The Extrusion Multiplier allows the fine-tuning of the extrusion flow rate - simply described as how much filament comes out of the nozzle. In other words, the Extrusion Multiplier setting in PrusaSlicer and the Flow rate setting in printer firmware are two ways to adjust the same thing, however, adjusting one of those two settings will not influence the value of the other.

This procedure is not necessary with a new printer coming from the factory, but rather applies for specific applications and filaments. The ideal value is different for every type of material and every color. It can even differ from spool to spool. Bear this in mind if you change type and brand of filament often or use cheap no-name brands.

How to spot an issue

This calibration is used to fix two common problems:

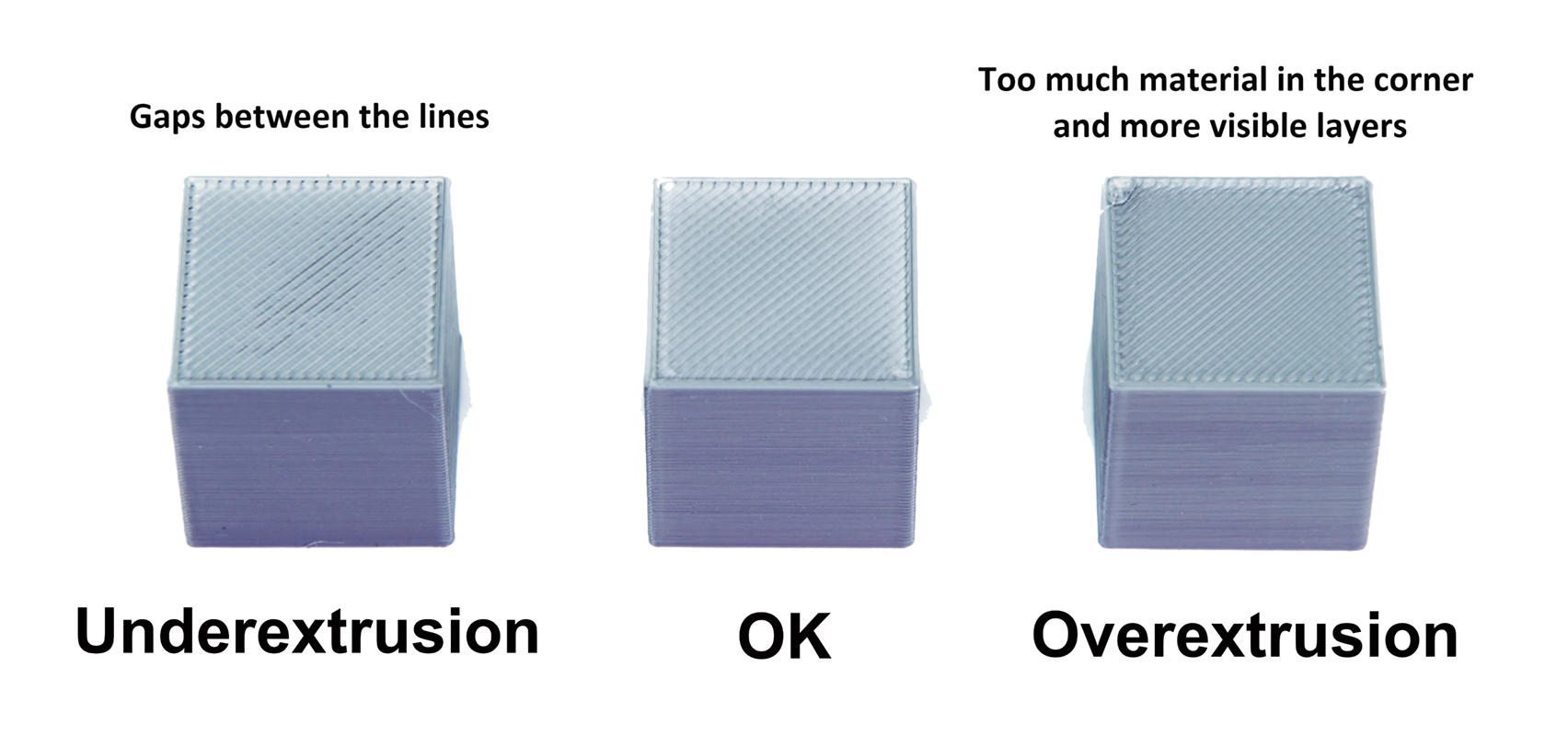

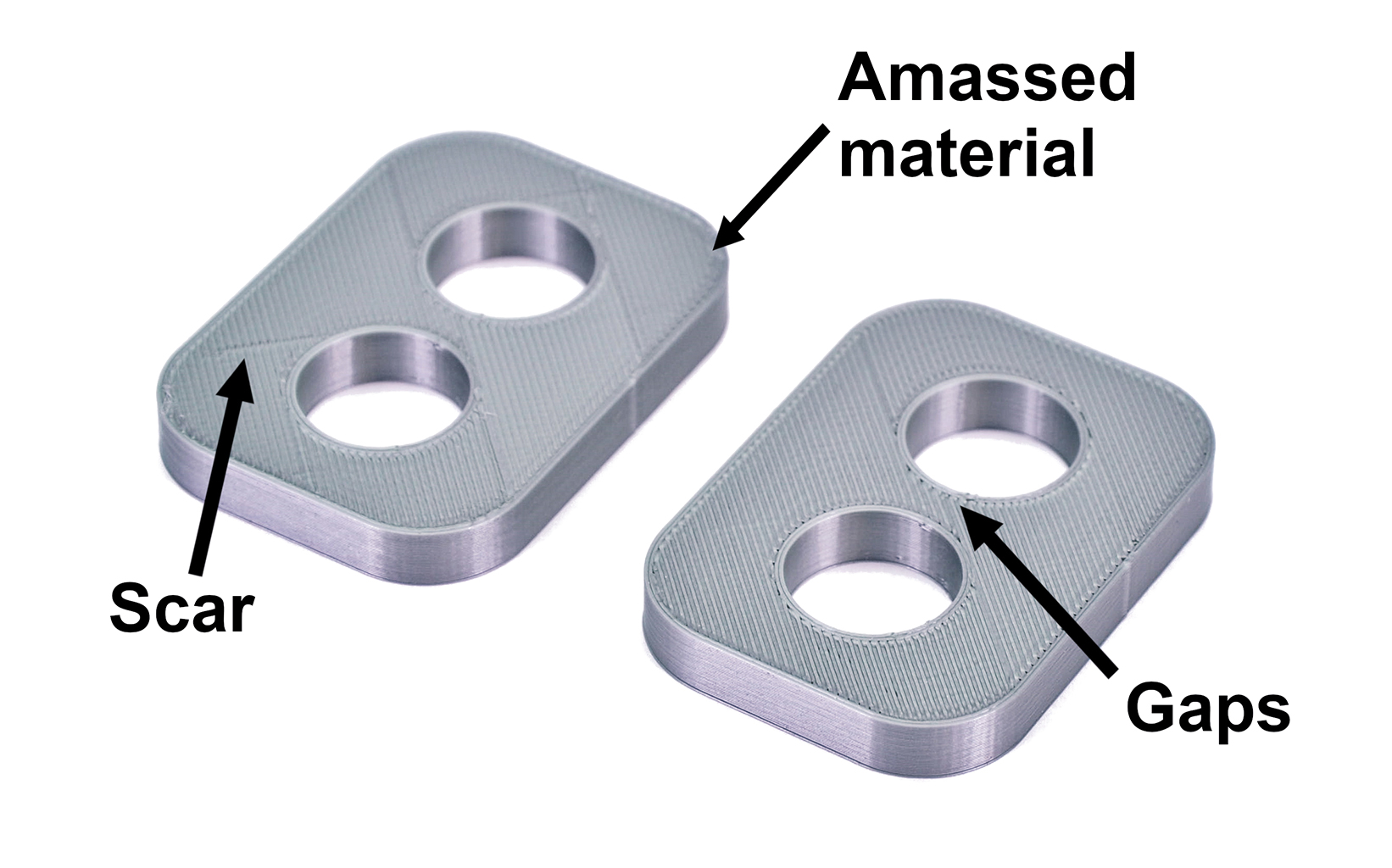

- Overextrusion - Too much material is extruded (flow is too high). It causes scarring of bottom layers and unnecessary material buildup on top layers.

- Minor under extrusion - Not enough material is extruded (flow is too low). It causes small gaps that appear between layer lines or perimeters.

Overextrusion is a common problem with many filament brands. It's especially problematic when you're trying to glue two parts of the model. If the top layer is over extruded, you'll end up with an uneven surface that will prevent a seamless connection between the two pieces.

How to do the calibration

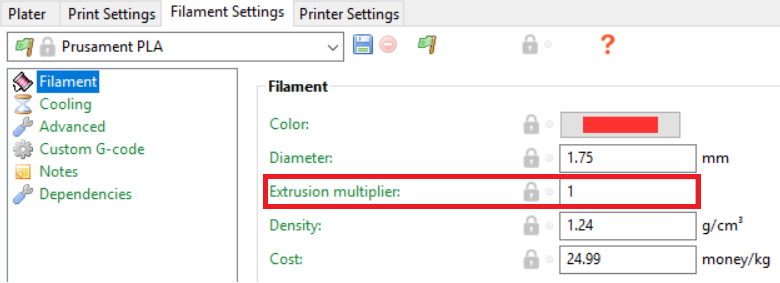

In PrusaSlicer, navigate to Filament Settings and look for Extrusion Multiplier. The default setting (for PLA) is 1, this value represents a percentage, 1 = 100%, 0.95 = 95% etc. Usually, the adjusted values can be between 0.9 and 1.1. To adjust it, simply rewrite the value.

In the printer menu, during a print, go to the Tune menu and then choose Flow. Again, the usual values can range between 90 and 110, although that does not mean you can't go above or below that.

Which method should I use?

There are two methods you can use to calibrate the Extrusion Multiplier, and we'll cover both of them in this article:

- Precise Method - using precision tools such as calipers or micrometers.

- Visual Method - an easy method based on observing the visual properties of your models.

The choice of the method depends entirely on your preferences; in the end, both yield similar results. Even the visual method will enable you to have perfectly fitting parts with smooth & flat top layers.

Precise Method

- Nozzle size = 0.4

- Extrusion width = 0.45

- Basic materials (PLA, ABS, PETG) Extrusion Multiplier = 1

If you wish to calibrate the printer with a bigger/smaller nozzle or layer heights above 0.2, then you will need to adjust these values as well.

- Download the Precision Method Cube STL.

- Slice it using the Vase Mode and your most-often used layer height and print it. You can find Vase mode (Print Settings → Layers and perimeters → Spiral vase).

- Make three or more measurements in the middle of each wall and calculate the overall average thickness.

- Calculate the extrusion multiplier using the following formula: Extrusion multiplier = (Extrusion width (0.45) / Average measured wall thickness).

- Adjust the Extrusion Multiplier in Filament Settings → Filament

- Re-print the cube with new settings and go back to step 3 if necessary.

Visual Method

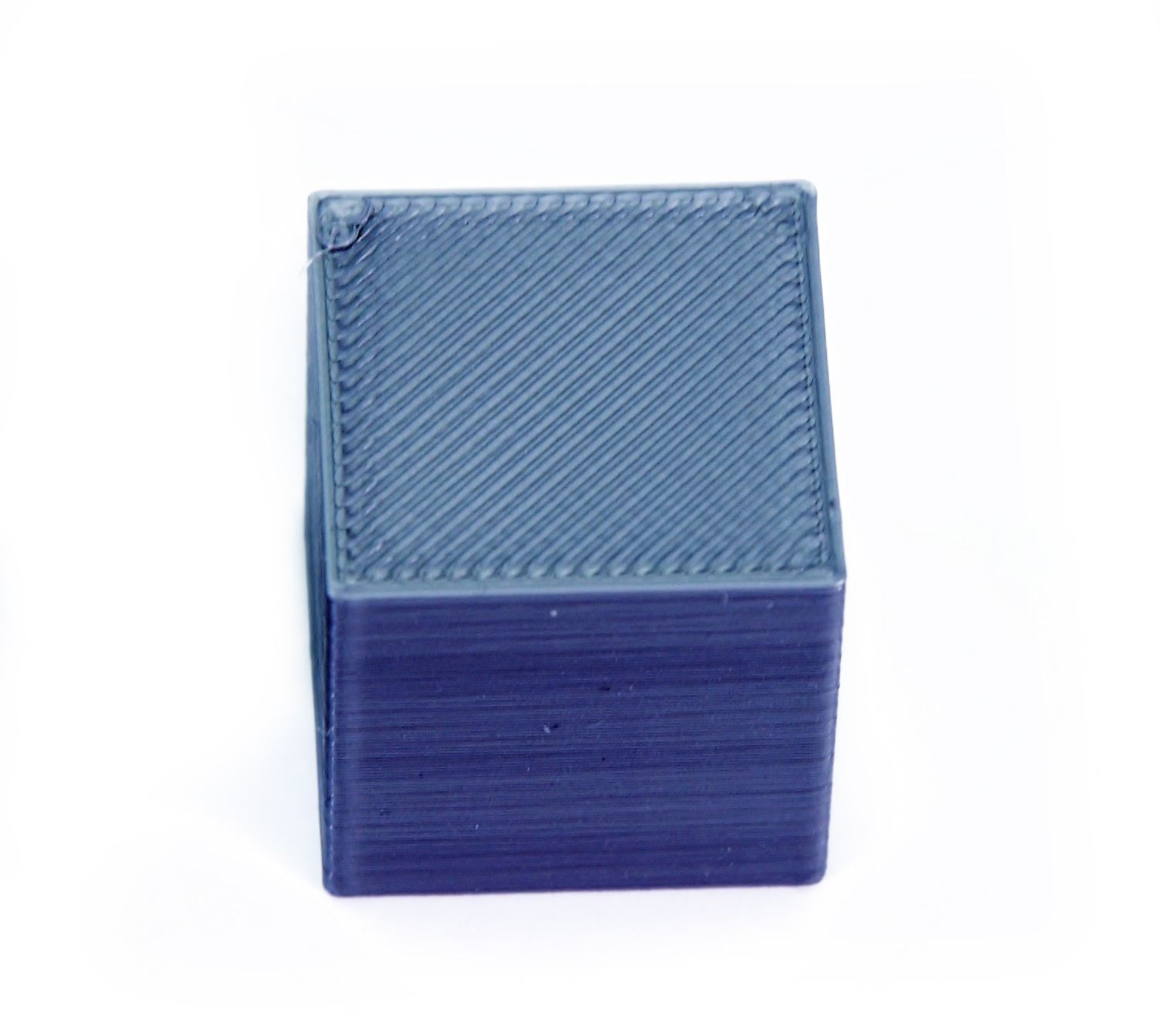

This method does not require any tools, only your sight. The point is to make sure your top layers are smooth, shiny, and without scarring or filament buildup near the perimeters.

- Download the Visual Method Cube.stl

- Slice it using the default Prusa PLA presets at 0.20mm layer height and print it.

- Inspect the top layer of your cube visually and with the tip of the finger.

- If the top is under extruded or not smooth, then re-adjust the Extrusion Multiplier accordingly by 1-2%.

- Repeat the steps above as long as needed.

If there is too much material near the perimeters, decrease the Extrusion Multiplier value.

If there are visible gaps between layer lines, increase the Extrusion Multiplier value. (Microscopic gaps near the perimeters are OK.)

49 comments

How? Prusa sells 5 different sizes of nozzles, so the guide should cover those scenarios.

I'm assuming the "extrusion width" field is the right value to replace 0.45 with. But I don't know how to account for different layer heights.

In the current example, the virtual thickness assigned in Prusa Slicer (external perimeters width) is 0.45 mm, so the formula is [0.45mm/real-average-thickness].

If you use a different nozzle (stock printer profile for the nozzle) the assigned stock external perimeter width will be different so, simply check in 'advanced > extrusion width > external perimeters'.

Lucas

I note that it's not on the list of relevant printers..

The note in prusa slicer suggests calibrating firmware esteps but that doesn't seem to be a thing prusa encourages for their printers.

I can see how this could get irritating having to calibrate each filament to each head. Am I looking in the wrong place?

The printer printed great when I assmbled it with default settings. However perfectionism comes with the hobby, so I noticed on the benchy for some of my old filaments some gaps on the cargo box, so did the "precice" procedure above to check. Sure enough my extrusion width was 0.41mm. So added an extrusion multiplier and tried again, it was still a little under, then adjusted the multpilier again. - (BTW I suggest you add that calculation as well (if you have a previous extrusion multiplier not equal to 1.)

I ended up with an extrusion multiplier of 1.13. I did the same for another filament (same brand) and got exactly the same multipler. I know the instructions say usually the value should be between 90 and 110% but outside this is still ok. However I wanted to check if this might indicate a mechanical problem with the extruder. (I assembled from kit).

I tried saving it as a new filament profile but it does not seem to show up when opening a new project.