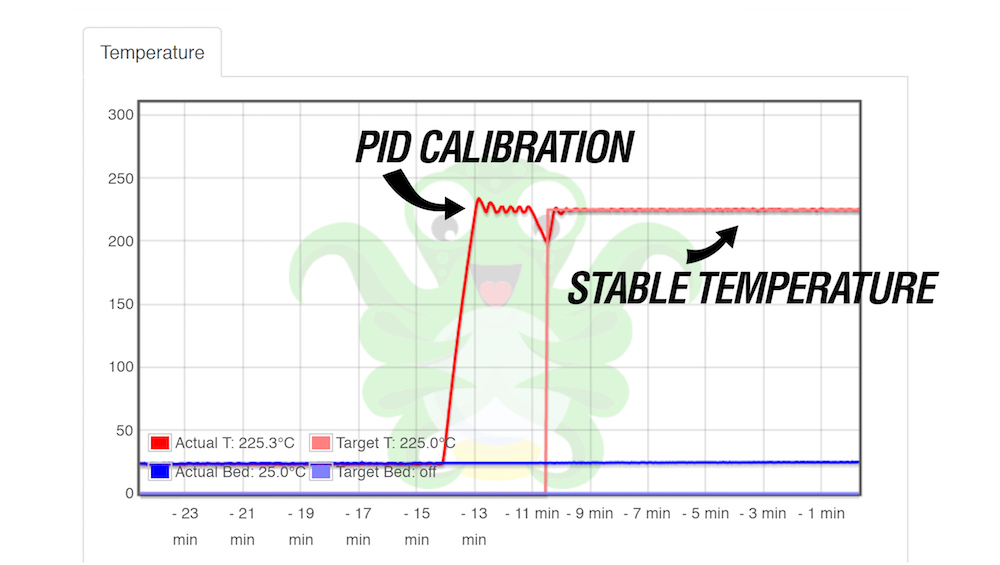

PID tuning is a calibration procedure that ensures the printer holds a stable target temperature at all times. PID (Proportional Integral Derivate) is used on the Original Prusa printers to maintain a stable temperature on the hotend. You can use the PID tuning to calibrate its values in case you are experiencing small fluctuations in temperature readings of your printer's nozzle (e.g +/- 5 °C).

If you are experiencing major temperature fluctuations, higher than +/-5 °C, there could be a problem with your fan or thermistor wire/connector.

How to perform PID tuning

Starting with firmware version 2.0.12., PID tuning is an optional calibration procedure, which is super easy to perform. It can be found in the LCD Menu -> Calibration -> PID calibration.

Follow these steps:

- Once you open the PID calibration menu, set the temperature at which the calibration should run.

- To achieve optimal results, select a temperature you use most often during your prints (e.g. the temperature for PLA, PETG, or other favorite material).

The PID tuning will increase the stability for all temperatures, it is not necessary to make it multiple times for different temperatures.

- The nozzle will heat up to the selected temperature in 5 cycles. During these cycles, the printer will determine the amount of power needed to reach the user-defined temperature and maintain it.

Be aware that PID tuning is not a solution for every temperature fluctuation issue. Always make sure that your printer is located in a dry environment with a stable temperature over 20 °C and no breeze.

Was this article helpful?

This action is available only to registered users. Please log-in.

7 comments

the last update, killed or broke or otherwise screwed up my thermistor, or ?

in fact I'm havin issues on this temperature fluctuation. now I will need to perform this type of PID tunning to troubleshoot what could be wrong.

how it is possible Prusa sell Upgrade from mk3s to mk3.5 and half of old funcionalities were left behind?

what is the timeline to have this implemented? and I as a customer what I will get for the money I spend from the upgrade that make my printer worke worst?

Best regards

Helder

Hello. We are sorry that you are having issues after upgrading your 3D printer. For troubleshooting, please contact our support team.

Hi Vinnie, we are aware that some features are missing and we will add them to the new firmware including the PID, Revo and others :)

Hi!

Not the same way. On the MINI, MK4, XL etc., the PID values are set to work with the stock heaters and there is no need to change them. However, there are PID-related G-code commands such as M301, M303, M304:

https://help.prusa3d.com/article/buddy-firmware-specific-g-code-commands_633112