- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- Using the printer

- Material guide

- Flexible materials

Flexible materials

- 3D models

- Material guide

- ABS

- ASA

- Composite materials (filled with carbon, kevlar or glass)

- Composite materials (with metal or wood particles)

- CPE

- Drying filament

- Flexible materials

- Basic info

- Description

- Best use

- Important rules for successful printing with flexible filaments

- Tips for successful printing

- Flexible filament

- Sample prints

- HIPS

- How to use Prusament refill

- NGEN

- PETG

- PLA

- Polyamide (Nylon)

- Polycarbonate (PC)

- Polypropylene (PP)

- PVB

- Resin yellowing and how to reduce it

- Resins

- Tested resins

- Water soluble (BVOH/PVA)

- Slicing

- Printer maintenance

- Prusa Connect & PrusaLink

Basic info

Description

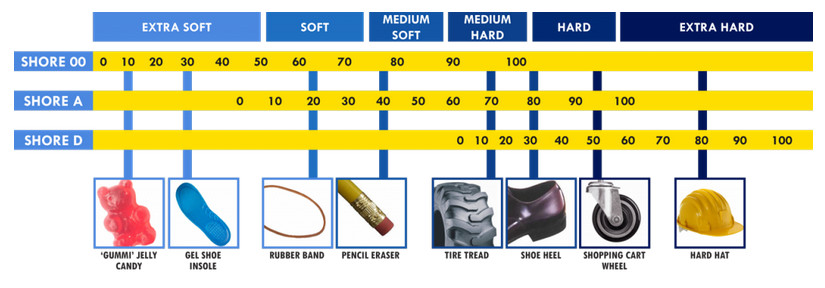

Flexible filaments are chemically and mechanically resistant materials. Individual layers hold strongly together and there is a great print surface adhesion (applies only for TPU and TPEE). Due to these qualities, it is necessary to print on a powder-coated sheet or use a special separator on the print surface (glue stick or Kapton tape). Flexible filaments are TPE (thermoplastic elastomer) material, however, they are distributed under various names, such as TPU, TPEE, etc. For example, TPU is basically a subtype of TPE material and the main difference between TPU and TPE is its shore hardness. TPU is usually around 60A-90A on the shore hardness scale. Generally speaking, the softer the filament is, the harder it is to print.

|

| Shore hardness scale, source: smooth-on.com |

Flexible filaments are usually very resistant to wear (scratching), stay flexible even in cold environments, and show great resistance against various solvents. Dimensions are stable, there is little to no shrinking or warping. Their tenacity and tensile strength are excellent: 3D-printed parts can withstand great stress before breaking. These properties make it suitable for printing spacing washers and other high-stress parts. With proper print settings, you could print stamps, RC tires, shoe soles, belts, etc.

Printing with flexible filaments is recommended only for experienced makers, considering various challenges during printing. We’re talking about frequent nozzle clogging, poor bridging and overhang characteristics, filament tangling into extruder gears, stringing, and oozing.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ Flexibility & tenacity |

✖ High print difficulty |

|

✔ Dimensional stability (low shrinkage) |

✖ Low printing speed |

|

✔ Good layer adhesion |

✖ Very bad bridging and overhangs |

|

✔ High mechanical and chemical resistance |

✖ Difficult support removal |

|

✖ Stringing | |

|

✖ Hygroscopic material (absorbs moisture) |

Best use

The best use of flexible filament is for printing spacing washers and other high-stress parts. With proper print settings, you could print stamps, RC tires, shoe soles, belts, etc.

Important rules for successful printing with flexible filaments

- Make sure the nozzle is unobstructed. If you’re not sure, do a cold pull to clean it completely.

- Loosen the idler so the gears push the filament through only very gently. If they press too hard, the filament might get entangled in the gears.

- If you print on a smooth or satin sheet, apply a separation layer on it (glue stick or Kapton tape should work). The powder-coated TXT sheet does not need any separation layer - the print will stick just fine and can be easily removed without damaging the surface.

- Print slowly. The slower, the better. A typical speed for flexible filaments is usually 20 mm/s, the maximal recommended speed is somewhere between 30 and 40 mm/s. With higher speeds, you risk clogging the nozzle or tangling filament into the gears. For Original Prusa printers, we recommend using the “Semiflex or Flexfill 98A” or “Filatech FilaFlex40” profiles that have proper speed settings.

- Increase the nozzle temperature by 5 °C, this will lower filament resistance. Keep print cooling turned off.

- Keep the filament dry. Flexible filaments tend to absorb moisture and can be hard to print when wet.

Tips for successful printing

Flexibility and slicer settings

Do you need better mechanical resistance? Set more infill and perimeters in PrusaSlicer. But if you need to retain the material flexibility, try to lower the number of perimeters and top/bottom layers. However, keep in mind that flexible filaments are not good at bridging and overhangs. A combination of thin layers and poor bridging can lead to ugly holes and protrusions.

Retractions

If you use a different program than PrusaSlicer, try to adjust retractions a little bit. With lower retractions, there is a lower risk of clogging the nozzle or filament tangling. It’s alright to turn the retractions off completely and then try to raise them and watch the results.

Printing supports

Supports may need more space in Z-axis. Try to increase it to 0,3 mm. Supports that are closer to your model might stick to it too strongly and might be difficult to remove. Increase 'XY separation between an object and its support to at least 100%.

Filament sensor

Remember that automatic filament change might not work properly with flexible filaments.

Do you want to know more about printing with flexible filaments? Check our blog article.

Flexible filament

The Original Prusa XL has a long path from the loading to the extruder nozzle. Due to its softness, Flexible filaments need special attention when being loaded in this printer. For that, follow the instructions in the video below:

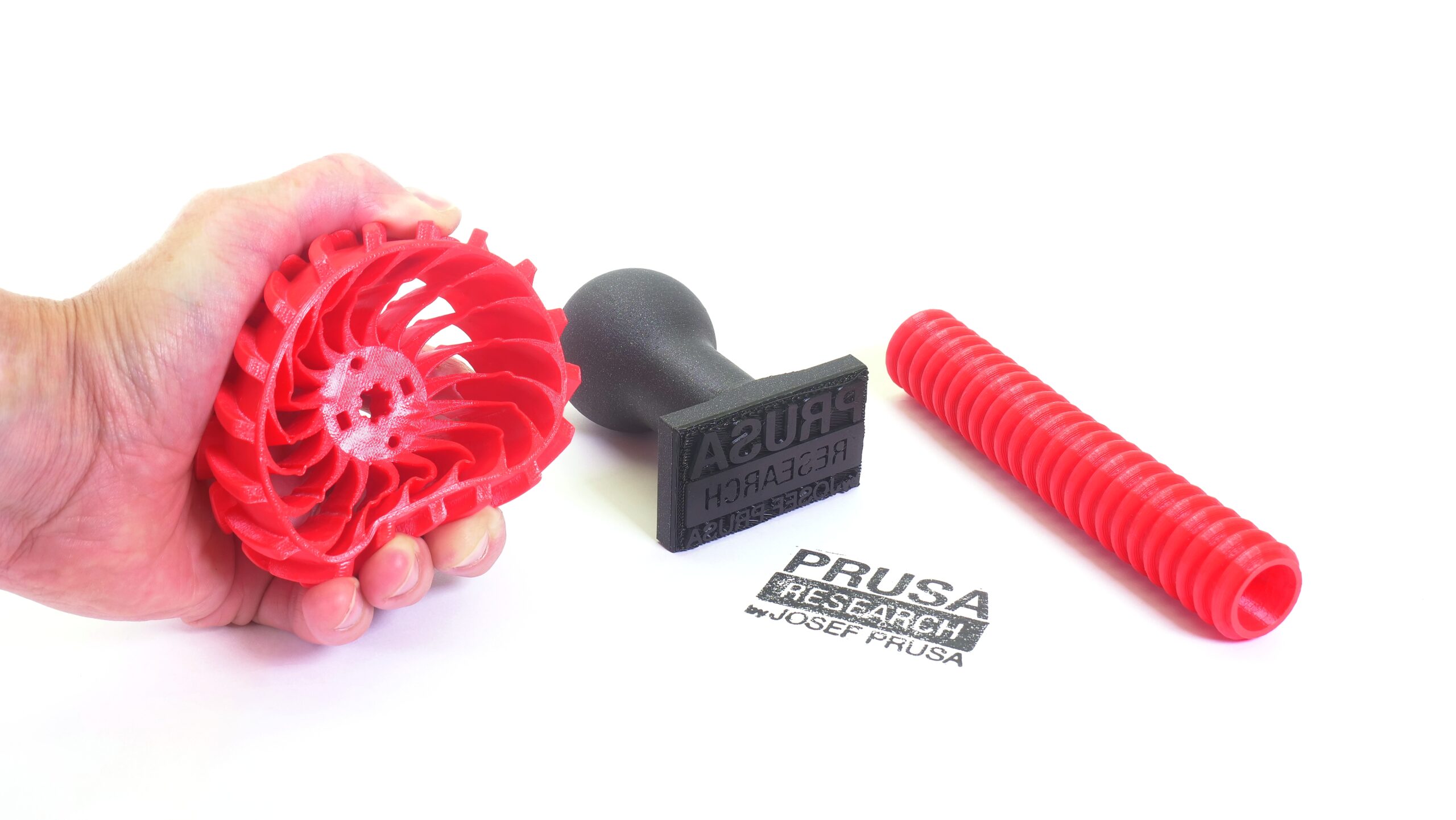

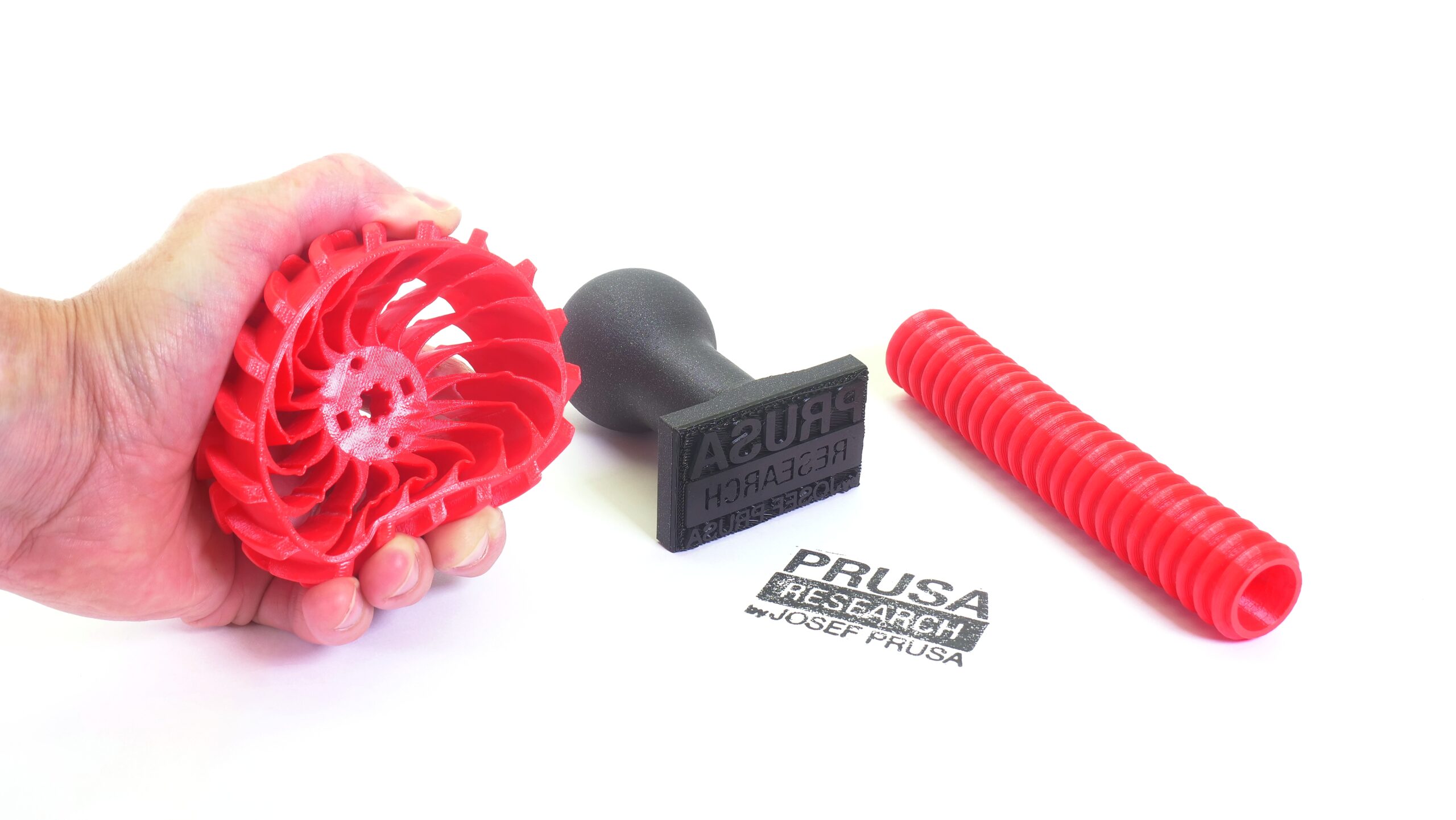

Sample prints

|  |

| Stamps, hoses, and tires | Example of filament flexibility |

|  |

| RC tires | GoPro and phone protection sleeve |

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.