The Original Prusa magnetic heatbed is designed to hold a removable, double-sided, flexible print sheet, specifically designed for easy removal of printed objects from the print surface.

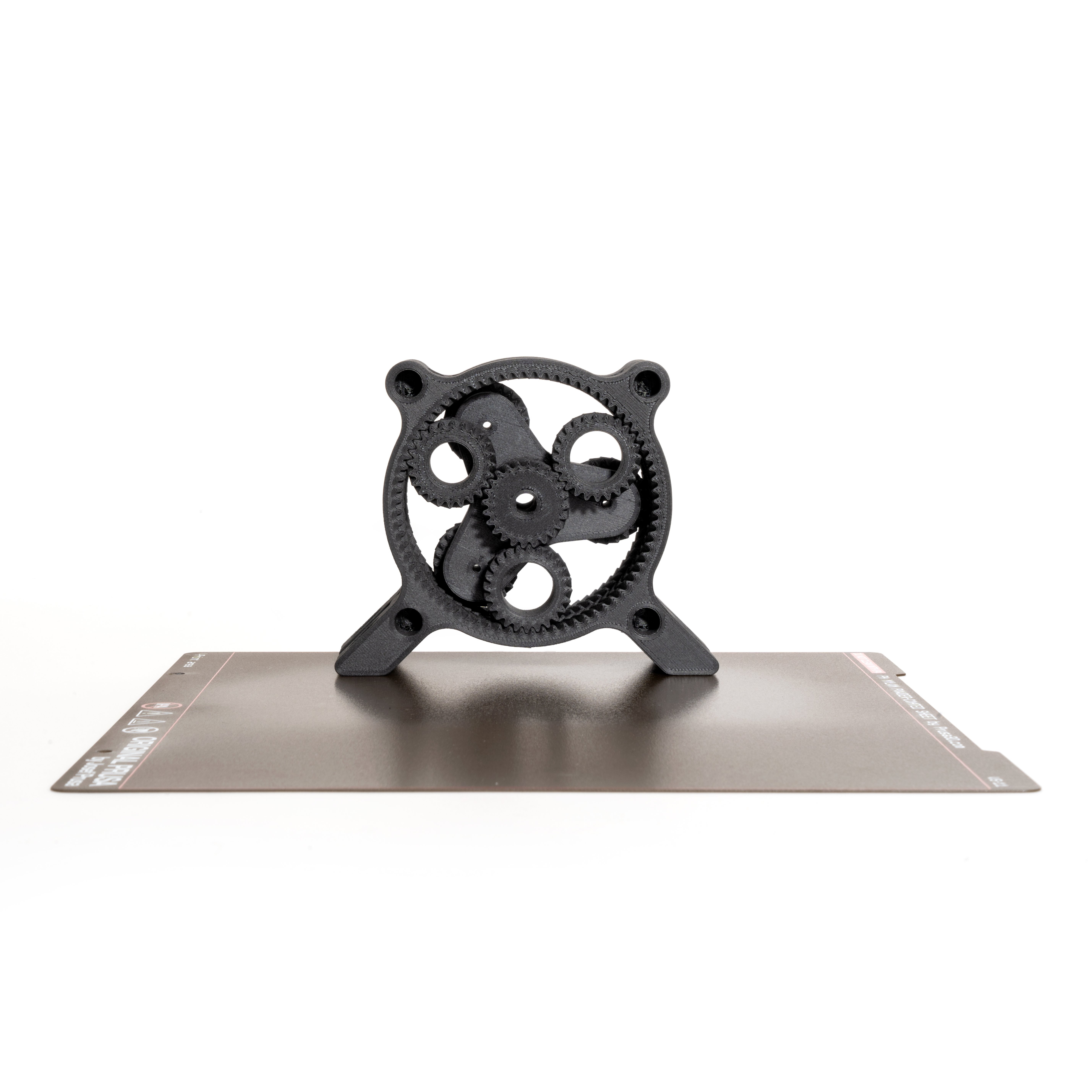

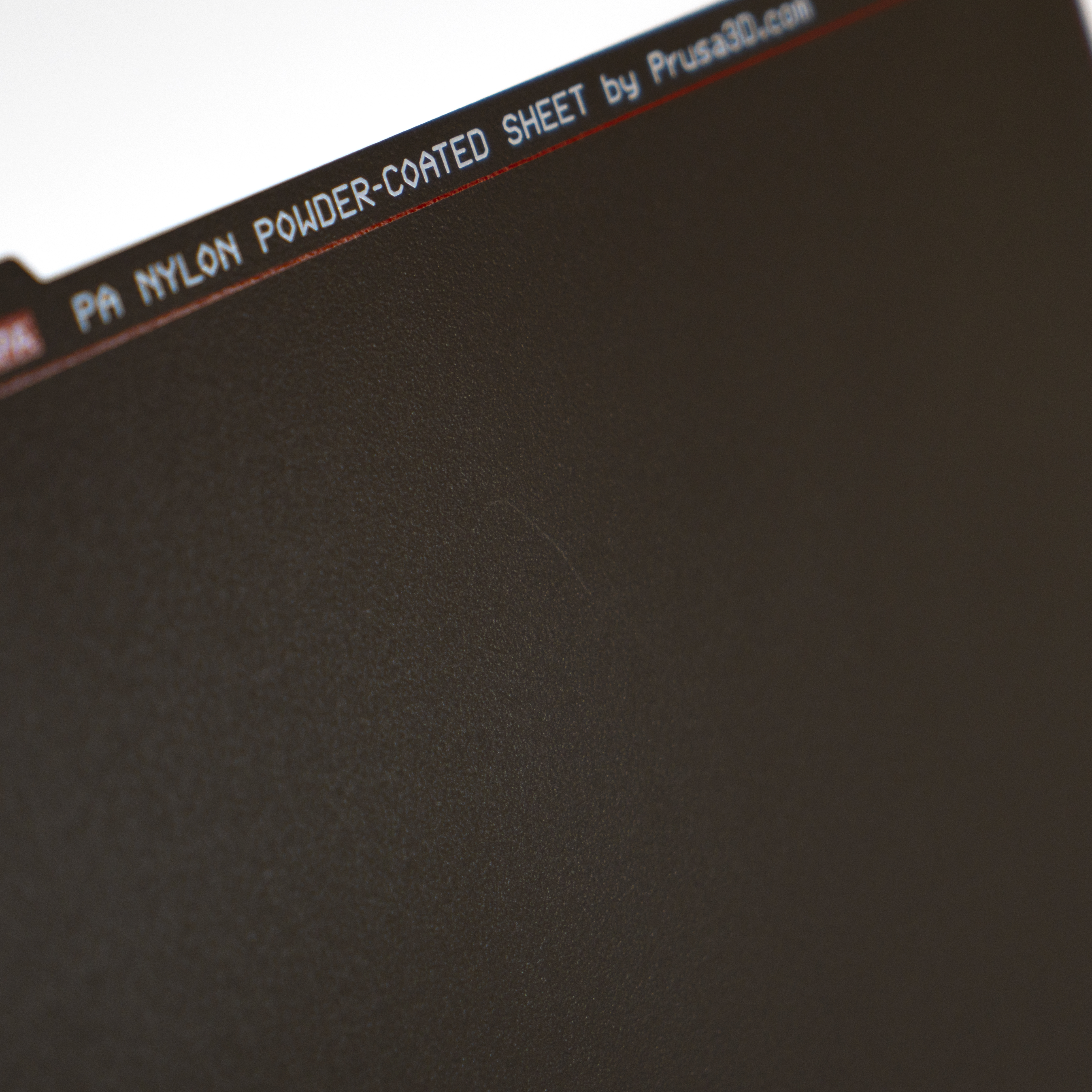

The special PA sheet is made for printing polyamides (Nylon) since their adhesion to standard PEI sheets is generally very poor. The sheet comes with a matt texture, similar to the satin print sheet with a PEI surface. The sheet is compatible with most polyamides and PETG. Other materials may have insufficient adhesion and should be printed on our standard PEI sheets.

|  |

| Special PA Nylon print sheet | The underside of a printed object |

Print sheet color

The exact color depicted in the e-shop and our knowledge base may differ from yours. All sheets are checked and verified to be within tight specifications. These specifications are both considering the manufacturing method and the sheet's function (adhesion and durability used with certain material types), but not the cosmetic aspect of the sheet or pattern left on printed parts. We can not guarantee the pattern left on your printed objects will match perfectly from sheet to sheet.

Main attributes

- Compatible with many types of polyamide.

- Made for printing without using a glue stick and other means of increasing adhesion.

- Slightly textured surface.

- Double-sided! Both sides can be used repeatedly.

- Easy maintenance and good adhesion qualities.

Considerations

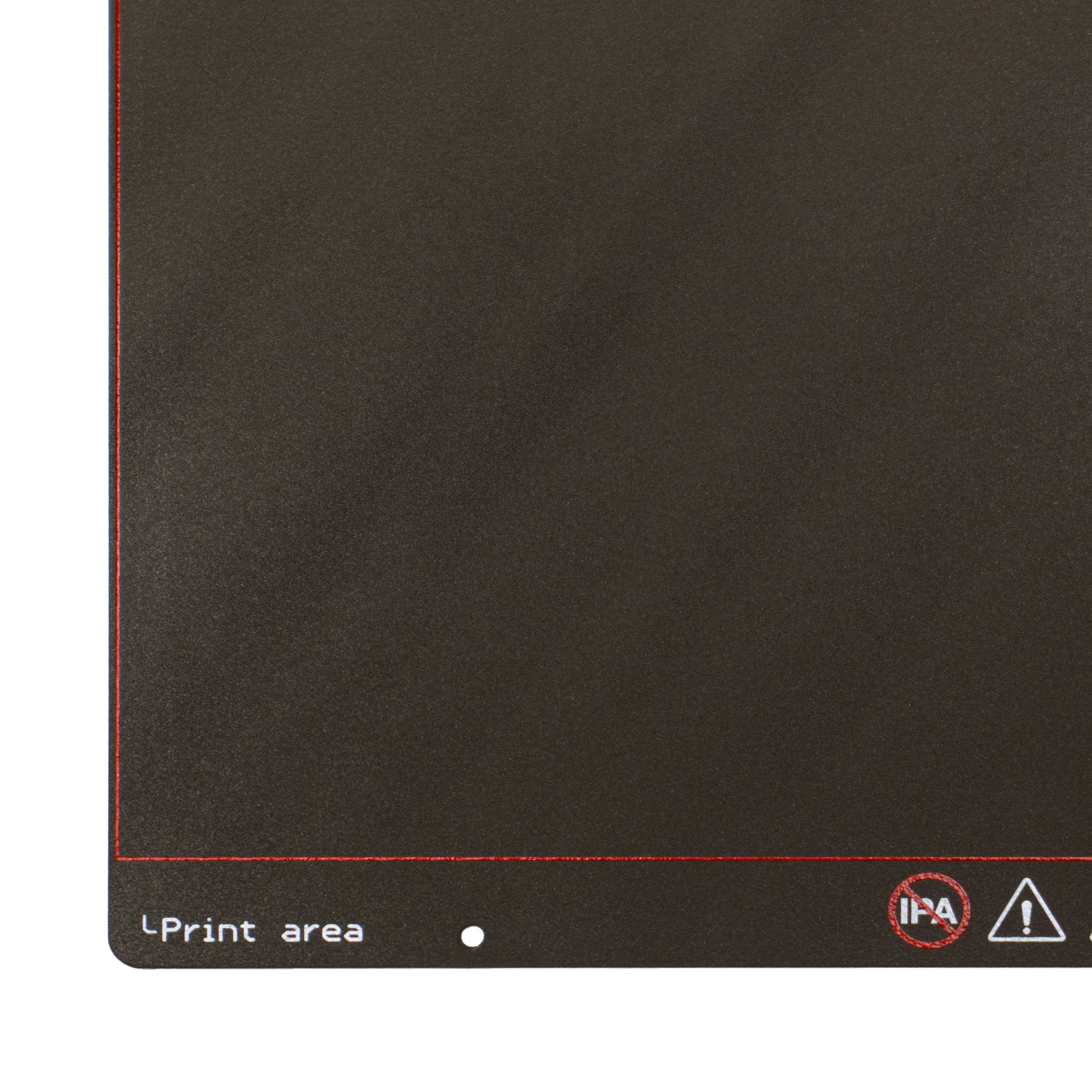

- Never clean the special PA Nylon sheet with acetone, IPA (isopropyl alcohol), or other alcohol-based solvents (window cleaners, Windex, etc.)! This will damage the surface.

- For easy print removal, wash the print surface with water before every printing.

- Check the proper first layer height. If the Live Z value is too low and the first layer is too squeezed, print removal may be difficult and may damage the sheet.

- PA Nylon sheet should be cleaned only with water and degreased with dish-washing soap.

- Some types of polyamide may be prone to warping and require using brim, or are suitable only for printing small parts and models with sparse infill.

- Keep the sheet as clean as possible! Any grease stain will decrease adhesion.

- The live Z value needs to be readjusted if you switch sheets in a printer that uses the PINDA for bed leveling. See スチールシートプロファイル.

- Not scratch-resistant! Do not use metal spatulas with sharp edges to remove the prints. Be extremely careful when removing the print.

- Some types of paper towels may leave traces on the sheet (fiber pieces).

Supported printers

Note that the sheets for the CORE One and the MK series sheets are interchangeable, just with different designs.

- CORE One

- XL (Also offered as a Factory second)

- HT90

- MK4/S, MK3.9/S, MK3.5/S, MK3/S/+, MK2.5/S (also offered as a Factory second)

Filaments

We have done a lot of testing and compiled our results for you to use. To easily see how to prepare your sheet for any filament type, please see our Material table.

Prints don’t stick

If your print surface is perfectly clean and all grease has been removed by wiping it with a paper towel soaked in water and dish-washing soap, the first layer height is set properly, and the print won’t stick, check out 1層目の問題.

Keep in mind that polyamides in general tend to warp more than other materials. Sometimes warping may be so strong that larger models (or with dense infill) detach from the surface, even over the best surface adhesion. If you experience such strong warping, we recommend using another type of PA for selected prints - for example, our Prusament PA11 Carbon Fiber shows almost no warping at all. You can find more in the articles about polyamide and warping.

PA Nylon print sheet has a special surface layer with a smooth texture and a matt look. The surface layer is partially translucent and may show a specific “texture” of lengthwise or diagonal lines, or varying color shades. These color variations are characteristic of the material under the topmost layer and don’t affect sheet performance.

Notes

As a result of the temperatures to which the plate is exposed during printing, its surface gradually becomes glossier or may develop smaller, duller areas. This visual change does not adversely affect the printing properties and is not considered a reason for a warranty claim.

Note that the PA Nylon sheet wear is especially noticeable at the Z probing points, where the nozzle leaves visible marks on the surface. This does not affect the surface adhesion and overall printability.

A new batch of the PA Nylon sheet will be released during July / August 2024. The new version will get a slightly rougher surface texture. This change will not affect the print sheet's functional properties. You can examine the changes in the gallery below.

|  |  |  |  |  |  |  |  |  |

| Example of a glossier surface | Diagonal lines | Minor scratch | Varying color shades | Scratched hole | Horizontal lines | Example of a glossier surface | Old texture (bottom) vs new texture (top) | Old texture (left) vs new texture (right) | Visible marks at Z-probing points |