- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- 3D models

- Material guide

- ABS

- Basic info

- Description

- Best use

- Tips for successful printing

- Sample prints

- ASA

- Composite materials (filled with carbon, kevlar or glass)

- Composite materials (with metal or wood particles)

- CPE

- Drying filament

- Flexible materials

- HIPS

- How to use Prusament refill

- NGEN

- PETG

- PLA

- Polyamide (Nylon)

- Polycarbonate (PC)

- Polypropylene (PP)

- PVB

- Resin yellowing and how to reduce it

- Resins

- Tested resins

- Water soluble (BVOH/PVA)

- Slicing

- Printer maintenance

- Prusa Connect & PrusaLink

Basic info

Description

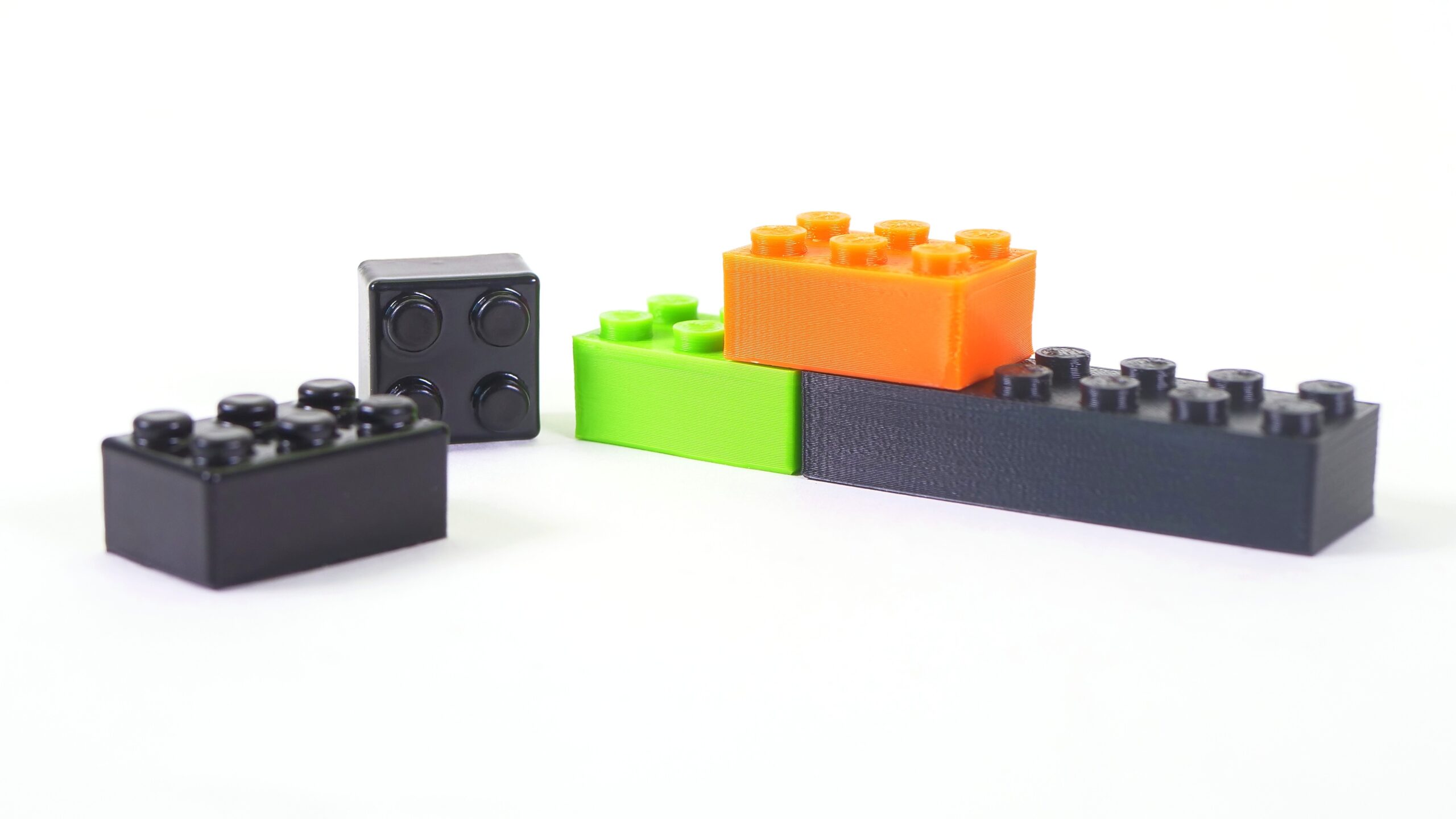

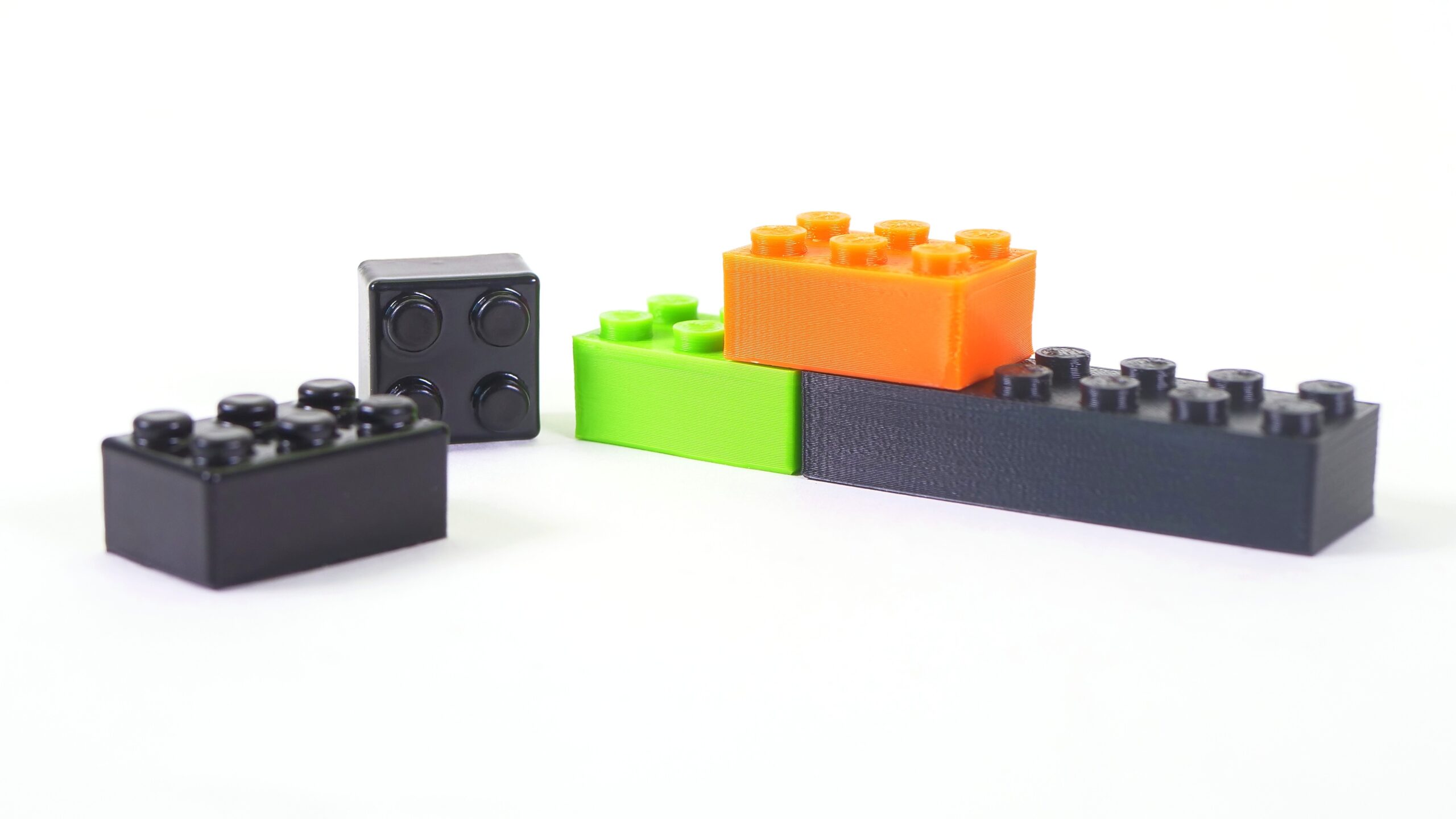

ABS (Acrylonitrile Butadiene Styrene) is basically a predecessor of ASA. ABS is generally used for making inexpensive, sturdy mechanical parts (LEGO bricks, car parts, cellphone parts, etc.). The material is tenacious and temperature resistant - this makes it suitable for engineering parts, etc. Compared to ASA, there is slightly worse UV resistance and more significant warping and odor during printing. Note that ABS parts used outdoor turn yellowish and more brittle over time.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ High tenacity & mechanical resistance |

✖ Significant warping |

|

✔ High temperature-resistance |

✖ Requires printer enclosure |

|

✔ Easy postprocessing |

✖ Potentially dangerous fumes (styrene) |

|

✔ Possibility of acetone smoothing and gluing |

Best use

The best use of ABS is for printing cheap technical parts requiring good heat and mechanical resistance or parts that need to be acetone smoothed.

Tips for successful printing

Try to keep a high ambient temperature

The bed should be heated at least up to 100 °C, the printer should be inside an enclosure with a higher ambient temperature.

It is also possible to make your own enclosure.

If you don’t have an enclosure, there’s one simple alternative: in PrusaSlicer, set the skirt value as high as possible. This will keep the model slightly warmer and mitigate the warping. Printing inside an enclosure can lead to deformation of the fan shroud and other plastic parts. This can affect the printer's functionality. In case your plastic parts tend to deform, we recommend printing them from a more temperature resistant material, for example Prusament PC Blend.

Shrinkage

You should keep in mind that ABS-printed parts tend to shrink slightly after cooldown. We recommend printing a testing object and comparing it with a source model. The shrinkage factor of this material is somewhere around 1-2%.

Removing prints

When removing prints with a large surface area, it is very important to let the part and sheet cool properly. You may have to assist the process using a spatula. Be gentle when flexing the sheet and removing the print as the smooth PEI foil can tear.

Printing with HIPS

If you print with MMU2S, you can use HIPS for printing supports - this material has similar print settings to ABS and can be easily dissolved in limonene.

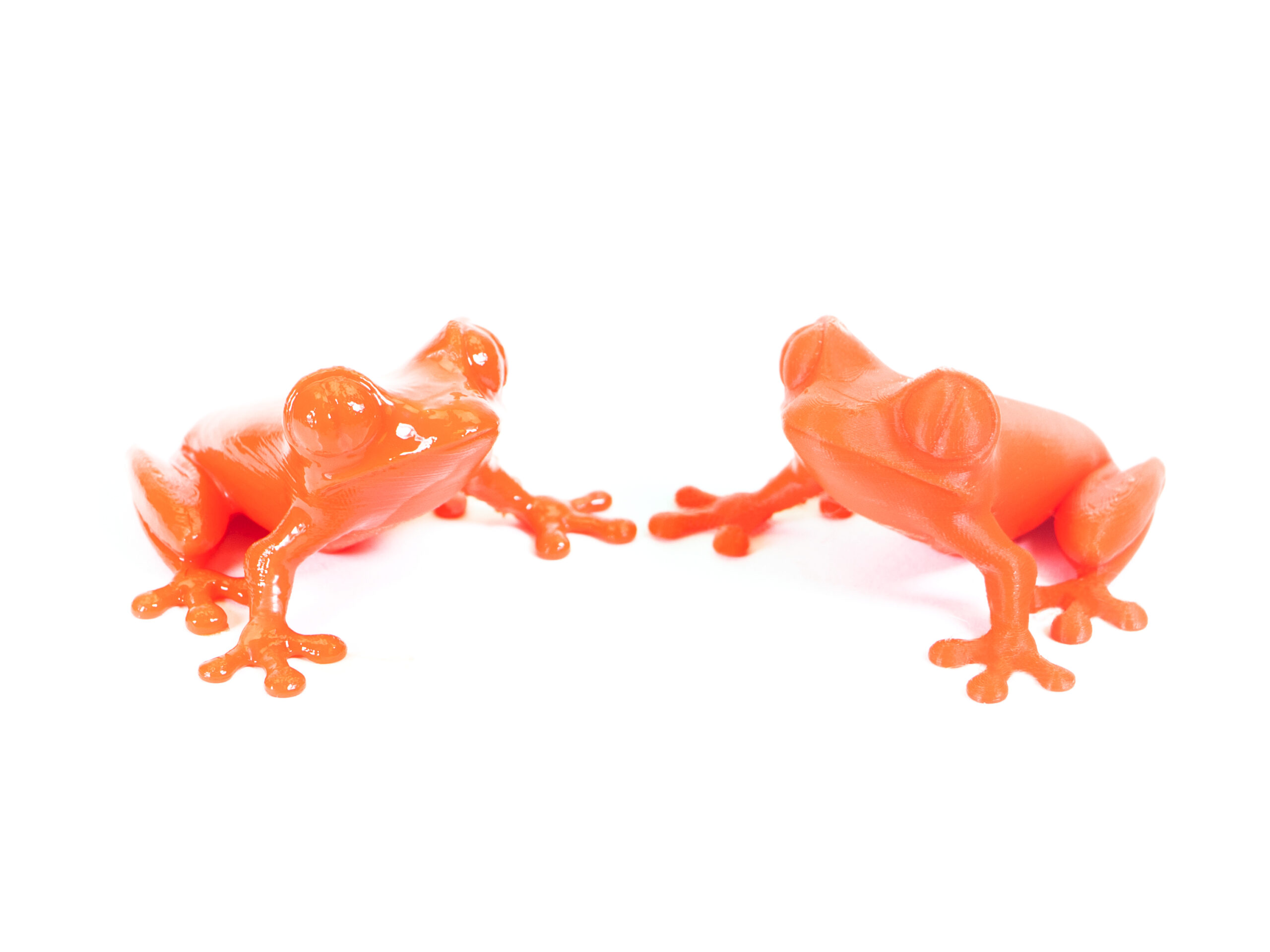

Chemical smoothing

ABS can be sanded wet and dry and smoothed with acetone fumes, just like ASA (see more in our article about chemical smoothing)

Sample prints

|  |

| Lego bricks | Acetone smoothed model |

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.