EasyPrint ist ein Cloud-basiertes Slicing-Dienstprogramm, mit dem Sie schnell ein Modell für den 3D-Druck von Ihrem Telefon, Tablet oder Computer vorbereiten und es über Prusa Connect an Ihren Drucker senden können. Es ist kostenlos auf der Printables-Website und in der Prusa App verfügbar.

Im Gegensatz zum leistungsstarken, aber komplexen PrusaSlicer ist EasyPrint von vornherein in seinem Umfang begrenzt. Der Benutzer muss nur einige wenige wichtige Einstellungen vornehmen, wie z. B. die Voreinstellung der Druckqualität und das Filamentmaterial. Alle anderen Einstellungen nimmt die Anwendung automatisch vor. Der grundlegende Arbeitsablauf wird im Folgenden beschrieben.

Technisch gesehen ist EasyPrint nur ein vereinfachtes Front-End für PrusaSlicer, das auf unseren Servern installiert ist und das eigentliche Slicing übernimmt. Sie können Ihre Projektdatei auch von EasyPrint als 3MF-Datei herunterladen und sie auf Ihrem Computer in PrusaSlicer öffnen. Auf diese Weise können Sie bei Bedarf eine Feinabstimmung der Einstellungen vornehmen oder das Projekt zur späteren Verwendung speichern.

Die Screenshots unten zeigen EasyPrint hauptsächlich auf einem Computer im Breitbildformat. Auf einem Tablet oder Smartphone ist das Layout etwas anders, um dem kleineren Bildschirm gerecht zu werden, aber die Gesamtfunktionalität ist die gleiche. Der Zugriff auf alle Funktionen erfolgt ausschließlich über die Touch-Steuerung.

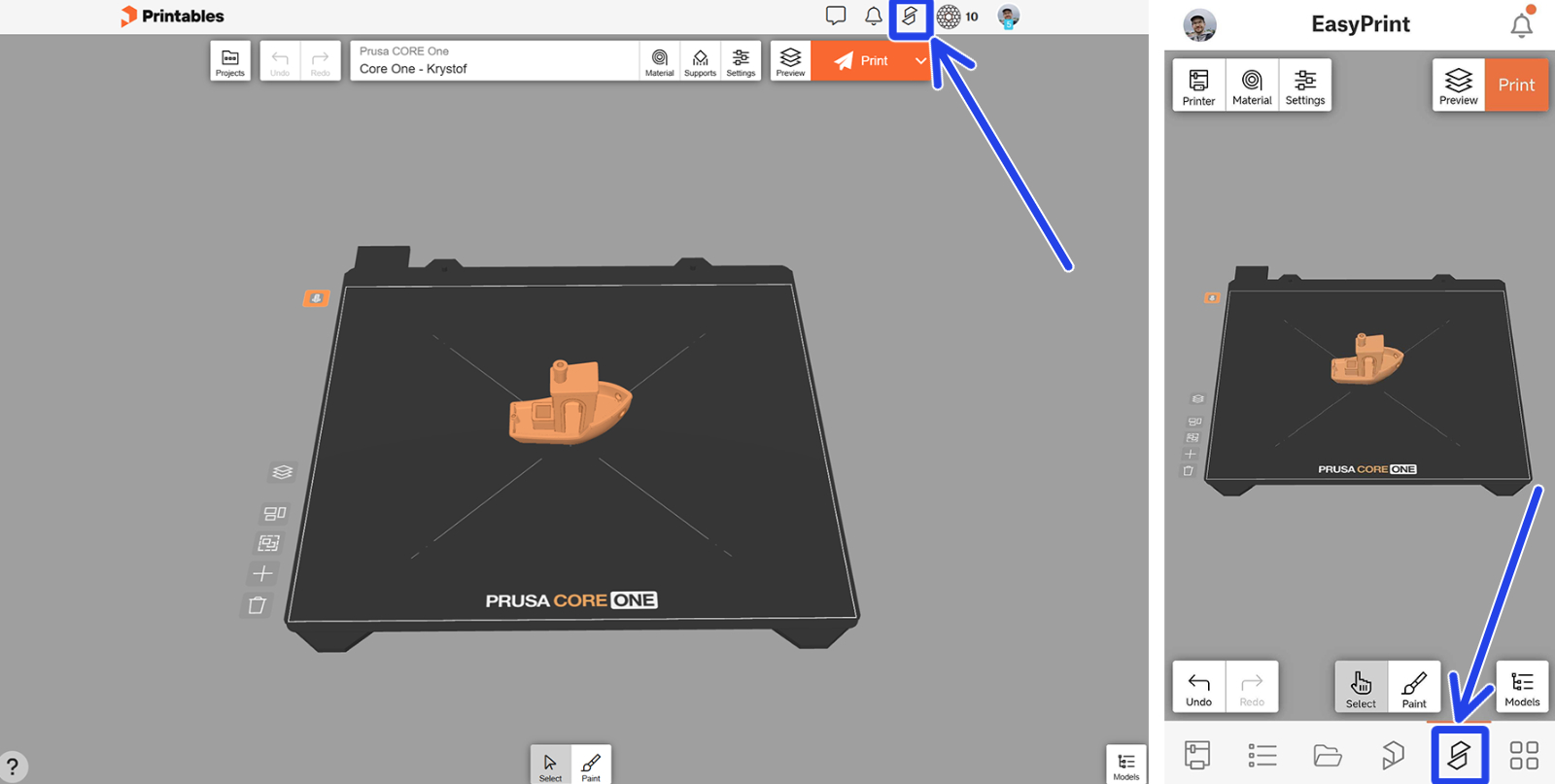

Zugang zu EasyPrint

Klicken Sie beim Durchsuchen von Printables auf die Schaltfläche EasyPrint im oberen Menü, um die EasyPrint-Schnittstelle zu öffnen. Innerhalb der Prusa App befindet sich diese Schaltfläche im unteren Menü.

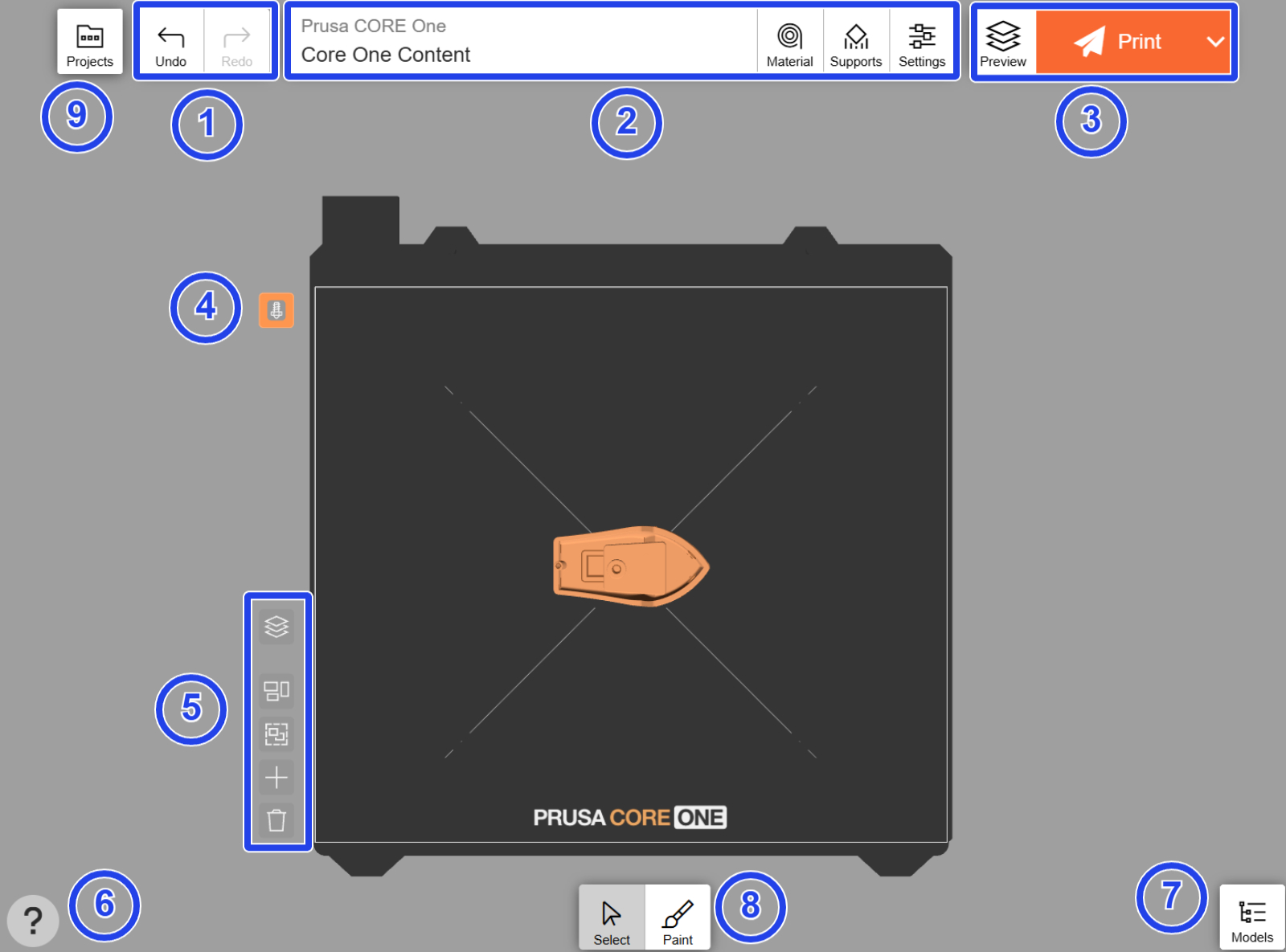

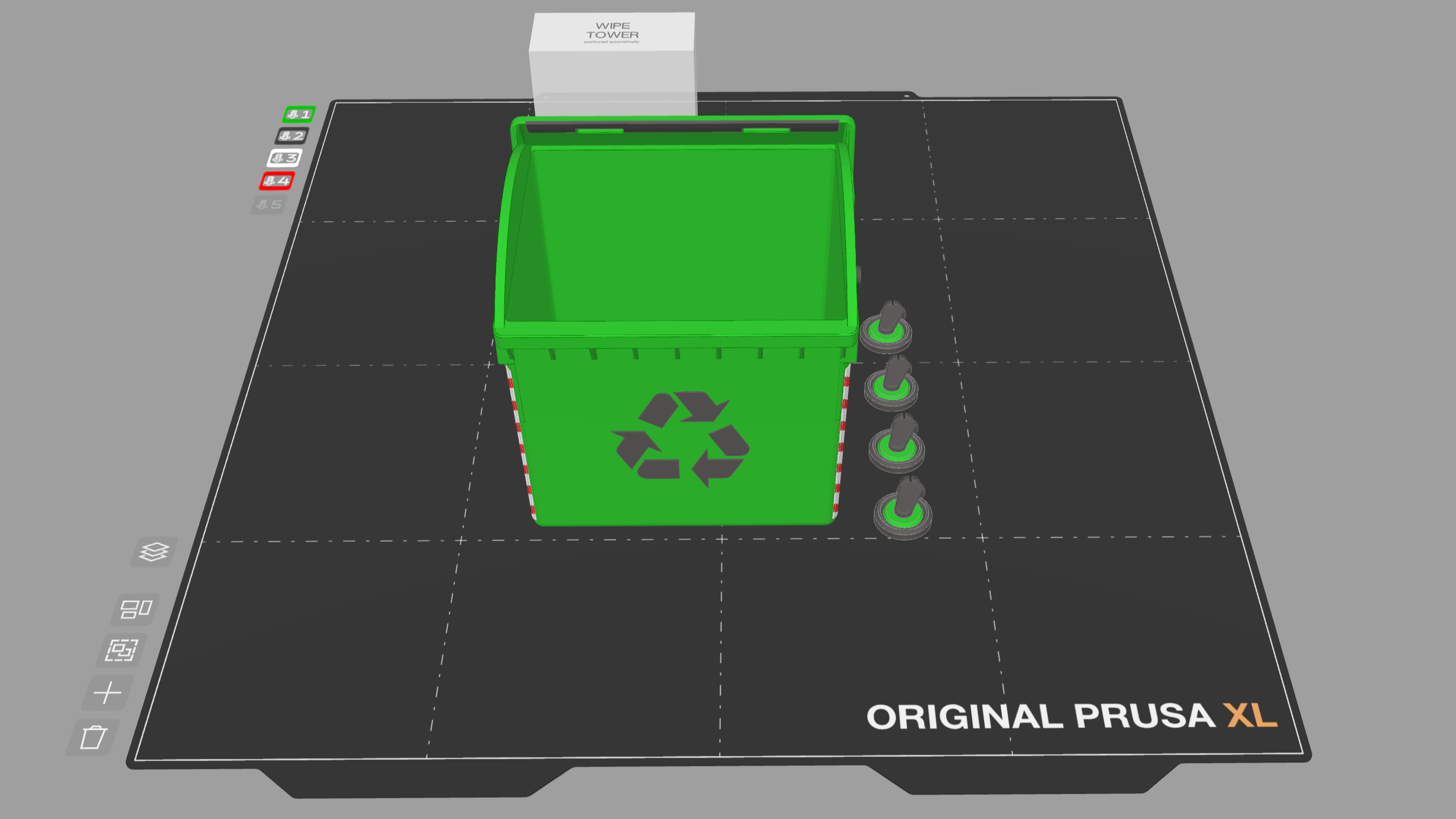

Die EasyPrint-Basisoberfläche enthält alle notwendigen Werkzeuge.

- Schaltflächen zum Wiederherstellen/Wiederholen;

- Druckeinstellungen;

- Export-Einstellungen.

- Werkzeugeinstellungen (zum Zuweisen von Farben für Multi-Werkzeug-Drucker, z.B. Original Prusa XL);

- Schaltflächen speziell für die Objekte auf diesem Bett: Vorschau umschalten, Objekte anordnen, alles auswählen, Modell hinzufügen und alles löschen;

- Tastaturkurzbefehle (nicht verfügbar auf Smartphones und Tablets);

- eine Liste der Modelle im Projekt;

- der Malwerkzeug Umschalter;

- die Registerkarte Projekte (nur auf dem PC verfügbar).

Der Hauptteil des Bildschirms besteht aus einer maßstabsgetreuen Darstellung des Druckblechs, auf dem Sie die Modelle, die Sie drucken möchten, verschieben und anpassen können.

Modellimport und Upload

Beim Durchsuchen von Printables wird neben allen kompatiblen Modellen die Schaltfläche EasyPrint angezeigt. Ab Juni 2025 werden STL- und 3MF-Dateien unterstützt. Klicken Sie auf die Schaltfläche, um das Modell zu Ihrer Druckliste hinzuzufügen, die als „Warenkorb“ für Modelle dient, die Sie drucken möchten.

Sobald Sie alle Modelle in Ihrer Druckliste haben, klicken Sie auf „Weiter“, um zum Slicing-Bildschirm zu gelangen. Alle Objekte aus Ihrer Druckliste werden automatisch auf einem virtuellen Druckbett angeordnet.

Sie können auch Modelle von Ihrem eigenen Gerät hochladen, indem Sie auf die Schaltfläche „Modelle“ in der unteren rechten Ecke klicken, dann auf Hinzufügen... und Modell hochladen. Auf derselben Registerkarte können Sie auch nach anderen Modellen aus Printables suchen und diese hinzufügen. Die Schaltfläche „+“ auf der linken Seite des Druckblechs kann ebenfalls verwendet werden, um Modelle hinzuzufügen.

Modellausrichtung und Maßstab

Es kann sein, dass Sie das Objekt drehen müssen, um seine Druckbarkeit zu verbessern (z.B. um die Anzahl der benötigten Stützen zu minimieren). Sie können dies ganz einfach tun, indem Sie das Objekt antippen und die Funktion Auf Fläche legen verwenden. Klicken Sie auf eine der markierten Flächen, um sie mit dem Druckbett auszurichten. Normalerweise werden Objekte so gedruckt, dass die größte Fläche die Platte berührt.

Bei einigen Objekten, die keine auffällige flache Seite haben, ist die Option Auf Fläche legen möglicherweise nicht verfügbar. In diesem Fall können Sie die Ausrichtung manuell mit dem Drehwerkzeug anpassen. Sie können die Pfeile verwenden, um das Objekt entlang seiner drei Achsen zu drehen. Wenn Sie den Mauszeiger/Finger entlang des Kreises halten, wird der Drehwinkel in 15-Grad-Schritten eingestellt. Alternativ können Sie die Drehwinkel auch manuell eingeben.

In ähnlicher Weise ermöglicht das Objektmenü das Verschieben und Skalieren des Objekts. Klicken Sie auf Mehr, um das Modell zu entfernen oder klonen (d.h. kopieren).

Sie können die Werkzeuge Drehen, Verschieben und Skalieren auf mehrere Objekte gleichzeitig anwenden. Um eine Mehrfachauswahl zu treffen, klicken Sie auf das erste Objekt und halten es gedrückt, bis es auf dem Druckbett wackelt. Das bedeutet, dass der Mehrfachauswahlmodus aktiv ist. Klicken Sie auf weitere Objekte, um sie der Auswahl hinzuzufügen, oder klicken Sie erneut, um sie wieder zu entfernen.

Drucker auswählen

Klicken Sie auf die Schaltfläche Drucker im oberen Menü, um alle Drucker, die Sie zu Prusa Connect hinzugefügt haben, und ihren aktuellen Status anzuzeigen. Sie können EasyPrint verwenden, um Druckdateien aus der Ferne an diese Drucker zu senden.

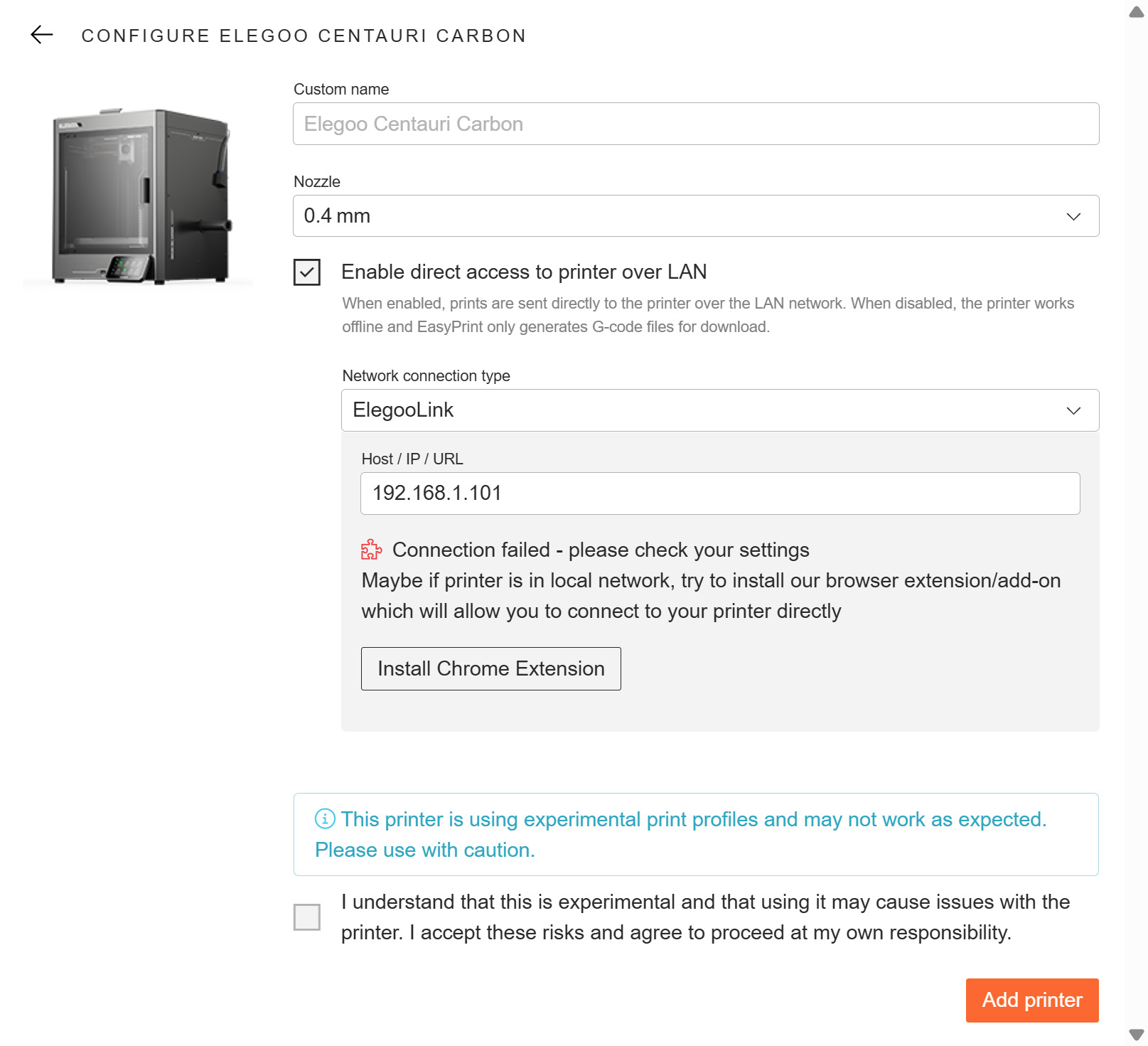

Bei Verwendung von EasyPrint über einen Desktop-Browser, der nicht mobil ist, ist das Senden von Dateien aus der Ferne auch mit Nicht-Prusa-Druckern über eine LAN-Verbindung möglich, indem Sie in der Konfiguration des Nicht-Prusa-Druckers die Option „Direktzugriff auf den Drucker über LAN aktivieren“ auswählen.

In diesem Fall ist es notwendig, einen Netzwerkverbindungstyp auszuwählen, mit der Option, unsere Browsererweiterung für die direkte Verbindung zum Drucker im Browser zu installieren - unser Konfigurationsmenü bietet diese Option an.

Diese Funktion ist derzeit in unserer PrusaApp und auf mobilen Browsern nicht verfügbar.

Sie können EasyPrint auch für Prusa-Drucker verwenden, die nicht bei Prusa Connect registriert sind, oder für Nicht-Prusa-Drucker im Offline-Modus. Verwenden Sie die Option Offline-Drucker hinzufügen, um das genaue Modell Ihres Druckers innerhalb jeder Produktfamilie zu finden. Wenn Sie nicht die Standarddüse verwenden, ändern Sie den Düsendurchmesser in den Druckeroptionen.

Material auswählen

Um das Druckmaterial festzulegen, wählen Sie zunächst den allgemeinen Typ (z. B. PLA, PETG usw.), dann den Hersteller und den Untertyp (z. B. Prusament – PETG Carbon Fiber). Wenn Ihre spezifische Filamentmarke nicht in der Liste aufgeführt ist, verwenden Sie eines der generischen Profile für das jeweilige Material.

Stützen aktivieren und Haftung verbessern

Aufgrund der Beschaffenheit der 3D-Drucktechnologie kann unter Teilen, die sonst in der Luft gedruckt würden, eine Stützstruktur erforderlich sein. Für Anfänger kann es schwierig sein, zu entscheiden, wann diese Stützen notwendig sind. Wenn Sie sich nicht sicher sind, ist es im Allgemeinen am sichersten, sie mit der Option „Überall – Organisch“ zu aktivieren. Jede Option verfügt über ein Bild, das veranschaulicht, welche Art von Stützen sie erzeugt.

Viele Modelle, die speziell für den 3D-Druck hergestellt werden, sind so konzipiert, dass keine Stützen benötigt werden. Dies ist hilfreich, da Stützen zusätzliche Druckzeit und Material erfordern. Schauen Sie in der Beschreibung des jeweiligen Modells nach, wo die Autoren in der Regel Tipps zur Aktivierung von Stützen geben.

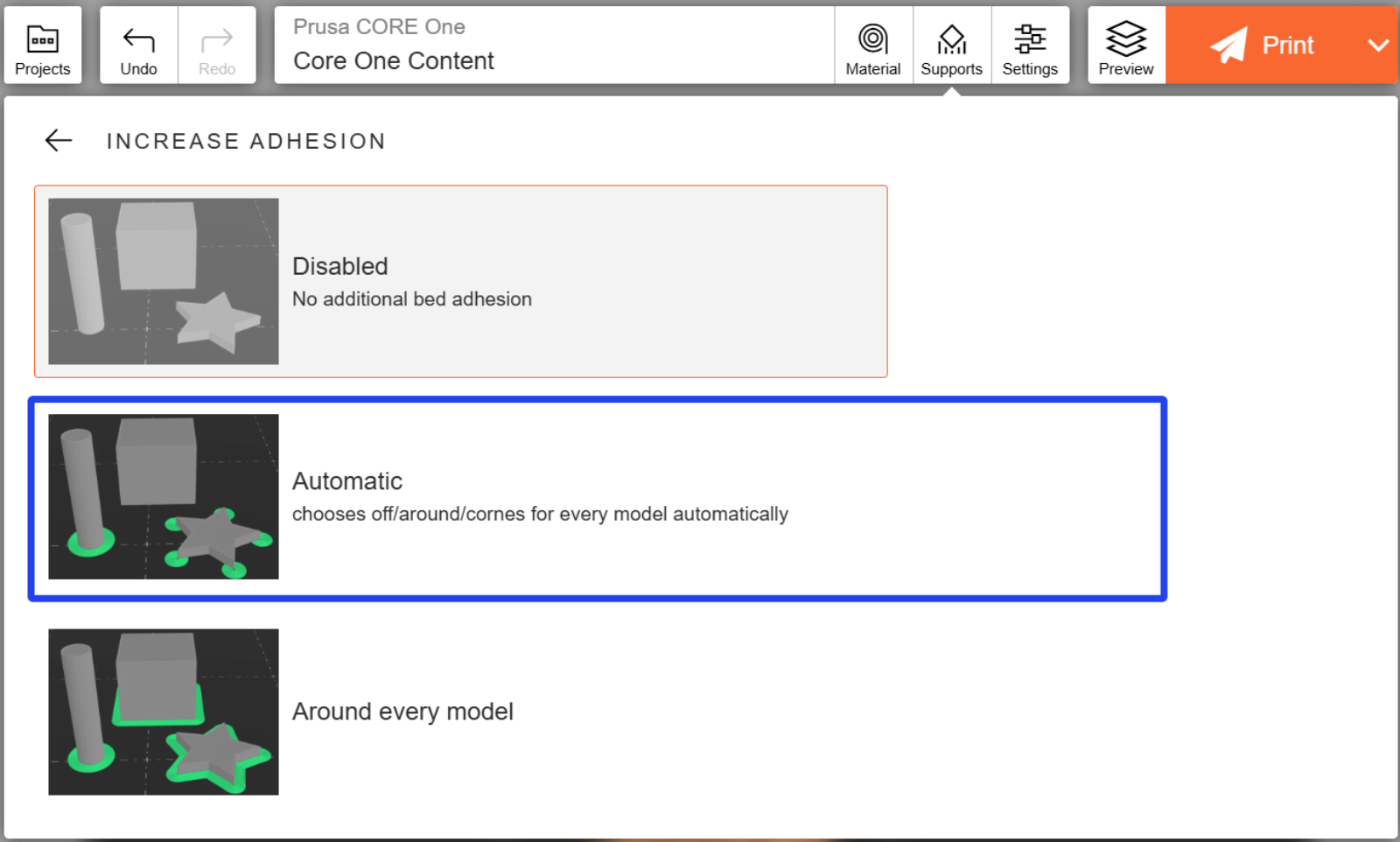

Objekte mit einer kleinen Basis können sich während des Drucks versehentlich vom Druckblech lösen. Wenn Sie Haftung erhöhen - automatisch aktivieren, fügt EasyPrint automatisch kleine Ränder (d.h. eine dünne Materialschicht, die nach dem Druck leicht entfernt werden kann) für Objekte hinzu, die dies benötigen.

EasyPrint erkennt auch automatisch mögliche Probleme während des Slicing-Prozesses und schlägt die Verwendung von Stützen und/oder erhöhter Haftung vor, wenn diese nicht aktiviert sind.

Anpassen der Druckeinstellungen

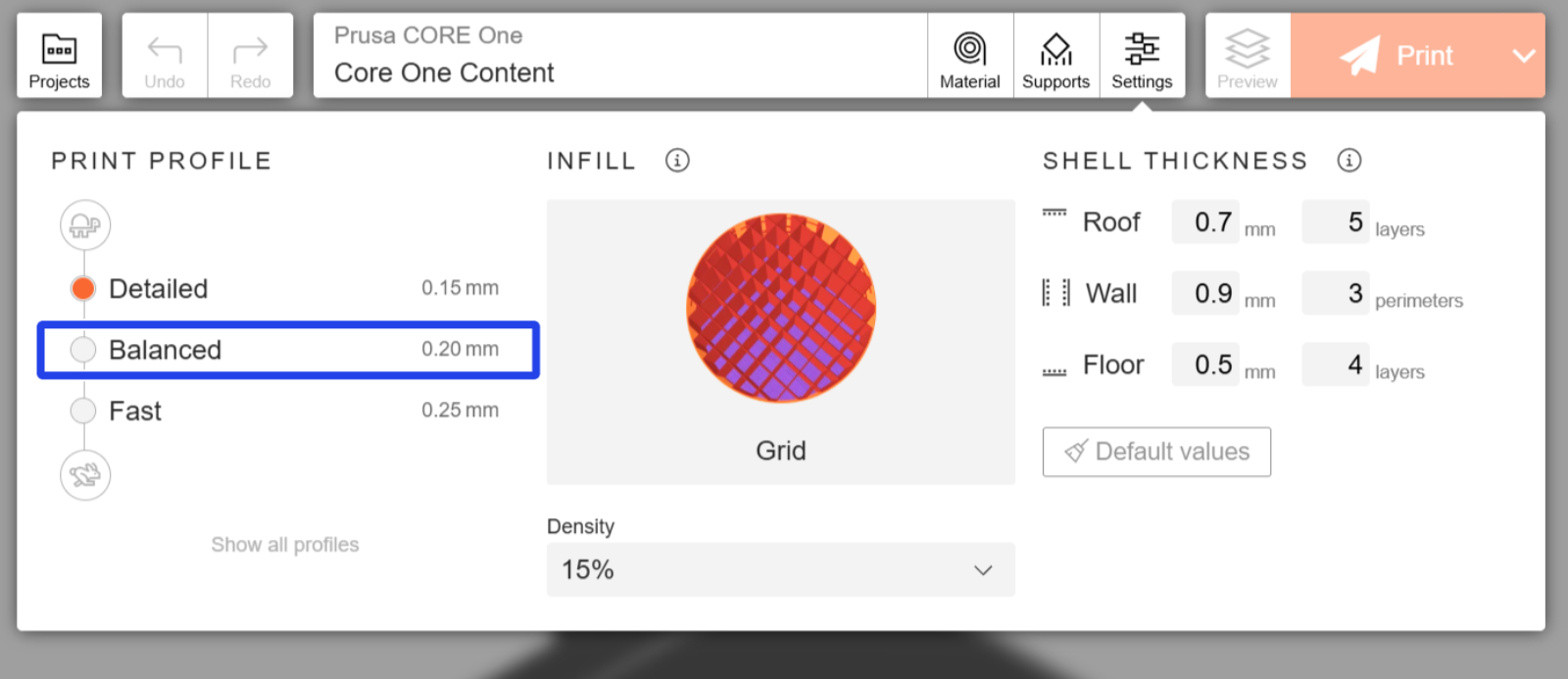

Wählen Sie auf der Registerkarte „Einstellungen“ eines der Druckprofile aus. Das Profil Balanziert bietet für die meisten Anwendungsfälle einen guten Kompromiss zwischen Qualität und Druckgeschwindigkeit.

Sie können auch einige Einstellungen, wie z. B. das Infill-Muster (d. h. die innere Struktur des gedruckten Modells), feinabstimmen. Die Muster sind in verschiedene Kategorien eingeteilt, die auf ihrer Druckgeschwindigkeit oder Haltbarkeit basieren.

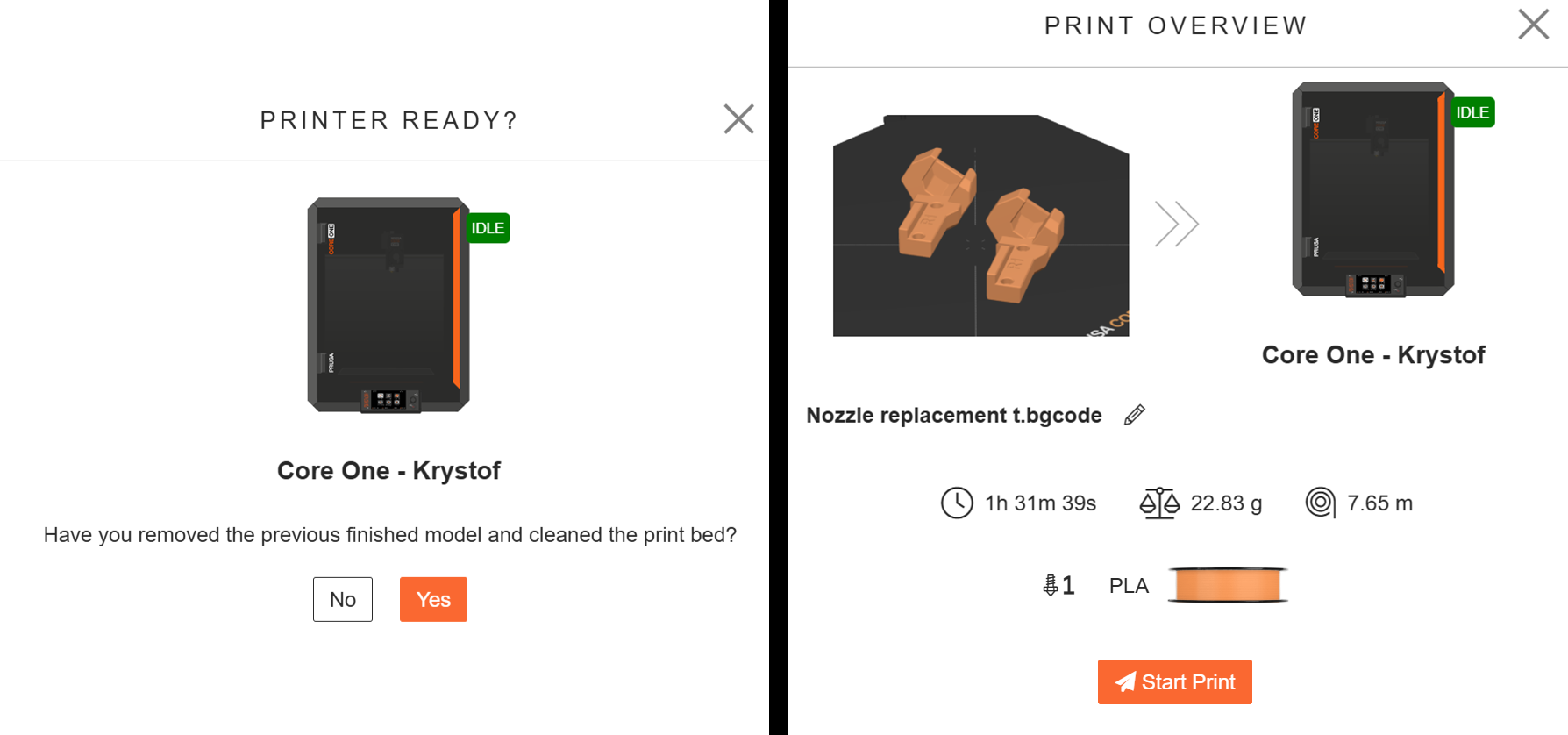

Wenn Sie alles eingestellt haben, klicken Sie auf Drucken. Damit wird Ihr Projekt zum Slicen an entfernte Server gesendet. Je nach der Komplexität Ihres Projekts und der Größe der Warteschlange kann dies eine Minute dauern.

Wenn Ihr Drucker gerade im Leerlauf ist und über das richtige Material verfügt, können Sie sofort mit dem Drucken beginnen. Andernfalls wird der G-Code in die Druckerwarteschlange aufgenommen. Auf dem abschließenden Bestätigungsbildschirm können Sie die Druckzeit sowie die verbrauchten Gramm und Meter an Filament überprüfen.

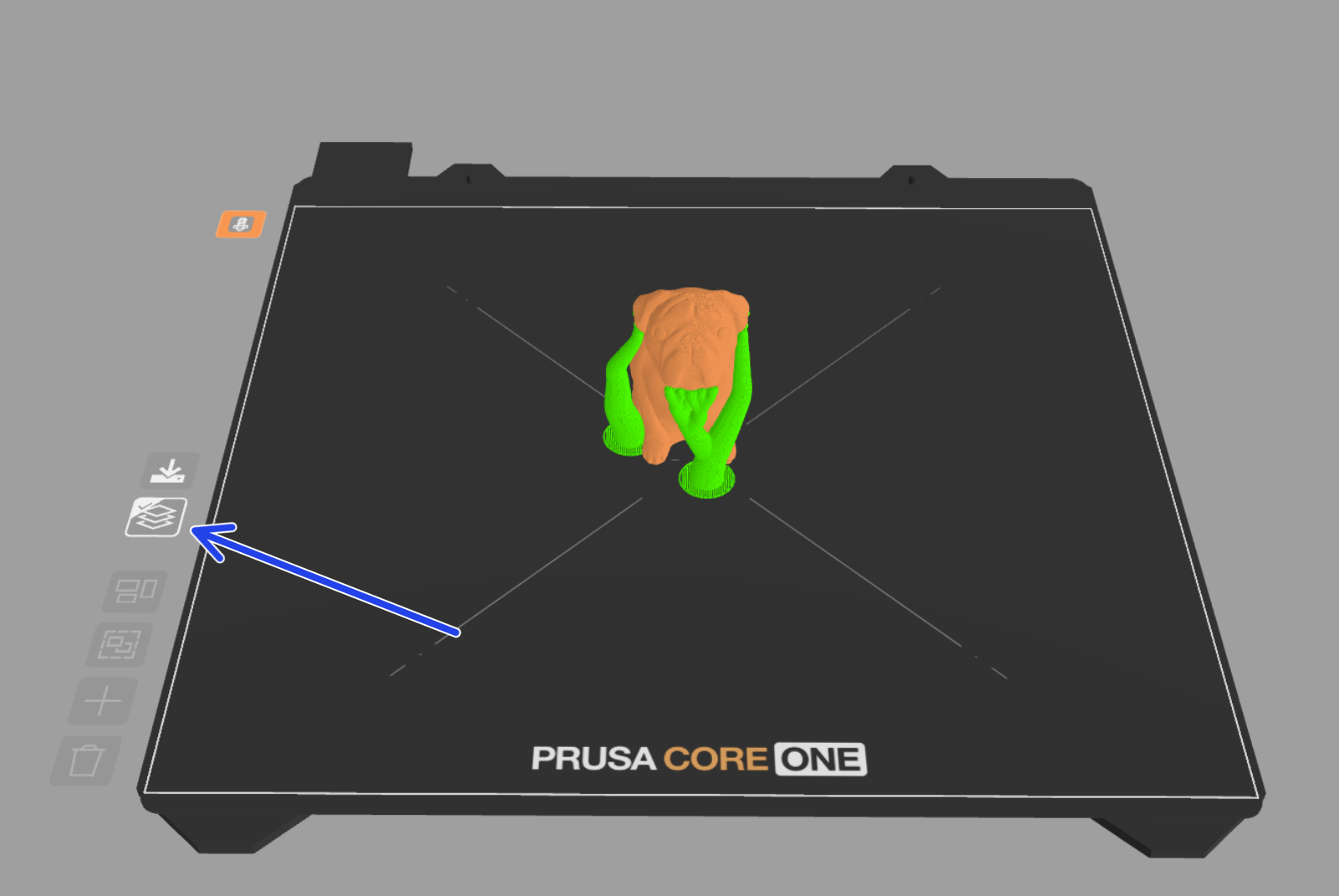

Optional können Sie die Vorschau des G-Codes anzeigen. Die Vorschau enthält die generierten Stützen (grün dargestellt) und ist eine gute Möglichkeit, eine letzte Kontrolle vor dem Drucken durchzuführen.

Arbeiten mit Gruppen

Modelle, die aus mehreren Teilen (Netzen) bestehen, werden als Gruppe in EasyPrint geladen. Alle Objekte in der Gruppe werden zusammen als ein Objekt verschoben, skaliert und gesliced. Im Bedienfeld Modelle können Sie die einzelnen Teile innerhalb der Gruppe überprüfen. Jedes Teil kann einzeln aus der Gruppe entfernt oder gelöscht werden. Alternativ können Sie auch auf ein Teil eines Modells auf dem Druckbett doppelklicken, um es manuell zu trennen.

Wenn Sie ein Objekt so verschieben, dass es ein anderes Objekt berührt, werden die Objekte automatisch zu einer Gruppe zusammengefasst. Sie können die Gruppe im Bedienfeld „Modelle“ wieder auflösen.

Arbeiten mit mehreren Betten

Sie können in EasyPrint nahtlos mit mehreren virtuellen Betten arbeiten. Alle Betten haben die gleichen Druckeinstellungen, aber jedes Bett wird separat gesliced und erzeugt seine eigene Druckdatei. Dies kann bei großen Projekten mit vielen Teilen nützlich sein. Wenn die Objekte in Ihrer Druckliste nicht auf ein einzelnes Bett passen, werden sie automatisch auf mehreren Betten angeordnet.

Alternativ können Sie ein beliebiges Objekt in den leeren Bereich ziehen, woraufhin dynamisch neue Betten erscheinen. Sobald Sie das Objekt ablegen, bleibt das Bett darunter bestehen.

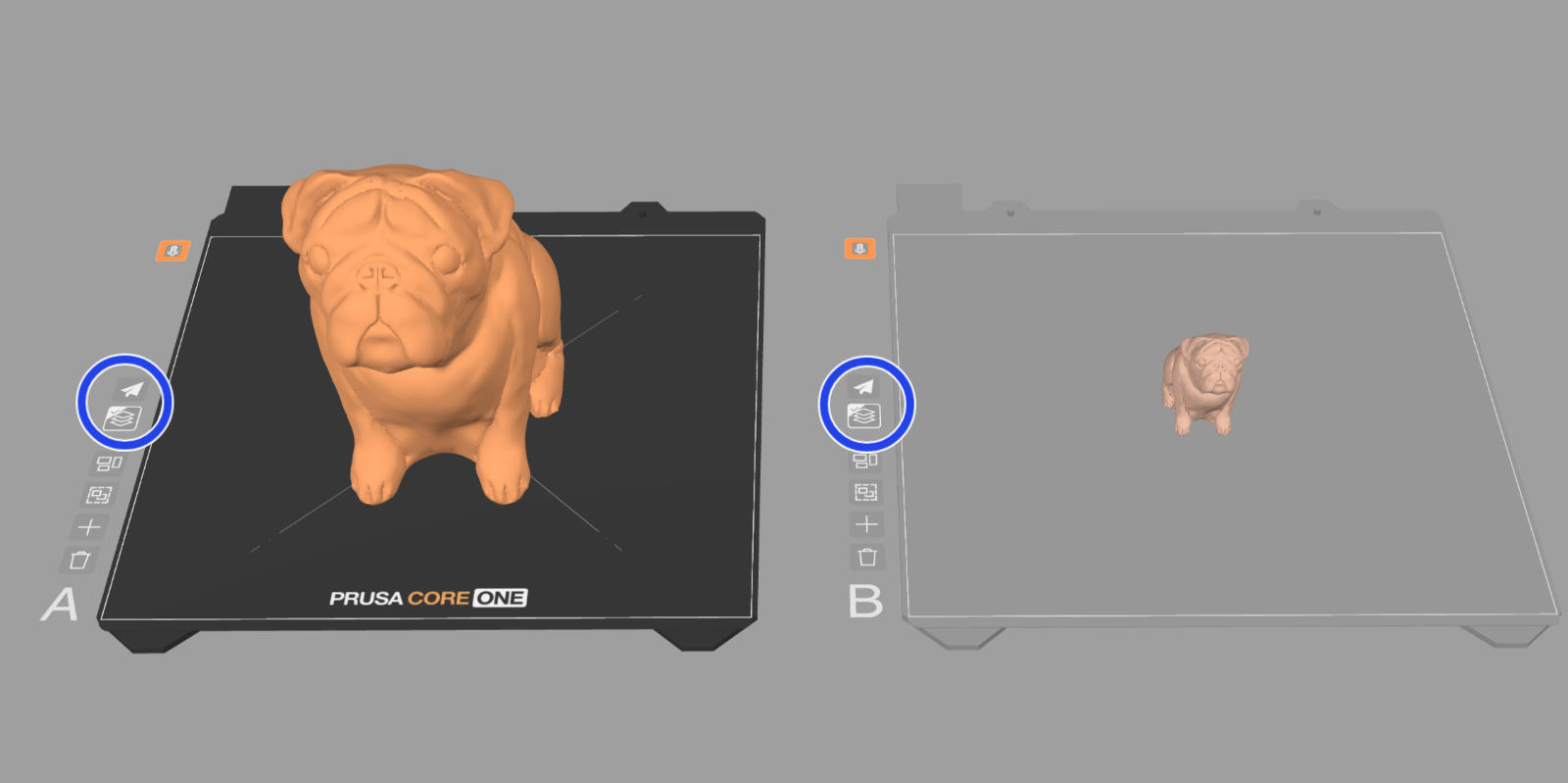

Es gibt immer ein aktives Bett, das Sie an seiner einfarbigen Farbe erkennen können (die inaktiven Betten sind halbtransparent). Nur das aktive Bett wird gesliced, wenn Sie auf Drucken oder Vorschau klicken. Klicken Sie auf ein inaktives Bett, um es zu aktivieren.

Wenn das Vorschausymbol auf der linken Seite jedes Bettes ein Häkchen in seiner Ecke zeigt, bedeutet dies, dass das Bett bereits gesliced wurde. Mit der Schaltfläche darüber können Sie die Datei schnell an den Drucker senden (oder den G-Code herunterladen, je nach dem von Ihnen gewählten Drucker).

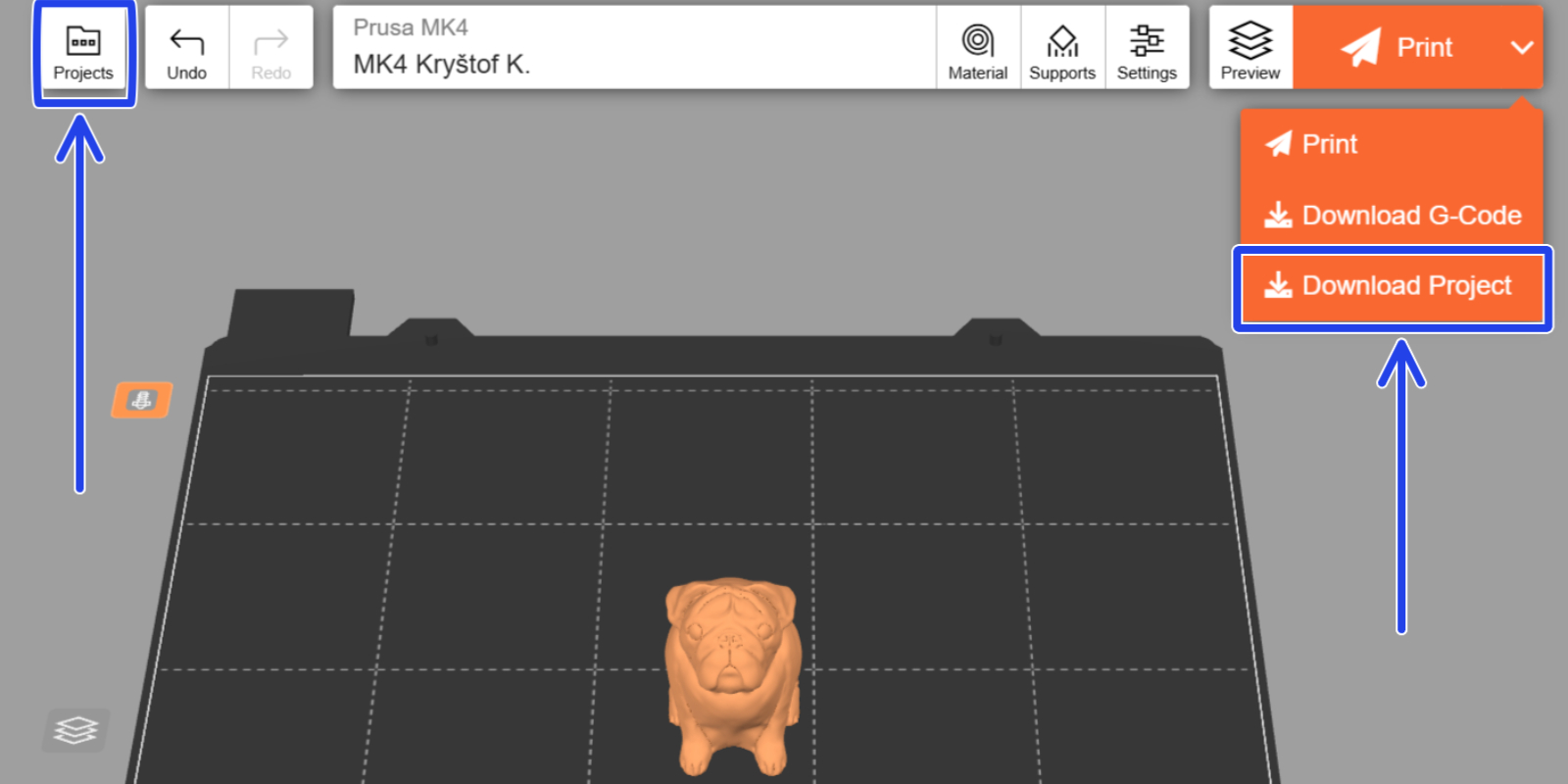

Projekte anzeigen und herunterladen

Bei der Verwendung von EasyPrint auf Ihrem Computer können Sie frühere Projekte durchsuchen, öffnen und löschen. Sie können auch das aktuelle Projekt als 3MF-Datei herunterladen. Dies kann nützlich sein, wenn Sie Ihr Projekt in PrusaSlicer feinabstimmen oder es mit jemandem teilen möchten.

Farben bemalen und zuweisen

EasyPrint kann auch mehrfarbige Druckdateien für Drucker mit Multi-Material-Fähigkeiten (z.B. Original Prusa XL oder Original Prusa MK4S mit dem MMU3 Upgrade) erzeugen.

Wählen Sie das Farbwerkzeug und fügen Sie ein weiteres Material (Farbe) hinzu. Wenn Sie auf das Objekt klicken, bemalt das intelligente Füllen-Werkzeug alle umliegenden Bereiche, bis es einen scharfen Winkel erreicht. Wenn Sie ein zweites Mal auf den bemalten Bereich klicken, wird der Schwellenwinkel leicht abgesenkt und die aktuelle Farbe weiter ausgedehnt.

Wenn Sie mit dem Ersetzen-Werkzeug auf eine beliebige Farbe klicken, werden alle Vorkommen dieser Farbe im Objekt durch die derzeit aktive Farbe ersetzt.

Sie können auch mehrfarbige 3MF-Projektdateien mit mehreren Teilen (Meshes) importieren, wie z. B. die Benchbin. Die vom Autor zugewiesenen Farben bleiben dabei erhalten.

Sie können auf ein Teil eines mehrteiligen Objekts doppelklicken, um ihm über die Schaltfläche Material/Farbe ändern eine Farbe zuzuweisen.

Sie können eine Farbe, die bereits auf mehrere Objekte angewendet wurde, auf der Registerkarte Materialien ändern.

Materialzuordnung

Sie können das jedem Werkzeug eines Multiwerkzeugdruckers zugewiesene Material ändern, indem Sie auf eines der Extrudersymbole auf der linken Seite des Druckbetts klicken. Ziehen Sie im Pop-up-Menü die Farben per Drag & Drop, um sie dem gewünschten Werkzeug zuzuordnen.

1 Kommentar