What happened?

The printer is showing the message "Check the heatbed heater & thermistor wiring for possible damage."

Error name: Bed preheat error

Error code: #31201 (CORE One) #35201 (CORE One L) #26201 (MK4S) #13201 (MK4) #27201 (MK3.9S) #21201 (MK3.9) #28201 (MK3.5S) #23201 (MK3.5)

This message is shown when, during the preheat, the printer does not increase more than 2 ºC for 20 seconds. The heating is paused so the issue can be fixed.

How to fix it?

CORE One L

CORE One, MK4/S, MK3.9/S, MK3.5/S

Make sure that the ambient temperature where the printer is is stable, and above 10 ºC.

This error can be caused by damage to either the heatbed thermistor or the heatbed power cable.

On the heatbed, check the following:

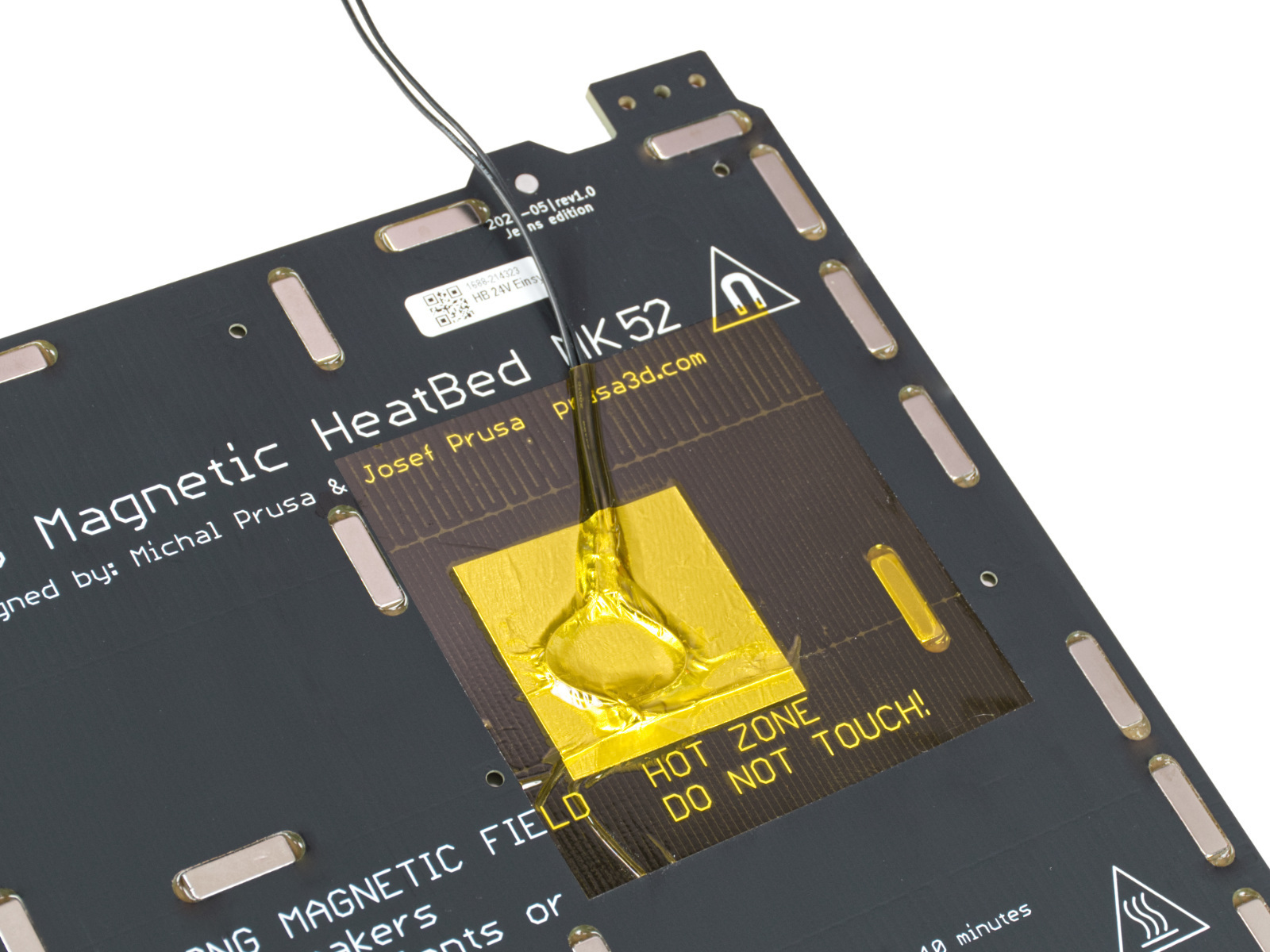

- See if the thermistor is firmly seated below the Golden Kapton tape.

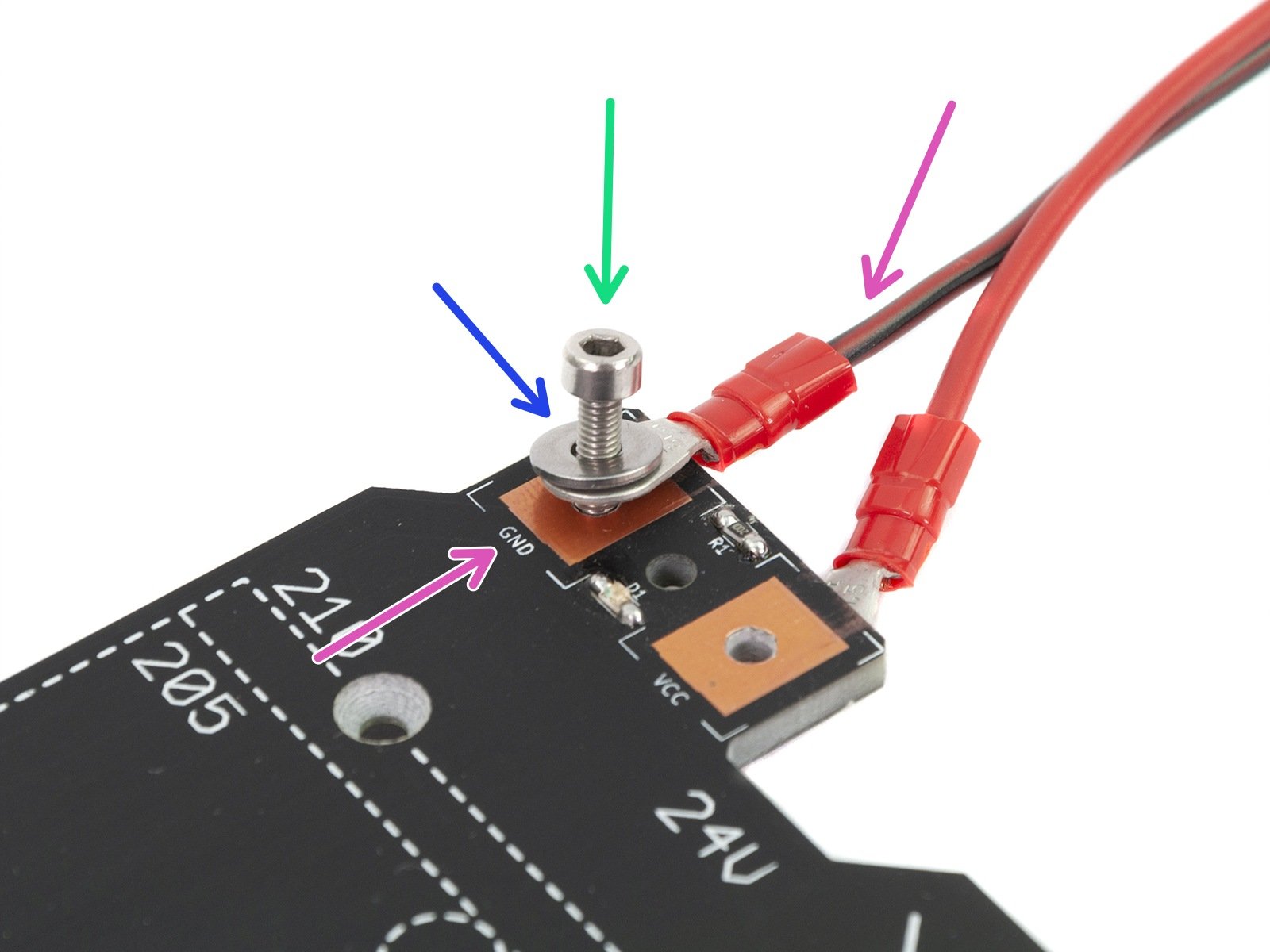

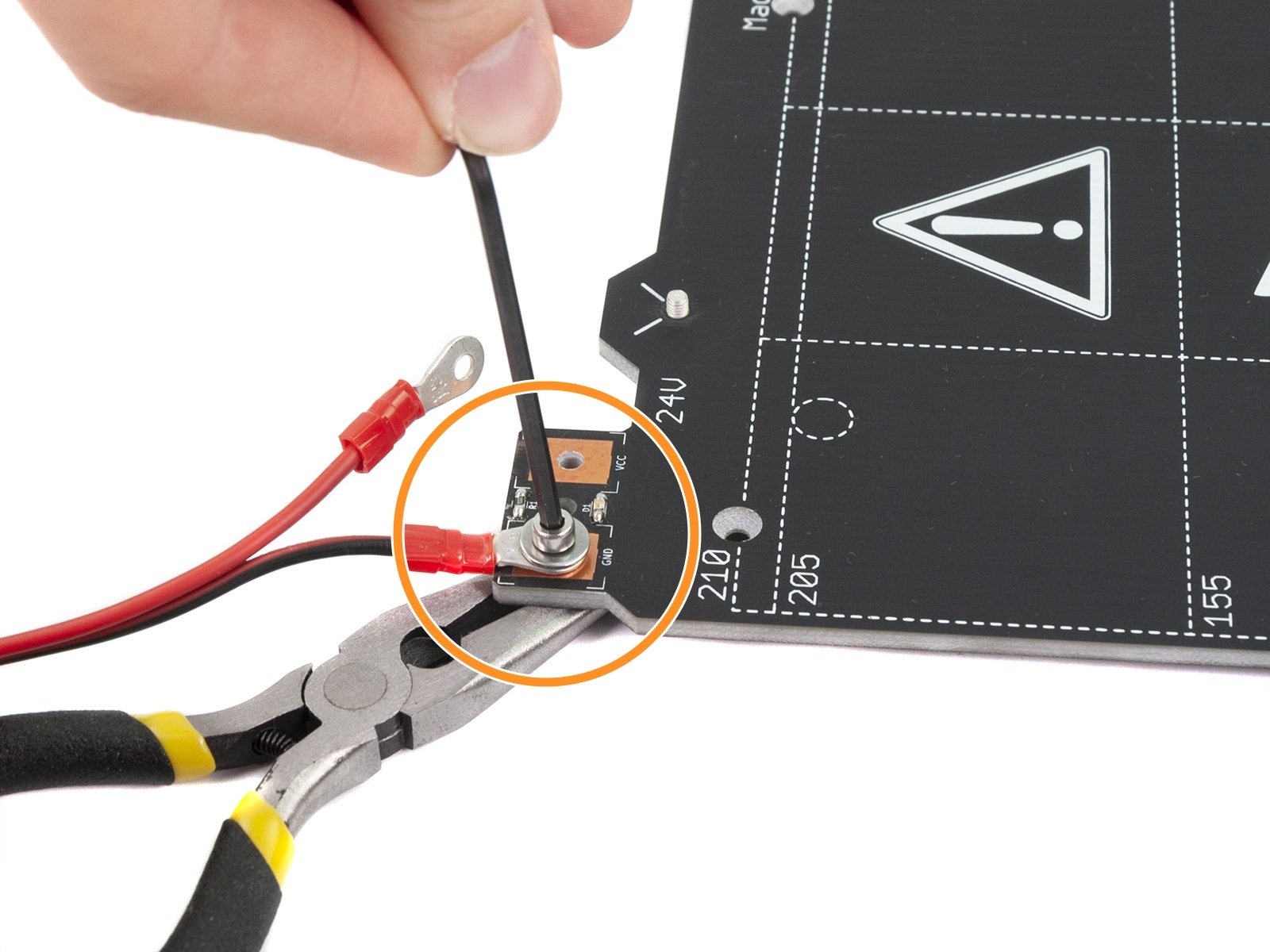

- Make sure that the washer is screwed above the round cable connector, not below it.

- Check if the M3nN nut is holding the screw firmly.

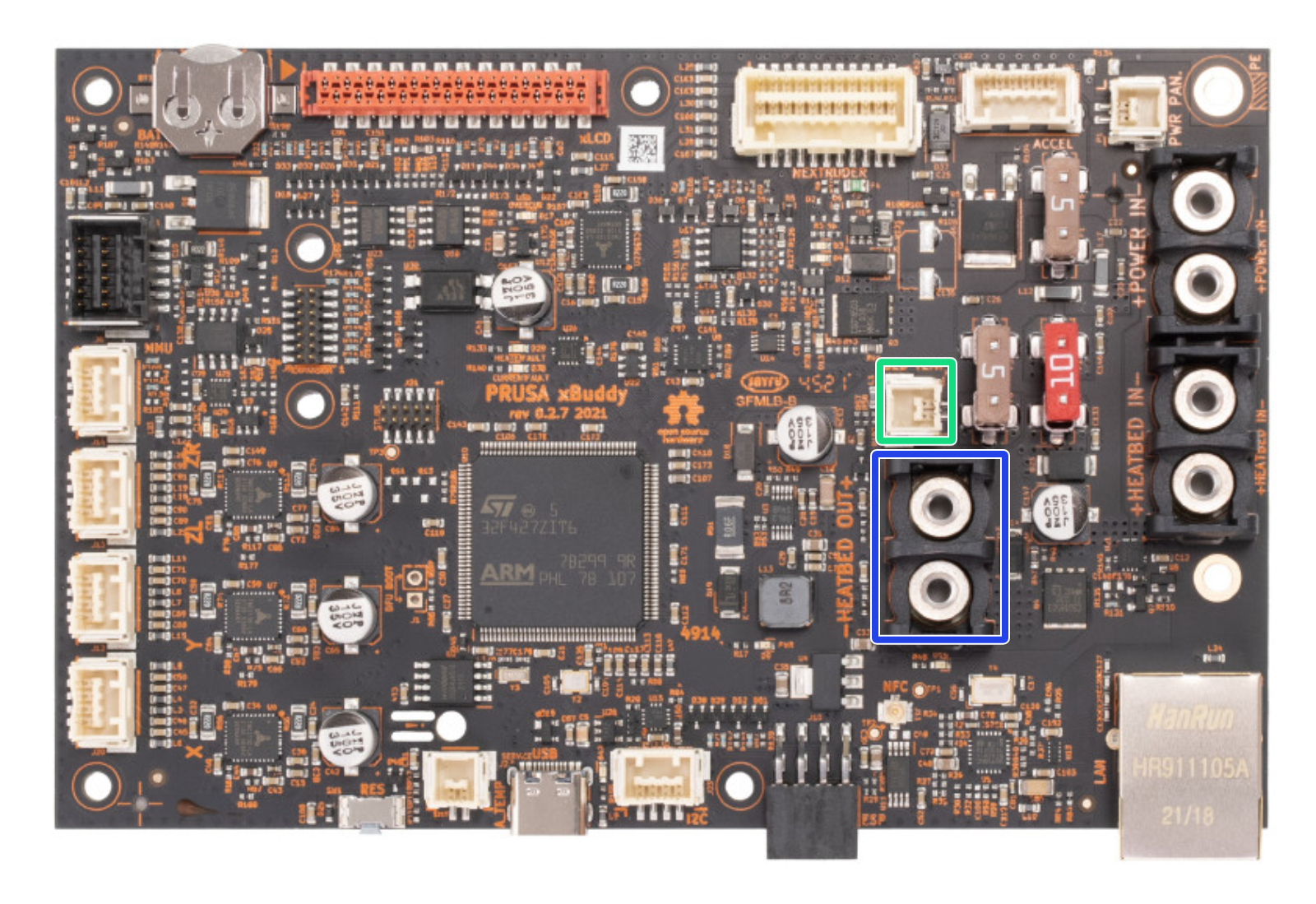

- Access the xBuddy board. Check the heatbed power cable, the heatbed thermistor, and the fuse that protects the heatbed.

|  |

|  |

In case all the items are correct, there might be an internal break in one of the cables. If you do not have a multimeter, it is possible to check the cables using the following test:

- Use a hairdryer to blow hot air at the heatbed.

- While doing that, check if there is any temperature change on the LCD screen.

- If there is a positive temperature change it means that the heatbed thermistor is working. In this case, the heater is defective.

- If there is no change at all, the heatbed thermistor is defective.

Multimeter check

In case you have a multimeter available, it is possible to check the resistance of the cables using the Multimeter usage guide.

8 comments

It's possible I was too delicate with them during the initial build. Another possibility, is that the table my printer was on originally was wobbly. Might have rattled the screw loose.

Regardless, cranking down those two connectors (which unfortunately required unscrewing the heat bed, and having my wife clamp the nut in place while I tightened, very difficult!) seems to have fixed the problem. 2 hours into a 3.5 hour PLA print with no error codes thrown my way.

Doing the automatic calibration, the bed heats up then faults out.

I manually ran the bed up to 120. It got there, held, and followed temp set points back down.

The thermistor and heater work.

The problem seems like the speed of changing temp.

Ideas or solutions?

Hello. Please contact our support team.