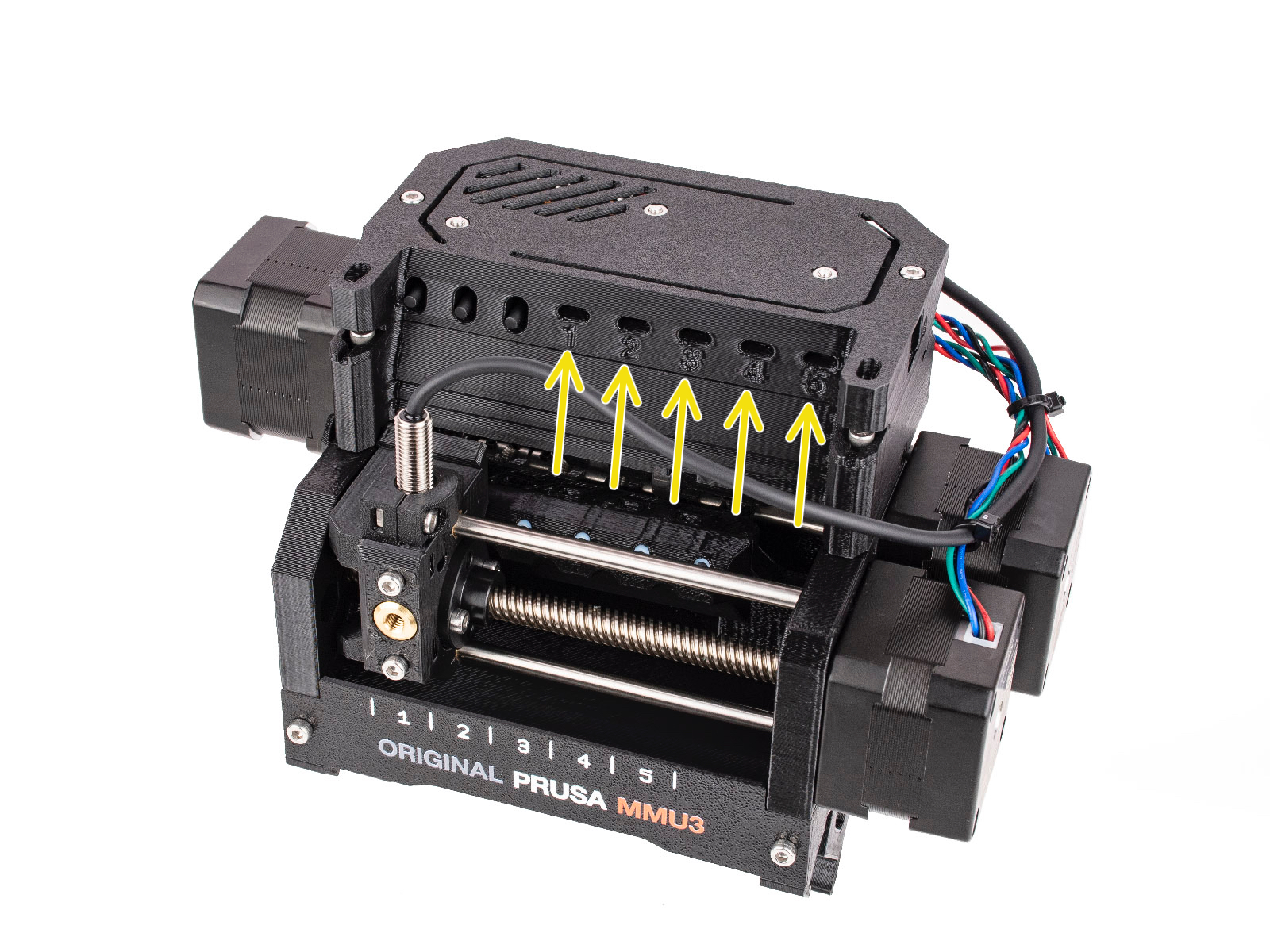

This article is describing the status of the LEDs located on the multi material unit. Together there are five LEDs on the unit that correspond to the five available filament positions.

Note that the earlier MMU2S firmware 1.0.6 or below behaves differently.

During the regular MMU operation:

- GREEN solid light: The MMU has a record of the given filament being loaded in the extruder.

- GREEN flashing light: There is a loading/unloading process going on.

- RED flashing light: There is a loading/unloading error with the given filament. The unit is waiting for user interaction.

- RED and GREEN flashing lights: Internal runtime error, refer to the error shown on the printer’s LCD.

MMU Firmware start:

After the MMU unit has been turned on or restarted, green LEDs light up from positions 5 to 1 shortly (~100ms). Each signalizes one component up and running:

- LED 5: Shift registers initialization

- LED 4: USART initialization

- LED 3: SPI communication initialization

- LED 2: motion system initialization

- LED 1: ADC initialization

If the MMU stops in this setup phase (the LEDs stay on and do not turn off), something is wrong with the electronics.

Then, a selftest routine is performed. It checks if the main control board behaves correctly and if all the signals from the microcontroller get to the TMC motor drivers on the control board properly. If the MMU unit suspects the communication with any of the three TMC motor drivers might not behave correctly, an error is shown. In that case, refer to the printer’s LCD screen.

LED lights indicate the ongoing phases of the selftest routine:

- LED 1: ok (green) / error (red) on STEP signal

- LED 2: ok (green) / error (red) on DIR signal

- LED 3: ok (green) / error (red) on ENABLE signal

- LED 4 indicates which TMC driver is being tested

- Idler = green

- Selector = red

- Pulley = green+red

- LED 5 is flashing green while the process is still ongoing.

Other LED lights on the unit:

There are also other less important LED indicators on the unit.

- A green LED on the MMU3 PD-board addon, on the back of the unit. It signalizes the board receiving power from the printer.

- An orange indicator "breathing" on the inside of the MMU unit, on the main control board, signalizes the electronics booting up.

- A red indicator on the top of the FINDA sensor signalizes the sensor being powered up and NOT detecting a filament.

1 comment

Hi David. For preloading filaments to MMU, you can select Preload to MMU on the printer’s screen - then select the desired filament position. If you need to load a filament into the extruder, use the Load to Nozzle function. You don’t necessarily need to move the selector manually into a certain spot in order to load or preload the filament - it will align automatically. Filament positions can be selected on the printer’s screen without the 1 second lag after a button press.

Yes, the MMU2S used to indicate the selector position using the LED light - and there were some problems with that such as MMU possibly indicating a wrong selector position before the selector was able to home. This behavior was replaced by the more logical one where the green light indicates the filament being loaded into the extruder. This gives you a clear indication of what state the MMU unit is in. Now, green light means, there is a filament loaded to extruder and has to be unloaded before the MMU can do other operations such as moving the selector, preloading filaments etc.