Prusament PETG Ultraglow green is the brightest glow-in-the-dark filament on the market. It is filled with the highest possible amount of strontium aluminate, which is the hardest material we ever used. It is highly abrasive, and it would be naive to think that a filament filled with such an additive would be as easy to print as common PLA and PETG. As always, we did our best to make it printable as easy as possible, but there are several things you should take into account:

- Use a hardened nozzle! This is the most abrasive material we’ve ever made. This thing eats our manufacturing line's metal components like they were nothing. It will destroy your brass nozzle in no time.

- Expect accelerated wear on PTFE tubes and hardened components. This includes hardened steel nozzles and Nextruder gears. Occasional printing won't be an issue, but regular high-volume use will shorten the lifespan of metallic components. If you want to be 100% sure, you can use the E3D DiamondBack nozzle, which is harder than strontium aluminate and won't wear out.

- A 0.6 mm nozzle diameter is recommended. While we provide 0.4 mm profiles, we strongly recommend larger diameters to prevent clogging. Standard (non-high-flow) nozzles work better for this material.

XL and CORE One/+/L Preparations

- Make sure your XL is properly set and calibrated before printing in multicolor. We strongly recommend going through our Prusa Academy course focusing on the XL use and maintenance.

- Long PTFE tubes may cause extra friction that leads to clogging. Make sure to lower the friction by bending the tubes as little as possible. This is mostly noticeable on the XL, CORE One/+, and CORE One L. In the CORE One family, the most critical parts are the Nextruder bowden bent and side filament sensor. We recommend removing the Nextruder bowden bent part from the PTFE tube and switching off the side filament sensor. The XL doesn’t need extra preparations. Just make sure the PTFE tube is bent as little as possible.

Nextruder bowden bent from CORE One

Drying the filament

Dry the filament before use (optional). While PETG doesn't absorb moisture as readily as some filaments, drying after prolonged storage significantly reduces stringing, oozing, and clogging - especially important for multi-color printing (XL).

Glow properties

Strontium aluminate can be charged by exposing it to a light source, such as a strong LED, a bulb, sunlight, or UV light. Generally speaking, warm and weak lights (common bulbs) charge it slowly and it will most likely not have the desired effect. The best way to charge it is by using UV light. Daylight or strong LED works as well, but slower.

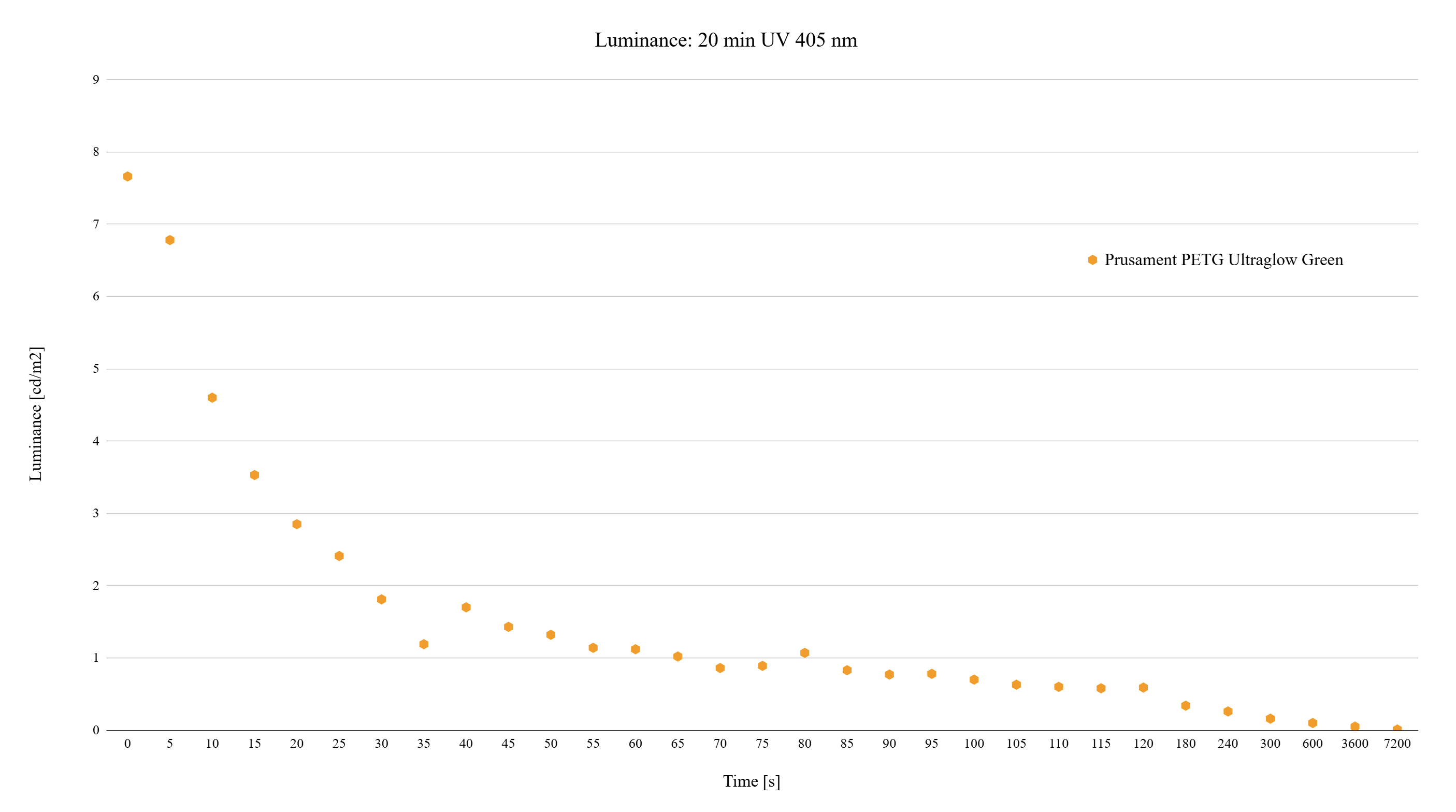

When charged, the filament glows strongly for several minutes, then the glow intensity gradually decreases. Most of the noticeable glow is emitted during the first 1.5 hours. However, in total darkness, a weak glow can be visible even after 6-8 hours after charging.

Measured glow intensity over time.