screws with springs, the door should then open by itself.

- If you have an MK3 or an MK2.5, unscrew both M3x40 screws under the hexagonal window (they also have springs on them).

- If you have an MK3S or an MK2.5S, unscrew the single M3x40 screw (also with a spring).

Filament stuck in the PTFE tube

If the filament is stuck in the white Teflon tube, you need to take the hotend out from the extruder. Use this guide to do so (steps 2 - 5). You will be left with the hotend exposed, hanging in front of you. Preheat it via LCD Menu -> Settings -> Temperatures -> Nozzle (260 °C if you have been using PLA or to 280 °C if you have been using PETG or ABS) and see if you can remove the filament by pulling it up from the PTFE tube using pliers.

Sometimes, it is necessary to remove the PTFE tube, in which case you need to push the black nylon collet down towards the heatsink, in order to release it. While still pushing down on the collet, pull the PTFE tube out.

If the PTFE tube has been permanently damaged by the clog or in the process of removing it, you can purchase a new one in our online store (MK3S, MK2.5S or MK2/S, MK3, MK2.5). When you insert the new PTFE tube, make sure again it is properly secured by the collet: you need to pull the collet up about 1 mm while, at the same time, pushing the PTFE tube down. Doing this will ensure there is no play as the PTFE tube cannot move inside the hotend. Failure to secure the PTFE tube can cause clogging.

Filament stuck inside the nozzle

If the PTFE tube is empty, some debris might be stuck in the nozzle. Unscrew it from the heater block (check this guide to see how to do that). There are two ways to clean it: mechanically or using chemical solvents.

- To clean the nozzle mechanically, once it is removed from the hotend, heat it up using a heat gun or possibly a hairdryer, and extract the stuck matter with needle-nose pliers or a pair of tweezers.

- If you were using PLA or ABS, it is possible to clean the nozzle chemically. ABS dissolves in acetone and PLA in tetrahydrofuran or ethyl acetate. Immerse your nozzle into one of these substances for a couple of hours to overnight and then use the needle-nose pliers or a pair of tweezers to remove the gooey mass.

After resolving the clog

Clean the Bondtech gears

If you have had a clog, they can also have collected residue grinding the filament which will, in turn, reduce their grabbing force on the filament. Make sure you clean this out. Open the idler door and clean out each groove of the gear using a toothpick or the acupuncture needle that came with the printer.

Cover the PTFE tube to avoid any debris falling in. You can use a cotton swab - it will reliably cover the tube without damaging it). After you're done cleaning, give it a good puff of air to clear any remains, while the PTFE tube is still covered.

Calibration

If you have changed the nozzle you should redo, at least, the First Layer Calibration, as this may have changed with the new nozzle.

If you have disassembled and reassembled the extruder and/or hotend, we recommend going through the full XYZ calibration, followed by the First Layer Calibration.

14 comments

One concern was that I moved the head way up, then down 50 mm a couple of times. Head would not respond normally to Z axis moving. Ultimately I did a reset and started my print. Then, when it calibrated for z-axis height it came way down and calibrated corr

The clogs are arguably more difficult to clear, not least because the demographic purchasing printers these days has less technical acumen, expecting the printer to be more of an appliance. This is the result of Prusa's own marketing hype.

At the very least, a revised version of this article is needed, canvassing the techniques needed to clear nozzle clogs on both the regular and CHT nozzle types. A discussion of prevention could also be included.