⬢For the following step please prepare:

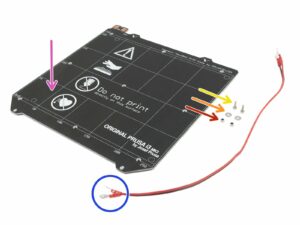

⬢Heatbed MK52 24V (1x)

⬢Power cable (1x)

⬢M3x10 screw (2x)

⬢M3/3,2/9/0,8 washer (2x)

⬢M3nN nylock nut (2x)

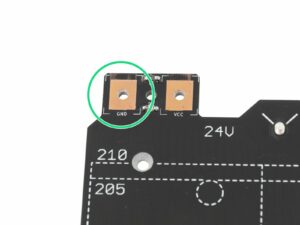

⬢IT IS VERY IMPORTANT to connect the power cable correctly. Before you start the assembly have a look at the pins. The one on the left with "GND" sign must be connected to the BLACK WIRE.

Hi Vinnie! Try using a dish-soapy water, clean and dry it up ;)

Ugh, this guide is either perfectly detailed or confusingly bouncing between steps...

It's just a reminder. Keep in mind...

IT IS VERY IMPORTANT to connect the power cable correctly. Before you start the assembly have a look at the pins. In the next step (Step3), the one on the left with "GND" sign must be connected to the BLACK WIRE.