⬢以下のステップに向けて、下記の部品を用意してください。

⬢Adapter-printer-mmu2s

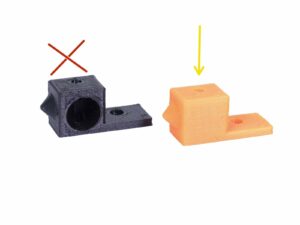

パッケージには、オレンジ色のアダプターのみが入っているはずです。ご自身でプリントされる場合は、

スチールボール用の穴が開いているものは使用しないでください。12/2020: The printed parts were slightly updated and the look may differ from those on the photos in this chapter. However, the assembly is the same.