EN

Login- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

Hello, how can we help?

Categories

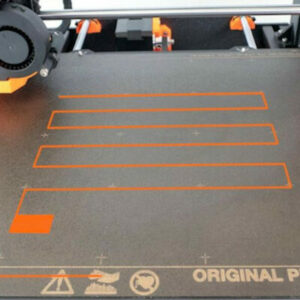

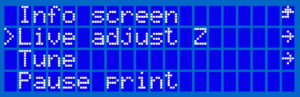

- Calibration

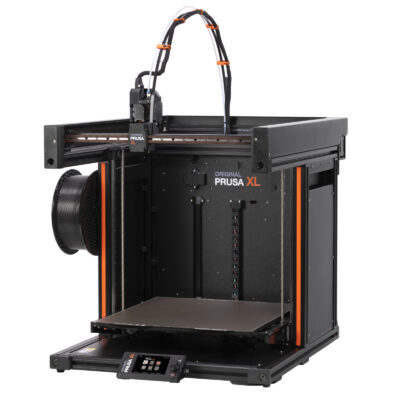

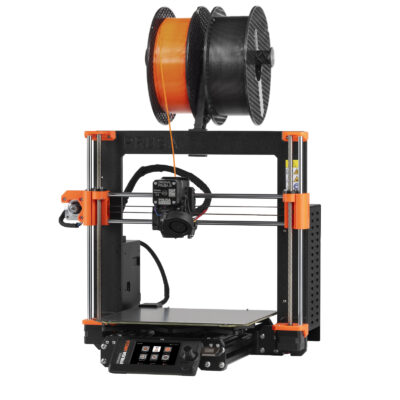

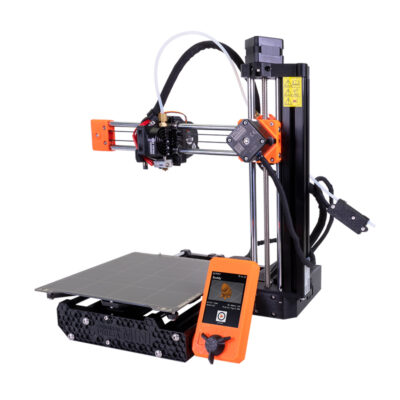

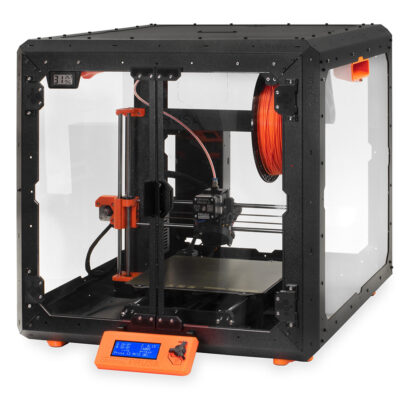

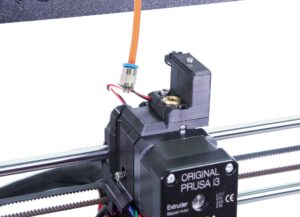

All information you need to know to learn how to calibrate your 3D printer to achieve perfect prints. - About your printer

Basic overview of your 3D printer and it's features, plus general Prusa Research info. - Using the printer

In this section, you can find material guides, printer troubleshooting and general info about using your printer. - Troubleshooting

Description of how to recognize and solve common problems, especially hardware and electronics related. - 3rd party accessories & Other projects

Learn about different nozzles, Raspberry Pi connection, Octoprint and more. - PrusaSlicer

The official documentation for the PrusaSlicer slicing software. From basic configuration to advanced settings like modifier meshes. - Printables

Printables.com

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.